Cobalt diselenide modified carbon fiber composite material and preparation method and application thereof

A technology of cobalt diselenide and composite materials, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of difficult synthesis, poor stability, low yield, etc., and achieve high activity and good stability. The effect of sex, synthesis method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Carbon felt (a total of three pieces, the volume is 1 × 1 × 0.3cm 3 , 1×1.5×0.3cm 3 and 1×2×0.3cm 3 , with a total mass of about 0.2 g) placed in a mixed solution of ethanol and water to ultrasonically remove surface oil.

[0036] Weigh 1 mmol of cobalt acetate and 1 mmol of sodium selenite and dissolve in a mixed solvent composed of 26 mL of diethylenetriamine and 13 mL of water, and stir for 10 minutes. Soak the treated carbon fiber felt in it and stir for 1 hour to form a mixture. Transfer the above mixture to a PTFE-lined 50mL reactor and seal it, react in a temperature-controlled oven at 180°C for 16 hours, take it out after completing the reaction and cool to room temperature; Dry in a vacuum environment for 6 hours to obtain CoSe 2 / CF composites.

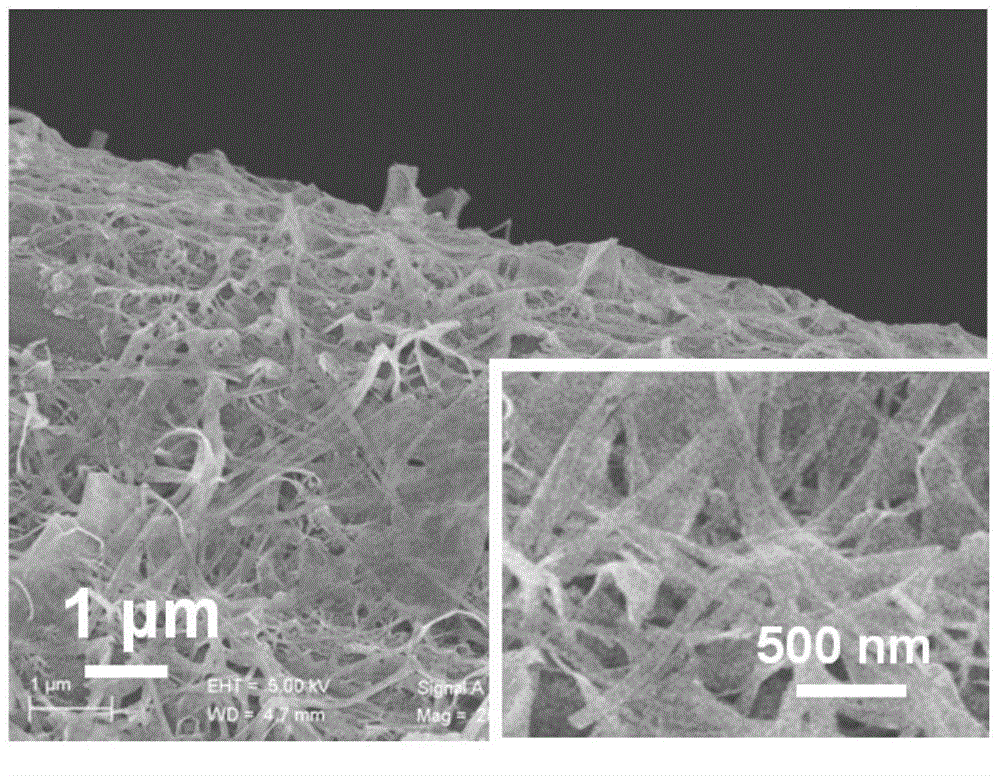

[0037] CoSe prepared in this example 2 SEM image of / CF composite material figure 1 As shown, the inset is a partially enlarged SEM image. As can be seen from the illustration, the carbon fiber surface is even...

Embodiment 2

[0039] The graphitized carbon fiber felt (three pieces in total, the volume is 1×1×0.5cm 3 , 1×1.5×0.5cm 3 and 1×2×0.5cm 3 , with a total mass of about 0.2 g) placed in a mixed solution of ethanol and water to ultrasonically remove surface oil.

[0040] Weigh 2 mmol of cobalt acetate and 2 mmol of sodium selenite and dissolve in a mixed solvent composed of 26 mL of diethylenetriamine and 13 mL of water, and stir for 10 minutes. Immerse the treated graphitized carbon fiber felt in it and stir for 1 hour to form a mixture.

[0041] The above mixture was transferred to a polytetrafluoroethylene-lined 50mL reactor and sealed, and then reacted in a temperature-controlled oven at 180°C for 16 hours. After the reaction was completed, it was taken out and cooled to room temperature; the product was washed with ethanol and heated at 60 ℃ in a vacuum environment for 6 hours to obtain CoSe 2 / CF composites.

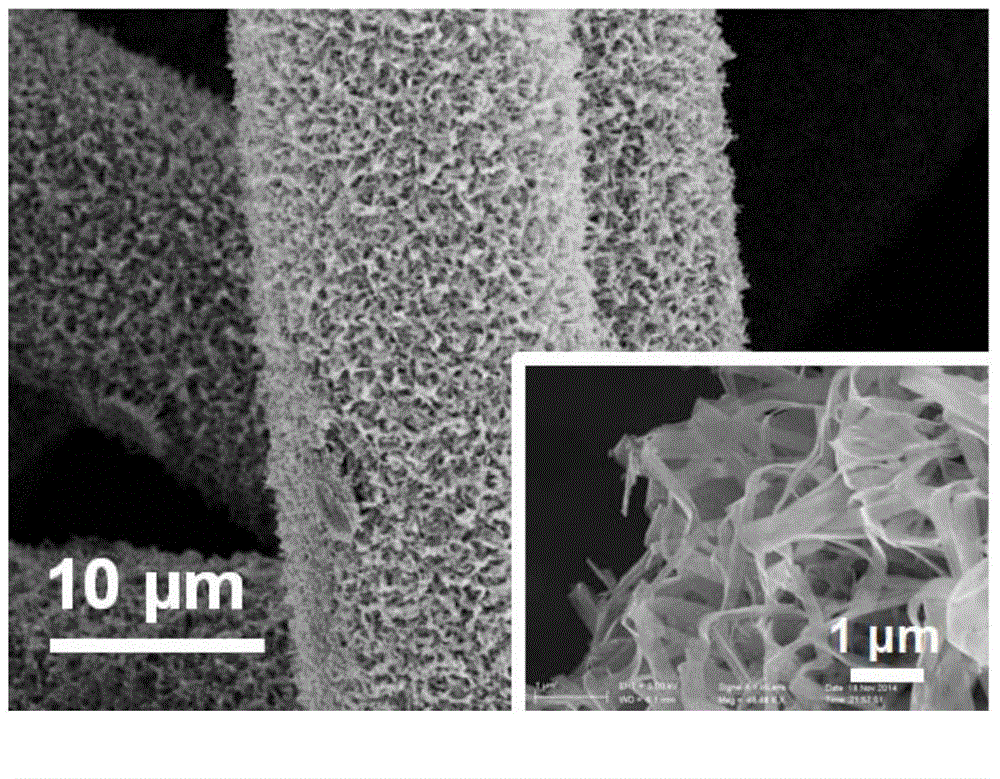

[0042] CoSe prepared in this example 2SEM image of / CF composite material...

Embodiment 3

[0052] Pre-oxidized graphite felt (a total of three pieces, the volume is 1 × 1 × 0.5cm 3 , 1×1.5×0.5cm 3 and 1×2×0.5cm 3 , with a total mass of about 0.2 grams) placed in a mixed solution of ethanol and water to ultrasonically remove surface oil.

[0053] Weigh 3mmol of cobalt acetate and 3mmol of sodium selenite and dissolve in a mixed solution composed of 26mL of diethylenetriamine and 13mL of water, and stir for 10 minutes.

[0054] Soak the treated pre-oxidized graphite felt in the above mixed solvent and stir for 1 hour to form a mixture. The above mixture was transferred to a polytetrafluoroethylene-lined 50mL reactor and sealed, and then reacted in a temperature-controlled oven at 180°C for 16 hours. After the reaction was completed, it was taken out and cooled to room temperature; the product was washed with ethanol and heated at 60 ℃ in a vacuum environment for 6 hours to obtain CoSe 2 / CF composites.

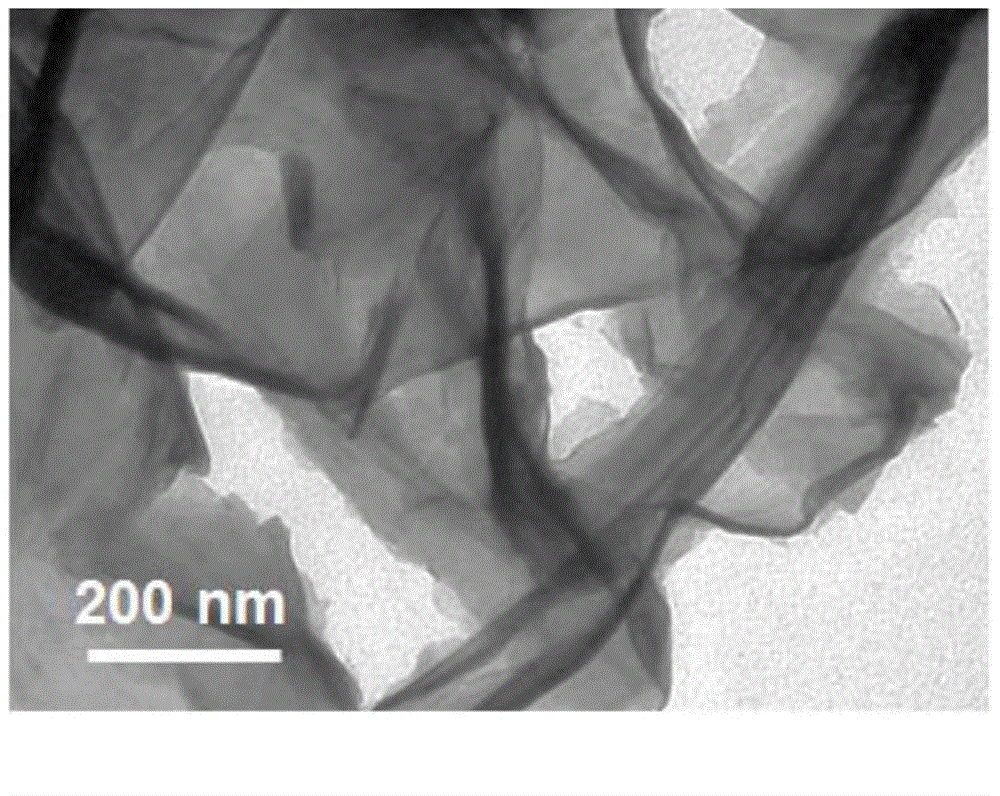

[0055] Figure 11 CoSe prepared for this example 2 The SE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com