Processing method based on chemical vapor flow spinning method for preparing carbon nanotube fiber in inert atmosphere

A technology of carbon nanotube fiber and process method, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc. It can solve the problems of high-temperature hydrogen danger and unfavorable industrial production, etc., and achieve the effect of good orientation, large output and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

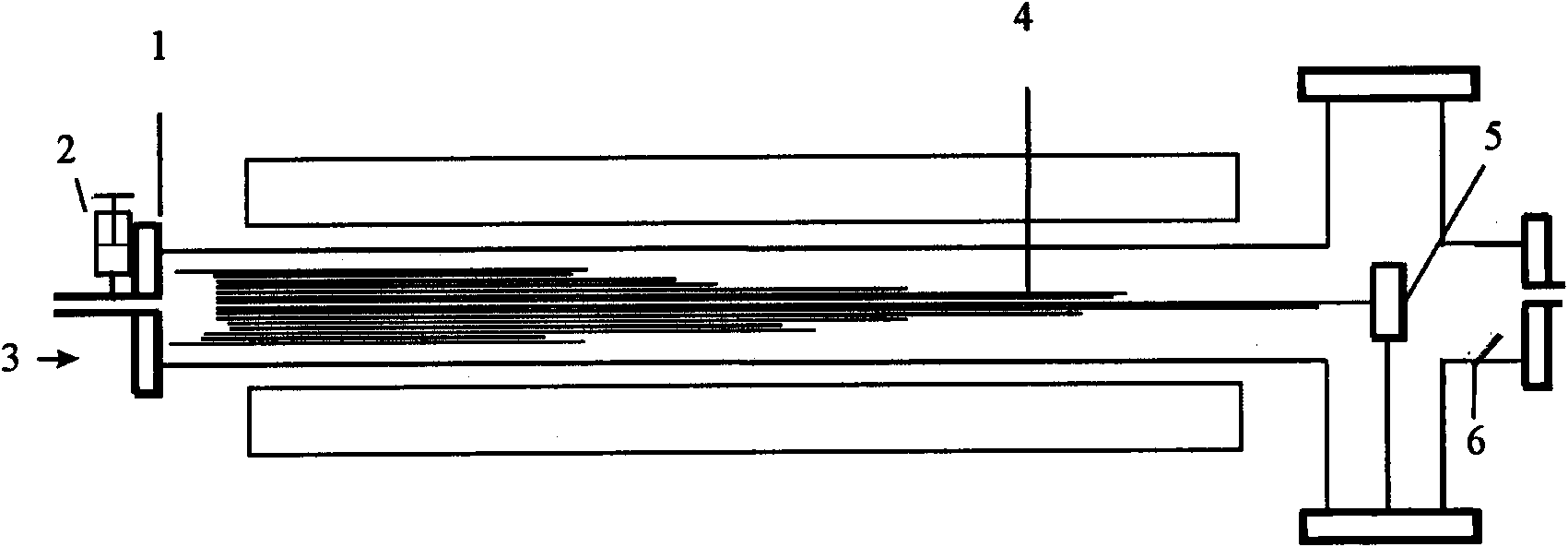

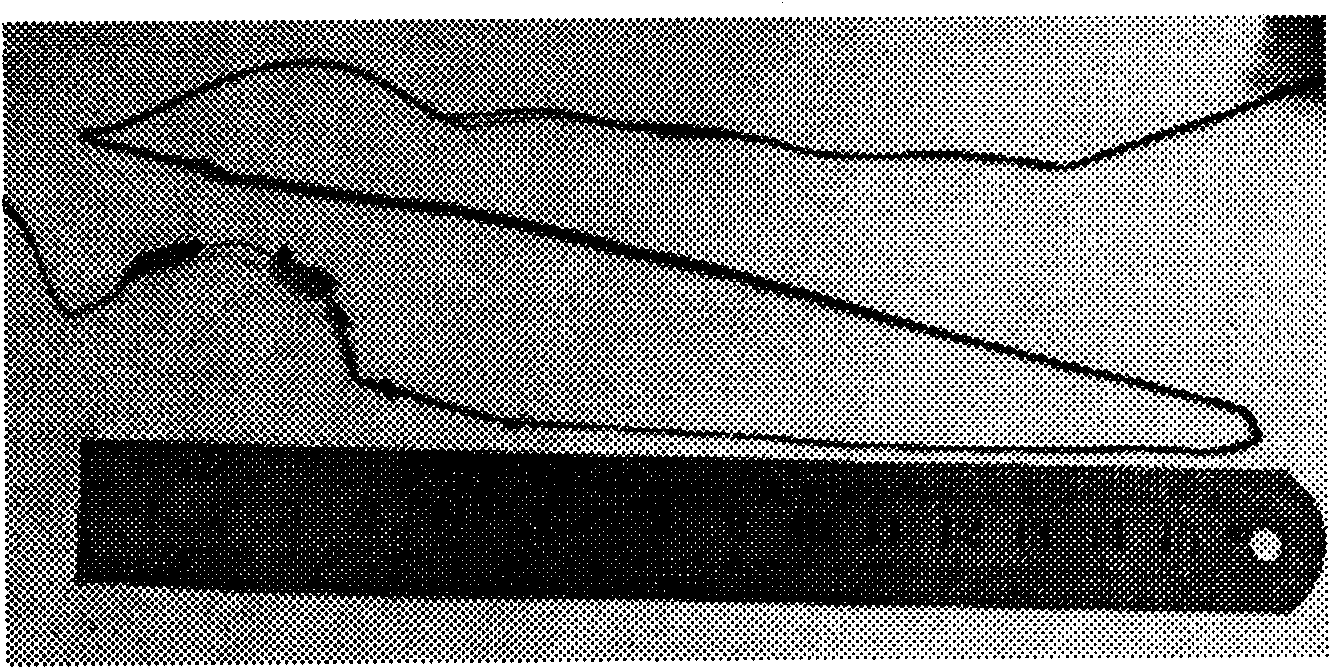

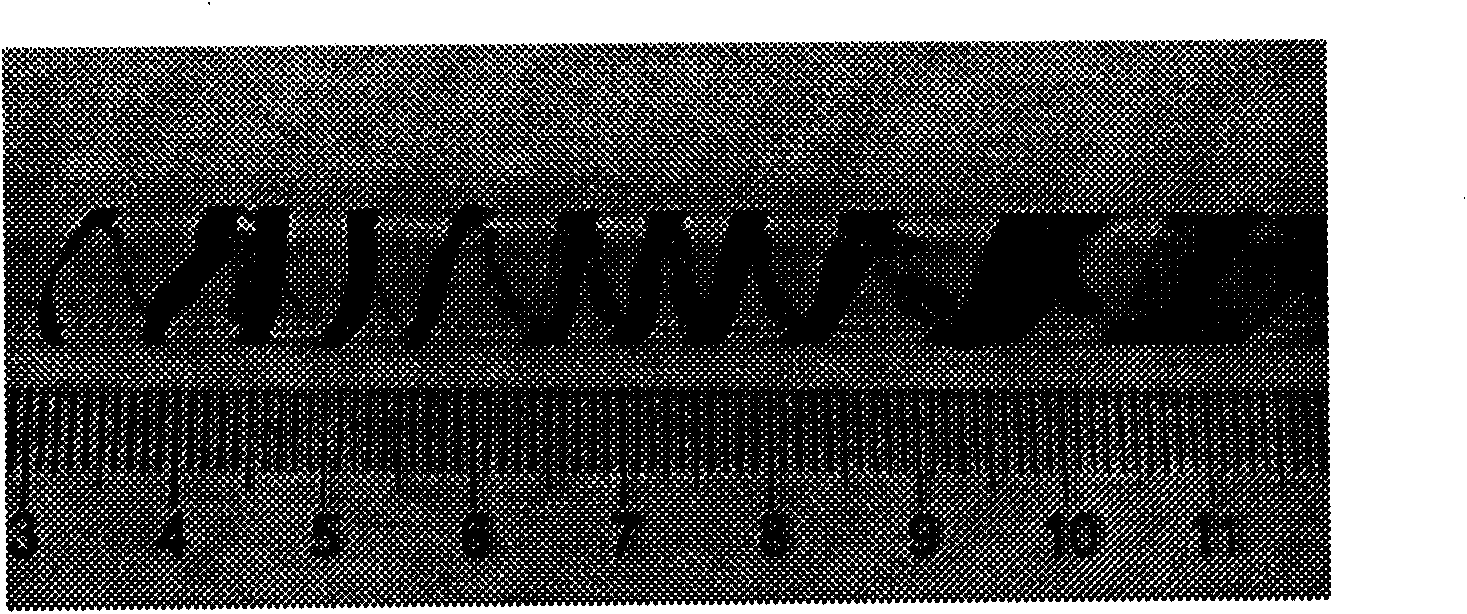

[0014] Example 1: Prepare a mixed solution containing 18.75g ethanol, 0.6g ferrocene, 0.10g thiophene, and 0.1g water, and then ultrasonically disperse the mixed solution for 10min to obtain a yellow reaction solution. After the temperature is 1150°C, the reaction liquid is injected into the airflow of 200ml / min argon as the carrier gas at a rate of 7.0ml / h. The reaction is carried out in the synthesis reactor, and through the observation of the mirror behind the quartz tube, it is found that the cylindrical carbon tube fiber will be formed in the high temperature zone of the quartz tube. The cylindrical fiber is driven by argon to continuously 'flow' from the reaction zone and reach the quartz tube. Tube intersection. At this time, when the motor at the end of the quartz tube is turned, the cylindrical fiber can be wound continuously on the winding rod.

Embodiment 2

[0015] Example 2: Prepare a mixed solution containing 18.75g of acetone, 0.6g of ferrocene, and 0.10g of thiophene, and then ultrasonically disperse the mixed solution for 10 minutes to obtain a yellow reaction solution. After the temperature of the tubular resistance furnace rises to the synthesis temperature of 1150°C , the reaction solution is injected into the gas stream of 200ml / min argon as the carrier gas at a rate of 7.0ml / h, the reaction solution meets the flange (300°C) and rapidly vaporizes at high temperature, and enters the high-temperature synthesis reactor driven by the carrier gas The reaction is carried out, and the cylindrical carbon tube fibers formed in the high temperature zone of the quartz tube are observed through the mirror behind the quartz tube. The cylindrical fiber is driven by argon gas to continuously 'flow' from the reaction zone and reach the intersection of the quartz tube. At this time, when the motor at the end of the quartz tube is turned, t...

Embodiment 3

[0016] Example 3: Prepare a mixed solution containing 18.75g of acetone, 0.6g of ferrocene, and 0.10g of thiophene, and then ultrasonically disperse the mixed solution for 10 minutes to obtain a yellow reaction solution. After the temperature of the tubular resistance furnace rises to the synthesis temperature of 1150°C , the reaction solution is injected into the airflow of 200ml / min nitrogen as the carrier gas at a rate of 7.0ml / h, the reaction solution meets the flange (300°C) and rapidly vaporizes at high temperature, and enters the high-temperature synthesis reactor driven by the carrier gas to carry out Reaction, through the observation of the mirror behind the quartz tube, it is found that the cylindrical carbon tube fiber will be formed in the high temperature zone of the quartz tube, and the cylindrical fiber is driven by argon to continuously 'flow' from the reaction zone and reach the intersection of the quartz tube. At this time, when the motor at the end of the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com