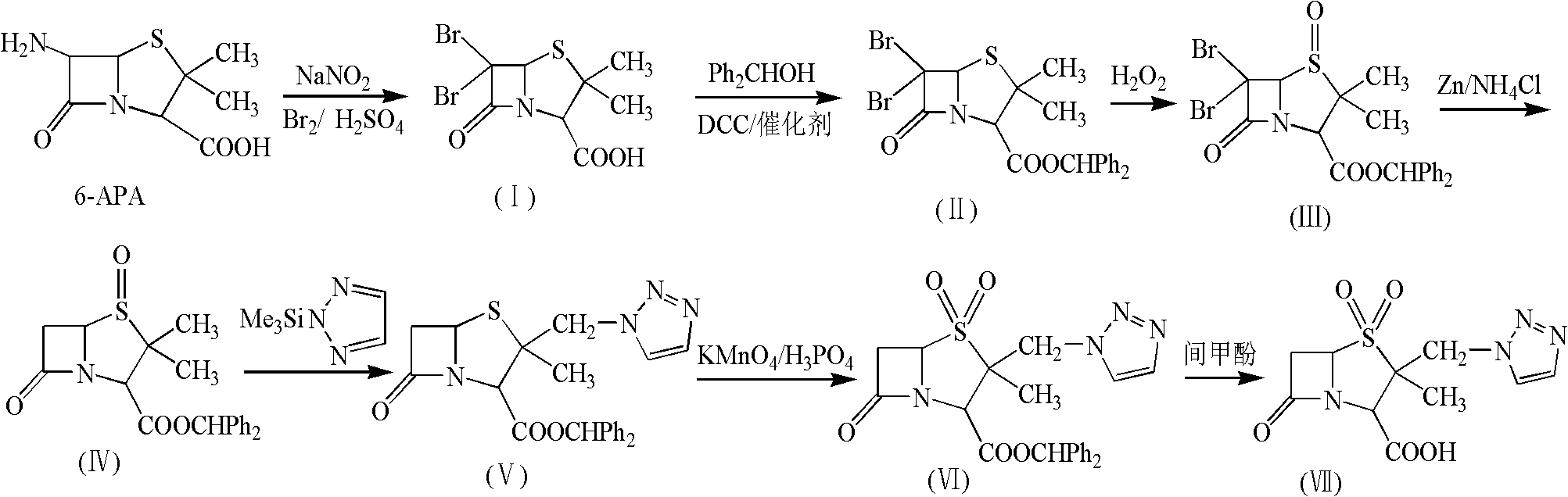

Tazobactam synthesis method

A technology for tazobactam and a synthesis method is applied in the synthesis field of β-lactamase inhibitor tazobactam, can solve the problems of low total yield, danger and explosion, and achieves simple operation, easy industrial production, The effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] (1) Add CH to a 1000mL three-necked bottle 2 Cl 2 300mL and 1.5mol.L -1 h 2 SO 4 100mL, stirred and cooled to 0°C, then added 36.5g (0.228mol) of bromine, 0.33g of hexadecyltrimethylammonium bromide and 10.5g (0.152mol) of sodium nitrite into the reaction liquid, and continued stirring to dissolve Then add 33g (0.152mol) of 6-APA in batches, and after stirring for 1h at 0-5°C, add 1mol.L -1 NaHSO 3 Until the solution is tested with KI-starch test paper and does not change color. Then let the layers stand, and the water layer was washed with 100mL CH 2 Cl 2 After two extractions, the organic layers were combined, followed by water, 7% NaHCO 3 Aqueous solution, saturated sodium chloride aqueous solution washing, the obtained CH containing 6,6-dibromopenicillanic acid 2 Cl 2 The solution was directly used in the next reaction.

[0059] (2) Add the CH of 6,6-dibromopenicillanic acid in a 1000mL three-necked bottle 2 Cl 2 Solution (about 400ml), after cooling ...

Embodiment 2

[0066] (1) Add CH to a 1000mL three-necked bottle 2 Cl 2 300mL and 1.5mol.L -1 h 2 SO 4 100mL, stirred and cooled to 0°C, then added 73g (0.456mol) of bromine, 1.65g of dodecyltriethylammonium bromide and 10.5g (0.152mol) of sodium nitrite into the reaction liquid, and kept stirring, after dissolving Add 33g (0.152mol) of 6-APA in batches, and after stirring for 1h at 0-5°C, add 1mol.L -1 NaHSO 3 Until the solution is tested with KI-starch test paper and does not change color. Then let the layers stand, and the water layer was washed with 100mL CH 2 Cl 2 After two extractions, the organic layers were combined, followed by water, 7% NaHCO 3 Aqueous solution, saturated sodium chloride aqueous solution washing, the obtained CH containing 6,6-dibromopenicillanic acid 2 Cl 2 The solution was directly used in the next reaction.

[0067] (2) Add the CH of 6,6-dibromopenicillanic acid in a 1000mL three-necked bottle 2 Cl 2 Solution (about 400ml), after cooling down to 5...

Embodiment 3

[0074] (1) Add CH to a 1000mL three-necked bottle 2 Cl 2 300mL and 1.5mol.L -1 h 2 SO 4 100mL, stirred and cooled to 0°C, then added 122g (0.762mol) of bromine, 2.2g of dodecyltrimethylammonium bromide and 35g (0.508mol) of sodium nitrite into the reaction solution, and kept stirring, dissolved and divided Add 55g (0.254mol) of 6-APA in batches, and after stirring for 1h at 0-5°C, add 1mol.L -1 NaHSO 3 Until the solution is tested with KI-starch test paper and does not change color. Then let the layers stand, and the water layer was washed with 100mL CH 2 Cl 2 After two extractions, the organic layers were combined, followed by water, 7% NaHCO 3 Aqueous solution, saturated sodium chloride aqueous solution washing, the obtained CH containing 6,6-dibromopenicillanic acid 2 Cl 2 The solution was directly used in the next reaction.

[0075] (2) Add the CH of 6,6-dibromopenicillanic acid in a 1000mL three-necked bottle 2 Cl 2 Solution (about 400ml), after cooling to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com