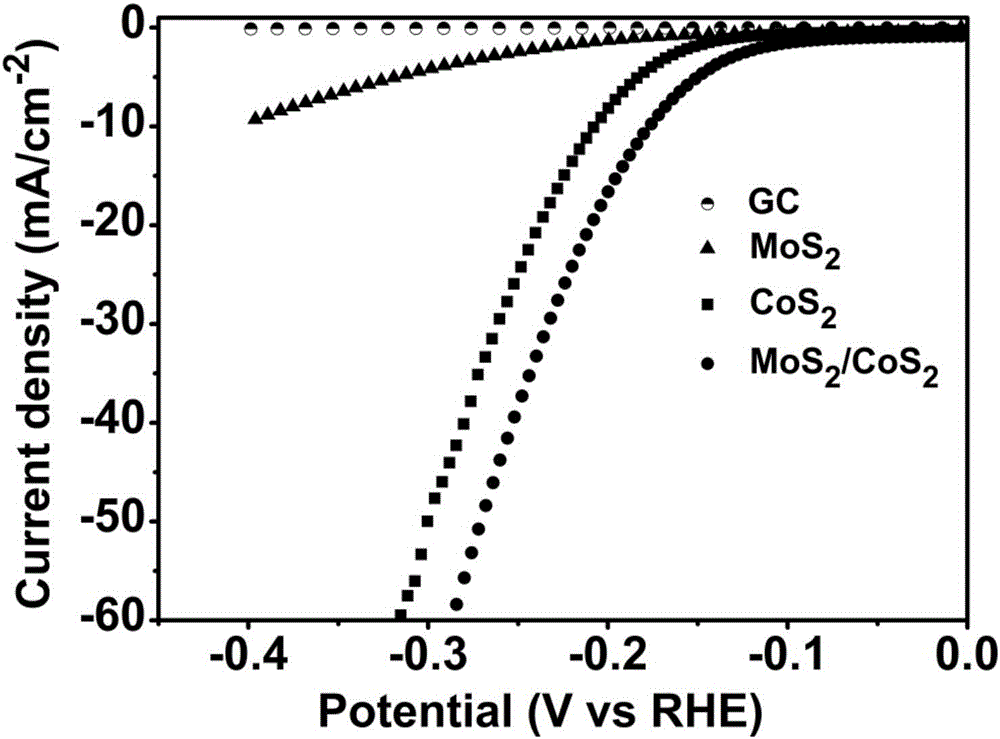

MoS2/CoS2 composite water-splitting hydrogen-production low-overpotential electrocatalyst and sulfidation preparation method thereof

An electrocatalyst and overpotential technology, applied in physical/chemical process catalysts, chemical instruments and methods, electrolysis processes, etc., can solve problems such as high overpotential and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Take 0.291 gram of cobalt nitrate hexahydrate solid particles, add 15 milliliters of deionized water in the reaction vessel and stir for 10 minutes to make it dissolve completely;

[0023] (2) Get 0.242 grams of sodium molybdate dihydrate solid particles in another reaction vessel, then add 15 milliliters of deionized water and stir for 10 minutes until sodium molybdate dihydrate is completely dissolved;

[0024] (3) Mix the solutions in step (1) and step (2), and then stir for 1.5 hours;

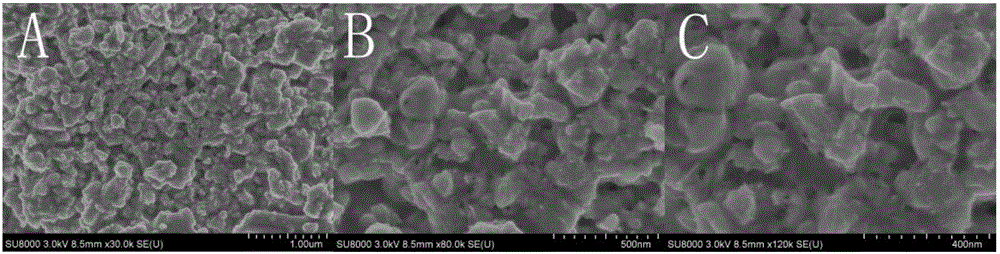

[0025] (4) the solution in the step (3) is transferred in the reactor of 100 milliliters with stainless steel substrate, then this reactor is put into the baking oven of the electric blast that has been warming up to 140 degrees Celsius in advance and keeps 12 hours, then When the temperature of the reaction kettle drops to room temperature, pour out the supernatant in the reaction kettle, wash the substrate 4 times with deionized water, and wash 3 times with absolute ethanol, an...

Embodiment 2

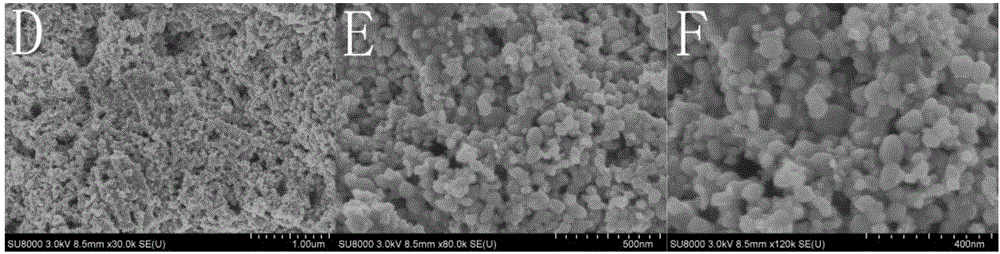

[0030] (1) Get 0.291 gram of cobalt nitrate hexahydrate solid particles and 0.121 gram of urea in the reaction vessel, add 30 milliliters of deionized water and stir for 30 minutes to dissolve the reactants completely;

[0031] (2) the solution in the step (1) is transferred in the reactor of 100 milliliters with stainless steel substrate, then this reactor is put into the baking oven of the electric blast that has been warming up to 140 degrees Celsius in advance and keeps 12 hours, then When the temperature of the reaction kettle drops to room temperature, the supernatant in the reaction kettle is poured out, the substrate is washed 4 times with deionized water, and 3 times with absolute ethanol, and then the washed product is placed in an electric blast at 80 degrees Celsius. Drying in the drying box for 24 hours has obtained the precursor of cobalt disulfide to be prepared;

[0032] (3) Weigh 70 mg of the precursor prepared in step (2) into the quartz boat, and weigh 3 gra...

Embodiment 3

[0036] (1) Weigh 0.242 grams of sodium molybdate dihydrate solid particles into the quartz boat, and weigh 3 grams of sublimed sulfur into another quartz boat, and then push the quartz boat containing the precursor into the tube Type furnace heating zone, and then push the quartz boat containing sublimated sulfur into the heating zone of the same tube furnace, and ensure that the quartz boat containing sublimated sulfur is located behind the quartz boat containing precursors, so that after high temperature sublimation The sulfur vapor passes through the precursor under the drainage of nitrogen, so that the precursor can be vulcanized;

[0037] (2) The air in the quartz tube in the tube furnace of step (1) is discharged, then feed nitrogen, set the program according to the heating rate of 40 degrees Celsius / min. The heating temperature is set to 400 degrees Celsius, and the holding time is set to 2 hours for roasting and vulcanization , when the temperature drops to room temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com