High heat resistance liquid modified bismaleimide resin and preparation method thereof

A technology of bismaleimide resin and bismaleimide, which is applied in the field of high heat resistance liquid modified bismaleimide resin and its preparation, can solve the problem of not taking into account the heat resistance and the inability to use and other problems, to achieve excellent heat resistance, easy to control, and meet the effects of industrialization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In a 500ml glass bottle equipped with a thermometer, a feeding funnel and a mechanical stirring device, add 80g of 3-aminobenzocyclobutene, raise the temperature to 135℃, and add 160g of 4,4'-bismaleyl within 1 hour The iminodiphenylmethane was kept for 2 hours to obtain a uniform transparent brown-red prepolymer.

[0055] The temperature was lowered to 80°C within 30 minutes, 36 g of bisphenol A diallyl ether and 12 g of divinylbenzene were added, and the temperature was kept for 15 minutes.

[0056] After the system is cooled to room temperature, add 24 g of 2-methylimidazole / cobalt acetylacetonate butanone solution with a solute ratio of 10%. After stirring, the mixture is evaporated on a rotary evaporator at 40°C to remove the solvent to obtain a liquid brownish red Transparent resin.

[0057] The resin has a viscosity of 289cP at 30°C tested by a rotary viscometer, showing excellent fluidity and excellent processing performance.

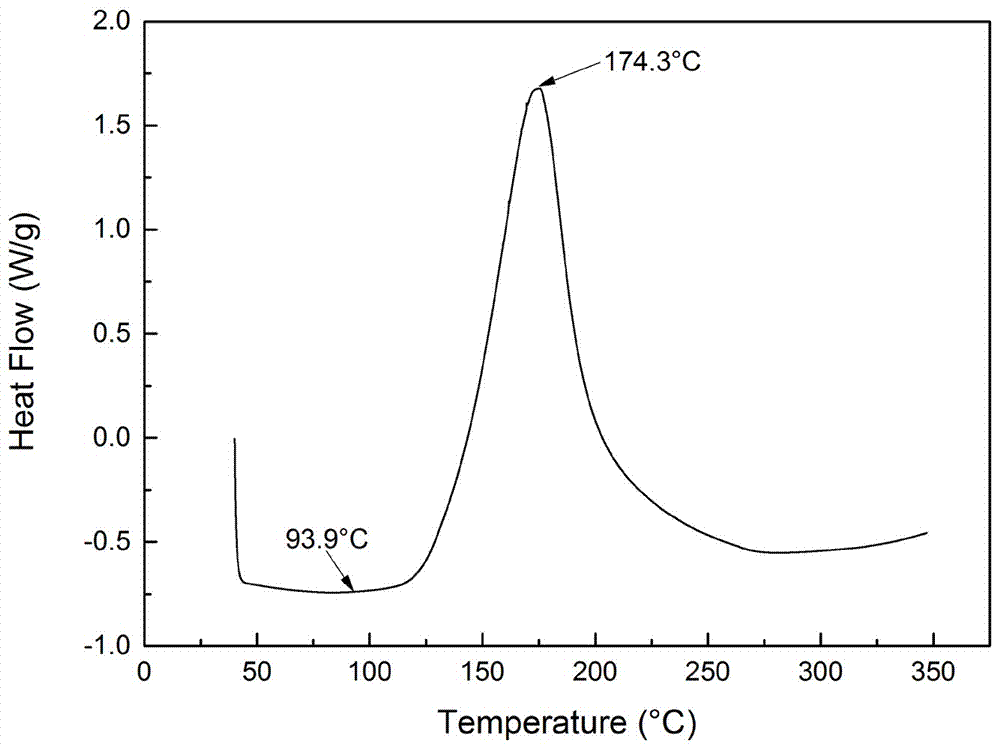

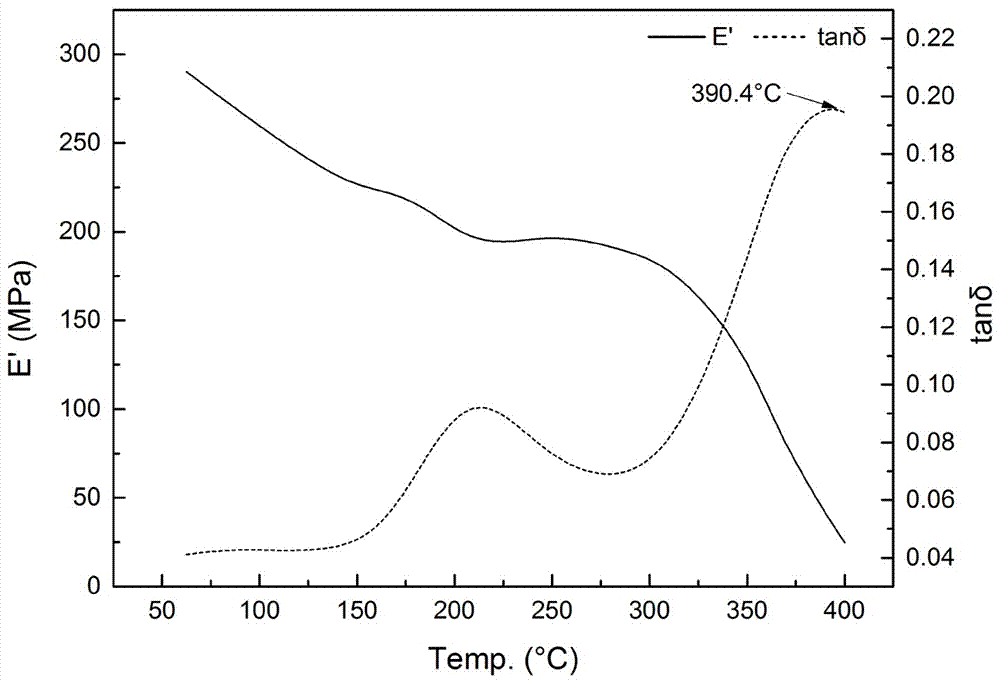

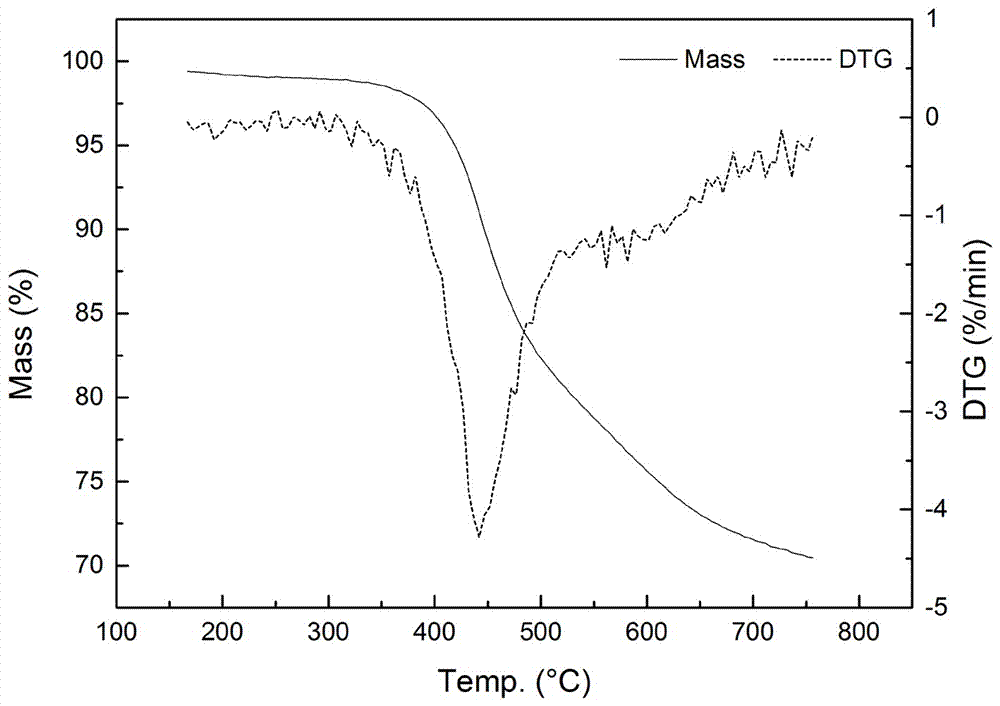

[0058] The curing activity of the obtaine...

Embodiment 2

[0061] In a 500ml glass bottle equipped with a thermometer, a feeding funnel and a mechanical stirring device, add 80g of 3-aminobenzocyclobutene, raise the temperature to 135℃, and add 160g of 4,4'-bismaleyl within 1 hour The imine diphenyl ether was kept and reacted for 2 hours to obtain a uniform and transparent brown-red prepolymer.

[0062] The temperature was lowered to 80°C within 30 minutes, 36 g of bisphenol A diallyl ether and 12 g of divinylbenzene were added, and the temperature was kept for 15 minutes.

[0063] After the system is cooled to room temperature, add 24 g of 2-methylimidazole / iron acetylacetonate solution in acetone with a solute ratio of 10%. After stirring, the mixture is evaporated on a rotary evaporator at 30°C to remove the solvent, and the liquid is brown-red and transparent. Resin.

Embodiment 3

[0065] In a 500ml glass bottle equipped with a thermometer, an addition funnel and a mechanical stirring device, add 80g of 3-aminobenzocyclobutene, heat up to 135℃, and add 140g of 4,4'-bismaleyl within 1 hour The imine diphenyl ether was kept and reacted for 2 hours to obtain a uniform and transparent brown-red prepolymer.

[0066] The temperature was lowered to 80°C within 30 minutes, 36 g of bisphenol A diallyl ether and 12 g of divinylbenzene were added, and the temperature was kept for 15 minutes.

[0067] After the system is cooled to room temperature, add 22 g of 2-ethyl-4-methylimidazole / nickel acetylacetonate solution in acetone with a solute ratio of 10%. After stirring, the mixture is evaporated on a rotary evaporator at 35°C to remove the solvent. A liquid brown-red transparent resin is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com