Manganese cobalt composite oxide (MnCo2O4) magnetic nanocrystal and preparation method thereof

A composite oxide and magnetic nanotechnology, which is applied in cobalt compounds, chemical instruments and methods, nanotechnology, etc., to achieve the effects of convenient operation, large-scale industrial production, and a wide range of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In the following, the present invention will be explained in further detail in conjunction with the accompanying drawings and embodiments.

[0033] Weigh 1.5794g KMnO 4 , 12.4970g Co(Ac) 2 4H 2 O, 2.6732g Mn(Ac) 2 , put into a 150ml beaker, add 85ml of Milli-Q water to the beaker, put in a magnet, and stir on a magnetic stirrer for half an hour to make the reactants mix evenly. Transfer the above reaction mixture into a 100ml polytetrafluoroethylene-stainless steel autoclave, seal the autoclave, put it in an oven, keep it at 180°C for 16-24 hours, and then take it out. After cooling, open the reaction kettle, centrifuge, wash the sample three times with Milli-Q water, vacuum-dry the obtained black precipitate, and the obtained black powder is the MnCo 2 o 4 Nanocrystalline.

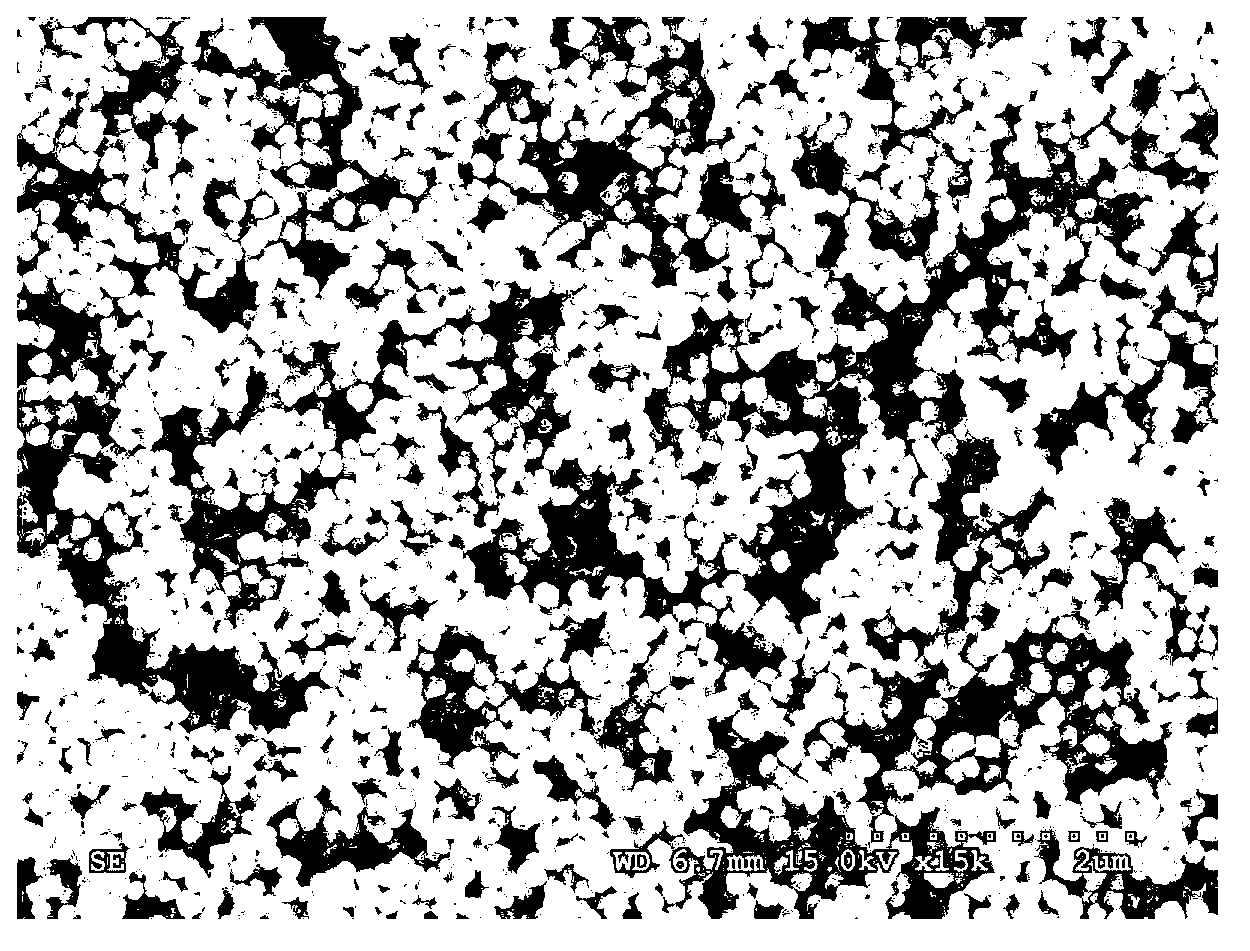

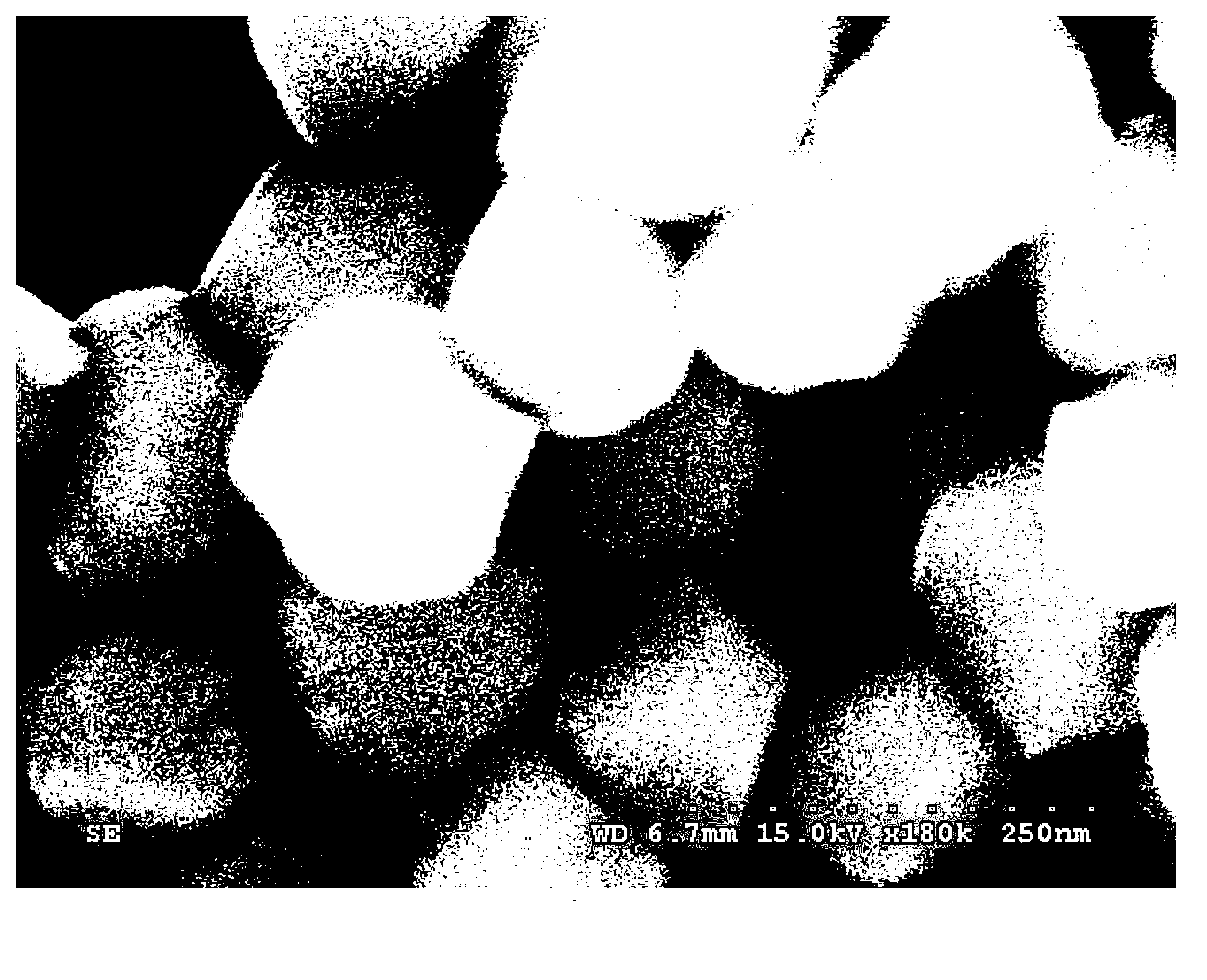

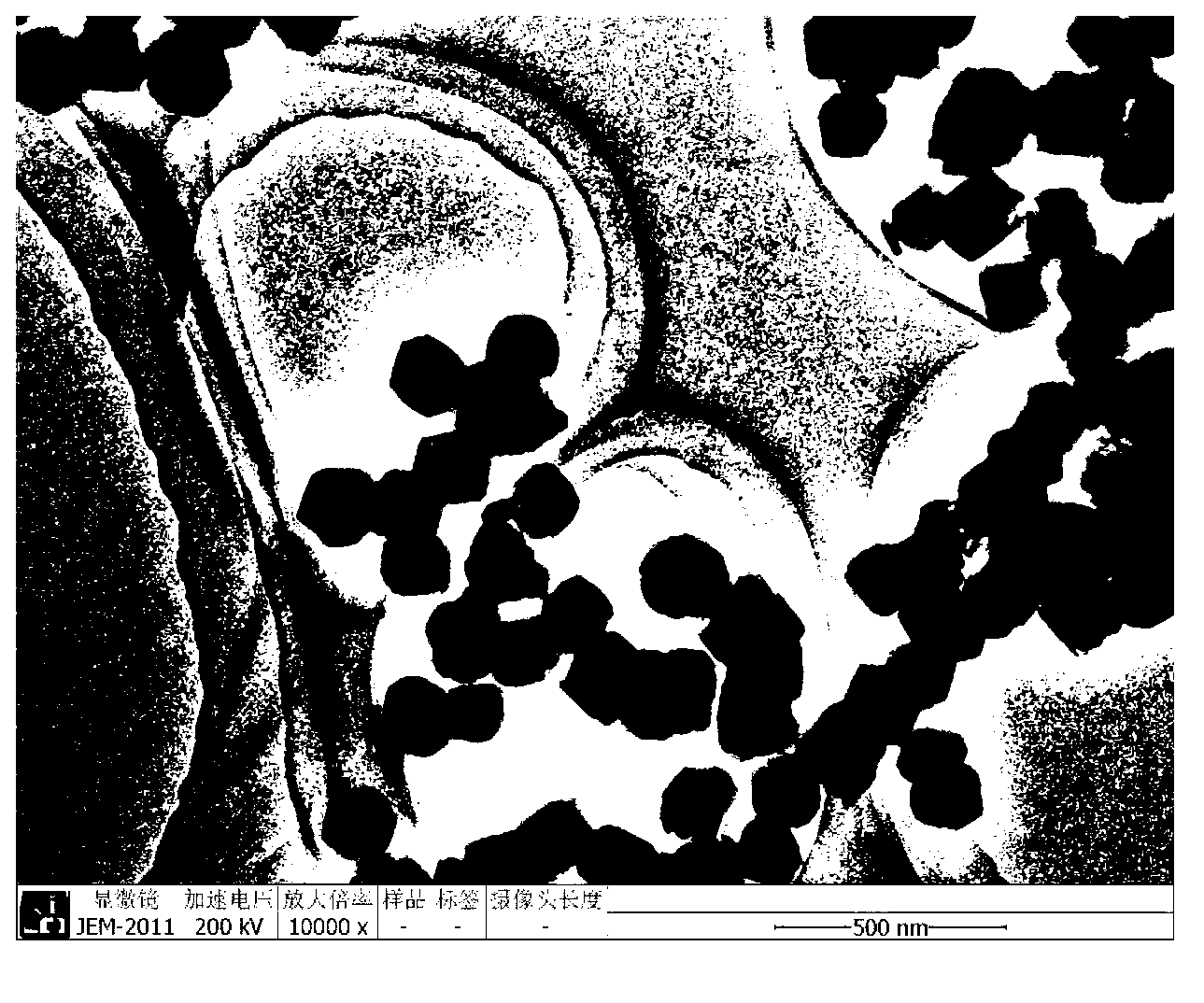

[0034] Figure 1 shows the prepared MnCo 2 o 4 Scanning electron microscope (SEM) photograph of magnetic nanocrystals. As can be seen from the above picture, the obtained MnCo 2 o 4 The mag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com