Silicon-carbon cathode material with artificial SEI layers, high specific volumetric capacity and cycle performance

A cycle performance and negative electrode material technology, which is applied in the field of lithium ion battery negative electrode materials and silicon-carbon composite lithium ion battery negative electrode materials, can solve the problems of poor stability of SEI film, low volume specific capacity, large volume change, etc., and achieve improved adhesion effect , improve the volume specific capacity, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

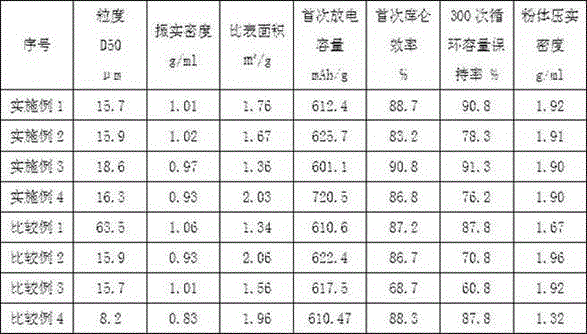

Examples

Embodiment 1

[0031] Example 1 Mesophase graphite microspheres with a median particle size of 60 μm were processed in a crushing and shaping device to have a median particle size of 7 μm and a specific surface area of 7.5 m 2 / g powder. Take 42.5g of the powder material and add it to the ball mill jar, and at the same time add 7.5g of silicon powder with a median particle size of 200nm and 500ml of absolute ethanol, and use zirconia balls in the ball mill at a speed of 450rpm for 10h. The slurry was transferred to a stirring tank, and 58 g of a 10% lithium acetate aqueous solution was added under stirring, and stirred for 1 h. Prepare 10% NH with deionized water 4 F aqueous solution, 22g of this NH 4 F aqueous solution was added dropwise into the complex solution of lithium acetate, graphite and silicon, and stirred for 30 min. The mixed solution was spray-dried on a spray-drying device at an exhaust air temperature of 105°C. The spray-dried material and PVDF were mixed and added to t...

Embodiment 2

[0032] Example 2 Mesophase graphite microspheres with a median particle size of 60 μm were processed in crushing and shaping equipment into a median particle size of 7 μm and a specific surface area of 7.5 m 2 / g powder. Take 42.5g of the powder material and add it to a ball mill jar. At the same time, add 7.5g of silicon with a median particle size of 200nm and 500ml of absolute ethanol in the ball mill with zirconia balls at a speed of 450rpm for 10h. The slurry was transferred to a stirring tank, and 29 g of a 10% lithium acetate aqueous solution was added under stirring, and stirred for 1 h. Prepare 10% NH with deionized water 4 F aqueous solution, 11g of this NH 4 F aqueous solution was added dropwise into the complex solution of lithium acetate, graphite and silicon, and stirred for 30 min. The mixed solution was spray-dried on a spray-drying device at an exhaust air temperature of 105°C. The spray-dried material and PVDF were mixed and added to the pan granulator ...

Embodiment 3

[0033] Example 3 Mesophase graphite microspheres with a median particle size of 60 μm were processed in a crushing and shaping device to have a median particle size of 7 μm and a specific surface area of 7.5 m 2 / g powder. Take 42.5g of the powder material and add it to a ball mill jar. At the same time, add 7.5g of silicon with a median particle size of 200nm and 500ml of absolute ethanol in the ball mill with zirconia balls at a speed of 450rpm for 10 hours. The slurry was transferred to a stirring tank, and 58 g of a 10% lithium acetate aqueous solution was added under stirring, and stirred for 1 h. Prepare 10% NH with deionized water 4 F aqueous solution, 22g of this NH 4 F aqueous solution was added dropwise into the complex solution of lithium acetate, graphite and silicon, and stirred for 30 min. The mixed solution was spray-dried on a spray-drying device at an exhaust air temperature of 105°C. The spray-dried material and PVDF were mixed and added to the pan granu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com