Preparation method of Li4Ti5O12-TiO2 composite electrode material

A technology for composite electrodes and preparation steps, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as environmental pollution and molten salt pollution to synthetic crystals, and achieve simple equipment and processes, excellent cycle stability, and simplified The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

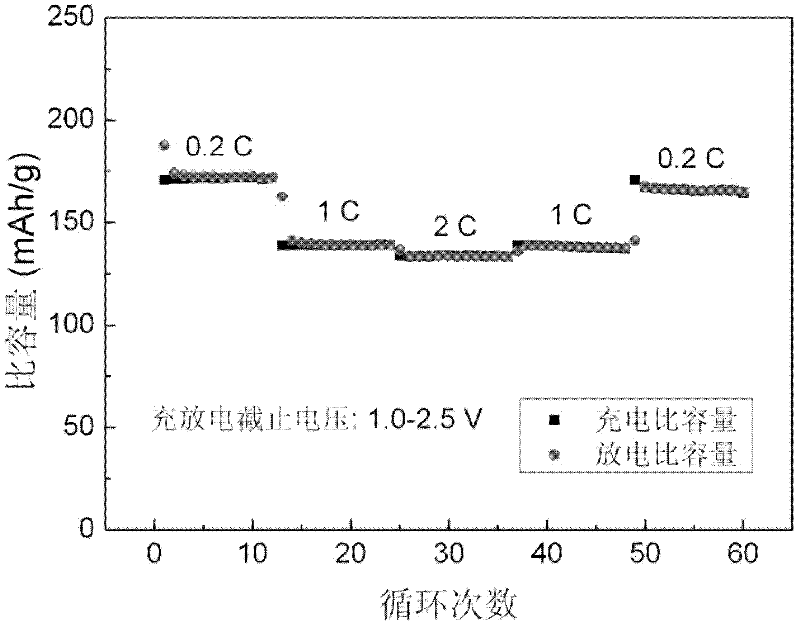

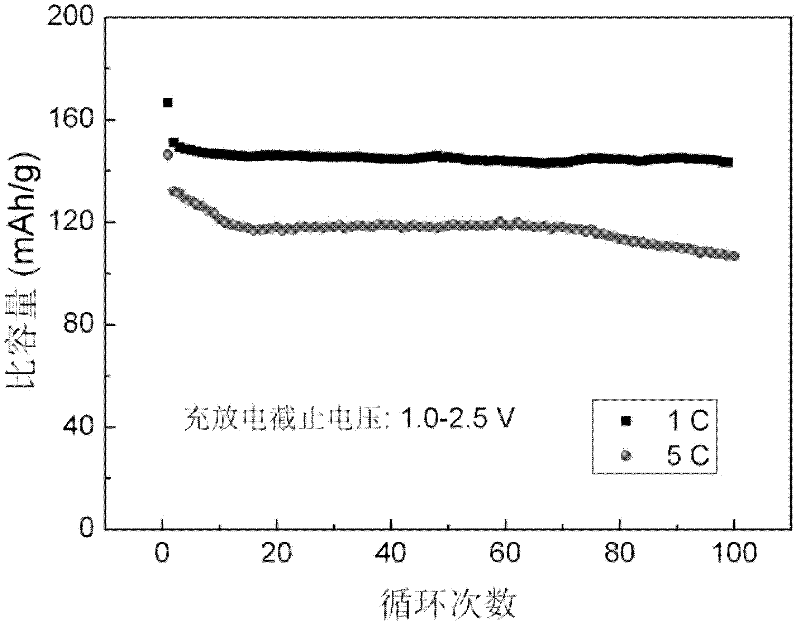

Embodiment 1

[0028] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%), mix with 50 ml of absolute ethanol, and form a clear solution under magnetic stirring; according to the atomic ratio Li / Ti = 1.4, weigh 1.000 g of analytically pure acetic acid Lithium (purity ≥ 99.0%) is added to the titanium-containing solution, and magnetic stirring is continued to form a clear solution containing lithium-titanium mixture; slowly add 2 ml of analytical pure ammonia water (content 25-28%), mix well, and form a milky white suspension liquid; transfer the suspension to a 100 ml Teflon-lined self-tightening autoclave, and place it in an oven at 180 o C was incubated for 24 hours; after cooling to room temperature, the product was washed with absolute ethanol, and filtered under vacuum at 80 o After vacuum drying in C oven, white amorphous Li 4 Ti 5 o 12 -TiO 2 Powder; under air atmosphere, with 5 o C / min rate of heating, the resulting powder at 600 o C for 2 hours, cooled to r...

Embodiment 2

[0032] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%), mix with 50 ml of absolute ethanol, and form a clear solution under magnetic stirring; according to the atomic ratio Li / Ti = 1.4, weigh 1.000 g of analytically pure acetic acid Add lithium (purity ≥ 99.0%) to the titanium-containing solution, continue magnetic stirring to form a clear solution containing lithium-titanium mixture; slowly add 1 ml analytical pure ammonia water (content 25~28%), mix well, and form a milky white suspension liquid; transfer the suspension to a 100 ml Teflon-lined self-tightening autoclave, and place it in an oven at 180 o C was incubated for 24 hours; after cooling to room temperature, the product was washed with absolute ethanol, and filtered under vacuum at 80 o After vacuum drying in C oven, white amorphous Li 4 Ti 5 o 12 -TiO 2 Powder; under air atmosphere, with 5 o C / min rate of heating, the resulting powder at 600 o C for 2 hours, cooled to room temperature ...

Embodiment 3

[0036] Weigh 2.383 g of analytically pure tetrabutyl titanate (purity ≥ 99.0%), mix with 50 ml of absolute ethanol, and form a clear solution under magnetic stirring; according to the atomic ratio Li / Ti = 1.2, weigh 0.857 g of analytically pure acetic acid Lithium (purity ≥ 99.0%) is added to the titanium-containing solution, and magnetic stirring is continued to form a clear solution containing lithium-titanium mixture; slowly add 2 ml of analytical pure ammonia water (content 25-28%), mix well, and form a milky white suspension liquid; transfer the suspension to a 100 ml Teflon-lined self-tightening autoclave, and place it in an oven at 180 o C was incubated for 24 hours; after cooling to room temperature, the product was washed with absolute ethanol, and filtered under vacuum at 80 o After vacuum drying in C oven, white amorphous Li 4 Ti 5 o 12 -TiO 2 Powder; under air atmosphere, with 5 o C / min rate of heating, the resulting powder at 600 o C for 2 hours, cooled to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com