Electrolyte for inhibiting growth of lithium dendrites and lithium battery

An electrolyte and lithium dendrite technology, which is applied in the field of electrolyte and lithium batteries, can solve problems such as poor safety, poor cycle performance, and low Coulombic efficiency, and achieve the goals of improving performance, inhibiting the growth of dendrites, and reducing side reactions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under the protection of argon gas, mix DOL and DME at a volume ratio of 1:1, add LiTFSI at a lithium salt concentration of 1 mol / L, stir to obtain a LiTFSI / (DOL+DME) solution, and then add the additive LiI, where LiI The mass fraction is 2%. Stir fully to make LiTFSI / (DOL+DME) functional electrolyte containing additives.

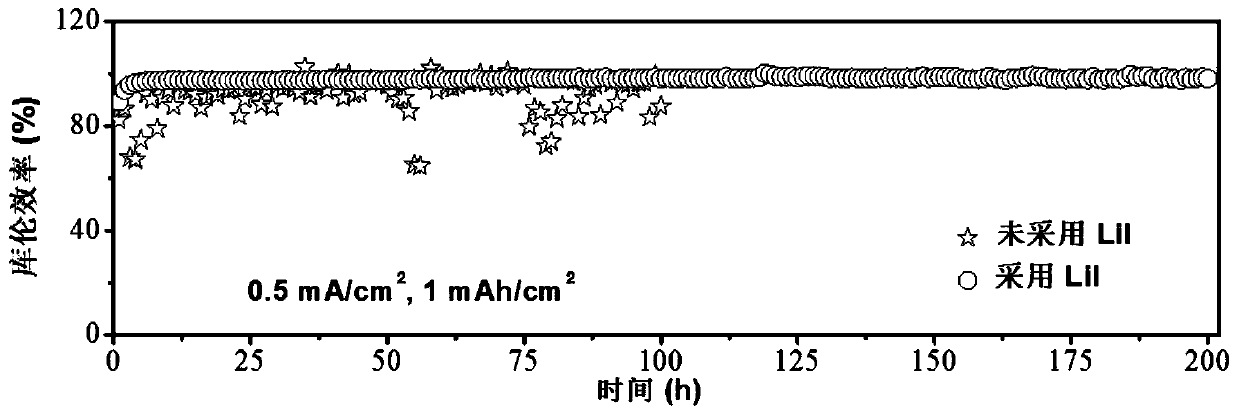

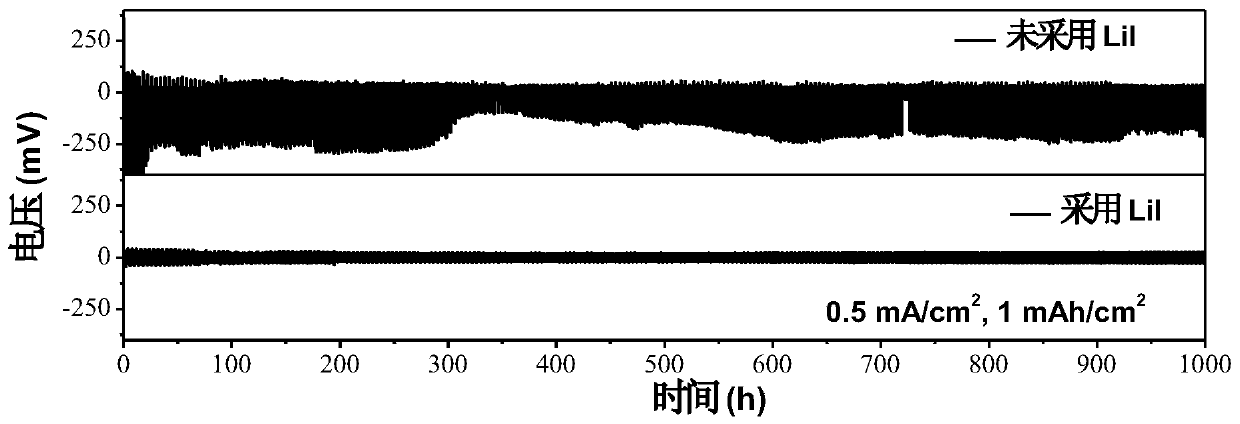

[0028] The metal lithium negative electrode was assembled into Li||Cu battery with LiTFSI / (DOL+DME) solution and LiTFSI / (DOL+DME) functional electrolyte as electrolyte, PP as separator, and copper foil. The test found that the current The density is 0.5 mA / cm 2 , The deposition capacity is 1 mAh / cm 2 Under conditions, the Coulomb efficiency of Li||Cu batteries containing LiI additives is still 98% after 200 cycles (see figure 1 ). Using LiTFSI / (DOL+DME) solution and LiTFSI / (DOL+DME) functional electrolyte as electrolytes, they were assembled into Li||Li symmetrical batteries, at a current density of 0.5 mA / cm 2 , The deposition capacity is 1 mAh / cm 2 Und...

Embodiment 2

[0030] Under the protection of argon gas, mix EC and DMC at a volume ratio of 1:1, and add LiPF at a lithium salt concentration of 1 mol / L 6 , Stir into LiPF 6 / (EC+DMC) solution, then add additive LiI, where the mass fraction of LiI is 2%, stir fully to make LiPF with additive LiI 6 / (EC+DMC) Functional electrolyte.

[0031] The lithium metal negative electrode was prepared with LiPF 6 / (EC+DMC) solution and LiPF 6 / (EC+DMC) The functional electrolyte is electrolyte, PP is diaphragm, and it is assembled with copper foil to form Li||Cu battery. The test found that the current density of Li||Cu battery with additives is 0.5 mA / cm 2 , The deposition capacity is 1 mAh / cm 2 Under the same conditions, the coulombic efficiency is still 94% after 80 cycles; while the Li||Cu battery composed of electrolyte without additives is only 61.2% after 80 cycles of the electrolyte under the same conditions. Example 1 figure 1 ). Respectively prepared LiPF 6 / (EC+DMC) solution and LiPF 6 / (EC+DMC) ...

Embodiment 3

[0033] Under the protection of argon gas, mix DOL and DME at a volume ratio of 1:1, and add LiCF at a lithium salt concentration of 1 mol / L 3 SO 3 , Stir into a homogeneous solution to obtain LiCF 3 SO 3 / (DOL+DME) solution, then add additives LiCl and LiNO 3 , The mass fraction of LiCl is 1%, LiNO 3 The mass fraction is 2%, and the mixing is sufficient to use LiCF with additives 3 SO 3 / (DOL+DME) Functional electrolyte.

[0034] The lithium metal negative electrode, respectively, with LiCF 3 SO 3 / (DOL+DME) solution and LiCF 3 SO 3 / (DOL+DME) The functional electrolyte is electrolyte, PP is diaphragm, which is assembled with copper foil to form Li||Cu battery. The test found that the current density is 2 mA / cm 2 , The deposition capacity is 4 mAh / cm 2 Under the same conditions, the Coulomb efficiency of the Li||Cu battery with additives is still 93% after 40 cycles; while the Li||Cu battery without additives is cycled for 40 cycles under the same conditions. Only 83.4% (refer to E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com