A kind of electrolyte additive for lithium metal negative electrode protection and its preparation method and application

An electrolyte and additive technology, applied in the field of electrolyte additives for lithium metal anode protection and their preparation, can solve the problems of uneven deposition, uneven current density distribution, potential safety hazards, etc., so as to improve deposition dissolution efficiency and inhibit growth. , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Preparation of LiTCNQ:

[0057] Weigh 1g TCNQ and 1.02g LiI, grind them evenly, then add them into 50mL acetonitrile solution and stir for 40min. React at 60-80°C, when the color of the solid product changes from yellow to purple, the reaction is completed, filter, wash the resulting product with acetonitrile, and finally recrystallize in ethanol solution, dry the resulting solid in a vacuum oven at 80°C for 12 hours, That is LiTCNQ with a purity of 98.5% to 99.5%.

[0058] LiTCNQ characterization:

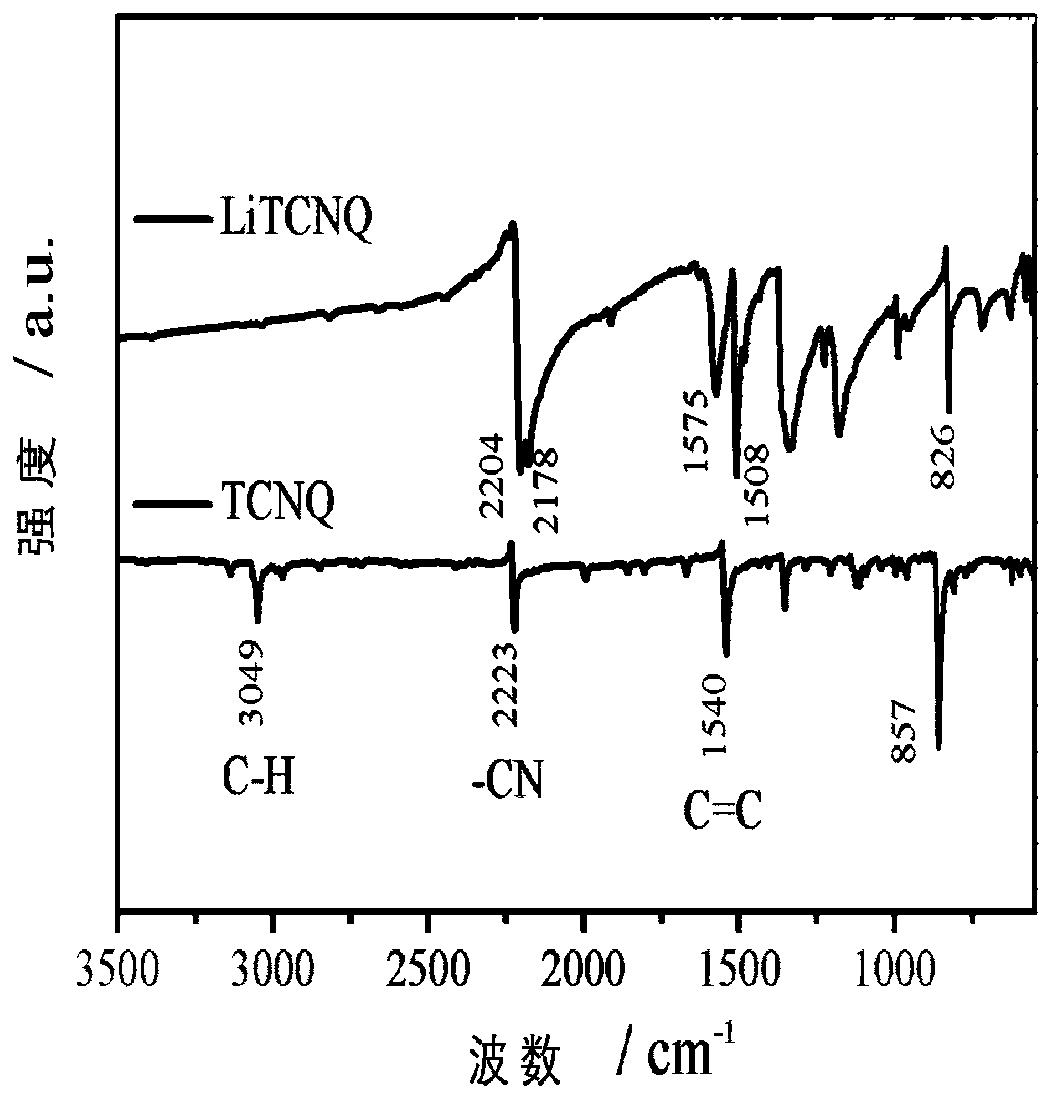

[0059] Do IR test to gained LiTCNQ, and compare with the IR spectrogram of raw material TCNQ, as figure 1 Shown, as can be seen from this figure, the compound (LiTCNQ) shown in formula (I) is synthesized successfully.

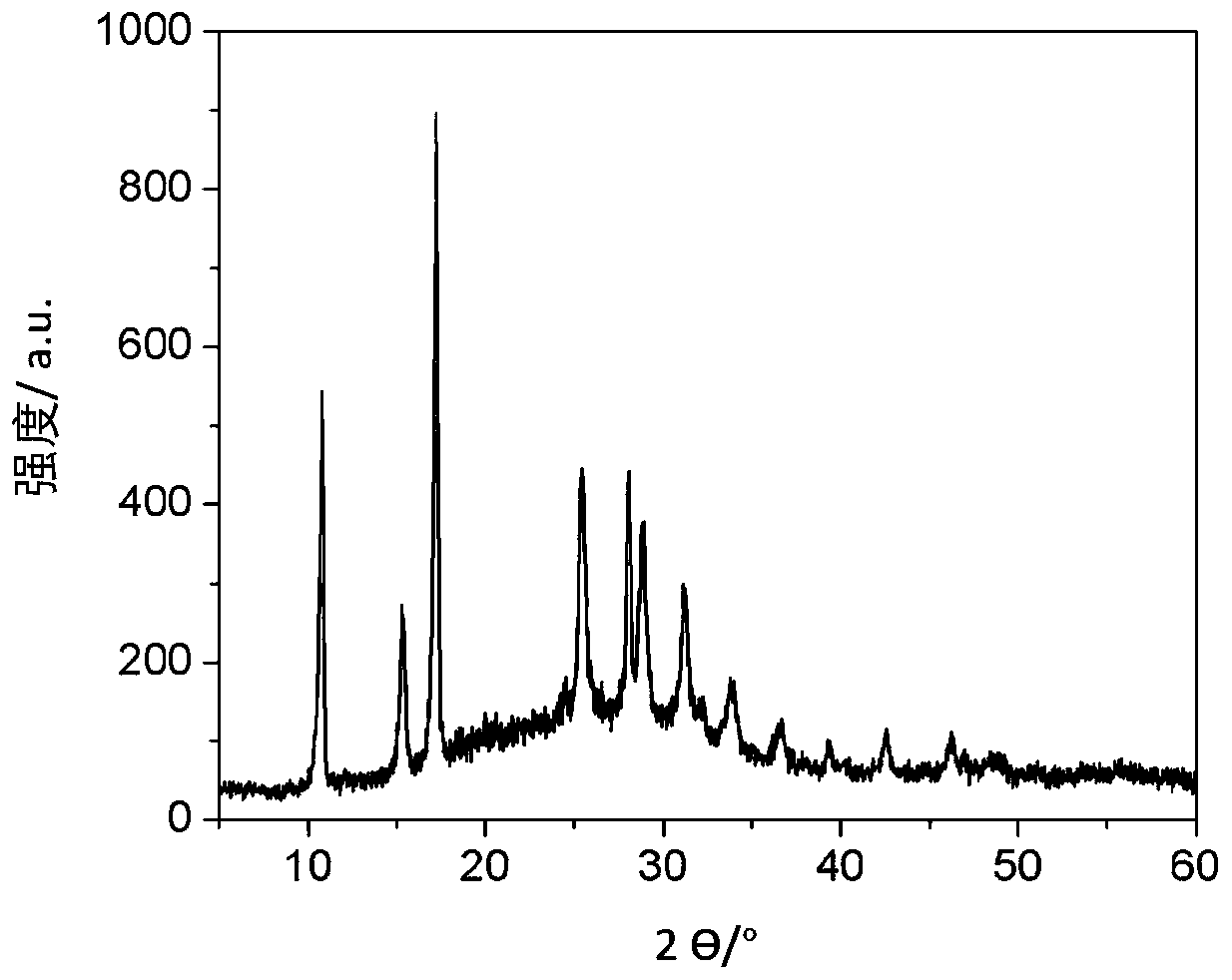

[0060] Carry out XRD test to the obtained LiTCNQ, the XRD figure is as follows figure 2 As shown, the results show that the prepared LiTCNQ is in crystalline form, and its X-ray diffraction pattern has characteristic peaks at 2theta of 10.5°, 15.2°, 17°...

Embodiment 2

[0068] LiTCNQ application:

[0069] Weigh 0.005g of LiTCNQ prepared by the method of Example 1, add to 1mL 1M LiPF 6 In the EC / EMC / DMC electrolyte (purchased from Zhangjiagang Guotai Huarong Chemical New Material Co., Ltd.), the small magnet was stirred for 30 minutes until the dissolution was complete, and the lithium battery electrolyte of the present invention (LiTCNQ accounted for 100% of the mass of the lithium battery electrolyte) was obtained. Min content is 0.2%-0.25%).

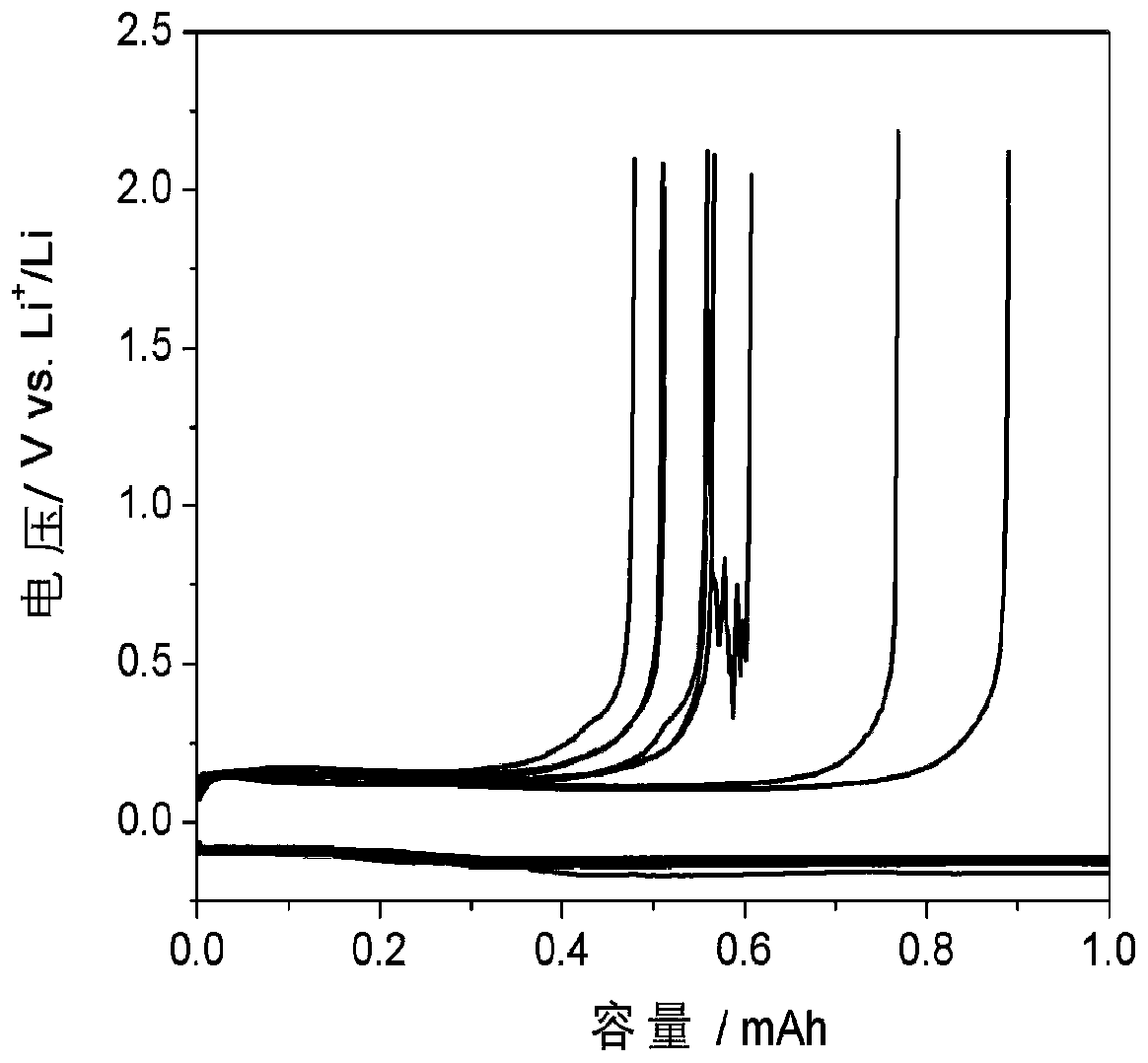

[0070] to LiPF 6 The stability of metal lithium on copper foil and the deposition and dissolution curve of metal lithium on copper foil in Li / Cu batteries with EC / EMC / DMC electrolyte were tested, and the specific performance is capacity (charge and discharge at 0.5mA for 2h) and Coulombic efficiency, the results see Figure 7 with 8 .

[0071] The stability of metal lithium on the copper foil and the deposition and dissolution curve of metal lithium on the copper foil in the Li / Cu battery of th...

Embodiment 3

[0074] LiTCNQ application:

[0075]Weigh 0.005g of LiTCNQ prepared according to the method of Example 1, add it to 1mL 1M LiTFSI DOL / DME electrolyte (purchased from Zhangjiagang Guotai Huarong Chemical New Material Co., Ltd.), stir for 30min with a small magnet until it dissolves completely, and obtain The lithium battery electrolyte of the present invention (LiTCNQ accounts for 0.2%-0.25% by mass of the lithium battery electrolyte).

[0076] The stability of metal lithium on copper foil and the deposition and dissolution curve of metal lithium on copper foil in Li / Cu batteries with LiTFSI DOL / DME electrolyte were tested, specifically expressed as capacity (charge and discharge at 0.5mA for 2h) and Coulombic efficiency, the results see Figure 11 with 12 .

[0077] The stability of metal lithium on the copper foil and the deposition and dissolution curve of metal lithium on the copper foil in the Li / Cu battery of the lithium battery electrolyte of the present invention have...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com