Normal-temperature stable high-efficiency environment-friendly sealing agent for aluminum and aluminum alloy

A technology of sealant and aluminum alloy, which is applied in the direction of electrolytic coating, surface reaction electrolytic coating, coating, etc., can solve the problems of uneven surface of aluminum workpiece, high weight loss of detection sealing hole, loss of gloss of sealing film, etc., to achieve Long service life, low price, and dense sealing film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

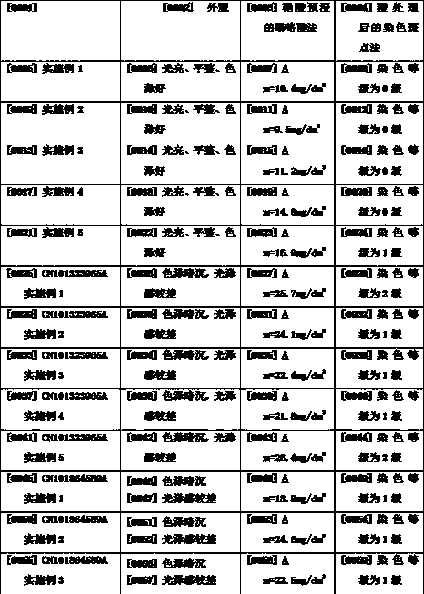

Examples

Embodiment 1

[0016] A stable and high-efficiency aluminum and aluminum alloy environmental protection sealing agent at room temperature, characterized in that: the environmental protection sealing agent is composed of 3% sodium acetate, 0.5% sodium benzoate, 0.5% urea, nonylphenol polyoxyethylene ether 10%, fatty alcohol polyoxyethylene ether 5%, sodium ethylenediaminetetramethylene phosphate 5%, sodium aminotriacetate 5%, disodium methylene bis-naphthalene sulfonate 2%, acetic acid 2%, tripolyphosphoric acid Sodium 2%, deionized water 65%.

[0017] Anodize the aluminum workpiece to prepare a 10-15 μm thick oxide film layer, then immerse the aluminum workpiece in the above-mentioned sealant at 30°C and adjust the pH value to 6 for 10 minutes, take out the aluminum workpiece, clean it, and air dry it.

[0018] After the hole is sealed, the surface of the aluminum product workpiece is bright and smooth, without water stains, yellow spots and powder frost.

[0019] By scanning electron micro...

Embodiment 2

[0022] A stable and high-efficiency aluminum and aluminum alloy environmental protection sealing agent at room temperature, characterized in that: the environmental protection sealing agent is composed of 6.5% sodium acetate, 0.5% lithium acetate, 2% sodium benzoate, cetyl sulfo Disodium phenoxybenzenesulfonate 15%, sodium ethylenediaminetetramethylene phosphate 10%, sodium diethylenetriaminepentamethylene phosphonate 5%, sodium potassium tartrate 5%, hydroxyalkylphenol polyoxyethylene ether 4 %, accelerator 2%, tartaric acid 5%, phosphoric acid 1%, sodium tripolyphosphate 2%, deionized water 42%.

[0023] Anodize the aluminum workpiece to prepare a 10-15 μm thick oxide film layer, then immerse the aluminum workpiece in the above-mentioned sealant at 30°C and adjust the pH value to 5.9 for 10 minutes, take out the aluminum workpiece, clean it, and air dry it.

[0024] After the hole is sealed, the surface of the aluminum product workpiece is bright and smooth, without water st...

Embodiment 3

[0028] A stable and high-efficiency aluminum and aluminum alloy environmental protection sealing agent at room temperature, characterized in that: the environmental protection sealing agent is composed of 10% sodium acetate, 1% lithium acetate, 2% sodium benzoate, 1% urea, polyethylene 12% pyrrolidone, 5% aminopropyltrimethoxysilane, 5% disodium methylene bis-naphthalene sulfonate, 3% sodium citrate, 3% hydroxyalkylphenol polyoxyethylene ether, 3% citric acid, Sodium dihydrogen phosphate 2%, sodium tripolyphosphate 2%, deionized water 51%.

[0029] Anodize the aluminum workpiece to prepare a 10-15 μm thick oxide film layer, then immerse the aluminum workpiece in the above-mentioned sealant at 28°C and adjust the pH value to 6.2 for 12 minutes, take out the aluminum workpiece, clean it, and air dry it.

[0030] After the hole is sealed, the surface of the aluminum product workpiece is bright and smooth, without water stains, yellow spots and powder frost.

[0031] By scanning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com