Silicon-based negative electrode material for lithium ion battery and preparation method thereof

A technology for silicon-based negative electrode materials and lithium-ion batteries, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as low compaction density and easy crushing, and achieve improved electronic conductivity, simple process, and improved The effect of cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

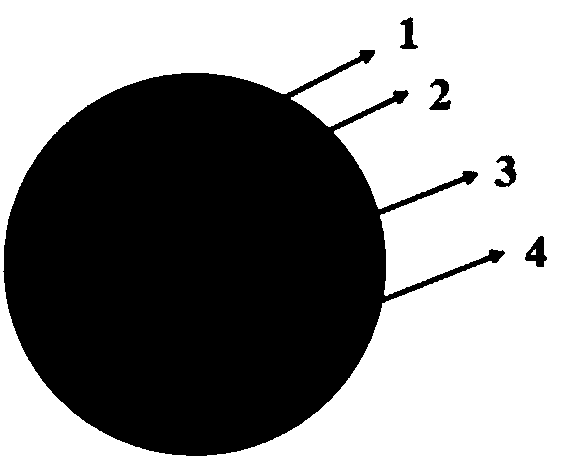

[0026] A silicon-based negative electrode material for a lithium-ion battery proposed by the present invention, the silicon-based negative electrode material includes an amorphous silicon dioxide substrate 2, a plurality of nano-silicon cores 1, a carbon coating layer 3 and a LiF coating layer 4;

[0027] Among them, a plurality of nano-silicon cores 1 are embedded in the amorphous silica matrix 2, the carbon coating layer 3 is coated on the amorphous silica matrix 2, and the LiF coating layer 4 is coated on the carbon coating layer 3. ;

[0028] The carbon coating layer 3 has a thickness of 100 nm, and the LiF coating layer 4 has a thickness of 1 nm.

[0029] A kind of preparation method of described lithium-ion battery silicon-based negative electrode material that the present invention proposes, comprises the following steps:

[0030] S1. Add 1g of nano-silica powder into 357ml of 0.1mol / L NaOH solution, react for 10min, add 0.3g of citric acid, stir and evaporate the solu...

Embodiment 2

[0034] A silicon-based negative electrode material for a lithium-ion battery proposed by the present invention, the silicon-based negative electrode material includes an amorphous silicon dioxide substrate 2, a plurality of nano-silicon cores 1, a carbon coating layer 3 and a LiF coating layer 4;

[0035] Among them, a plurality of nano-silicon cores 1 are embedded in the amorphous silica matrix 2, the carbon coating layer 3 is coated on the amorphous silica matrix 2, and the LiF coating layer 4 is coated on the carbon coating layer 3. ;

[0036] The carbon coating layer 3 has a thickness of 1 nm, and the LiF coating layer 4 has a thickness of 50 nm.

[0037] A kind of preparation method of described lithium-ion battery silicon-based negative electrode material that the present invention proposes, comprises the following steps:

[0038] S1. Add 1g of nano-silica powder into 8.9ml of 1mol / L NaOH solution, react for 10min, add 0.03g of citric acid, stir and evaporate the soluti...

Embodiment 3

[0041] A silicon-based negative electrode material for a lithium-ion battery proposed by the present invention, the silicon-based negative electrode material includes an amorphous silicon dioxide substrate 2, a plurality of nano-silicon cores 1, a carbon coating layer 3 and a LiF coating layer 4;

[0042] Among them, a plurality of nano-silicon cores 1 are embedded in the amorphous silica matrix 2, the carbon coating layer 3 is coated on the amorphous silica matrix 2, and the LiF coating layer 4 is coated on the carbon coating layer 3. ;

[0043] The carbon coating layer 3 has a thickness of 40 nm, and the LiF coating layer 4 has a thickness of 35 nm.

[0044] A kind of preparation method of described lithium-ion battery silicon-based negative electrode material that the present invention proposes, comprises the following steps:

[0045] S1. Add 1g of nano-silica powder into 200ml of 0.1mol / L KOH solution, react for 10min, add 0.15g of citric acid, stir and evaporate the solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com