Electrolyte for lithium manganate power battery

A power battery and electrolyte technology, which is applied to secondary batteries, circuits, electrical components, etc., can solve problems such as capacity attenuation, cycle performance reduction, and manganese dissolution, so as to improve stability, storage time, and safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] LiPF as lithium salt 6 Dissolved in the mixed solvent of ethylene carbonate (EC) / ethyl methyl carbonate (EMC) / diethyl carbonate (DEC) / propylene carbonate (PC) (mass ratio is 30 / 10 / 50 / 10) to obtain a solution, where LiPF 6 The concentration is 1M. Then add vinylene carbonate (VC) to the solution by 2% of the total weight of the electrolyte, add ethanolamine by 0.1% of the total weight of the electrolyte, add biphenyl by 3% of the total weight of the electrolyte, and add biphenyl by 3% of the total weight of the electrolyte. 0.2% of trifluoroethyl phosphorous acid (TTFP) was added to obtain the desired electrolyte.

[0023] The electrolyte was injected into a lithium manganese oxide soft-pack battery with a single capacity of 10Ah. After formation and capacity separation, the normal temperature cycle performance, high temperature 60°C cycle performance and safety performance of the battery were tested.

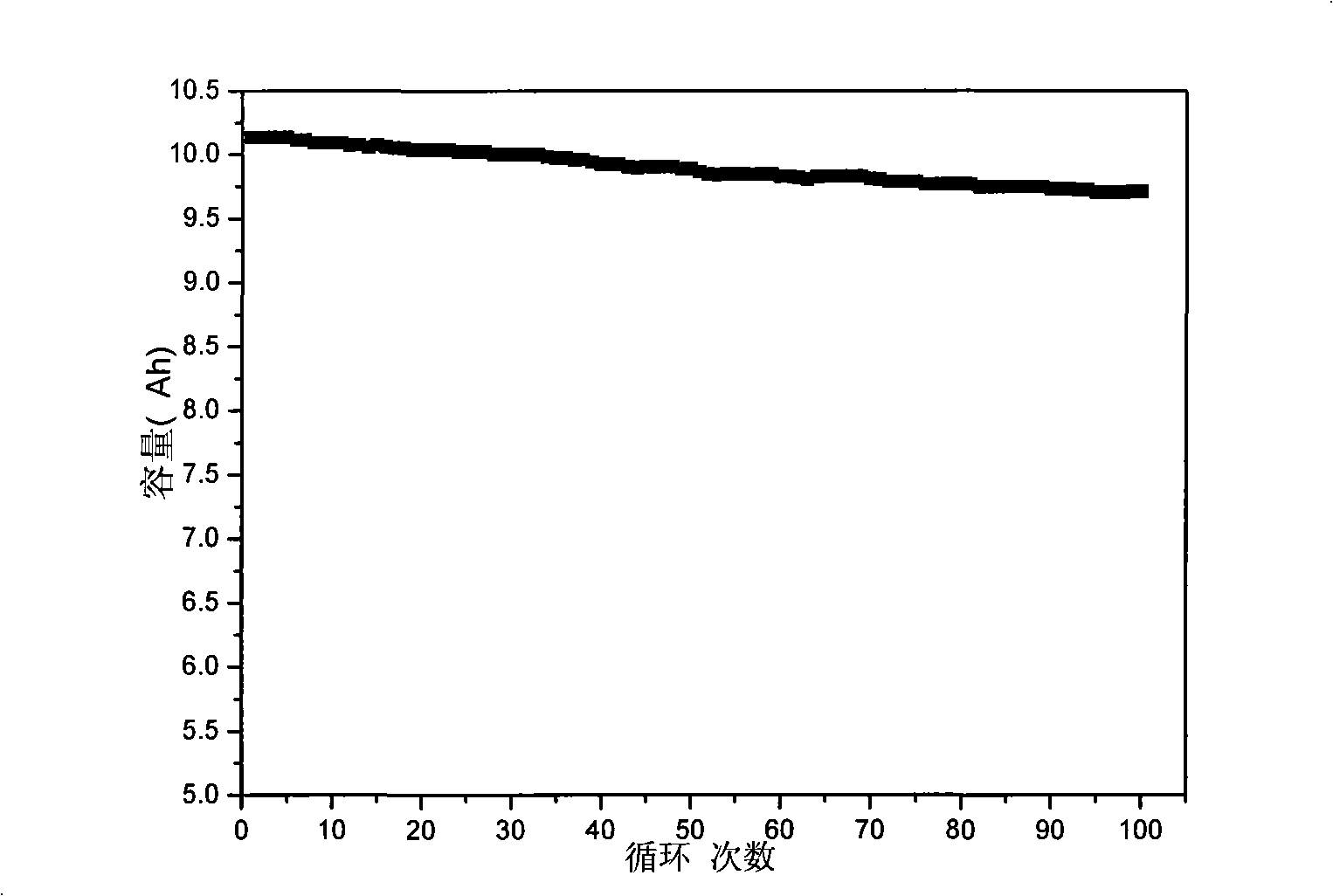

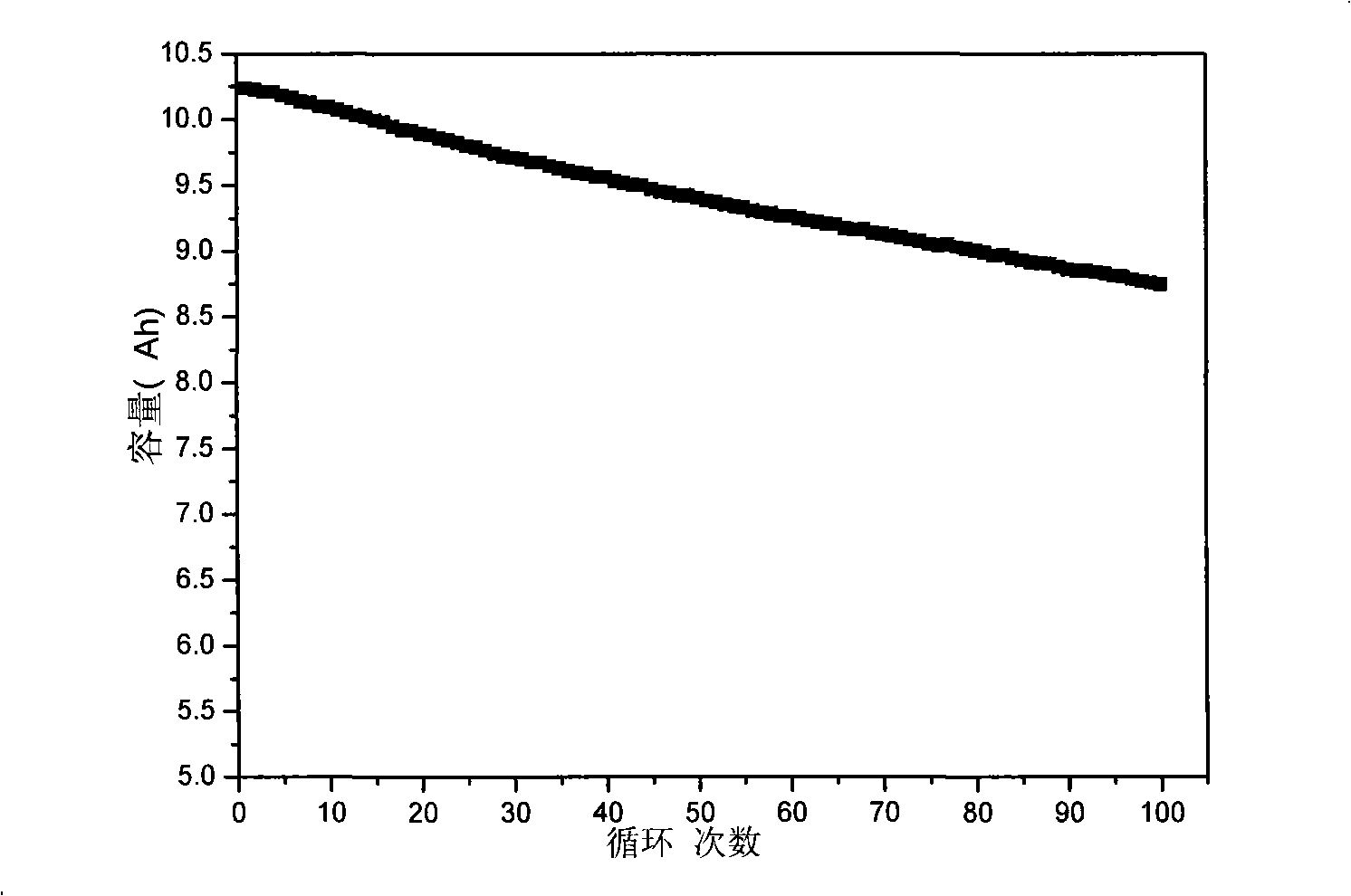

[0024] figure 1 The middle curve is the normal-temperature cycle...

Embodiment 2

[0028] LiPF as lithium salt 6 Dissolved in the mixed solvent of ethylene carbonate (EC) / ethyl methyl carbonate (EMC) / diethyl carbonate (DEC) / propylene carbonate (PC) (mass ratio is 30 / 10 / 50 / 10) to obtain a solution, where LiPF 6 The concentration is 1M. Then add vinylene carbonate (VC) to the solution by 1% of the total weight of the electrolyte, add 1,3-propiolactone sulfonate (1,3-PS) by 2% of the total weight of the electrolyte, and Hexamethyldisilazane was added at 0.05% of the total weight of the electrolyte, biphenyl was added at 5% of the total weight of the electrolyte, and pyrimidine was added at 0.2% of the total weight of the electrolyte to obtain the desired electrolyte.

Embodiment 3

[0030] LiPF as lithium salt 6 Dissolved in the mixed solvent of ethylene carbonate (EC) / ethyl methyl carbonate (EMC) / diethyl carbonate (DEC) / propylene carbonate (PC) (mass ratio is 30 / 10 / 50 / 10) to obtain a solution, where LiPF 6 The concentration is 1M. Then add vinylene carbonate (VC) to the solution by 1% of the total weight of the electrolyte, add 1,4-sulfonic acid butyrolactone (1,4-BS) by 2% of the total weight of the electrolyte, and Add heptamethyldisilazane to 0.01% of the total weight of the electrolyte, add 3-chloroanisole to 7% of the total weight of the electrolyte, and add phenylisocyanate to 2% of the total weight of the electrolyte to obtain the desired electrolyte liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com