Method for improving cycling stability of lithium ion battery anode material

A lithium-ion battery, cycle stability technology, applied in battery electrodes, secondary battery repair/maintenance, circuits, etc., can solve problems such as failure to achieve commercialization, and achieve the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

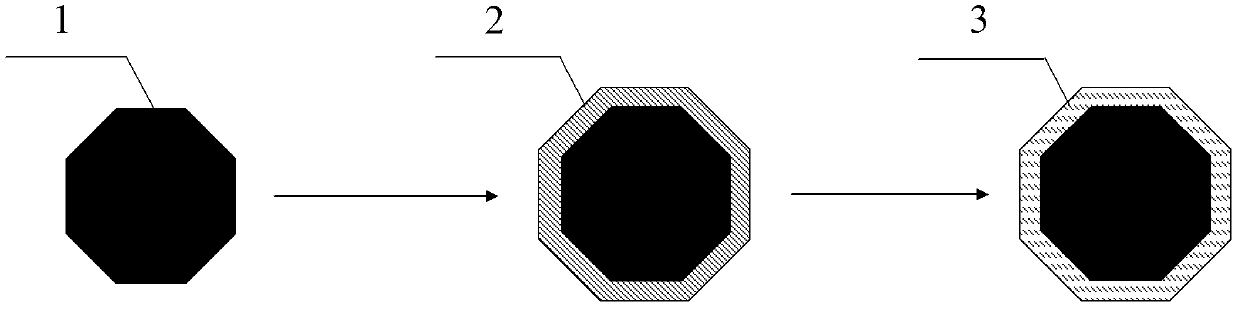

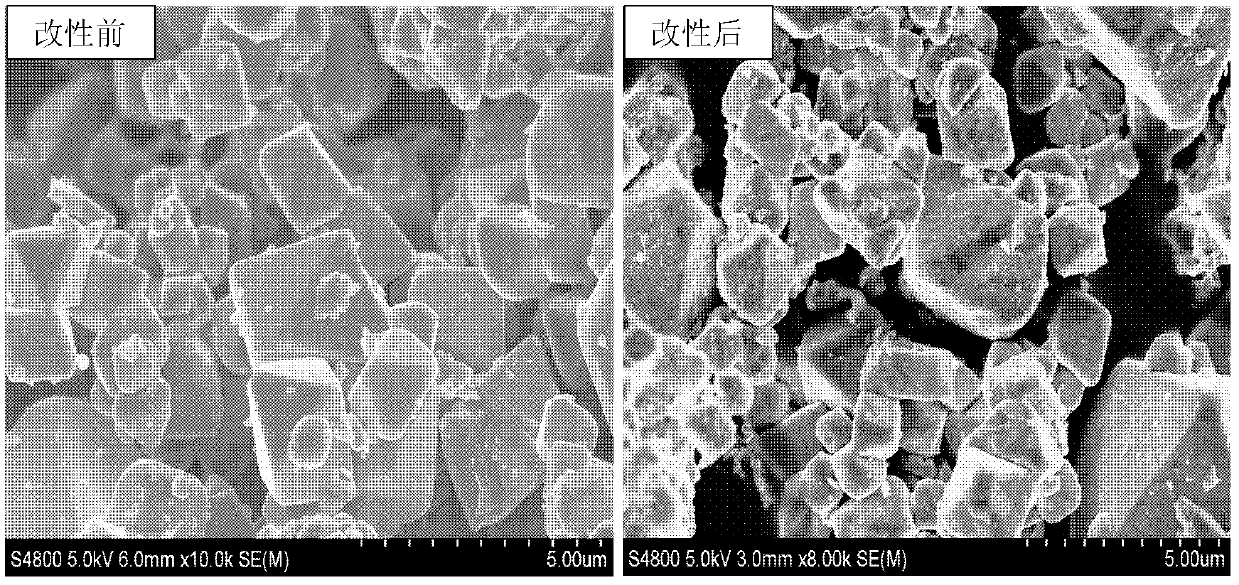

Embodiment 1

[0032] Weigh 0.067gNaHCO 3 , 0.075gAl(NO 3 ) 3 9H 2 Dissolve O in 10ml of deionized water respectively, disperse 2g of lithium manganate particles in the sodium bicarbonate solution, stir rapidly for 10min, then add the aluminum nitrate solution dropwise into the above suspension under rapid stirring, continue stirring for 30min, and use for precipitation The precursor was obtained by washing with deionized water three times and drying at 80 °C for 5 h. Put the precursor in a muffle furnace, raise the temperature to 300°C at a rate of 3°C / min, keep it in the air for 2h, and cool it down to room temperature naturally to obtain the aluminum oxide-coated lithium manganate cathode material.

Embodiment 2

[0034] Weigh 0.067gNaHCO 3 , 0.075gAl(NO 3 ) 3 9H 2 Dissolve O in 10ml of deionized water respectively, disperse 2g of the prepared manganese lithium silicate particles in the sodium bicarbonate solution, stir rapidly for 10min, then add the aluminum nitrate solution dropwise to the above suspension under rapid stirring, continue After stirring for 30 min, the precipitate was washed three times with deionized water and dried at 80° C. for 5 h to obtain a precursor. The precursor was placed in a muffle furnace, the temperature was raised to 300°C at a rate of 3°C / min, and kept in air for 2h, and then cooled to room temperature naturally to obtain the aluminum oxide-coated lithium manganese silicate cathode material.

Embodiment 3

[0036] Weigh 0.067gNaHCO 3 , 0.075gAl(NO 3 ) 3 9H 2 O were respectively dissolved in 10ml of deionized water, 2g of the prepared nickel-cobalt lithium manganese oxide particles were dispersed in the sodium bicarbonate solution, stirred rapidly for 10min, and then the aluminum nitrate solution was added dropwise to the suspension under rapid stirring, Stirring was continued for 30 min, the precipitate was washed three times with deionized water and dried at 80° C. for 5 h to obtain a precursor. Put the precursor in a muffle furnace, raise the temperature to 300°C at a rate of 3°C / min, and keep it in the air for 2h, and cool it down to room temperature naturally to obtain the alumina-coated nickel-cobalt-lithium-manganese-oxide cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com