Rich-lithium positive electrode material of lithium ion battery having coreshell structure and preparation method of rich-lithium positive electrode material

A lithium-ion battery, core-shell structure technology, applied in the field of electrochemistry, can solve the problems of not comprehensively improving the electrochemical performance of materials, reducing the initial capacity of materials, poor high-rate discharge performance, etc., and achieving excellent charge-discharge cycle ability, wide Commercial use, the effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1 First, weigh a certain amount of commercial spherical precursor [Ni 0.4 co 0.2 mn 0.4 ](OH) 2 with LiOH.H 2 O, mix and put into the agate mortar and grind for about 0.5h, mix well;

[0034]2 Then put the ground mixture in a tube furnace, and perform high-temperature calcination under air atmosphere, first at 450°C for 12 hours, then at 800°C for 8 hours, and naturally cool to room temperature to obtain the matrix material Li[Ni 0.4 co 0.2 mn 0.4 ]O 2 .

[0035] 3. Weigh a certain amount of citric acid, wherein citric acid: lithium acetate + manganese acetate (molar ratio) = 1:1, add deionized water to make a 100mL solution, the concentration is 0.2mol / L, and the 2 has been weighed The matrix material Li[Ni 0.4 co 0.2 mn 0.4 ]O 2 Add it into the solution, put it in a water bath at 80°C for stirring, and obtain solution A.

[0036] 4 According to the cladding layer Li 2 MnO 3 : Base material Li[Ni 0.4 co 0.2 mn 0.4 ]O 2 (Molar ratio)=1:9, weigh and fo...

Embodiment 2

[0042] 1-4 steps are the same as embodiment 1

[0043] 5 Put the gel in 4 into a vacuum oven at 100°C to dry for 24 hours, take it out, grind it, put it into a tube furnace, pretreat it at 500°C for 8 hours, and then heat it up to 900°C for two hours to obtain a core-shell gel Ternary materials of structure.

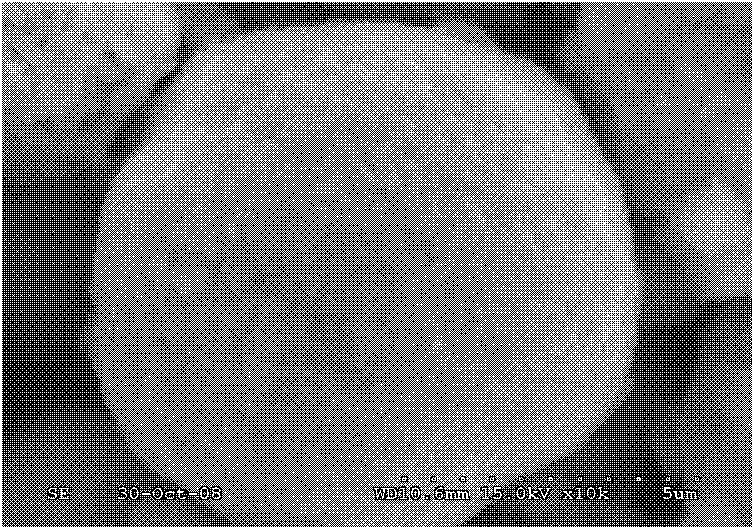

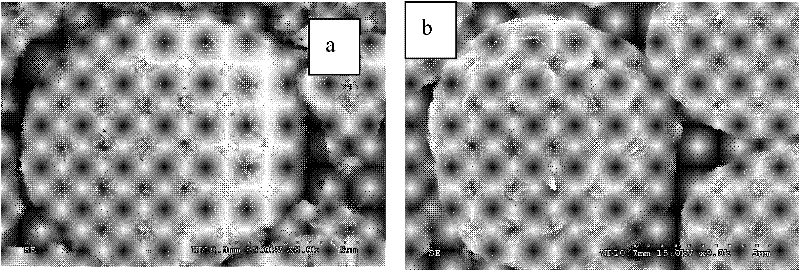

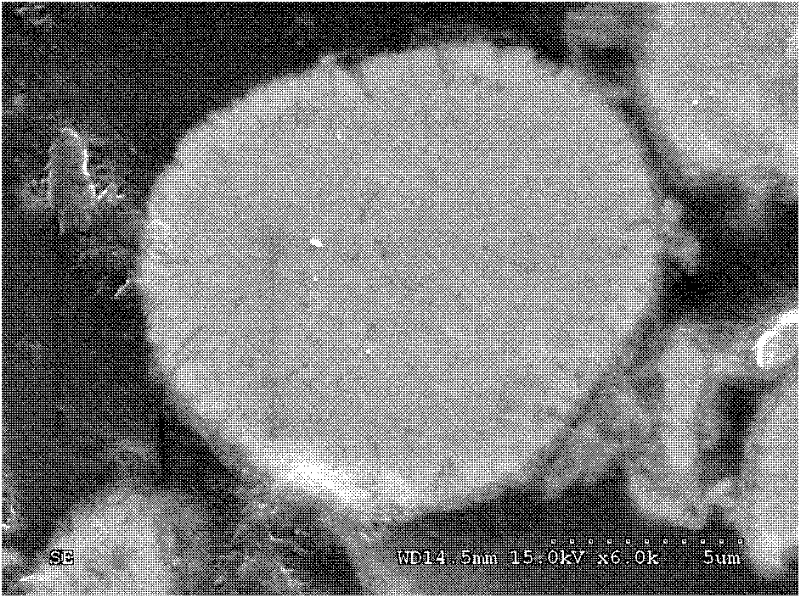

[0044] In Examples 1 and 2, ternary materials with a core-shell structure were synthesized at different temperatures. From figure 2 It can be seen that the coated ternary material particles still maintain a spherical shape, and their size is slightly larger than that before coating, and a layer of dense small particles is adsorbed on the surface of the particles. From image 3 The cross-sectional view of the sample particles after coating can also be seen that the material has an obvious coating layer, showing a core-shell configuration.

[0045] From Figure 4 It can be seen from the XRD pattern in the sample that after coating, the sample is still in the α-NaFeO2...

Embodiment 3

[0048] Steps 1-3 are the same as Example 1

[0049] 4 The surface of the base material is subjected to Li 2 MnO 3 of wrapping. According to the cladding layer Li 2 MnO 3 : matrix material (molar ratio)=1:12, weigh and form Li 2 MnO 3 Lithium acetate and manganese acetate are required, wherein lithium acetate: manganese acetate (molar ratio) = 2.05: 1, and lithium acetate and manganese acetate are added to deionized water to form 50 mL of solution B.

[0050] 5 Put the gel in 4 into a vacuum oven at 100°C to dry for 24 hours, take it out, grind it, put it into a tube furnace for pretreatment at 450°C for 5 hours, and then heat it up to 700°C for 10 hours to obtain a gel with a core-shell structure Ternary material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com