Patents

Literature

52results about How to "Control acidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

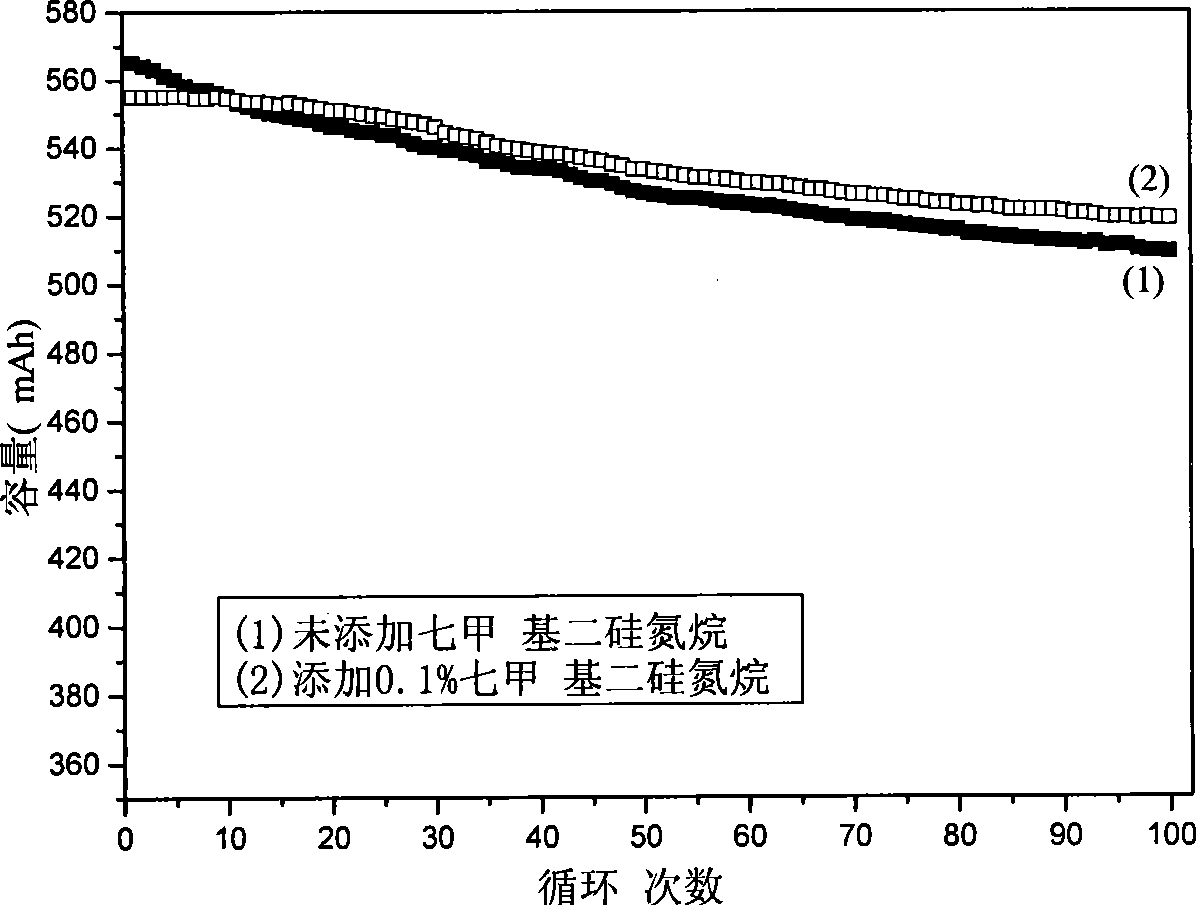

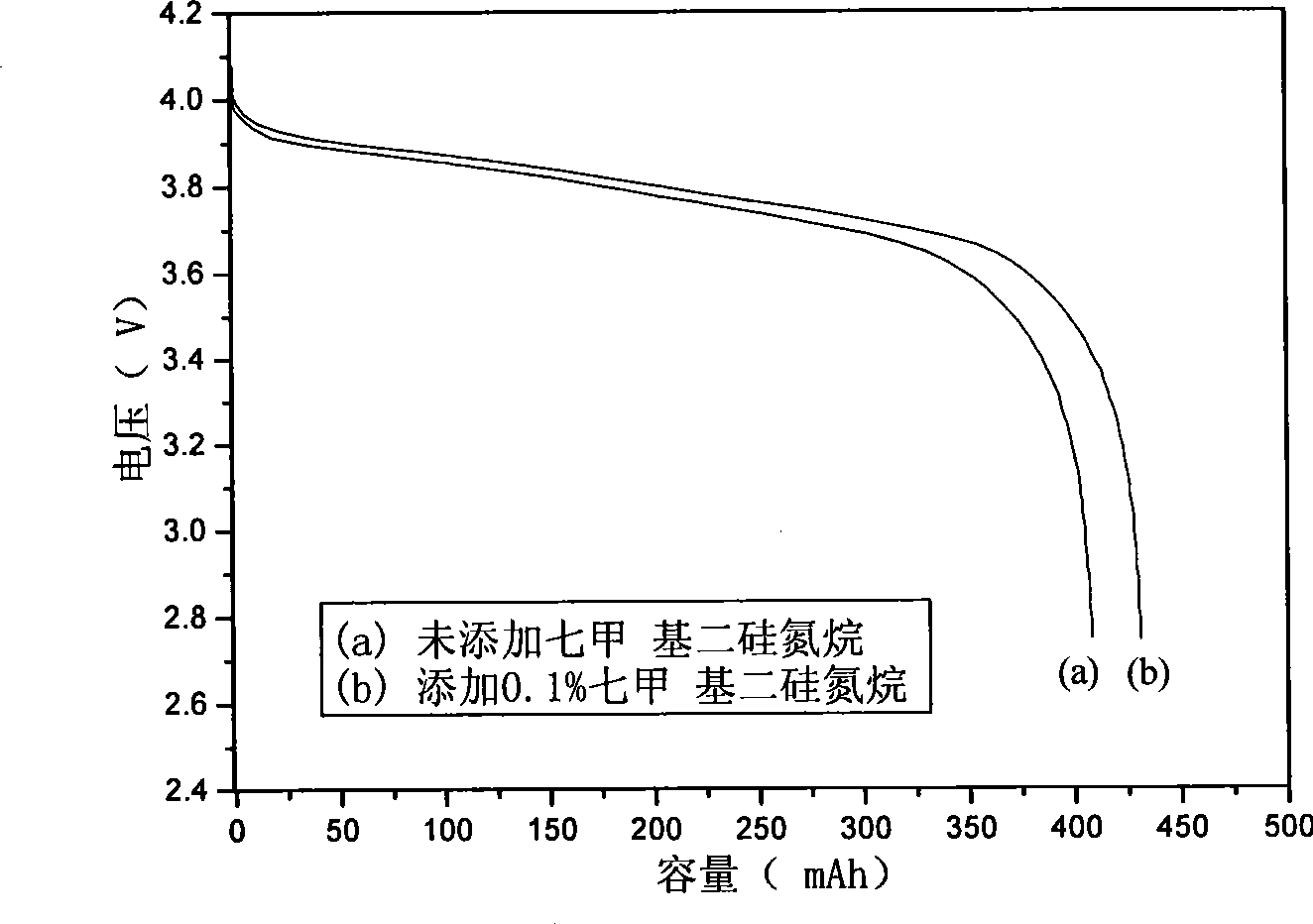

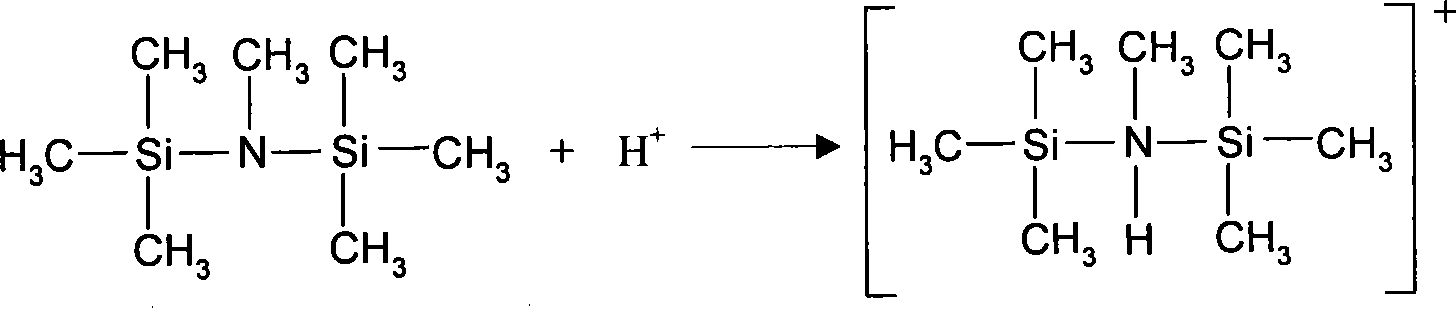

Electrolysis liquid for lithium manganate battery

The invention discloses electrolyte solution of a manganic acid lithium battery. The electrolyte solution comprises lithium salt, non-aqueous organic solvent, film-forming additive and stabilizing additive, namely seven-methyl two-silazane. Because the stabilizing additive, seven-methyl two-silazane is added into the electrolyte solution, the acidity of the electrolyte solution can be controlled. The cycle life and the high temperature storage performance of a lithium ion battery can be improved by using the electrolyte solution to prepare a battery.

Owner:GUANGZHOU TINCI MATERIALS TECH

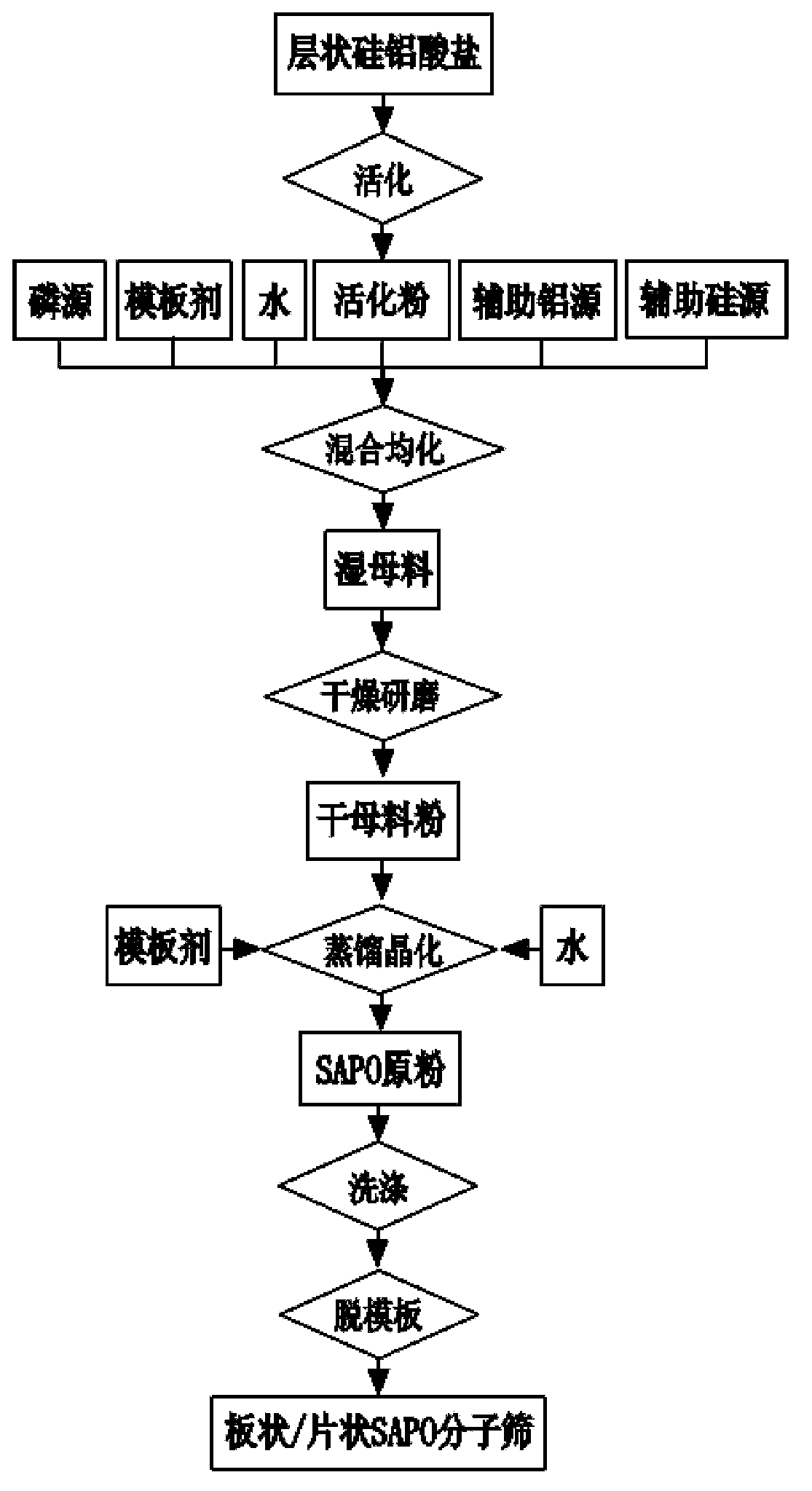

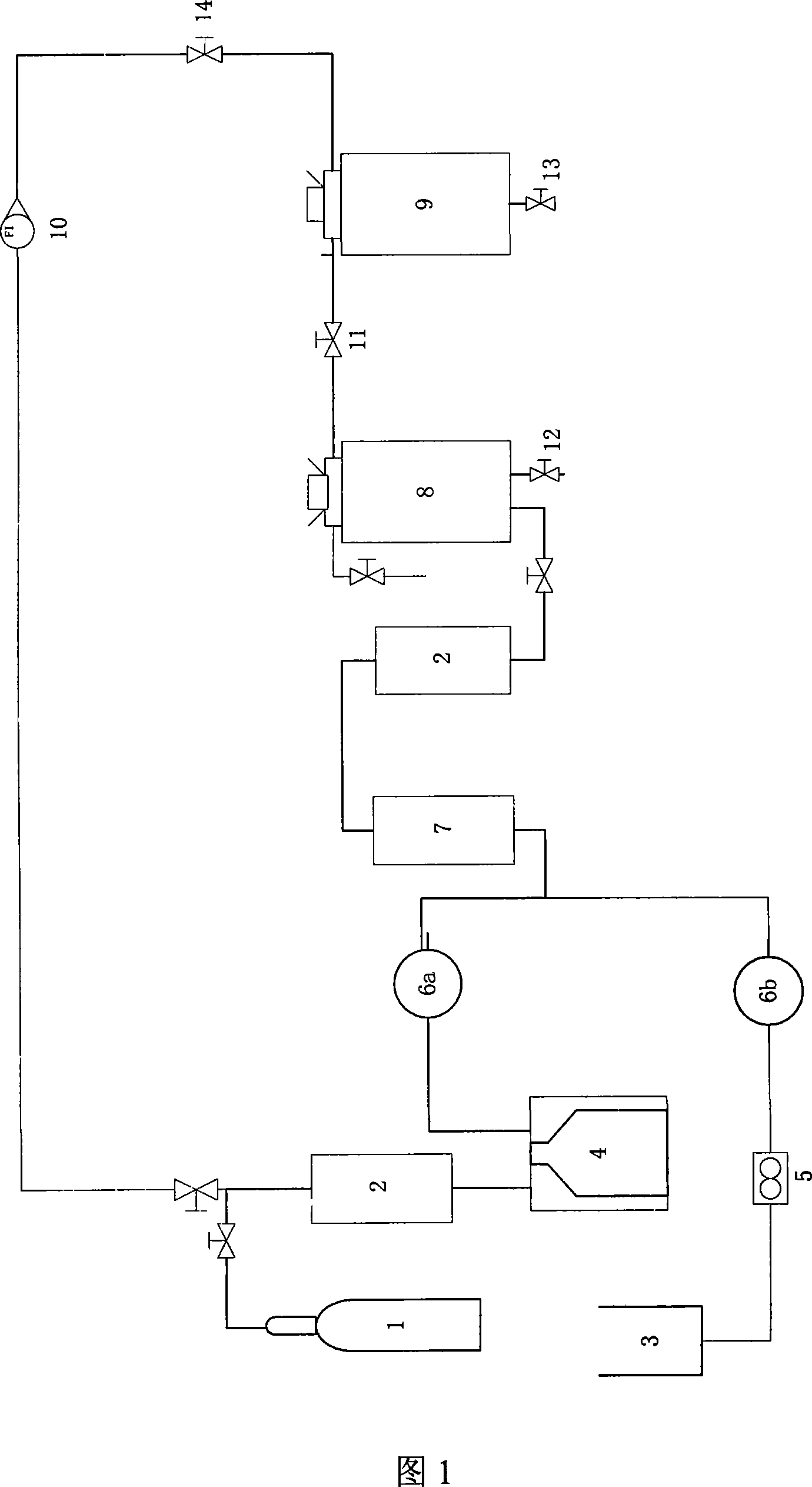

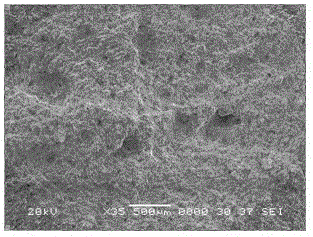

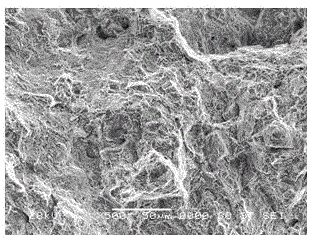

SAPO molecular sieve, and preparation method and purpose thereof

ActiveCN103964457AShorten the diffusion distanceImprove diffusion efficiencyMolecular sieve catalystsMolecular-sieve and base-exchange phosphatesMolecular sieveChemistry

The invention discloses an SAPO molecular sieve, which has single crystals in sheet structure. The SAPO molecular sieve has moderate pore size, and can be used as a catalyst with long service life for olefin preparation from methanol. The invention also discloses a preparation method of the SAPO molecular sieve. The method us as below: activating a raw material of layered aluminosilicate, mixing the raw material with an phosphorus source and water, and homogenizing to obtain a wet masterbatch; drying and grinding the wet masterbatch to obtain a dry powder; and finally distilling the dry powder for crystallization, so as to obtain a raw powder for sheet SAPO molecular sieve. The method requires addition of a template agent, realizes low cost synthesis of SAPO molecular sieve and high additional value utilization of natural layered aluminosilicate, accelerates the rate of diffusion of various substances in the channels of the molecular sieve, increases the diffusion efficiency, and the advanategs of low equipment investment, simple operation and environment-friendliness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

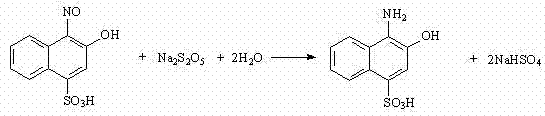

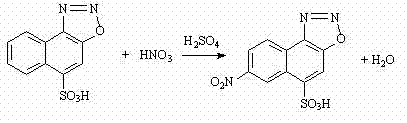

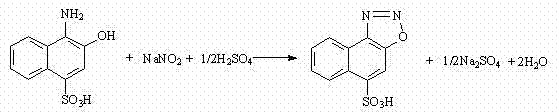

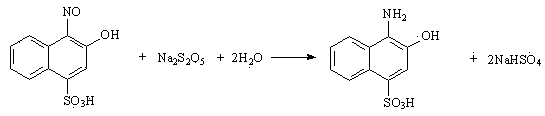

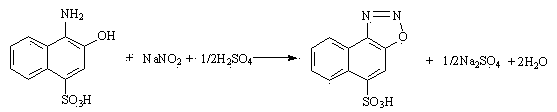

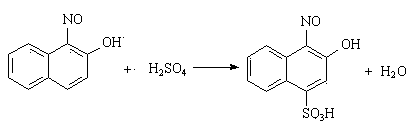

Production method of 6-nitro-1,2,4-sulfonic acid

ActiveCN102516195AReduce dosageReduce manufacturing costOrganic chemistryToxic materialSodium nitrite

The invention relates to a production method of a dye intermediate, i.e., 6-nitro-1,2,4-sulfonic acid. The method is characterized in that: the 6-nitro-1,2,4-sulfonic acid is obtained by taking ethyl naphthol as a major raw material and performing procedures including nitrosification, neutralizing, sulfonation reduction displacement, diazotization, acidification, nitration and the like. Due to the adoption of the method, the problems of the production of a large amount of high-COD (Chemical Oxygen Demand) waste water and waste gas and high production cost existing in a production process can be solved. In the method, ethyl naphthol is dissolved by raising the temperature naturally, so that a liquid caustic soda dissolving method is replaced, the using amount of liquid caustic soda and sulfuric acid is reduced, production cost is reduced, and the production of waste water is reduced; a diazonium resisting method is adopted for diazonium, so that the production of toxic waste gas is reduced, the yield of diazonium is increased, and production cost is reduced; the diazonium resisting method is adopted, and solid sodium nitrite is added, so that the production of waste water can be reduced; and in diazonium, copper sulfate is taken as a catalyst, so that reaction speed is increased, the occurrence of side reactions is reduced, and yield is increased.

Owner:JIANGSU YUANZHENG CHEM

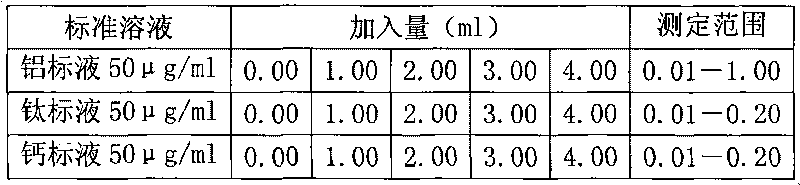

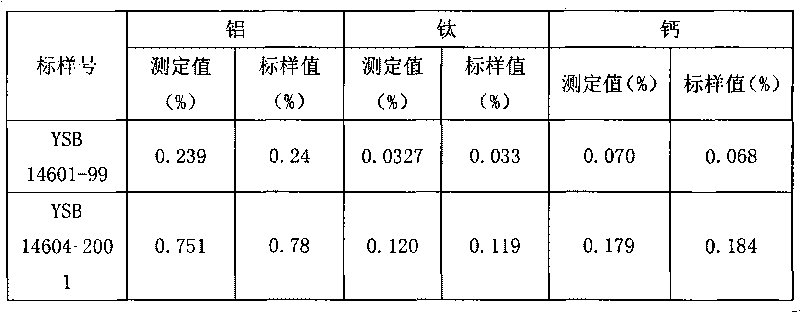

Method for measuring content of Al, Ti and Ca in low-carbon silicon iron

InactiveCN101750407AQuick analysisAccurate analysisAnalysis by thermal excitationPollutionInductively coupled plasma atomic emission spectroscopy

The invention relates to a method for measuring the content of Al, Ti and Ca in low-carbon silicon iron, which comprises the following steps: dissolving a sample through a nitric acid and a hydrofluoric acid, after fuming the sample through a perchloric acid, adding a proper amount of hydrochloric acid, and heating to dissolve a salt; diluting to a certain volume with water; introducing atomization solution into an inductively coupled plasma atomic emission spectrometer; measuring the intensity of a spectral line to be tested; and calculating the concentration of a corresponding element of the substance to be tested according to the intensity of the spectral line which is measured by the standard substance at known concentration. The method has the advantages of capacity of quickly and accurately analyzing the content of Al, Ti and Ca in the low-carbon silicon iron and no pollution.

Owner:ANGANG STEEL CO LTD

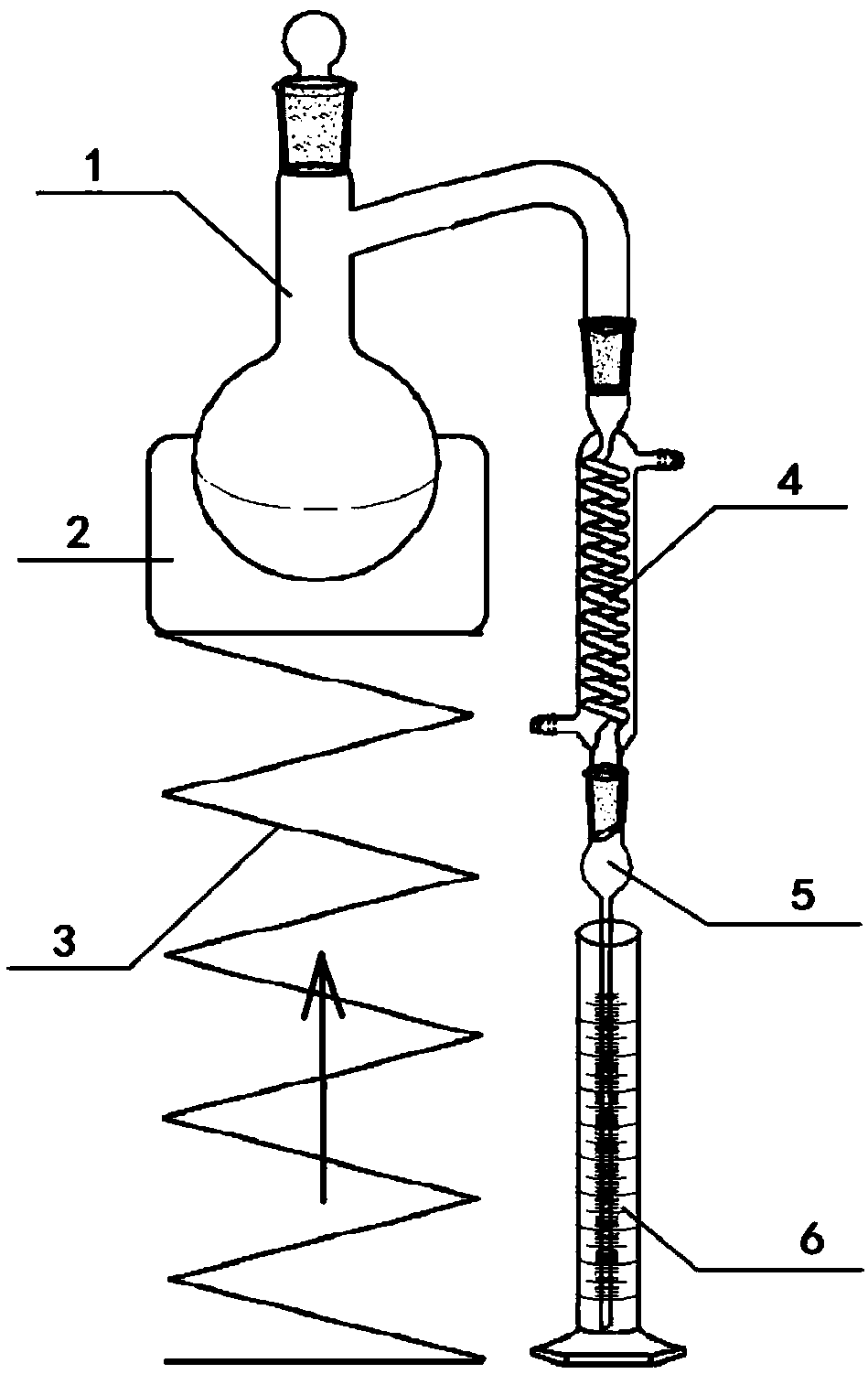

Supercritical carbon dioxide method for extracting high purity rhubarb free anthraquinones

InactiveCN101053596AControl aciditySimple processAntibacterial agentsPlant ingredientsOrganic solventExcess acid

The invention discloses a method for extracting highly purified rhubarb dissociated anthraquinone by a hypercritical CO2 extraction method, including leaching the material with organic solvent to get leaching liquid, hydrolyzing the combined anthraquinone, balancing out the superfluous acid with inorganic alkali or acid after hydrolytic reaction, getting hydrolytic leaching liquid; injecting the hydrolytic leaching liquid into the extraction vessel for a hypercritical CO2 extraction, entering to the separation vessel after the extraction; recycling separated CO2, collecting discharging rhubarb dissociated anthraquinone and organic solvent, steaming out the organic solvent decompressly, obtaining the rhubarb dissociated anthraquinone powder. The invention adopts the liquid feed to effectively control the material liquid acidity in the extraction vessel and prevent the equipment corrosion and potential safety problems; meanwhile, it does not need install and detach the extraction vessel by entrainer pump liquid feed so that the extraction is processed continuously and greatly saves the extraction time and improve the output in unit time.

Owner:ZHEJIANG UNIV

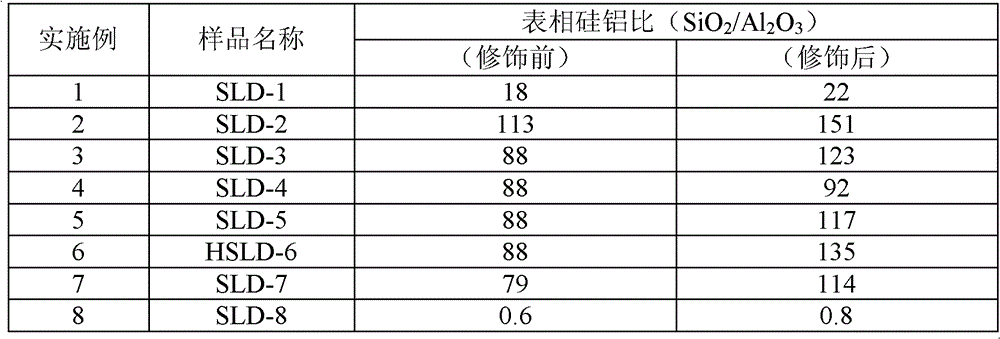

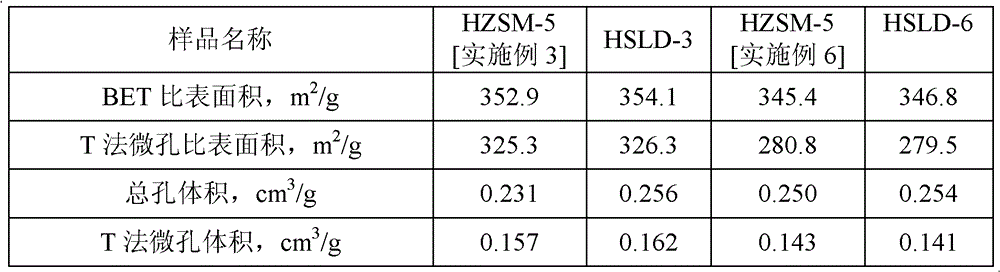

External surface modification method of microporous molecular sieve

ActiveCN102794193AAvoid influenceControl acidityCatalytic crackingMolecular sieve catalystsSurface phaseMolecular sieve

The invention provides an external surface modification method of a microporous molecular sieve, which comprises the following steps: mixing silicasol and a microporous molecular sieve, carrying out liquid deposition to initiate physical adsorption between the molecular sieve and the silicasol, filtering, drying and roasting to prepare the external-surface-modified microporous molecular sieve. In the invention, colloidal particles of the silicasol are larger than pores of the selected molecular sieve, thereby preventing the colloidal particles from entering the inside of the pores; and when the silicasol particles are adsorbed onto the external surface of the molecular sieve, drying and roasting are utilized to remove water in the colloidal particles, so that the colloidal particles are firmly attached onto the external surface of the molecular sieve. The XPS (X-ray photoelectron spectroscopy) measurement indicates that the modified molecular sieve has obviously higher surface phase silica-alumina ratio than the un-modified molecular sieve. The improved Hammett tracer method measurement on the acid quantity of the external surface of the molecular sieve before and after modification proves that the modified molecular sieve has lower acid quantity on the external surface.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

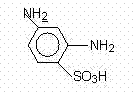

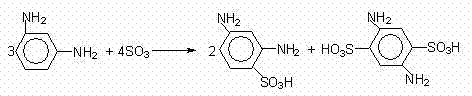

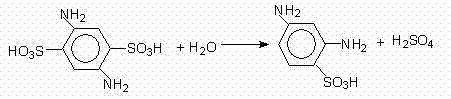

Production method of 2,

InactiveCN102516137AImprove product qualityHigh product yieldSulfonic acid preparationSolubilityOrganic solvent

4-diaminobezene sulfonic acid and salt thereof The invention relates to a production method of a dye intermediate 2,4-diaminobezene sulfonic acid. The method is characterized by using m-phenylenediamine as a main raw material and comprising operations of sulfonation, hydrolysis and refining to prepare the 2,4-diaminobezene sulfonic acid. The invention also provides a preparation method of 2,4-diaminobezene sulfonic acid ammonium salt or sodium salt by using the 2,4-diaminobezene sulfonic acid prepared by the above method, so as to solve problems of low reaction efficiency, high sulfonation temperature, secondary pollution caused by usage of organic solvent and acid-containing processing in the production process. The method of the invention employs addition of fusing m-phenylenediamine to increase solubility of the m-phenylenediamine in the sulfuric acid and reduce generation of side reaction; m-phenylenediamine and sulfuric acid are added respectively to control the acidity of the reaction system at a required acidity, control generation of side reaction and increase product quality and product yield; grading control of acidity and temperature maintains stable proceeding of reaction; and addition of hydrolysis increases yield of the product, improves product quality and reduces production cost.

Owner:JIANGSU YUANZHENG CHEM

Preparation method for low carbon alkane dehydrogenation catalyst

InactiveCN104289219AAvoid churnAvoid gatheringHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDispersity

The invention discloses a preparation method for a propane dehydrogenation catalyst. Without hydrogen reduction, a reaction feed gas is directly introduced and the Pt reduction degree is controlled to improve the stability and sulfur tolerance of the catalyst. The method omits of the drying roasting process, can effectively remove chlorine from the catalyst without hydrothermal treatment, and can significantly improve the activity, selectivity, stability and sulfur tolerance of the catalyst without hydrogen reduction. The preparation method is simple. The catalyst prepared by the method can avoid excessive alkali loss, improve the dispersity of Pt based catalyst active metals, form more secondary active phases, and ultimately improve the selectivity of the target product propylene and the catalyst activity, stability and sulfur tolerance.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

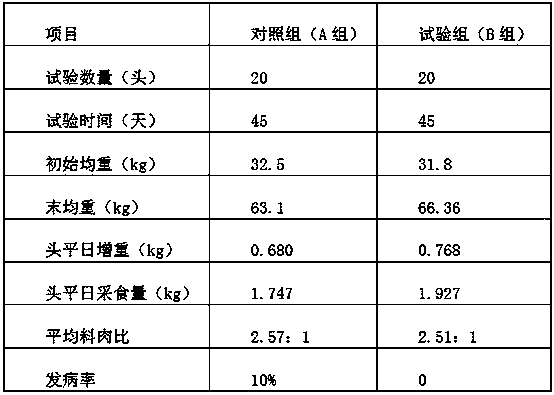

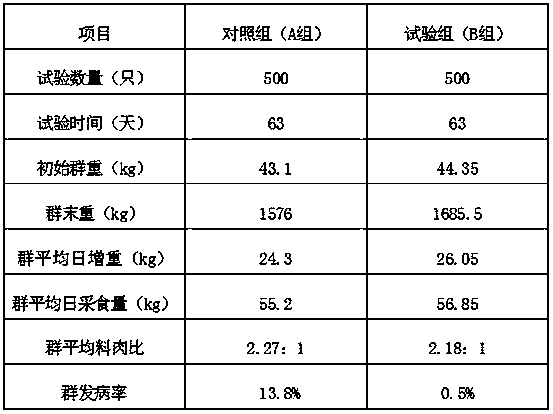

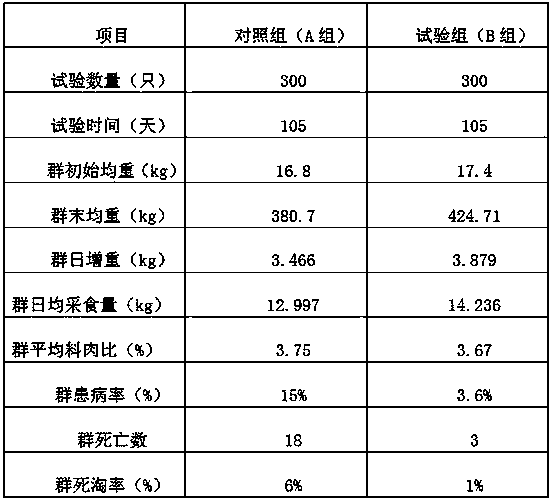

Whole fermentation livestock and poultry complete feed as well as preparation method and application thereof

ActiveCN110150495AAffect palatabilityControl acidityFood processingAnimal feeding stuffBiotechnologyTrace element

The invention discloses whole fermentation livestock and poultry complete feed as well as a preparation method and application thereof. The whole fermentation livestock and poultry complete feed is characterized in that various raw materials and additives in the complete feed are scientifically picked and compounded; during the fermentation, all raw materials in the prepared complete feed powder take part in fermentation; proper fermentation bacterial agents are selected; the fermentation depth is controlled, so that the whole fermentation livestock and poultry complete feed is obtained. The whole fermentation livestock and poultry complete feed has the product indexes that the moisture content is 28 to 35 percent; the viable count is 3 to 8*10<8> cfu / g; the PH value is 5.5 to 6.5; the contents of each trace element and major elements reach the America NRC nutrition standard recommended lowest value of + / -3 percent; the content of coarse protein is the America NRC nutrition standard recommended lowest value of + / -3 percent through being metered by dry substances; the shelf life is 150 to 180 days. The recipe is scientific; the preparation method is simple; the effect is obvious; the practical production application of the whole fermentation livestock and poultry complete feed to scaled production preparation and livestock and poultry culture is realized; the feed and the methodare suitable for being widely popularized and used.

Owner:黄石市佳兴生物科技有限公司

Method for increasing yield of strong aromatic Huisha baijiu

ActiveCN106434241AProperly control the acidityControl acidityAlcoholic beverage preparationChemistryFermentation

The invention belongs to the technical field of liquid making and particularly relates to a method for increasing the yield of strong aromatic Huisha baijiu. The method for increasing the yield of the strong aromatic Huisha baijiu is provided to achieve the technical purpose. The method comprises the steps of conducting drying in a spreading mode and adding yeast on the vinasse obtained after distilling for baijiu and adding yeast, adding the yeast in an upper layer grain groove before putting into a cellar, putting the yeast after being evenly mixed for fermentation, distilling after finishing the fermentation, so that the Huisha baijiu is obtained. According to the method for increasing yield of the strong aromatic Huisha baijiu, the Huisha baijiu yield can be greatly increased on the premise of guaranteeing the high baijiu quality.

Owner:WULIANGYE

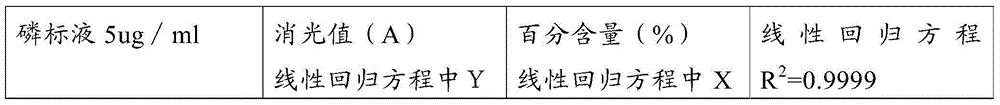

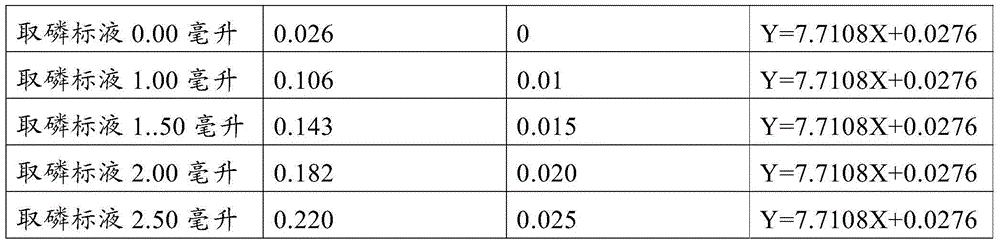

Method for measuring phosphorus in silicon iron by using photometric method

InactiveCN104458623AExtended service lifeLow costColor/spectral properties measurementsIron fluorideAbsorbance

The invention relates to a method for measuring phosphorus in silicon iron by using a photometric method. The method comprises a control experiment and a sample determination experiment, wherein the control experiment comprises the following steps: taking phosphorus standard solutions with same concentration and gradient volume respectively, adding the phosphorus standard solutions into a beaker in which quantitative pure iron powder and quantitative pure aluminum foil or pure aluminum powder are added in advance, dissolving a to-be-measured sample by adopting nitric acid and hydrofluoric acid, oxidizing to orthophosphoric acid by using perchloric acid with smoke emission until hydrofluoric acid is cleaned and dried, transferring into a beaker in tall form, adding nitric acid immediately, adding sodium nitrite until a brown precipitate disappears, boiling for 10 seconds, adding ammonium molybdate and tartaric acid, shaking, adding iron fluoride, and reducing into phosphomolybdenum blue by using stannous chloride, measuring absorbance respectively at 680nm in a spectrophotometer by taking water as a reference, and drawing a working curve or calculating a regression equation; and the sample determination experiment comprises the following steps: performing the same experimental steps in the beaker, then measuring the absorbance at 680nm in the spectrophotometer, and contrasting to obtain the phosphorus content by comparing with the working curve or the regression equation of the control experiment.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

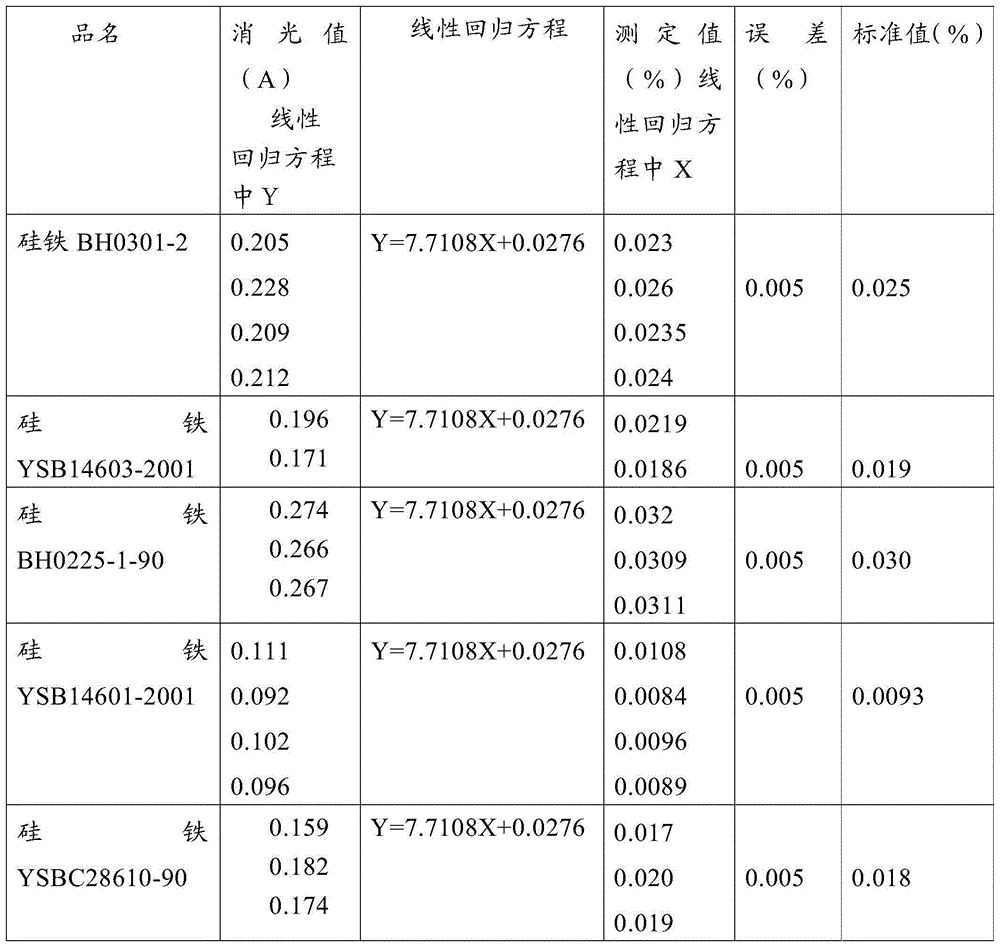

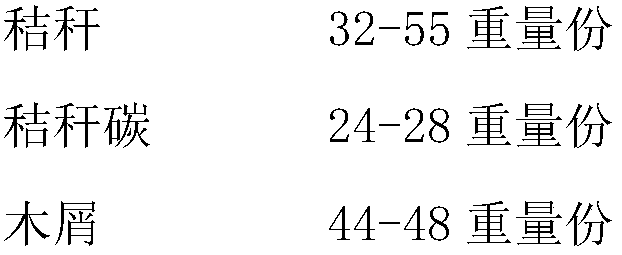

Biomass compound fuel

InactiveCN108239562AHigh level of clean energyImprove the level ofBiofuelsSolid fuelsOil and greaseHigh carbon

The invention provides a biomass compound fuel which consists of straw, straw carbon, wood chips, rice straw, a combustion improver, a potassium removal agent, high-carbon alcohol, caustic soda and grease. The fuel is transformed for a coal-fired boiler, to reduce the equipment cost and fuel cost of an enterprise; the fuel gas a relatively high clean energy grade; by adopting the straw, straw carbon, wood chips and rice straw as main materials, the cost is low, and little environmental pollution is caused; the caustic soda can control the biomass acidity and reduce corrosion and coking of theequipment caused by the fuel; the fuel is made into an ellipse with an overall dimension of 3.5*2.5*1.58cm, and such size is applicable to the fuels of various fixed-grate and chain-grate boilers, wherein the standard lower heat value is higher than 5000kcal, the sulfur content is less than 0.3%, the content of volatile matters is 35%, the ash content is less than 10%, and the content of the fixedcarbon is greater than 50%.

Owner:TIANJIN HELAN TECH CO LTD

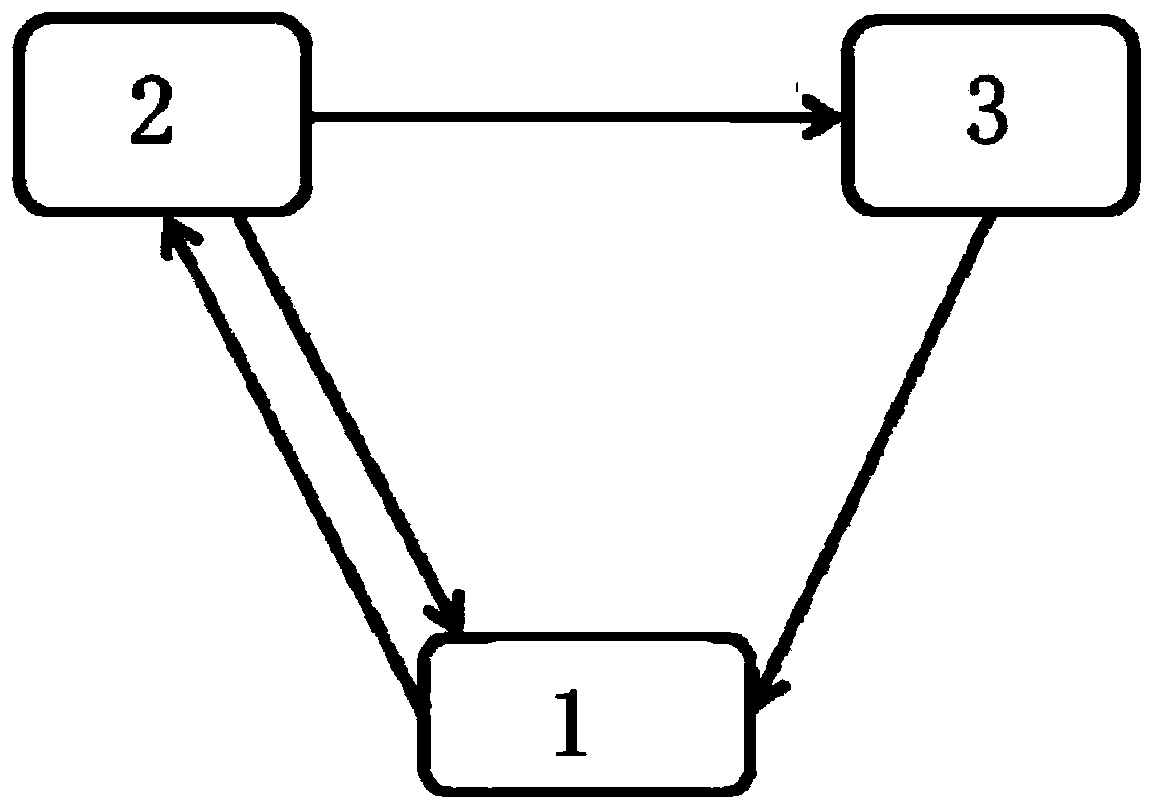

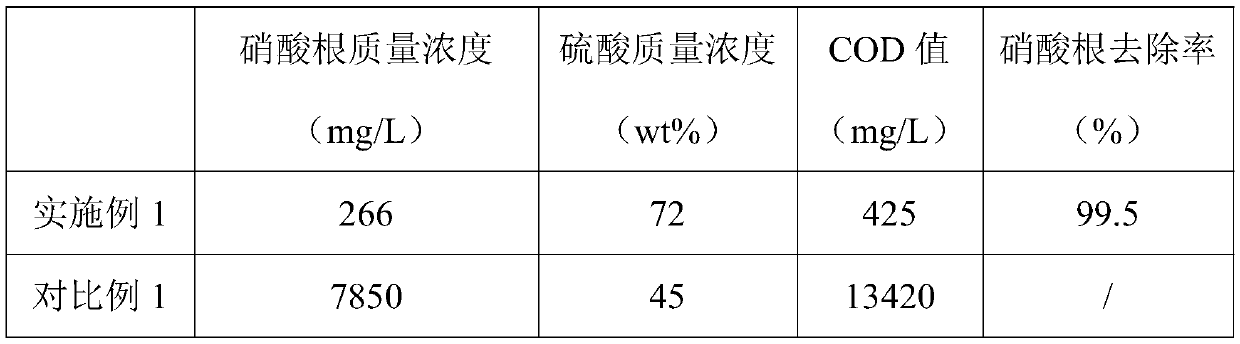

Method and device for reducing nitrate radicals in acid solution

ActiveCN111484117AReduce contentReduce pollutionWater contaminantsWater/sewage treatment by reductionNitrogen oxideNitrogen gas

The invention provides a method for reducing nitrate radicals in an acid solution. According to the method, an acid solution containing the nitrate radicals is subjected to pre-reduction, the nitrateradicals are reduced to be in a nitrite radical state, then catalytic reduction is carried out, the nitrite radicals are directly reduced to be nitrogen, nitrate radical ions in the acid solution areremoved, and a generated gas is low in nitrogen oxide content, free of pollution to air and harmless to a human body; meanwhile, the method has the advantages of simple operation conditions and process, the invention further provides a device for reducing the nitrate radicals in the acid solution, and the device is simple and easy to operate and has great industrial application value.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

Production method of 6-nitro-1,2,4-sulfonic acid

The invention relates to a production method of a dye intermediate, i.e., 6-nitro-1,2,4-sulfonic acid. The method is characterized in that: the 6-nitro-1,2,4-sulfonic acid is obtained by taking ethyl naphthol as a major raw material and performing procedures including nitrosification, neutralizing, sulfonation reduction displacement, diazotization, acidification, nitration and the like. Due to the adoption of the method, the problems of the production of a large amount of high-COD (Chemical Oxygen Demand) waste water and waste gas and high production cost existing in a production process can be solved. In the method, ethyl naphthol is dissolved by raising the temperature naturally, so that a liquid caustic soda dissolving method is replaced, the using amount of liquid caustic soda and sulfuric acid is reduced, production cost is reduced, and the production of waste water is reduced; a diazonium resisting method is adopted for diazonium, so that the production of toxic waste gas is reduced, the yield of diazonium is increased, and production cost is reduced; the diazonium resisting method is adopted, and solid sodium nitrite is added, so that the production of waste water can be reduced; and in diazonium, copper sulfate is taken as a catalyst, so that reaction speed is increased, the occurrence of side reactions is reduced, and yield is increased.

Owner:JIANGSU YUANZHENG CHEM

Method for removing surface covering of steel failure fracture

InactiveCN106226145AAvoid reactionControl acidityPreparing sample for investigationSodium bicarbonateSulfonate

The invention relates to a method for removing surface covering of a steel failure fracture. The method comprises the following steps: preparing a cleaning solution, wherein each 100mL of solution includes 3-10mL of pure phosphoric acid, 0.1-0.15mL of fatty alcohol polyoxyethylene ether, 0.1-0.15g of sodium dodecyl sulfonate, and the balance of deionized water; cleaning a fracture specimen by an ethanol ultrasonic method for more than 5 min; placing the fracture specimen into the cleaning solution, placing in a constant temperature water bath with temperature of 30 to 50 DEG C, and placing stirring magneton in the cleaning solution system; repeatedly cleaning until the fracture specimen shows clear metallic luster; cleaning the fracture specimen by a sodium bicarbonate solution; and cleaning the fracture specimen for more than 2 min by using ethanol ultrasonic, taking out the sample and drying. The method can conveniently and effectively remove the compact covering on the fracture surface under the condition that the fracture morphology characteristics are not damaged.

Owner:JIANGYIN XINGCHENG GOLD MATERIALS CO LTD

Detection method of ammonia content in coal ash

InactiveCN109060693AImprove accuracyControl acidityColor/spectral properties measurementsSocial benefitsDistillation

The invention provides a detection method-distillation spectrophotometry of ammonia content in coal ash. The method comprises sample pretreatment, distillation absorbing treatment, indophenol blue spectrophotometry development measurement, ammonia concentration computation in a sample solution and the computation of ammonia content in the coal ash. Through the detection method provided by the invention, the influences of many coal ash insoluble matters and large impurity ion interference when the absorption photometry is used for detection are sufficiently considered; the distillation absorbing treatment is performed after adopting acid-soluble pretreatment, and the accuracy of the detection result is improved, so that the data has comparability and repeatability. The detection method provided by the invention has low requirements on sample environment, instrument equipment and maintenance, is large in applicable range, precise in detection and easy to implement; the detection method has good social benefit, environment and economic benefit after being promoted.

Owner:TIANJIN BUILDING MATERIAL PROD QUALITY SUPERVISION & INSPECTION CENT +2

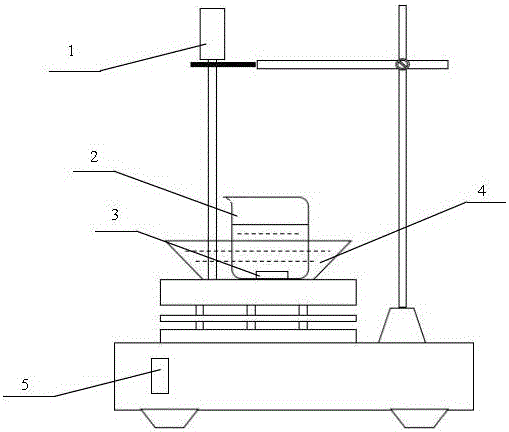

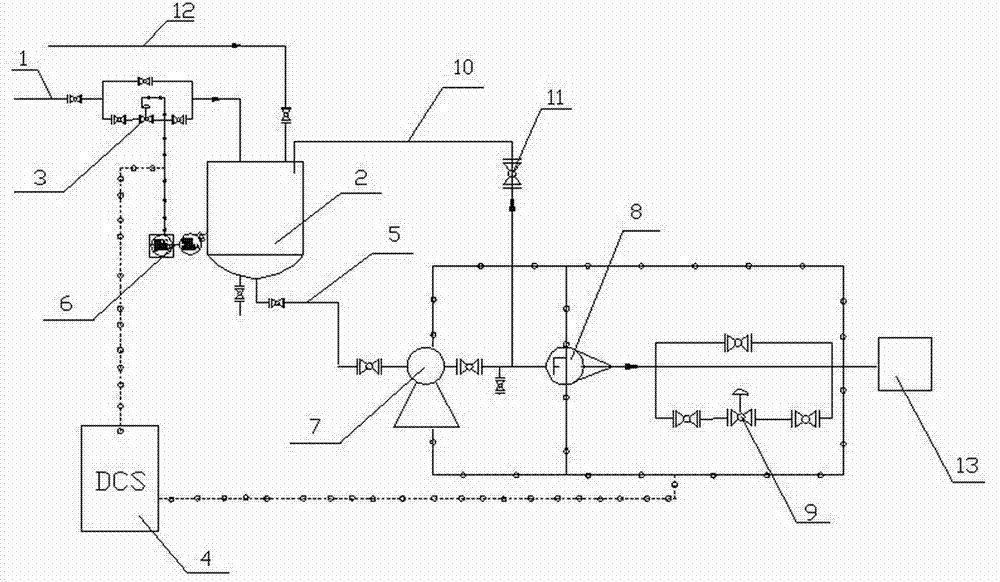

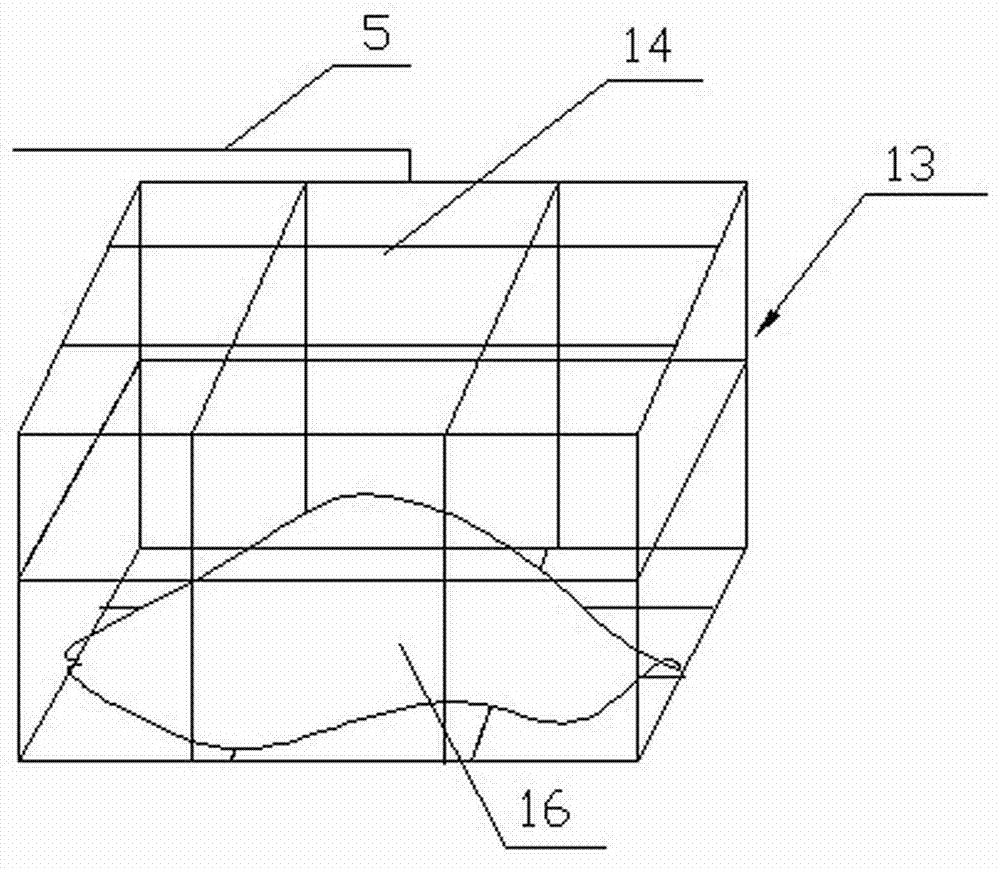

System for automatically controlling adding of proportioned water to fermented grains during white wine brewing

InactiveCN103045432APenetrate fastJoin precisionAlcoholic beverage preparationAutomatic controlSprayer

The invention discloses a system for automatically controlling the adding of proportioned water to fermented grains during white wine brewing. The system comprises a proportioned water temperature control device, a proportioned water usage control device and a sprinkler, wherein the proportioned water temperature control device comprises a steam automatic regulating valve, a temperature transmitter and a DCS (Distributed Control System), wherein the steam automatic regulating valve and the temperature transmitter are respectively connected with the DCS; the proportioned water usage control device comprises an explosion-proof centrifugal pump and a scraper flowmeter; the explosion-proof centrifugal pump and the scraper flowmeter are respectively connected with the DCS; the sprinkler comprises a sprayer adopting a net structure formed by a plurality of spraying pipes of which the interiors are communicated; and spray holes for spraying proportioned water are formed in the spraying pipes. The system can automatically control proportioned water temperature and the accurately control the proportioned water usage.

Owner:宜宾金喜来大观园酒业有限责任公司

Lithium ion battery electrolyte capable of reducing moisture content and acidity and preparation method thereof

InactiveCN102088112AControl acidityElectrolyte performance is normalSecondary cells servicing/maintenanceOrganic solventPhysical chemistry

The invention relates to the technical field of lithium ion battery electrolyte, in particular to a lithium ion battery electrolyte capable of reducing moisture content and acidity and a preparation method thereof. The electrolyte contains lithium salt, organic solvent and additive; and alkaline weak-acid lithium salt used for maintaining the acidity of the electrolyte at a lower level is also added in the electrolyte, or lithium elements used for controlling the moisture content of the electrolyte are also added in the electrolyte, wherein the adding quantity of the lithium salt or lithium elements accounts for 0.01 to 1 percent of the electrolyte. By adopting the technical scheme, the alkaline weak-acid lithium salt such as Li2CO3, LiF or the like is added in the lithium ion battery electrolyte for controlling the acidity of the electrolyte at a lower level. The lithium elements are added for controlling the moisture content of the electrolyte by utilizing self-activity. The stability of the electrolyte obtained in the invention can be maintained, and the quality guarantee period of the electrolyte can be prolonged.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Edible pickled dasheen petiole product and processing method thereof

The invention relates to an edible pickled dasheen petiole product and a processing method thereof. The pickled product is prepared from the following raw materials in parts by weight: 80-120 parts ofdasheen petiole, 3-4 parts of salt, 4-10 parts of chilies and 1-3 parts of garlic. The salted dasheen petiole product is prepared by the following steps of cleaning, airing, fermentation, pickling and packaging. The method has simple manufacturing process, can effectively control the moisture and acidity of the dasheen petiole in pickling process and prevent the dasheen petiole from rotting or souring in fermentation process, and can add different auxiliary pickling materials according to different tastes in different regions. The product contains no preservative, is nutritious and healthy, and has a long shelf life.

Owner:建始县好硒奇农产品开发有限公司

Process for producing lotus seed spirit

ActiveCN101831371BIncrease ethyl caproate contentStrong fragranceAlcoholic beverage preparationBiotechnologyYeast

The invention relates to a process for producing lotus seed spirit. The process comprises the following steps of: selecting and crushing lotus seeds, moistening and stewing the crushed lotus seeds at the high temperature, adding water into the lotus seeds, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into a cylinder to perform large dreg fermentation, discharging fermented grains from the cylinder, distilling the lotus seeds to obtain first dreg spirit and rest secondary dreg yeast, and adding a stirring material into the secondary dreg yeast in a ratio of 1: 0.4-0.6, wherein the stirring material is prepared after the lotus seeds are selected, crushed, moistened at the high temperature and stewed; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform secondary dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain secondary dreg spirit or rest third dreg yeast; adding water into the lotus seeds again, spreading the lotus seeds to be cool, adding yeast into the lotus seeds, feeding the lotus seeds into the cylinder to perform third dreg fermentation, discharging the fermented grains from the cylinder, and distilling the lotus seeds to obtain third dreg spirit; and blending the first dreg spirit and the second dreg spirit, or blending the first dreg spirit, the second dreg spirit and the third dreg spirit, and putting the blended spirit into storage and ageing the spirit. Therefore, the process can effectively control the acidity during fermentation, reasonably increase the activity of enzyme, reduce purification, effectively inhibit impurity bacteria, improve the content of ethyl acetate and ethyl caproate in the spirit, reduce the methanol in the spirit, enrich the mouthfeel, and keep the fragrance of the sprit thick.

Owner:浙江硒莲液富硒科技有限公司

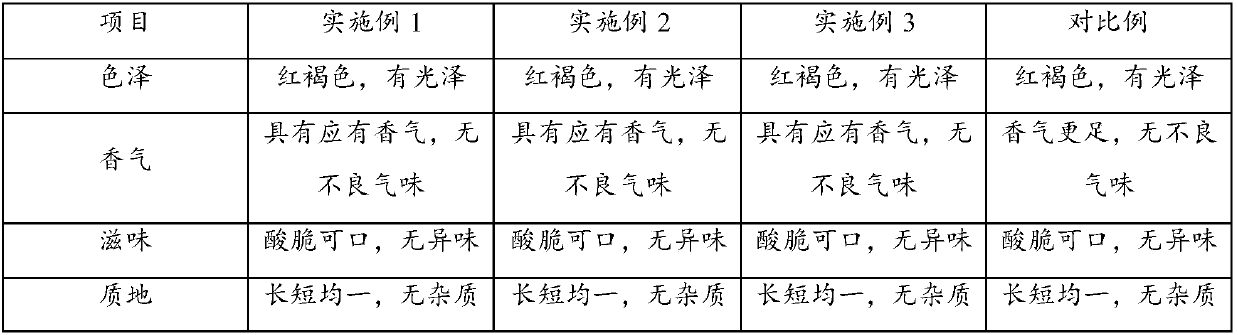

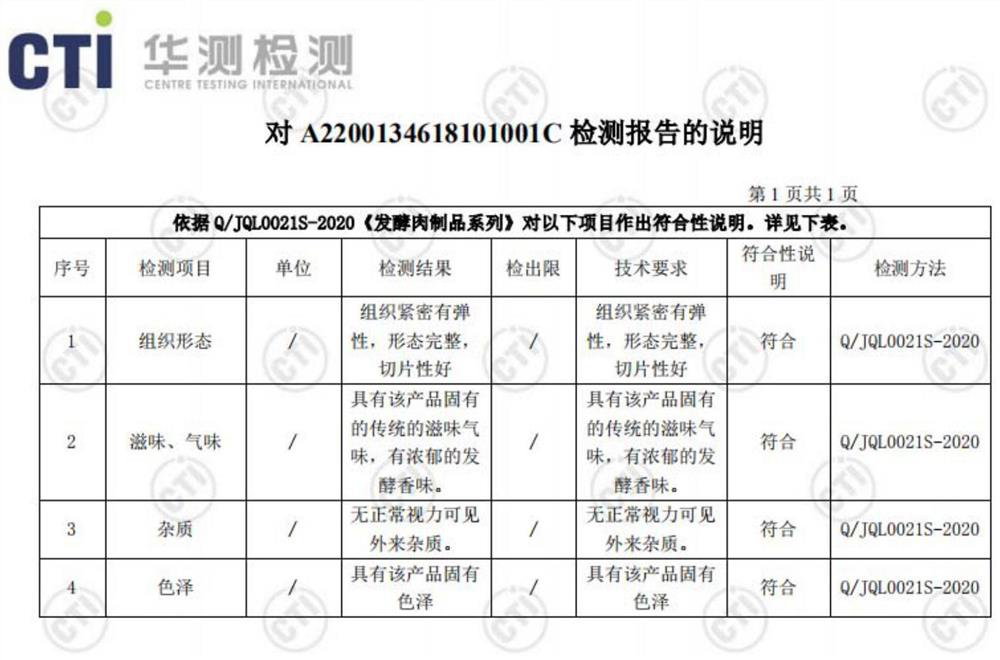

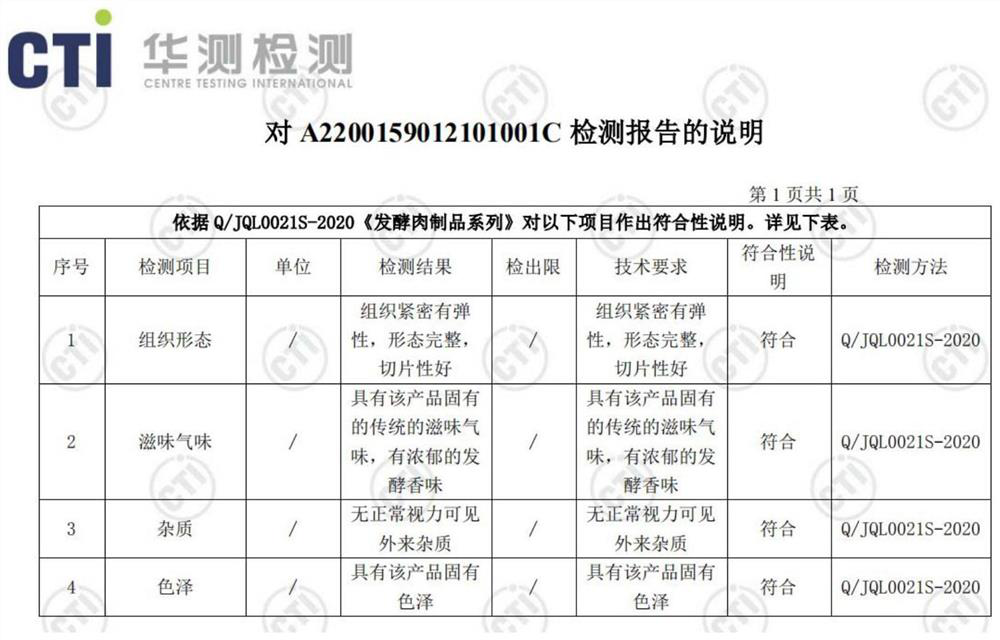

Rapid gradient fermentation process for normal-temperature ready-to-eat leisure fermented meat and application of rapid gradient fermentation process

PendingCN111869831APrevent oxidationShort fermentation cycleSugar food ingredientsMeat/fish preservation by heatingBiotechnologyLactobacillus sake

The invention provides a rapid gradient fermentation process for normal-temperature ready-to-eat leisure fermented meat and an application of the rapid gradient fermentation process. The normal-temperature ready-to-eat leisure fermented meat comprises the following strains in percentage by mass of 20-25% of lactobacillus sake, 20-25% of pediococcus acidilactici, 20-25% of staphylococcus xylosus, 15-25% of staphylococcus carnosus and 10-20% of staphylococcus vitulinus. Compared with the prior art, a design compound bacteria is used for fermentation, a three-stage rapid gradient fermentation production process is designed, the processing time of products is short, the acidity of the products better conforms to the mouth feel of Chinese people, the products are more moist, the mouth feel requirement of consumers is met, and in addition, the shelf life of the products is long.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS +1

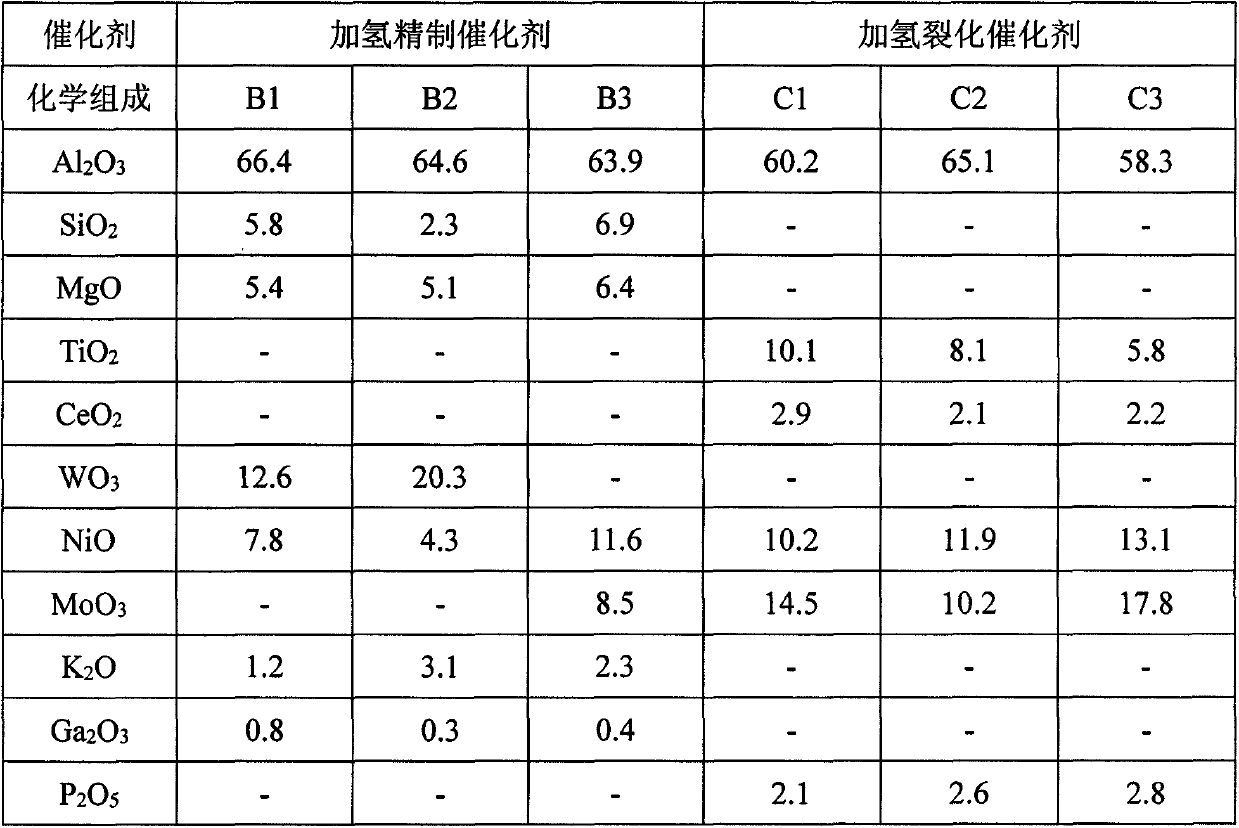

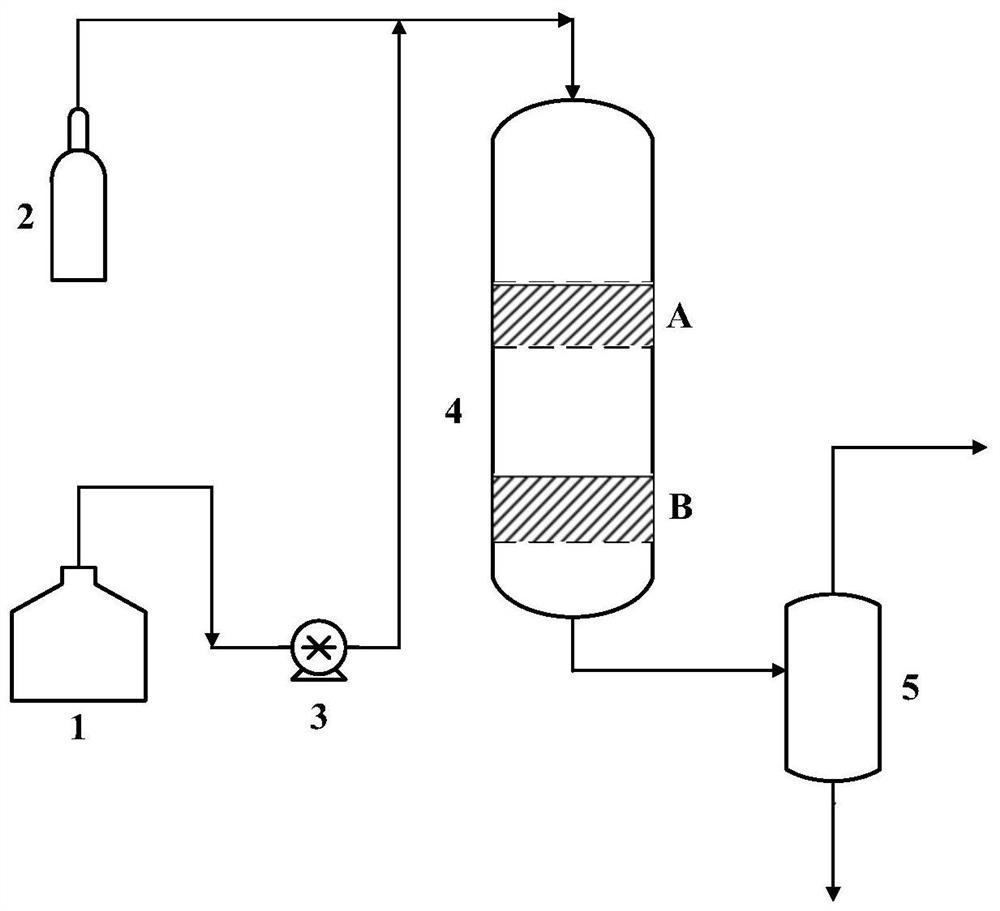

Method for preparing diesel by hydrogenating anthracene oil of coal tar

ActiveCN103695030AImprove stabilityInhibit coke cloggingTreatment with hydrotreatment processesPotassiumCerium

The invention relates to a method for preparing diesel by hydrogenating anthracene oil. The method comprises the following steps: reacting anthracene oil in hydrogenation reaction region containing a first catalyst; allowing the product oil obtained in the hydrogenation reaction region to enter a hydrocracking reaction region containing a second catalyst to react to prepare a diesel component finished product. The method has the advantages that hydrofining catalysts can realize hydrodesulfurization, hydrodenitrification and hydrodeoxygenation of coal tar and can improve activity, so that aromatic hydrocarbon is saturated and subjected to ring opening; an aid potassium is added into the catalysts, so easy-to-coke substances of the coal tar can be inhibited from coking and blocking reactors and the stability of the catalysts is improved; the acidity of a carrier is effectively controlled by adjusting the adding ratio of titanium dioxide and cerium dioxide of the carrier, so that hydrocracking activity and selectivity are improved; the titanium dioxide has strong adsorption capability on sulfur, so desulfuration is promoted; the cerium dioxide has high melting point, so the stability of the carrier is improved and the service life of the catalysts is prolonged.

Owner:NINGBO JINYUANDONG PETROCHEM ENG TECH +1

Preparation of hypochlorous and disinfectant liquid

Two processes of preparing HClO disinfectant. NO.1 a. Electrolysis NaCl solution with no diaphragm, made molNaCl:mol NaClO>1:1; b. Electrolysis further electrolytic solution from a besides positive pole at diaphragm cell. HCl produced neutralizes NaClO to form HCl. NO.2 Electrolysis NaCl solution with no diaphragm to be NaClO, HClO and HCl. Mix the produced solution from a and b to form HClO.

Owner:EAST CHINA UNIV OF SCI & TECH

Solid acid catalyst for transesterification, preparation method of solid acid catalyst and preparation method of vitamin A palmitate

ActiveCN112517025AAddress mechanical propertiesControl acidityMetal/metal-oxides/metal-hydroxide catalystsPreparation by transesterificationPtru catalystSolid acid

The invention discloses a solid acid catalyst for transesterification, a preparation method of the solid acid catalyst and a preparation method of vitamin A palmitate. The catalyst is structurally marked as S2O8<2-> / MxPyOz@N<w+>-CNT, wherein S2O8<2-> is an active component, and MxPyOz is an oxygen-containing metal phosphide. According to the catalyst, the problem of mechanical properties of a solid acid catalyst is solved by utilizing blending modification of carbon nanotubes, active components are loaded on an amorphous oxygen-containing metal phosphorus compound, so that massive loss of theactive components of the traditional solid acid catalyst in a reaction system is avoided, and the acid strength of the catalyst is controlled by adopting a silane passivation technology, the serious problem that byproducts are generated in the transesterification process of a traditional solid acid catalyst is solved. The catalyst is used for preparation of vitamin A palmitate, and the process hasthe advantages of simple operation, high catalytic efficiency, environmental protection, and continuous production.

Owner:WANHUA CHEM GRP CO LTD

Preparation process of long-chain alkyl (meth) acrylate

PendingCN112174817ASolving the self-aggregation problemControl acidityOrganic compound preparationCarboxylic acid esters preparationPolymer scienceMeth-

The invention discloses a preparation process of long-chain alkyl (meth) acrylate, which adopts a polymerization inhibitor composition containing phenothiazine accounting for at least 10% of the totalmass of the composition as a polymerization inhibitor for esterification reaction. The invention solves the problem of self-polymerization in the post-treatment process, can effectively control the acidity of the product to obtain a colorless or white high-purity product, and has the advantages of high yield and expanded application range of the product; in addition, according to the preparationprocess, polymerized excessive (methyl) acrylic acid is recycled, so that a large amount of acid wastewater is prevented from being generated, and the comprehensive benefit is increased.

Owner:ZHEJIANG KANGDE NEW MATEIRALS

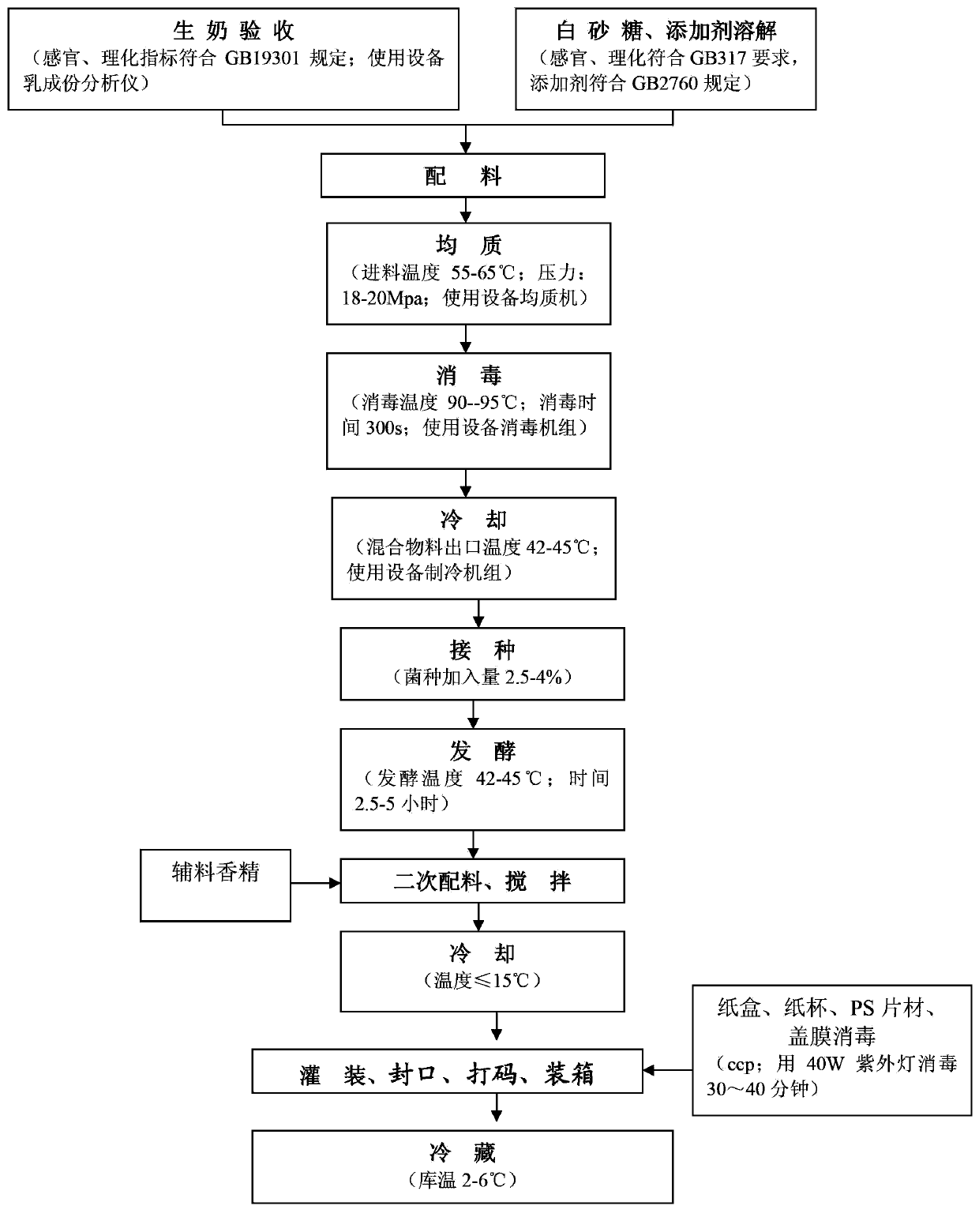

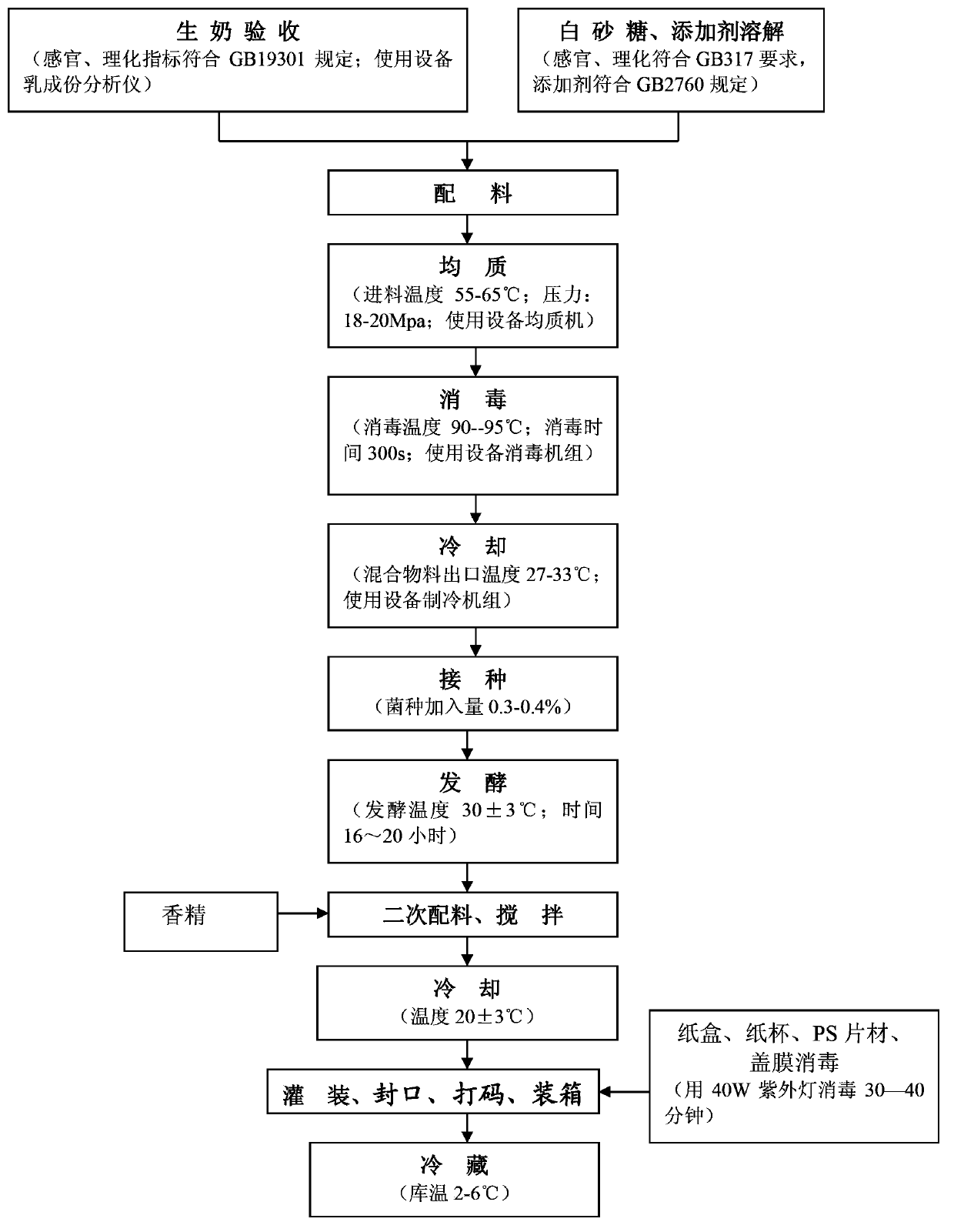

Preparation method for disturbing yoghurt

InactiveCN103385296ADelayed fermentationImprove labor efficiencyMilk preparationMixed materialsRefrigeration

The invention relates to a preparation method for disturbing yoghurt. The preparation method comprises the following successive steps: acceptance inspection of raw milk; acceptance inspection of accessory materials; batching; homogenization; sterilization; primary cooling; inoculation; fermentation; secondary batching; stirring; secondary cooling; filling; sealing; coding; binning; and refrigeration; wherein temperature for primary cooling and inoculation is 27 to 33 DEC C, a strain accounting for 0.3 to 0.4% (wt%) of a mixed material is inoculated, fermentation is carried out in a fermentation cylinder at a temperature of 30 + / - 3 DEG C for 16 to 20 h and is terminated when acidity reaches 65 to 70 DEG C T, and fermentation broth is cooled to a temperature of 20 + / - 3 DEG C in secondary cooling. Compared with inoculation temperature of 42 to 45 DEG C in a traditional process, inoculation temperature the invention is controlled to be 27 to 33 DEG C, so the fermentation speed of the yoghourt decreases, acidity slowly increases, an acidity generation speed is slowed down, and acidity of the yoghourt can be better controlled in actual operation; with the preparation method, the quality of the produced yoghourt is improved and stable, fermentation can be reasonably carried out at night, on-duty time of a worker is shortened, and labor efficiency is improved.

Owner:YANGZHOU YANGDA KANGYUAN DAIRY

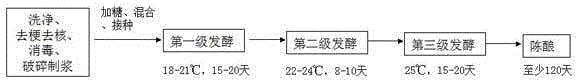

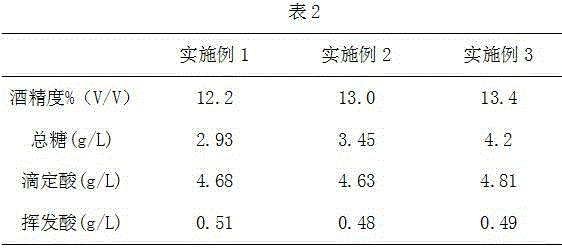

Dry loquat wine and making method thereof

ActiveCN104479960AGreat tastePrevent browningAlcoholic beverage preparationMicroorganism based processesFlavorLactobacillus buchneri

The invention provides a making method of dry loquat wine. The method comprises the following steps: Saccaromycescerevisiae and Lactobacillus buchneri are used for primary fermentation and secondary fermentation of washed loquat whose stalks and pits are removed, the primary fermentation is performed at the temperature of 18-21 DEG C for 15-20 days, and the secondary fermentation is performed at the temperature of 22-24 DEG C for 8-10 days; then Candida utilis is used for tertiary fermentation which is performed at the temperature of 25 DEG C for 15-20 days; and aging is performed for at least 120 days after fermentation is finished. The invention further provides the dry loquat wine made with the method. The dry loquat wine and the making method thereof have the advantages as follows: threat to a human body due to addition of sulfur dioxide is avoided, browning can be effectively prevented, the acidity can be effectively controlled, the dry loquat wine with excellent taste can be obtained without additional operation, and the obtained loquat wine tastes good and has typical flavor of the loquat wine.

Owner:SICHUAN ACAD OF FOOD & FERMENTATION INDS

Natural plant acidulant and preparation method thereof

InactiveCN110214920AControl acidityProduct quality is stable and controllableFood scienceBlood lipidsFood science

The invention discloses a natural plant acidulant and a preparation method thereof. The acidulant is prepared from, by weight, 1-4 parts of Chinese dates, 4-8 parts of wild jujubes, 1-4 parts of hawthorn fruits and 0.06-0.48 part of lactic acid bacteria. The solid natural plant acidulant is prepared through extracting, fermenting, concentrating and drying. The acidulant prepared through the preparation method is good in taste and high in acidity, can serve as a sourness modifier to be added into food with the effects of enhancing immunity and reducing blood lipid, can adjust the taste of products, and can also enhance the health-care effect of the products.

Owner:河北康平健康产业有限责任公司

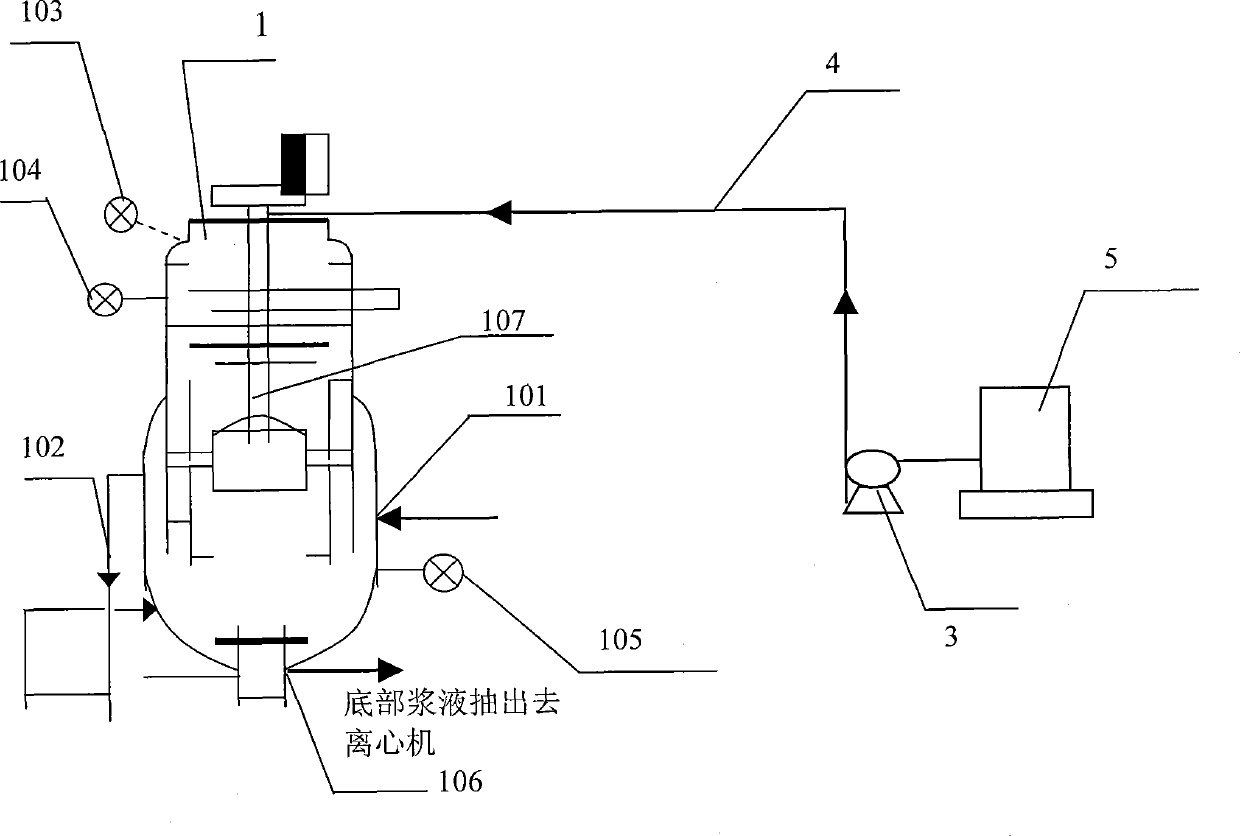

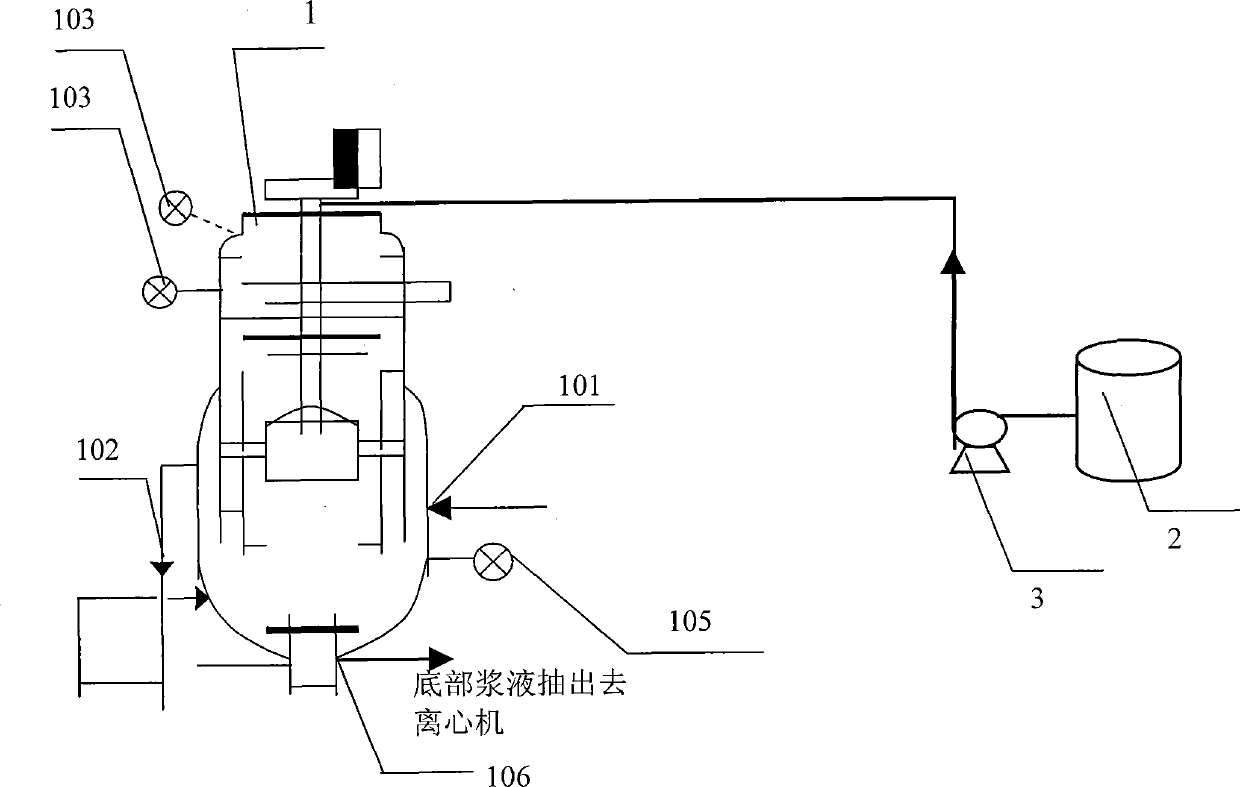

Spraying and washing process of ammonium sulfate crystallizer by non-saturator method

ActiveCN102381719BTake advantage ofEasy to optimizeSolution crystallizationAmmonia compoundsDistillationEvaporation

The invention discloses a spraying and washing process of an ammonium sulfate crystallizer by a non-saturator method, comprising the steps of: spraying and washing the ammonium sulfate crystallizer by ammonia still stronger ammonia water obtained by an ammonia distillation process; washing the attachment on the inner surface of the ammonium sulfate crystallizer; and controlling the acidity of the circulating mother liquor in the ammonium sulfate crystallizer. The mass concentration of the ammonia still stronger ammonia water is 3-6% at 40-55 DEG C. The invention has the maximum advantage of combining the ammonium sulfate crystallizer by non-saturator method with technical characteristics of ammonia distillation, washing ammonium sulfate crystal and attachment on the inner surface of the washing crystallizer by temperature of ammonia and stronger ammonia water in ammonia evaporation stronger ammonia water generated by ammonia distillation and neutralizing a part of free acid in the ammonium sulfate liquor in condition that the production flow does not change. The invention is beneficial to optimize and improve the ammonium sulfate crystallization process and comprehensively utilizing ammonia resources as an important means of energy conservation and emission reduction.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

A kind of preparation method of low carbon alkane dehydrogenation catalyst

InactiveCN104289219BAvoid churnAvoid gatheringHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneDispersity

The invention discloses a preparation method for a propane dehydrogenation catalyst. Without hydrogen reduction, a reaction feed gas is directly introduced and the Pt reduction degree is controlled to improve the stability and sulfur tolerance of the catalyst. The method omits of the drying roasting process, can effectively remove chlorine from the catalyst without hydrothermal treatment, and can significantly improve the activity, selectivity, stability and sulfur tolerance of the catalyst without hydrogen reduction. The preparation method is simple. The catalyst prepared by the method can avoid excessive alkali loss, improve the dispersity of Pt based catalyst active metals, form more secondary active phases, and ultimately improve the selectivity of the target product propylene and the catalyst activity, stability and sulfur tolerance.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com