Supercritical carbon dioxide method for extracting high purity rhubarb free anthraquinones

A free anthraquinone, supercritical technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of long auxiliary time for loading and unloading, hidden dangers in production safety, and limited volume. It is beneficial to large-scale industrial production, preventing equipment corrosion and potential safety hazards, and achieving high product yield and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

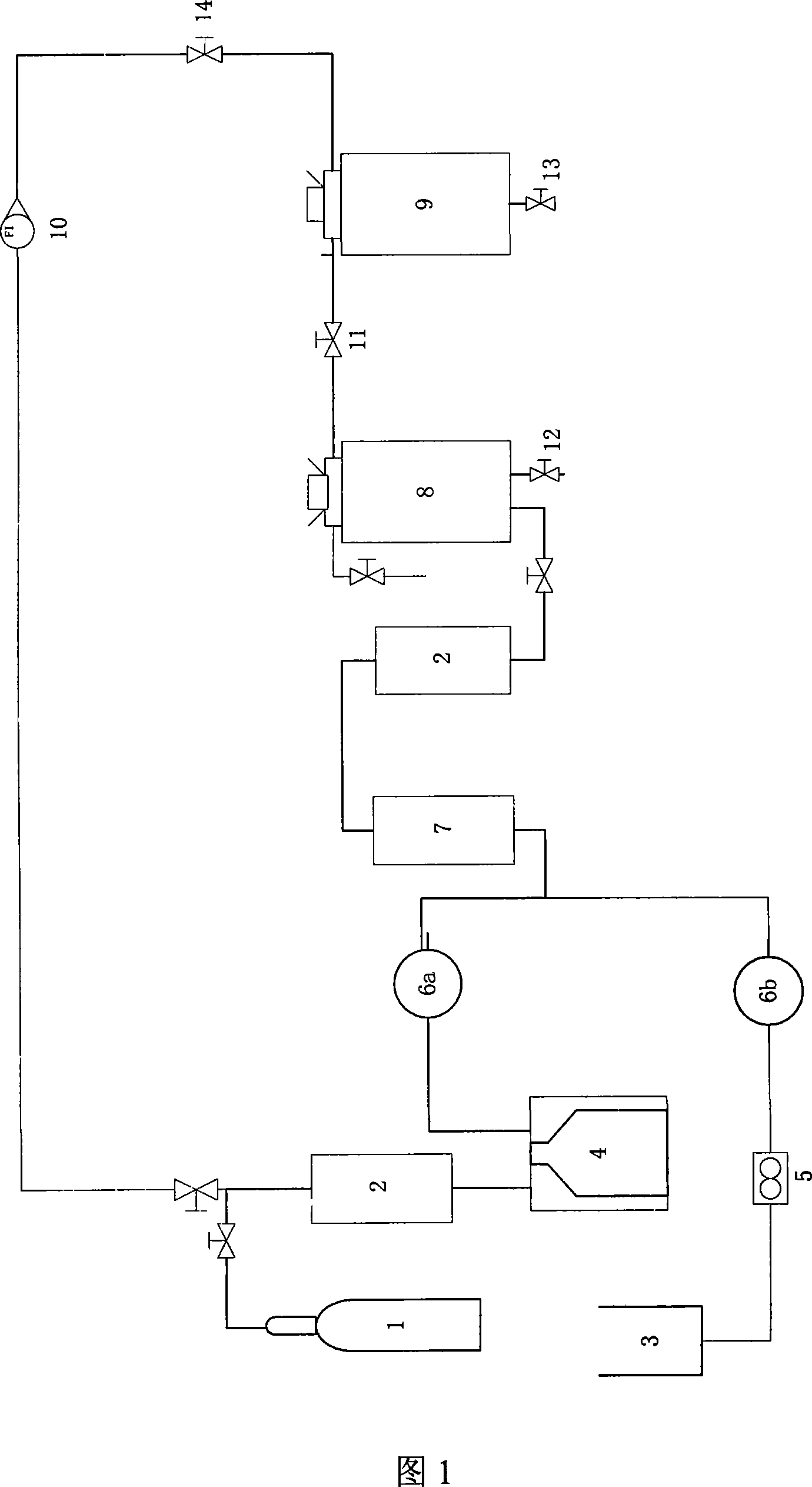

[0028] Referring to accompanying drawing 1, when supercritical carbon dioxide fluid continuously extracts rhubarb free anthraquinone, at first raw material powder is leached with organic solvent to obtain rhubarb leaching liquid; Neutralization with base follows. Heat the extraction kettle 8 and the separation kettle 9 to the set temperature, and simultaneously open the booster plunger pump 6a to pressurize the extraction kettle 8 to the set pressure (close the front valve 11 of the separation kettle 9 at this time). Pour the rhubarb leaching solution treated by acid hydrolysis and alkali neutralization into the entrainer tank 3, and continuously pump it into the extraction tank 8 at a certain flow rate by the entrainer pump 6b. Now open the front valve 11 of the separation kettle 9 to control the flow of circulating carbon dioxide, so that rhubarb anthraquinone and the organic solvent continuously flow into the separation kettle 9 from the extraction kettle 8 at a certain rat...

Embodiment 2

[0033] According to the technical process of Example 1, take 250 grams of 80-100 mesh rhubarb crude drug powder (2.81 g of rhubarb total anthraquinones / 100 g of rhubarb powder), and add it to a percolation bed of φ4×80 cm. Percolation leaching was carried out with ethanol at 60°C. The amount of ethanol is 2000mL, the flow rate is 1.2L h -1 , after about 1.67h, the leaching was finished, and 1770mL of ethanol leaching solution was collected;

[0034] Add 20 mL of concentrated hydrochloric acid (36%, w / w) to the ethanol leaching solution, mix well, and hydrolyze at 70° C. for 2 hours. It is detected that rhubarb-bound anthraquinone is completely converted into free form. Finish the reaction, add 25 grams of calcium carbonate powder in the reaction solution, and adjust the pH of the reaction solution to be 6.6.

[0035] Adjust the temperature of the extraction tank of the supercritical carbon dioxide fluid extraction equipment to 50°C, the pressure to 25MPa, the temperature of ...

Embodiment 3

[0037] According to the technical process of Example 1, take 250 grams of 80-100 mesh rhubarb crude drug powder (2.81 g of rhubarb total anthraquinones / 100 g of rhubarb powder), and add it to a percolation bed of φ4×80 cm. Percolation leaching was carried out with ethanol at 40°C. The amount of ethanol is 2000mL, the flow rate is 1.0L·h -1 , after about 2 hours, the leaching was finished, and 1800 mL of ethanol leaching solution was collected;

[0038] Add 20 mL of concentrated hydrochloric acid (36%, w / w) to the ethanol leaching solution, mix well, and hydrolyze at 50° C. for 2 hours. It is detected that rhubarb-bound anthraquinone is completely converted into free form. Finish the reaction, add 25 grams of calcium carbonate powder in the reaction solution, and adjust the pH of the reaction solution to be 6.8.

[0039] Adjust the temperature of the extraction tank of the supercritical carbon dioxide fluid extraction equipment to 50°C, the pressure to 15MPa, the temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com