Dry loquat wine and making method thereof

A technology of loquat wine and dry type, applied in the field of dry type loquat wine and its brewing, can solve problems such as human health hazards, achieve the effects of low production cost, prevent browning, and control acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

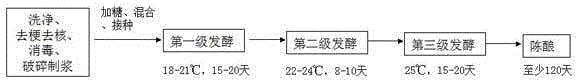

Method used

Image

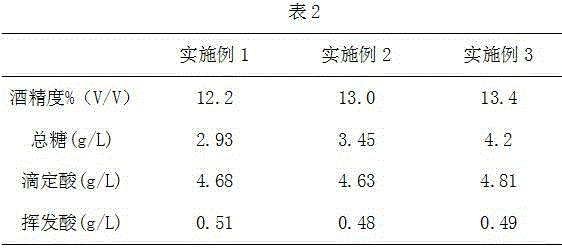

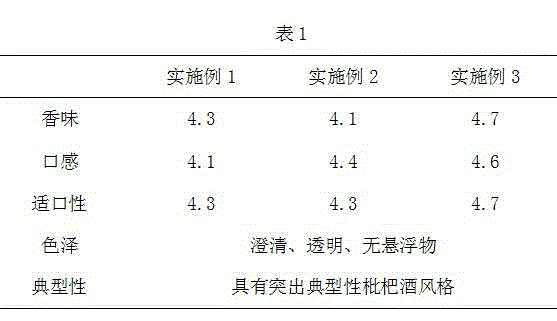

Examples

Embodiment 1

[0030] 1) After the washed loquats are destemmed and cored, sterilized and sterilized, they are crushed and made into pulp;

[0031] 2) In parts by weight, mix 10 parts of sugar and 80 parts of pulp obtained in step 1);

[0032] 3) Mix the activated Saccaromyces cerevisiae and Lactobacillus buchneri at a ratio of 2:1 by volume, and inoculate the result of step 2), with an inoculum volume of 8%;

[0033] 4) First-stage fermentation: put the product obtained in step 3) in a sealed sterile fermenter, ferment at a temperature of 18°C for 20 days, and take the fermentation liquid;

[0034] 5) Second-stage fermentation: put the fermented liquid obtained in step 4) in a sealed sterile fermenter, and ferment at 22°C for 10 days;

[0035] 6) Third-stage fermentation: Inoculate Canida utilis on the result of step 5), the inoculation amount is 2%, and ferment at 25°C for 20 days;

[0036] 7) Aging the product obtained in step 6) at 25-30°C for 120 days.

Embodiment 2

[0038] 1) After the washed loquats are destemmed and cored, sterilized and sterilized, they are crushed and made into pulp;

[0039] 2) In parts by weight, mix 15 parts of sugar and 90 parts of pulp obtained in step 1);

[0040] 3) Mix the activated Saccaromyces cerevisiae and Lactobacillus buchneri at a ratio of 2:1 by volume, and inoculate the result of step 2), with an inoculum volume of 10%;

[0041] 4) First stage fermentation: put the product obtained in step 3) into a sealed sterile fermenter, ferment at a temperature of 21°C for 15 days, and take the fermentation liquid;

[0042] 5) Second-stage fermentation: put the fermented liquid obtained in step 4) in a sealed sterile fermenter, and ferment at 24°C for 8 days;

[0043] 6) The third stage of fermentation: inoculate Canida utilis on the result of step 5), the inoculum amount is 3%, and ferment at 25°C for 15 days;

[0044] 7) Aging the product obtained in step 6) at 25-30°C for 180 days.

Embodiment 3

[0046] 1) After the washed loquats are destemmed and cored, sterilized and sterilized, they are crushed and made into pulp;

[0047] 2) In parts by weight, mix 13 parts of sugar and 88 parts of pulp obtained in step 1);

[0048] 3) Mix the activated Saccaromyces cerevisiae and Lactobacillus buchneri at a ratio of 2:1 by volume, and inoculate the product obtained in step 2), with an inoculum volume of 9%;

[0049] 4) First stage fermentation: put the product obtained in step 3) into a sealed sterile fermenter, ferment at a temperature of 19°C for 18 days, and take the fermentation liquid;

[0050] 5) Second-stage fermentation: put the fermented liquid obtained in step 4) in a sealed sterile fermenter, and ferment at 23°C for 9 days;

[0051] 6) The third stage of fermentation: inoculate Canida utilis on the result of step 5), the inoculum amount is 2.5%, and ferment at 25°C for 18 days;

[0052] 7) Aging the product obtained in step 6) at 25-30°C for 160 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com