Preparation method for disturbing yoghurt

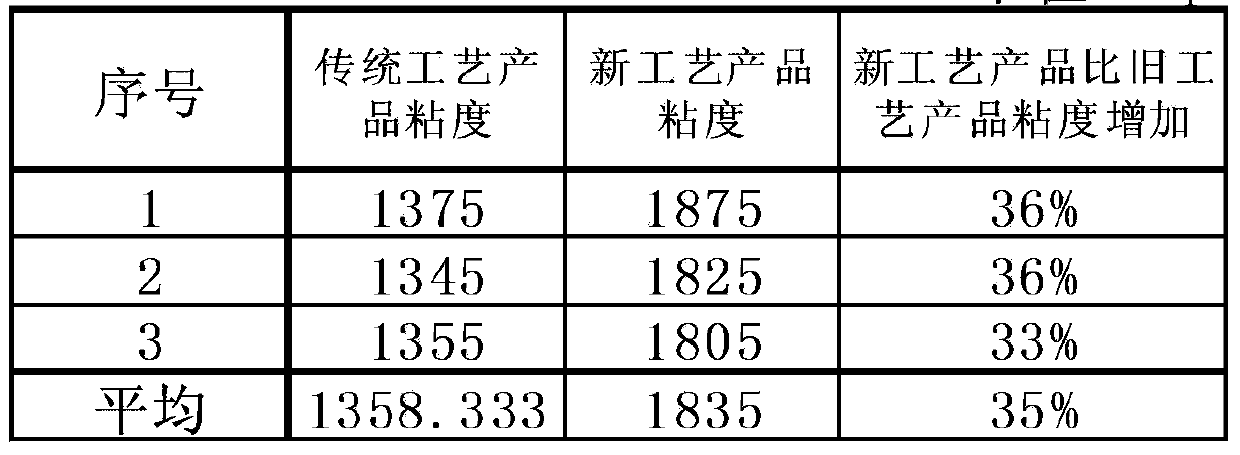

A yogurt and stirring type technology is applied in the field of preparation of stirring yogurt, which can solve the problems of product instability, difficult to control fermentation acidity, low acidity, etc., and achieve the effects of improving product quality stability, shortening on-the-job time, and improving product acidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

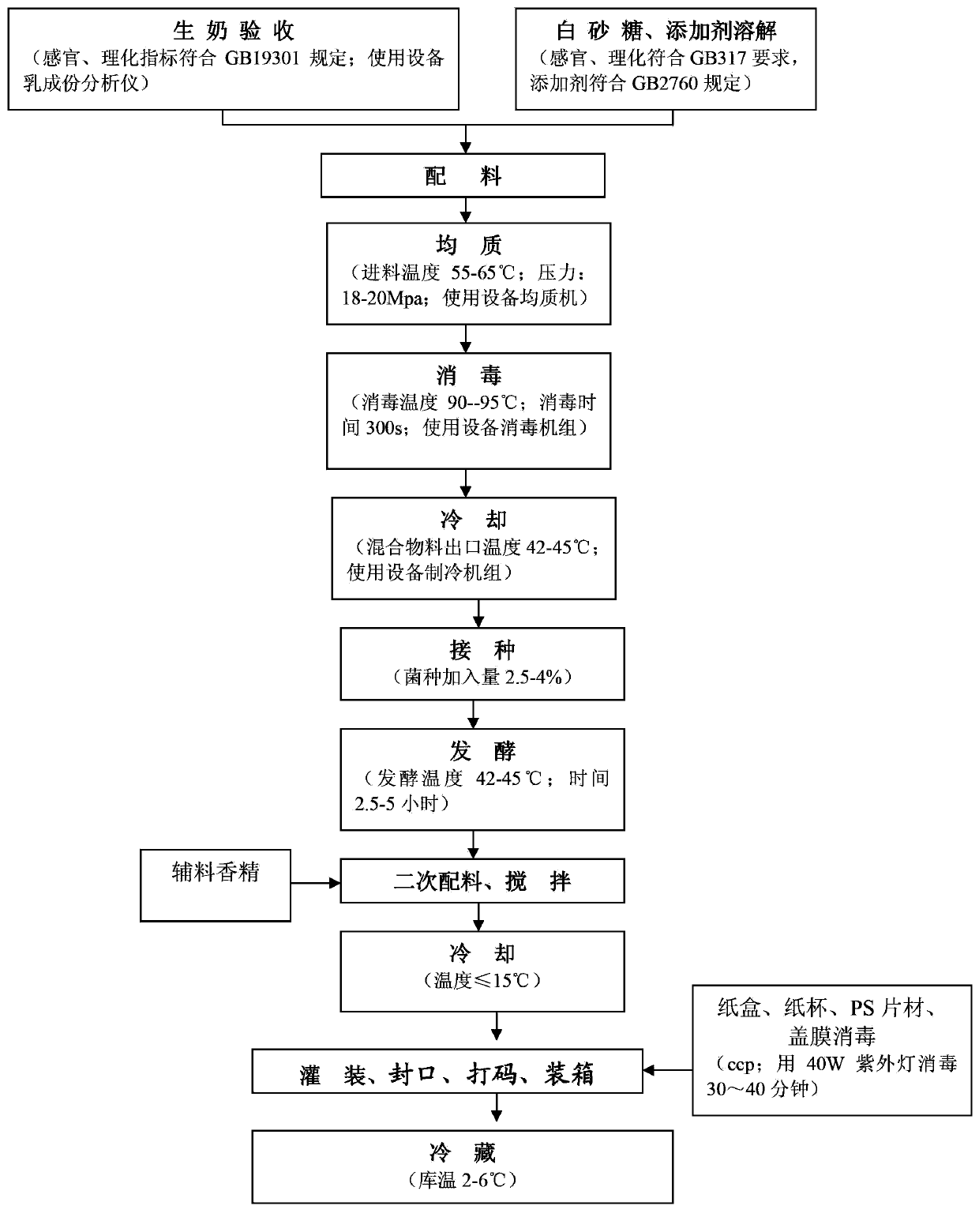

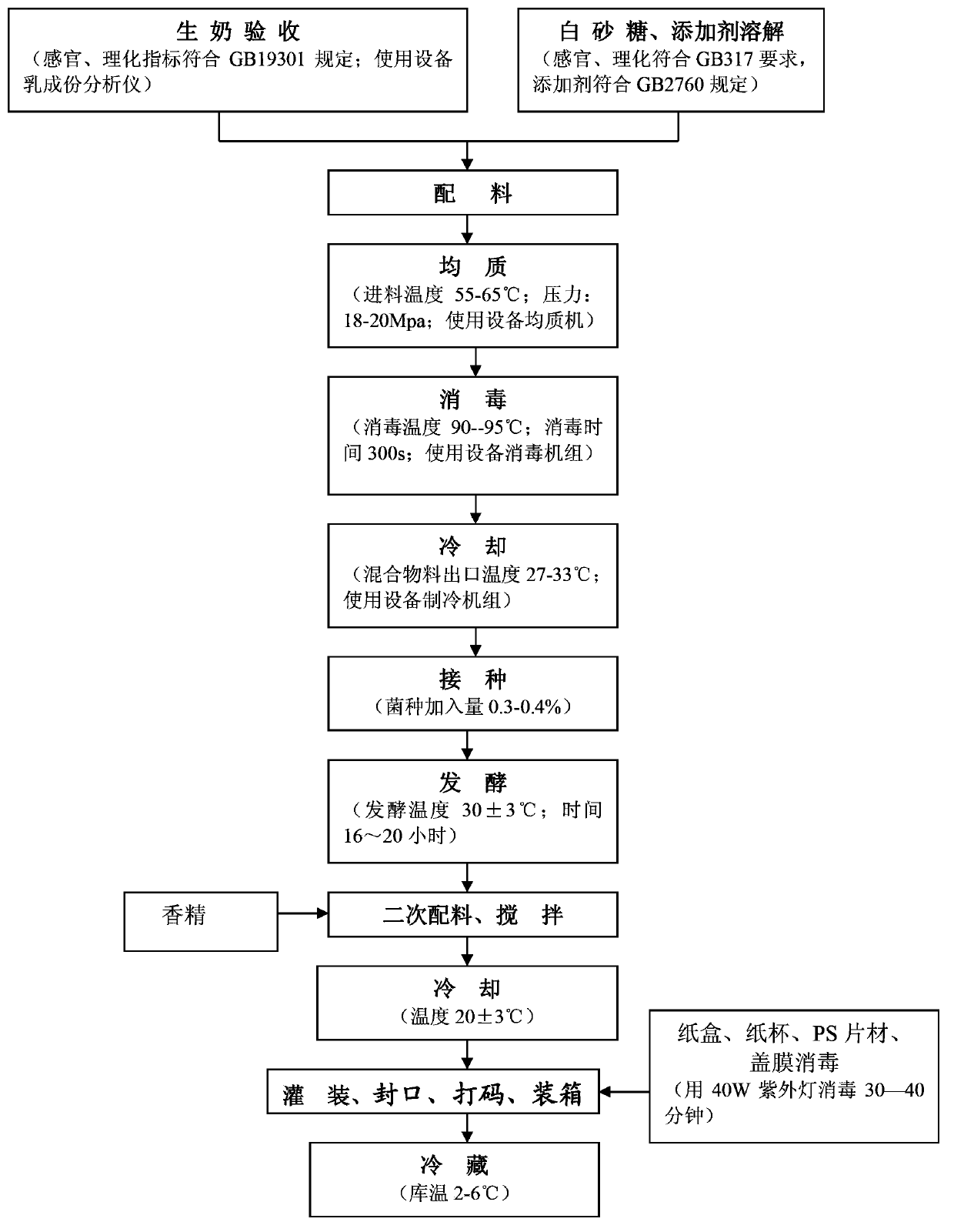

[0025] like figure 2 As shown, a method for preparing stirred yoghurt includes the following steps in sequence: raw milk acceptance, auxiliary material acceptance, batching, homogenization, disinfection, primary cooling, inoculation, fermentation, secondary batching, stirring, secondary cooling, filling , sealing, coding, packing, refrigeration,

[0026] The homogenization is to preheat the prepared raw materials to 55-65°C, and perform homogenization to obtain a mixed material, and the homogenization pressure is 18-20Mpa;

[0027] The disinfection is to sterilize the homogenized mixed material for 300 seconds with an equipment sterilizer at 90-95°C;

[0028] The primary cooling and inoculation is to cool the sterilized mixed material and keep the outlet temperature at 27-33°C, and insert 0.3-0.4% (percentage by weight) of bacteria accounting for the weight of the mixed material;

[0029] The fermentation is carried out in a fermentation room at 30±3°C, the fermentation tim...

Embodiment 1

[0032] Acceptance of raw and auxiliary materials;

[0033] a Raw milk inspection, according to GB19301-2010 "Raw Milk" inspection of raw milk;

[0034] b Acceptance of white granulated sugar auxiliary materials, white granulated sugar, sensory, physical and chemical meet the requirements of GB317;

[0035] According to the production plan quantity of the next day, according to the planned ingredients (per ton) at 2 p.m.: Preheat 85% (weight percentage) of fresh milk to 40-45 degrees, add 6% (weight percentage) of white sugar and Dissolve 0.25% (weight percent) stabilizer together, mix well, and dilute to 100% with water.

[0036] Homogenization: Preheat the prepared raw materials to 55-65°C for homogenization, and the homogenization pressure is 18-20Mpa;

[0037] Disinfection: Disinfection temperature 90~95℃; Disinfection time 300s;

[0038] Cooling and inoculation: the outlet temperature of the mixed material after disinfection is cooled to 28-30°C, and the amount of bacte...

Embodiment 2

[0045] Acceptance of raw and auxiliary materials;

[0046] a Raw milk inspection, according to GB19301-2010 "Raw Milk" inspection of raw milk;

[0047] b Acceptance of white granulated sugar auxiliary materials, white granulated sugar, sensory, physical and chemical meet the requirements of GB317;

[0048] According to the production plan quantity of the next day, according to the planned ingredients (per ton) at 2 p.m.: Preheat 90% (weight percentage) of fresh milk to 40-45 degrees, add 5% (weight percentage) of white sugar and 0.5% (percentage by weight) of the stabilizer is dissolved together, mixed evenly during batching, and replenished to 100% (percentage by weight) with water.

[0049] Homogenization: Preheat the prepared raw materials to 55-65°C for homogenization, and the homogenization pressure is 18-20Mpa;

[0050] Disinfection: Disinfection temperature 90~95℃; Disinfection time 300s;

[0051] Cooling and inoculation: After disinfection, the outlet temperature is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com