Efficient biological fertilizer production method

A production method and technology of biological fertilizer, which are applied in microbial treatment, animal carcass fertilizer, combined biological treatment, etc., can solve the problems of slow fermentation speed, inability to fully decompose organic fertilizer raw materials, and affecting the efficacy of bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

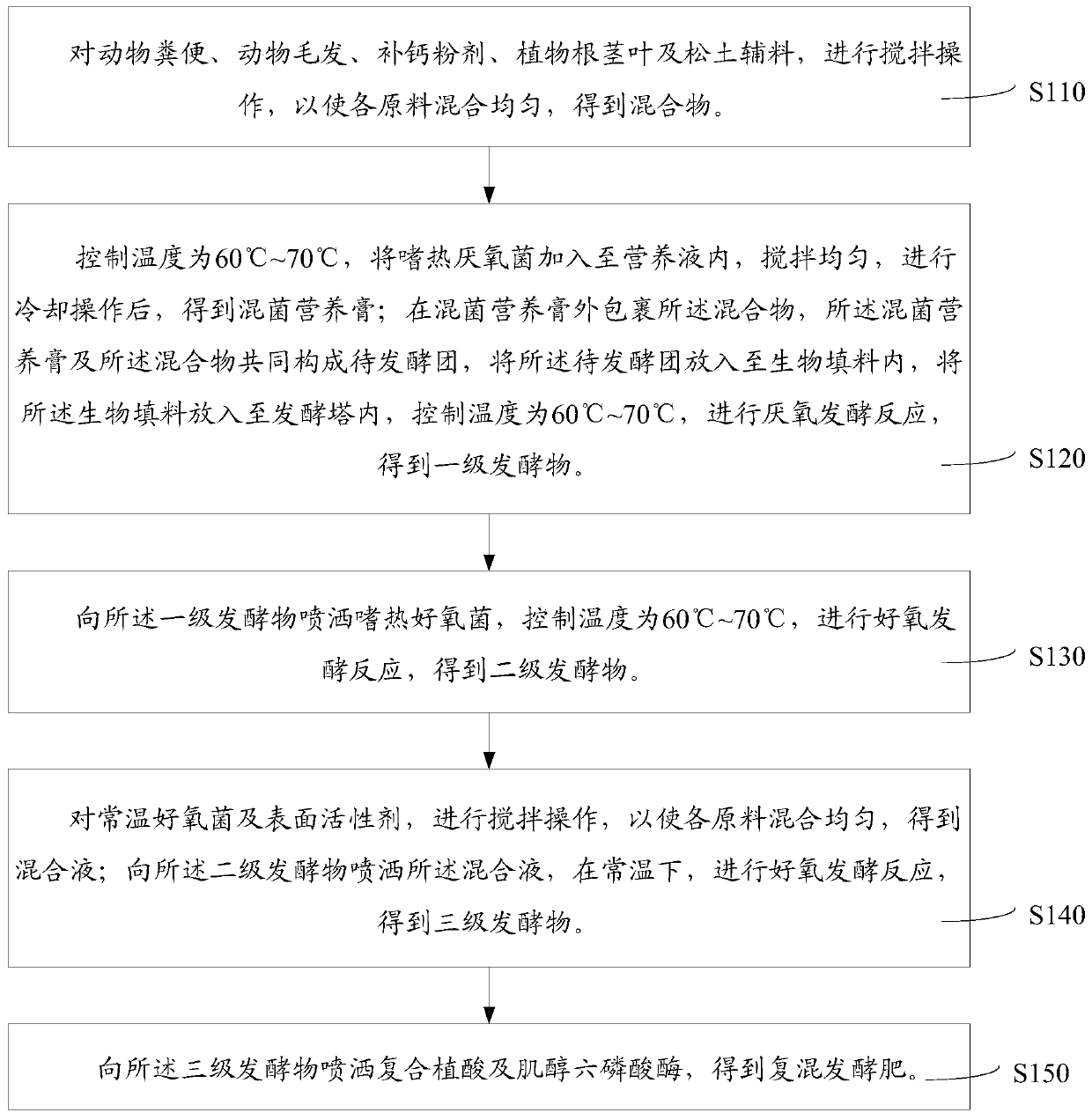

Method used

Image

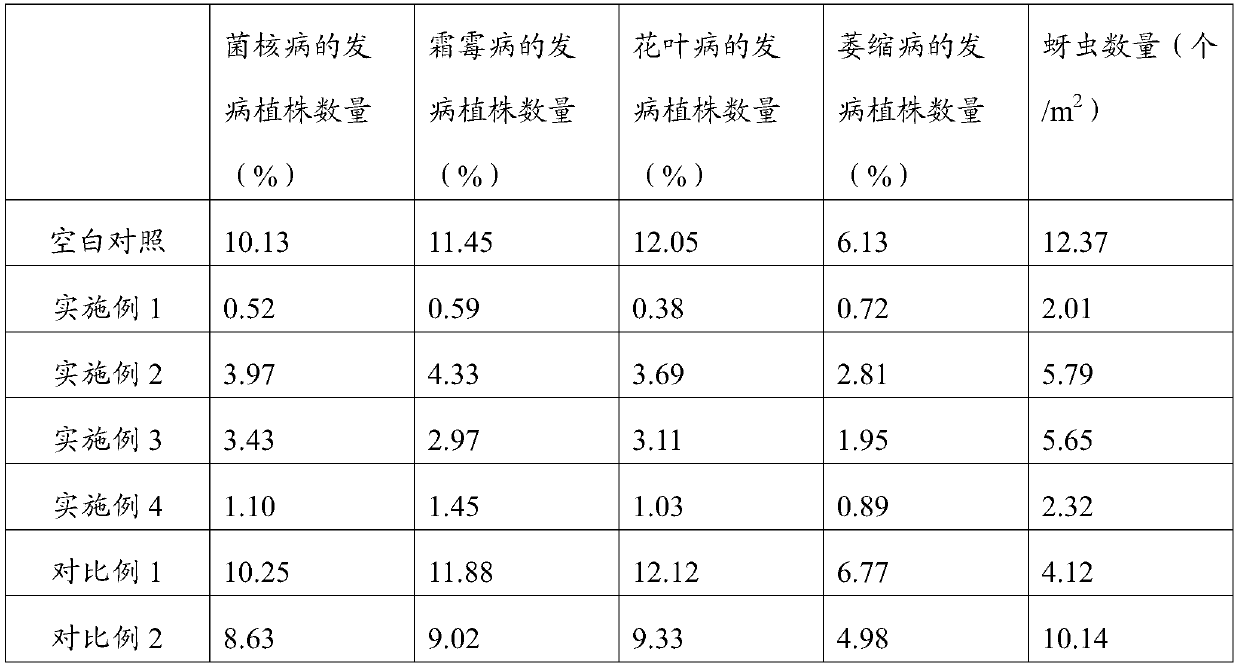

Examples

Embodiment approach

[0030] In one embodiment, a high-efficiency biological fertilizer is made of the following raw materials in parts by weight: 60-80 parts of animal manure, 5-10 parts of animal hair, 10-20 parts of calcium supplement powder, 10-20 parts of plant roots, stems and leaves, pine 20-40 parts of soil auxiliary material, 0.4-1 part of thermophilic anaerobic bacteria, 0.4-1 part of thermophilic aerobic bacteria, 1-2 parts of room temperature aerobic bacteria, 8-12 parts of compound phytic acid, 0.2 parts of phytase ~1 part and 0.02~0.2 parts of surfactant.

[0031] It should be noted that this high-efficiency biological fertilizer contains animal manure, animal hair, calcium supplement powder, plant roots, stems and leaves, loose soil auxiliary materials and microbial agents, which are safe and non-toxic. The scientific ratio of various raw materials makes this high-efficiency biological fertilizer rich Contains nitrogen, phosphorus, potassium, calcium, zinc and other trace elements an...

Embodiment 1

[0097] S111, stir 60kg chicken manure, 10kg chicken feathers, 8kg shell powder, 2kg eggshell powder, 5kg mulberry root stem leaves, 5kg mint root stem leaves, 5kg dandelion root stem leaves, 5kg coptis root stem leaves, 10kg mushroom residue and 10kg rice bran Operate so that the raw materials are mixed uniformly to obtain a mixture.

[0098] S121, control the temperature at 60°C, add 1 kg of Steder hyperthermococcus into 5 kg of nutrient solution, stir evenly, and perform cooling operation to obtain a mixed bacteria nutrient cream; wrap the mixture outside the mixed bacteria nutrient cream, and the mixed Bacterial nutrient paste and the mixture together constitute the dough to be fermented, put the dough to be fermented into the biological filler, put the biological filler into the fermentation tower, control the temperature at 60°C, and carry out anaerobic fermentation reaction , to obtain a primary fermentation product.

[0099] S131, spraying 0.3 kg of Bacillus stearother...

Embodiment 2

[0104] S112, 80kg of sheep manure, 5kg of wool, 10kg of sheep bone meal, 10kg of fish bone meal, 6kg of potato roots, 4kg of citrus roots, 20kg of sawdust and 20kg of activated carbon are stirred so that the raw materials are evenly mixed to obtain a mixture to be fermented .

[0105] S122, control the temperature at 70°C, add 0.4 kg of Steder hyperthermococcus into 4 kg of nutrient solution, stir evenly, and after cooling, obtain a mixed-bacteria nutrient cream; wrap the mixture outside the mixed-bacteria nutrient cream, and The mixed bacteria nutrition paste and the mixture together constitute the dough to be fermented, put the dough to be fermented into the biological filler, put the biological filler into the fermentation tower, control the temperature at 70°C, and carry out anaerobic fermentation reaction , to obtain a primary fermentation product.

[0106] S132, spraying 0.25kg of Bacillus stearothermophilus and 0.75kg of Thermus thermophilus to the primary fermented pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com