Method for measuring content of Al, Ti and Ca in low-carbon silicon iron

A calcium content, carbon silicon technology, applied in the field of determination of aluminum titanium calcium content in low-carbon ferrosilicon, can solve the problems of long analysis cycle, chemical pollution, etc., and achieve the effect of cumbersome steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

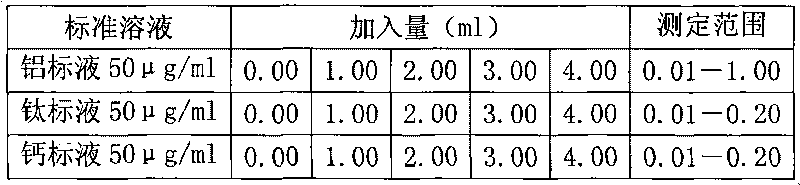

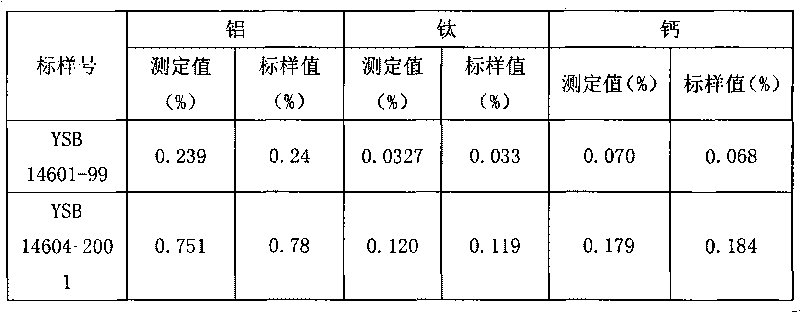

[0009] A method for measuring the content of aluminum titanium calcium in low-carbon ferrosilicon, the method dissolves the sample with nitric acid and hydrofluoric acid, after perchloric acid fumes, add an appropriate amount of hydrochloric acid, heat to dissolve the salt; then dilute with water to With a certain volume, the atomized solution is introduced into the inductively coupled plasma atomic emission spectrometer, and the spectral line intensity of the element to be measured is measured; according to the spectral line intensity measured by the known concentration standard substance, the concentration of the corresponding element of the substance to be measured is obtained.

[0010] Specific examples are as follows:

[0011] 1. Reagents

[0012] 1.1 Hydrochloric acid (1:1 aqueous solution).

[0013] 1.2 Nitric acid (ρ1.42g / mL).

[0014] 1.3 Hydrofluoric acid (ρ1.13g / mL).

[0015] 1.4 Perchloric acid (ρ1.67g / mL).

[0016] 1.5 NaOH (10% aqueous solution)

[0017] 1.6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com