Method for removing surface covering of steel failure fracture

A technology of surface covering and fracture, which is applied in the field of fracture analysis of steel failure samples, can solve the problems of broken fracture morphology, toxic reagents, and incomplete cleaning, so as to protect the fracture and substrate, improve cleaning efficiency and effect, The effect of quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

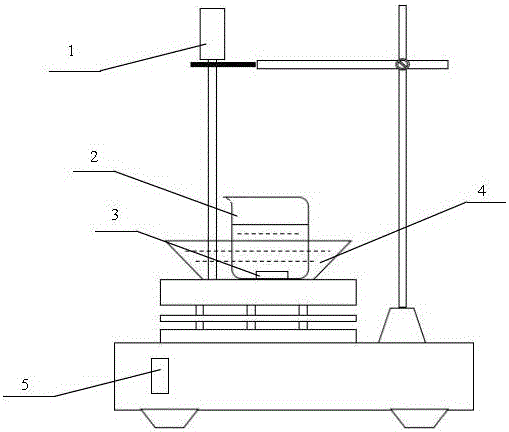

Method used

Image

Examples

Embodiment 2

[0045] The steps and operation methods adopted in this embodiment are the same as those in Embodiment 1. See Table 1 for the specific proportioning, time, number of repetitions, and total time.

Embodiment 3

[0047] The steps and operation methods adopted in this embodiment are the same as those in Embodiment 1. See Table 1 for the specific proportioning, time, number of repetitions, and total time.

Embodiment 4

[0049] The steps and operation methods adopted in this embodiment are the same as those in Embodiment 1. See Table 1 for the specific proportioning, time, number of repetitions, and total time.

[0050] Table 1

[0051]

[0052] As can be seen from the above table 1, the present invention has quick operation, short processing time and obvious effect.

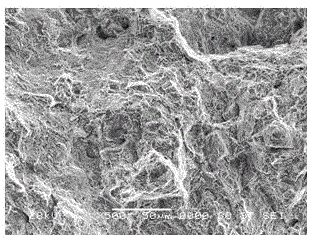

[0053] Such as figure 2 ,3 As shown, the fracture surface of the fresh fracture sample is not covered, and the fracture source area can be seen to be dimple-shaped, and the fracture mode is ductile fracture.

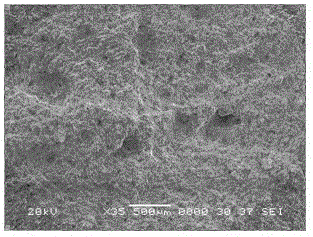

[0054] Such as Figure 4 , 5 As shown, it is the SEM microscopic image of the same fracture sample in a humid corrosive atmosphere for a long time. There is a layer of covering on the surface of the fracture, so the source of the fracture cannot be judged based on the microscopic morphology of the fracture.

[0055] Such as Figure 6 As shown, the coating of the fracture was determined by energy spectroscopy to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com