Solid acid catalyst for transesterification, preparation method of solid acid catalyst and preparation method of vitamin A palmitate

A solid acid catalyst, a technology for transesterification, which is used in the preparation of the mutual reaction between ester groups, chemical instruments and methods, catalysts for physical/chemical processes, etc. Achieve the effect of solving mechanical performance problems, avoiding a large amount of loss, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

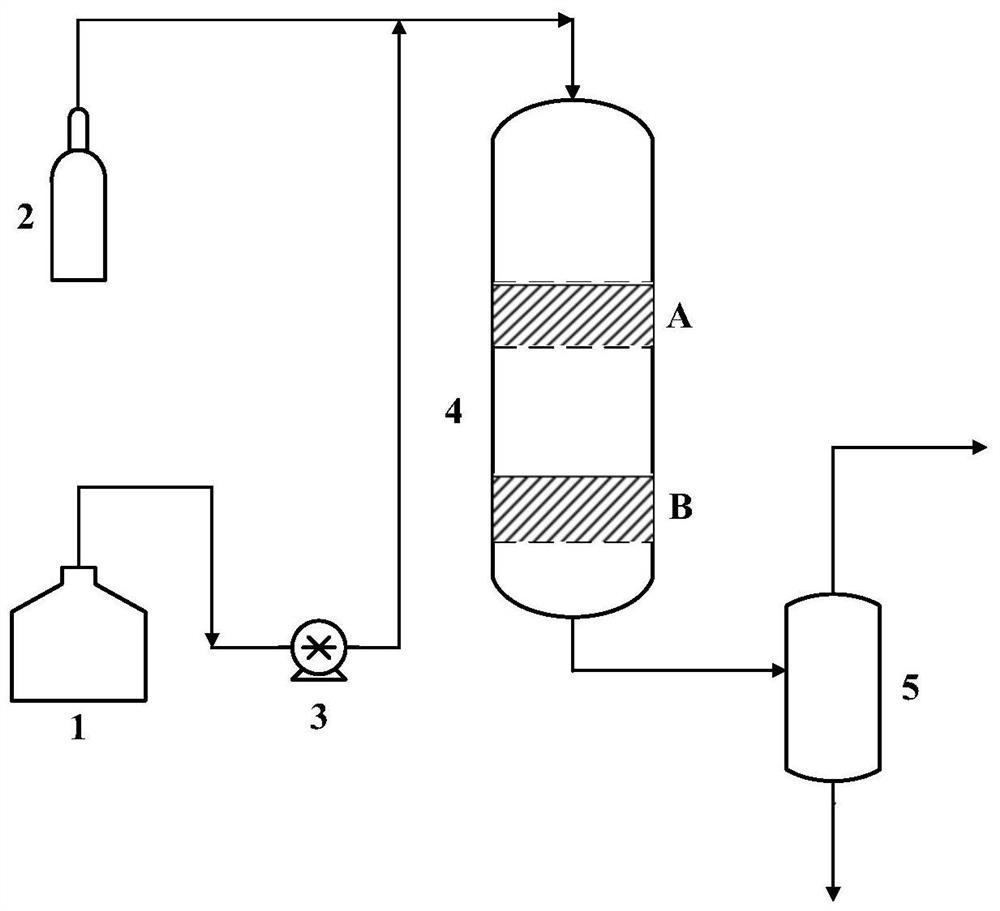

Image

Examples

Embodiment 1

[0049] Modified Catalyst S 2 o 8 2- / Fe 3+ -CNT@Ni 3 Preparation of PO:

[0050] (1) Dissolve 1 mol of nickel acetylacetonate in a mixed solution of 500 mL of deionized water and ethylene glycol (the volume ratio of water to ethylene glycol is 0.4:1), and stir thoroughly. Add a 1% potassium carbonate aqueous solution dropwise, add dropwise for 1 hour to adjust the pH of the solution to 7.5, add 4 mol of triphenylphosphine to the above solution, reflux at 300°C for 4 hours, and dry the obtained precipitate under nitrogen blanketing for use.

[0051] (2) 20g of carbon nanotube powder is placed in 100ml of 98% concentrated sulfuric acid, immersed at 100°C for 5h, filtered, and the filtered black solid is placed in 500mL, 1mol / L ferric chloride aqueous solution to obtain a yellow slurry , and the obtained solid was filtered and dried under the protection of nitrogen for further use. The metal content in the obtained metal-doped modified carbon nanotubes was measured by ICP t...

Embodiment 2

[0055] Modified Catalyst S 2 o 8 2- / Fe 3+ -CNT@Ni 3 Preparation of PO:

[0056] (1) Dissolve 1 mol of nickel acetylacetonate in a mixed solution of 500 mL of deionized water and ethylene glycol (the volume ratio of water to ethylene glycol is 0.5:1), and stir thoroughly. Add a 2% potassium carbonate aqueous solution dropwise, add dropwise for 1 hour to adjust the pH of the solution to 8.0, add 5 mol of triphenylphosphine to the above solution, reflux at 400° C. for 5 hours, and dry the obtained precipitate under nitrogen blanketing for use.

[0057] (2) 30g of carbon nanotube powder is placed in 100ml of 98% concentrated sulfuric acid, soaked at 110°C for 6h, filtered, and the resulting black solid is placed in 500mL, 1.3mol / L ferric chloride aqueous solution to obtain a yellow slurry, The resulting solid was filtered and dried under nitrogen protection for future use. The metal content in the obtained metal-doped modified carbon nanotubes was measured by ICP to be 7.5 ...

Embodiment 3

[0061] Modified Catalyst S 2 o 8 2- / Fe 3+ -CNT@Co 3 PO 2 Preparation of:

[0062] (1) Dissolve 1 mol of cobalt acetylacetonate in a mixed solution of 500 mL of deionized water and ethylene glycol (the volume ratio of water to ethylene glycol is 0.6:1), and stir thoroughly. Add a 3% potassium carbonate aqueous solution dropwise, add dropwise for 1 hour to adjust the pH of the solution to 8.2, add 6 mol of triphenylphosphine to the above solution, reflux at 500° C. for 6 hours, and dry the resulting precipitate under nitrogen for use.

[0063] (2) 40g of carbon nanotube powder is placed in 100ml of 98% concentrated sulfuric acid, soaked at 120°C for 7h, filtered and taken out, and the resulting black solid is placed in 500mL, 1.7mol / L ferric chloride aqueous solution to obtain a yellow slurry , and the obtained solid was filtered and dried under the protection of nitrogen for further use. The metal content in the obtained metal-doped modified carbon nanotubes was measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mobile phase | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com