Biomass compound fuel

A biomass and fuel technology, applied in the direction of biofuels, waste fuels, fuels, etc., can solve the problems of non-use, high pollution, etc., and achieve the effects of less environmental pollution, low cost, and reducing corrosion and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

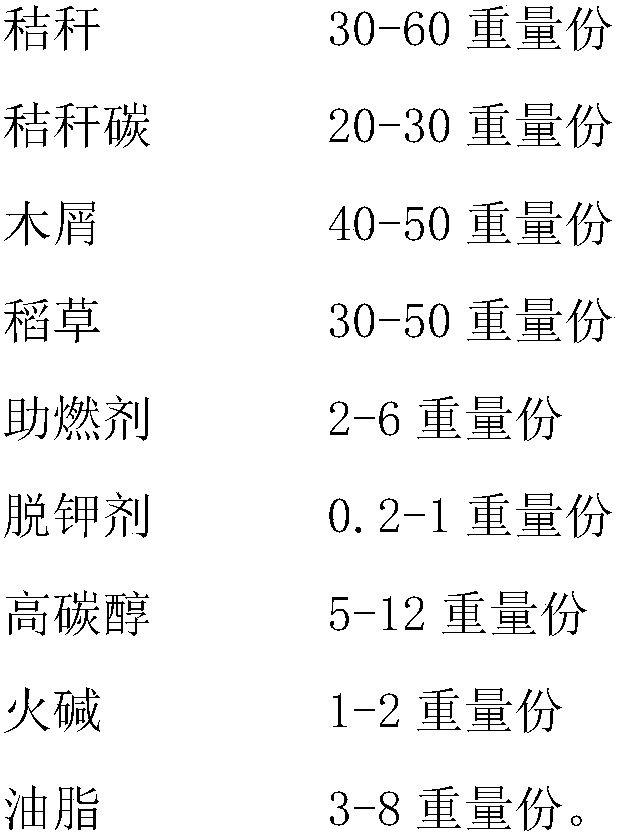

[0016]

[0017] Among them, magnesium bismuth is used as a combustion aid; alcohols with a carbon molecular number of 6 are used for high-carbon alcohols; coal tar is used as oil.

Embodiment 2

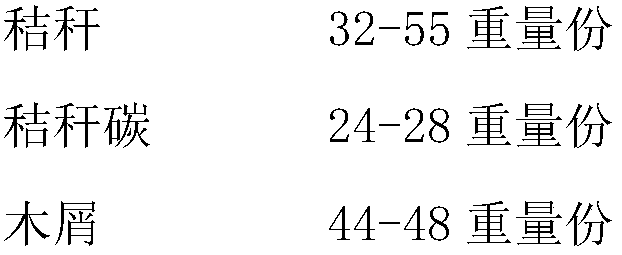

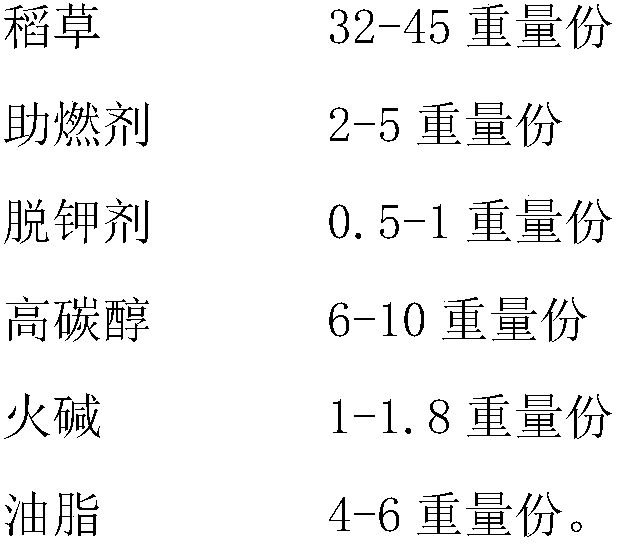

[0019]

[0020]

[0021] Among them, magnesium nitrate is used as a combustion aid; alcohols with a carbon molecular number of 7 are used for high-carbon alcohols; heavy oil is used for fats and oils.

Embodiment 3

[0023]

[0024] Among them, magnesium oxide is used as a combustion aid; alcohols with a carbon molecular number of 8 are used for high-carbon alcohols; and vegetable oil is used for fats and oils.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com