Method for preparing diesel by hydrogenating anthracene oil of coal tar

A technology for coal tar and anthracene oil, which is applied in the fields of hydrogenation treatment process, petroleum industry, and hydrocarbon oil treatment. It can solve the problems that hydrogenation products cannot reach diesel oil and are not suitable, and achieve improved activity and selectivity and strong adsorption. ability, activity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

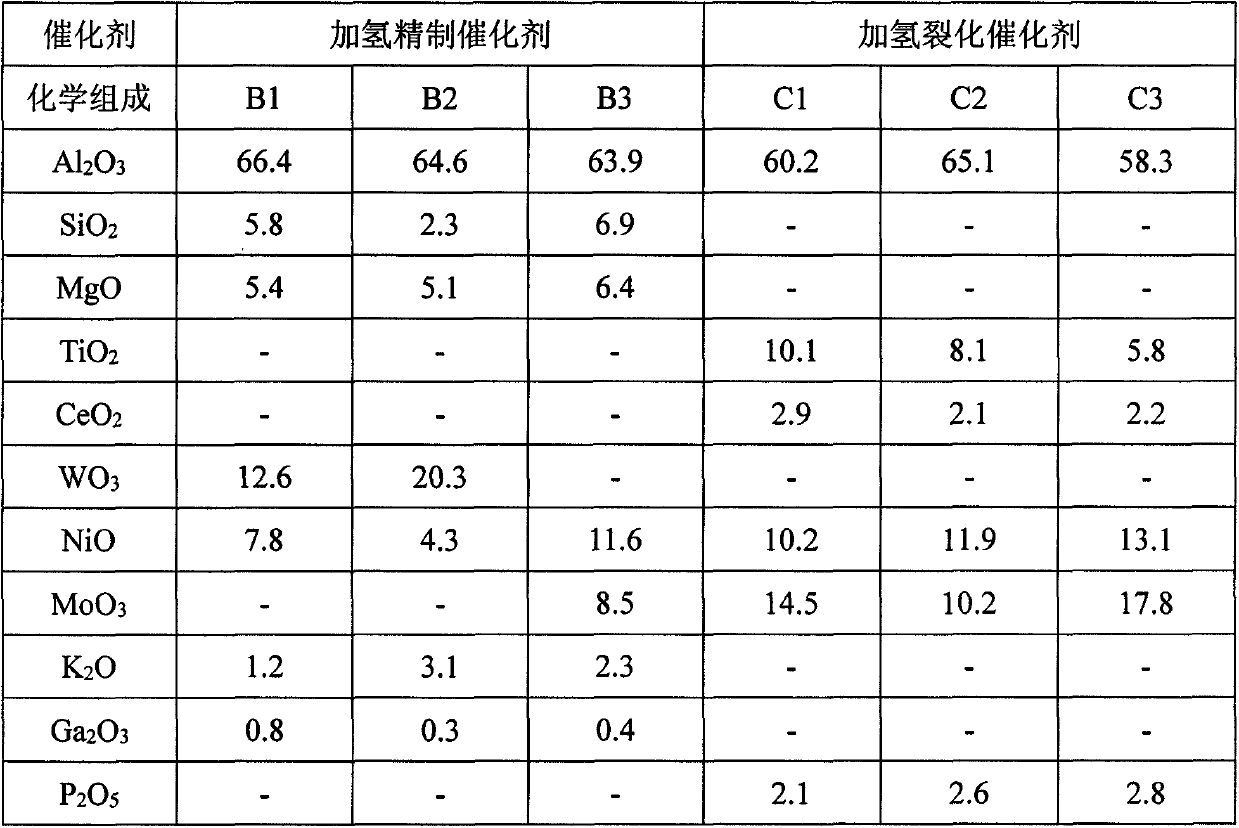

[0032] The hydrorefining catalyst (i.e., the first catalyst, the same below) used in this embodiment is B1, the hydrocracking catalyst (i.e., the second catalyst, the same below) is C1, and the contents of each component are shown in Table 2. The hydrodemetallization agent is a commercial FZC-103 catalyst. The following is the specific process of using this process to hydrogenate anthracene oil in a fixed-bed reactor to obtain diesel.

[0033] (1) Fill 150ml of hydrofinishing catalyst B1 and 20ml of demetallizing agent FZC-103 in the hydrofinishing reaction zone of the fixed bed reactor, and fill 120ml of hydrocracking catalyst C1 in the hydrocracking reaction zone.

[0034] (2) The anthracene oil raw material is continuously input by a plunger type metering pump, the feed temperature of the anthracene oil is 120° C., and the feed rate is 1 ml / min.

[0035] (3) According to the operating conditions of the hydrofining reaction zone: the reaction temperature is 360°C, the react...

Embodiment 2

[0037] The hydrorefining catalyst used in this example is B2, the hydrocracking catalyst is C2, and the contents of each component are shown in Table 2. The hydrodemetallization agent is a commercial FZC-103 catalyst. The following is the specific process of using this process to hydrogenate anthracene oil in a fixed-bed reactor to obtain diesel.

[0038] (1) Fill 200ml of hydrofinishing catalyst B2 and 20ml of demetallizing agent FZC-103 in the hydrofinishing reaction zone of the fixed bed reactor, and fill 150ml of hydrocracking catalyst C2 in the hydrocracking reaction zone.

[0039] (2) The anthracene oil raw material is continuously input by a plunger type metering pump, the feed temperature of the anthracene oil is 120° C., and the feed rate is 0.8 ml / min.

[0040] (3) According to the operating conditions of the hydrofining reaction zone: the reaction temperature is 370°C, the reaction pressure is 13MPa, the volume ratio of hydrogen to oil is 1500:1, and the volume spa...

Embodiment 3

[0042] The hydrorefining catalyst used in this example is B3, the hydrocracking catalyst is C3, and the contents of each component are shown in Table 2. The hydrodemetallization agent is a commercial FZC-103 catalyst. The following is the specific process of using this process to hydrogenate anthracene oil in a fixed-bed reactor to obtain diesel.

[0043] (1) Fill 200ml of hydrofinishing catalyst B3 and 25ml of demetallizing agent FZC-103 in the hydrofinishing reaction zone of the fixed bed reactor, and fill 180ml of hydrocracking catalyst C3 in the hydrocracking reaction zone.

[0044] (2) The anthracene oil raw material is continuously input by a plunger type metering pump, the feed temperature of the anthracene oil is 150° C., and the feed rate is 1.0 ml / min.

[0045] (3) According to the operating conditions of the hydrofining reaction zone: the reaction temperature is 370°C, the reaction pressure is 14MPa, the volume ratio of hydrogen to oil is 1500:1, and the volume spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com