System for automatically controlling adding of proportioned water to fermented grains during white wine brewing

A technology of brewing wine and measuring water, which is applied in the field of liquor brewing system. It can solve the problems of uneven addition of "water" to lees, low liquor yield, and starch loss, so as to avoid starch loss, control the acidity of lees, The effect of improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

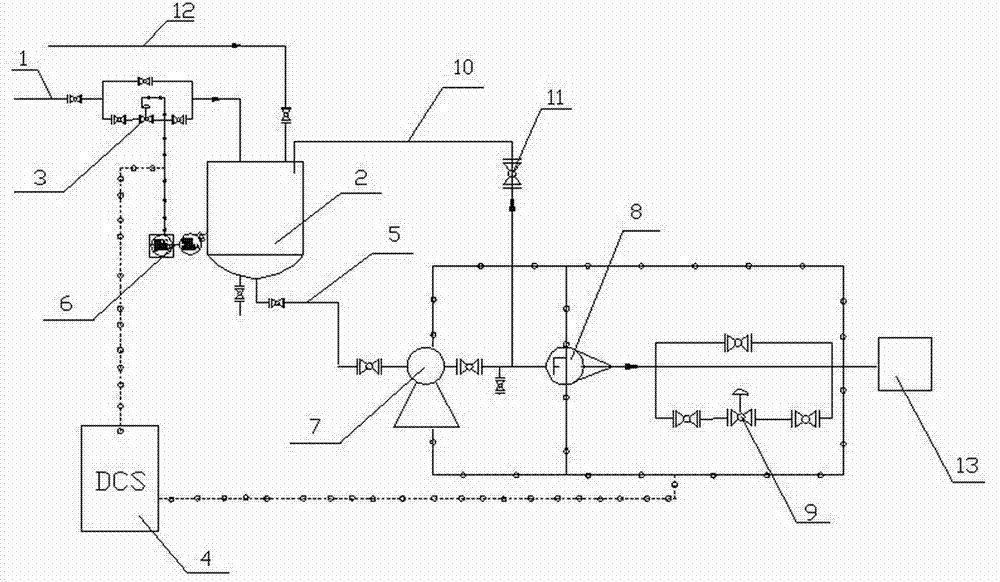

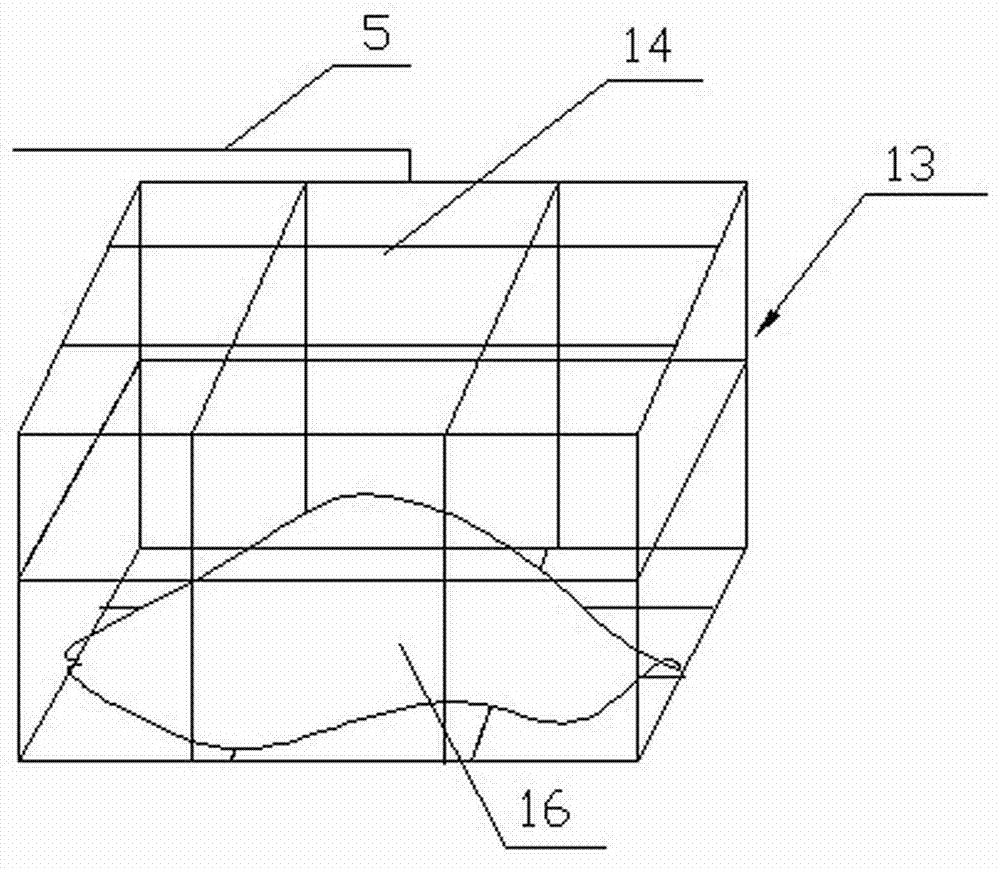

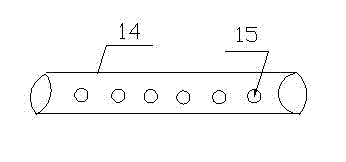

[0034] A kind of system for adding water automatically for wine cultivation of liquor brewing, such as figure 1As shown, it includes a steam pipeline 1, a water measuring tank 2, a water measuring delivery pipeline 5 communicating with the water measuring tank 2, a water measuring temperature control device, a water consumption control device and a spraying device, and the water measuring temperature control device includes The steam automatic regulating valve 3, the DCS control system 4, the temperature transmitter 6 connected to the water measuring storage tank 2 for sensing the water temperature in the water measuring storage tank 2 arranged on the steam pipeline 1, the steam automatic regulating valve 3, the temperature The transmitters 6 are respectively connected to the DCS control system 4, and the temperature transmitters 6 and the steam automatic regulating valve 3 are in a chain relationship (the chain relationship is: set a value on the DCS control system, when it is...

Embodiment 2

[0045] Such as figure 1 As shown, compared with Embodiment 1, the water output end of the scraper flowmeter 8 is connected to the automatic water metering valve 9, and the heated water is passed through the explosion-proof centrifugal pump 7, the scraper flowmeter 8, and the water metering valve. The automatic regulating valve 9 opens the output, and injects the automatic spraying control device to measure the water for the bad cultivation; the automatic regulating valve 9 for measuring water is connected with the DCS control system 4, and the explosion-proof centrifugal pump 7, the scraper flowmeter 8 and the automatic water measuring The regulating valve 9 is a chain relationship. In the DCS control system, the required amount of water is input, and the automatic water measuring valve 9 is automatically opened. After about 5 bills, the explosion-proof centrifugal pump 7 is automatically opened to deliver the water. When the scraper flowmeter 8 measures the output volume Whe...

Embodiment 3

[0050] Compared with Embodiment 1 and Embodiment 2, in actual work, after the water measurement is added, the water measurement automatic regulating valve 9 is automatically closed, and the explosion-proof centrifugal pump 7 has not stopped working in time, so the water measurement circulation pipeline 10 is set. To relieve the pressure and prevent the phenomenon of "pressurization", one end of the water measuring circulation pipeline 10 communicates with the water measuring storage tank 2, and the other end communicates with the water measuring delivery pipeline between the explosion-proof centrifugal pump 7 and the scraper flowmeter 8 5 are connected, the above also includes a valve 11 on the water measuring circulation pipe 10, when the automatic water regulating valve 9 is automatically closed, the water thrown out by the explosion-proof centrifugal pump 7 has not stopped working in time through the water measuring circulation pipe 10 and flows back to the water measuring T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com