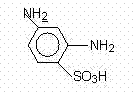

Production method of 2,

A diaminobenzenesulfonic acid and production method technology, applied in the direction of sulfonic acid preparation, organic chemistry, etc., can solve the problems of secondary pollution of acid-containing wastewater, high sulfonation temperature, low reaction yield, etc., to reduce production costs, The effect of increasing product yield and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

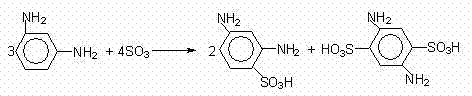

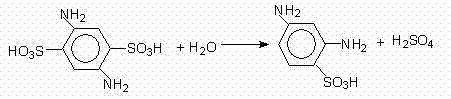

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a kind of production method of 2,4-diaminobenzenesulfonic acid, its steps are as follows:

[0025] (1) Add 98% sulfuric acid and 104.5% sulfuric acid to the reaction kettle, turn on the jacket cooling water, slowly and evenly add molten m-phenylenediamine, and add m-phenylenediamine after 1.5 hours; 98% sulfuric acid, 104.5% sulfuric acid and The weight ratio of m-phenylenediamine is 1.80:0.93:0.5;

[0026] (2) Slowly add 104.5% sulfuric acid and m-phenylenediamine; after the addition, heat up to 60°C and keep stirring for 20 minutes; the weight ratio of 104.5% sulfuric acid and m-phenylenediamine is 1.70:0.5; step (2) add The m-phenylenediamine is 0.9 times of the m-phenylenediamine added in step (1);

[0027] (3) Slowly add 104.5% sulfuric acid. After the addition, slowly raise the temperature to 100°C within 1 hour, turn off the steam, let the temperature rise slowly to 130°C, stir and react for 3 hours, and take samples for analysis. Diamine HPLC con...

Embodiment 2

[0030] Embodiment 2, a kind of production method of 2,4-diaminobenzenesulfonic acid, its steps are as follows:

[0031] (1) Add 98% sulfuric acid and 104.5% sulfuric acid to the reaction kettle, turn on the jacket cooling water, slowly and evenly add molten m-phenylenediamine, and add m-phenylenediamine after 2.5 hours; 98% sulfuric acid, 104.5% sulfuric acid and The weight ratio of m-phenylenediamine is 1.85: 0.96: 0.5;

[0032] (2) Slowly add 104.5% sulfuric acid and m-phenylenediamine; after the addition, heat up to 90°C and keep stirring for 40 minutes; the weight ratio of 104.5% sulfuric acid and m-phenylenediamine is 1.80:0.5; step (2) add The m-phenylenediamine is 1.1 times of the m-phenylenediamine added in step (1);

[0033] (3) Slowly add 104.5% sulfuric acid. After the addition, slowly raise the temperature to 130°C within 2 hours, turn off the steam, let the temperature rise slowly to 140°C, stir and react for 5 hours, and take samples for analysis. Diamine HPLC ...

Embodiment 3

[0036] Example 3, in the step (1) of the production method described in Example 1, the acidity is controlled at 100.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com