Preparation method and application of hydrogel

A hydrogel, water bath heating technology, applied in medical science, prosthesis, etc., can solve problems such as the influence of gel stretchability, increasing difficulty and steps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

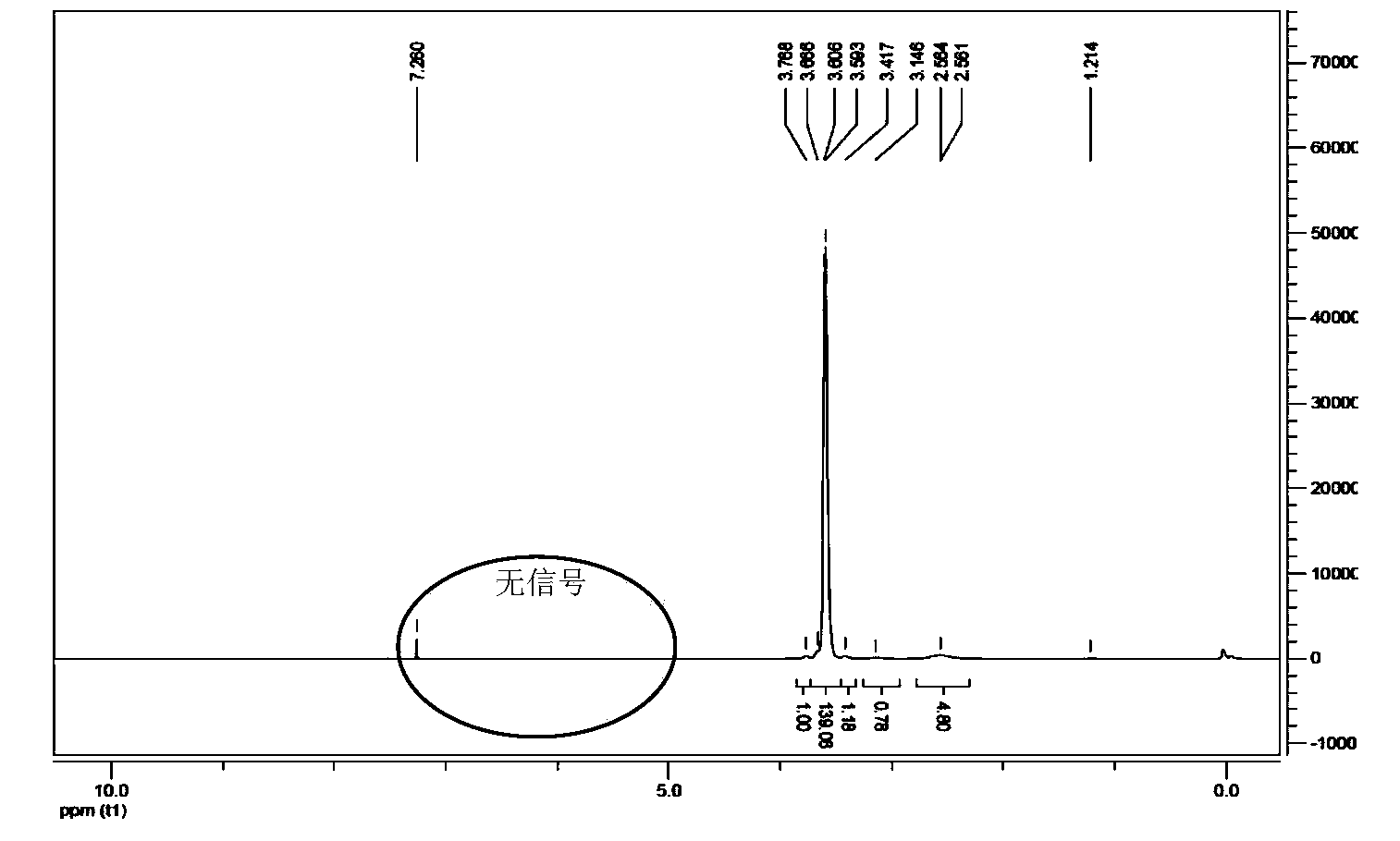

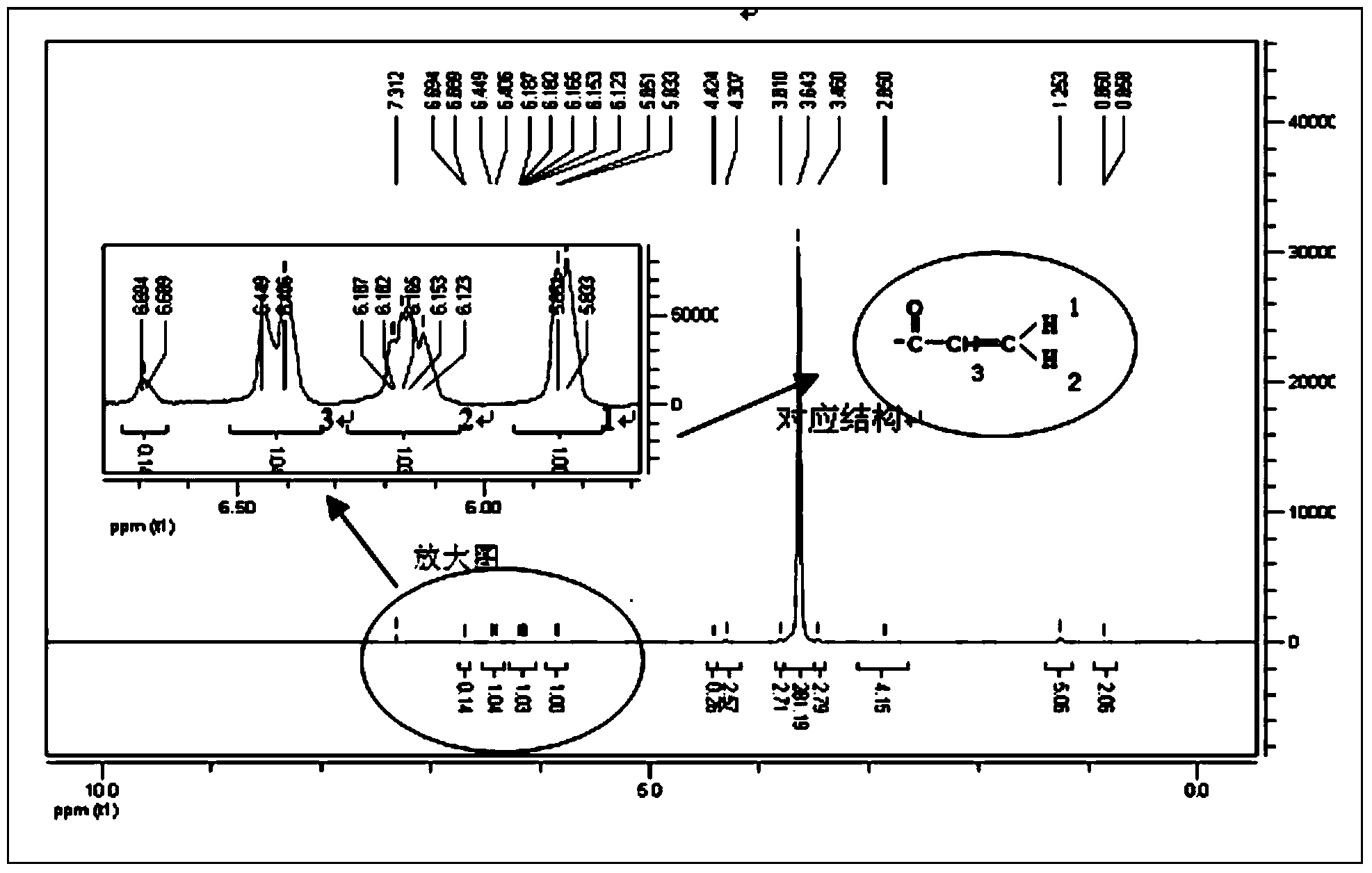

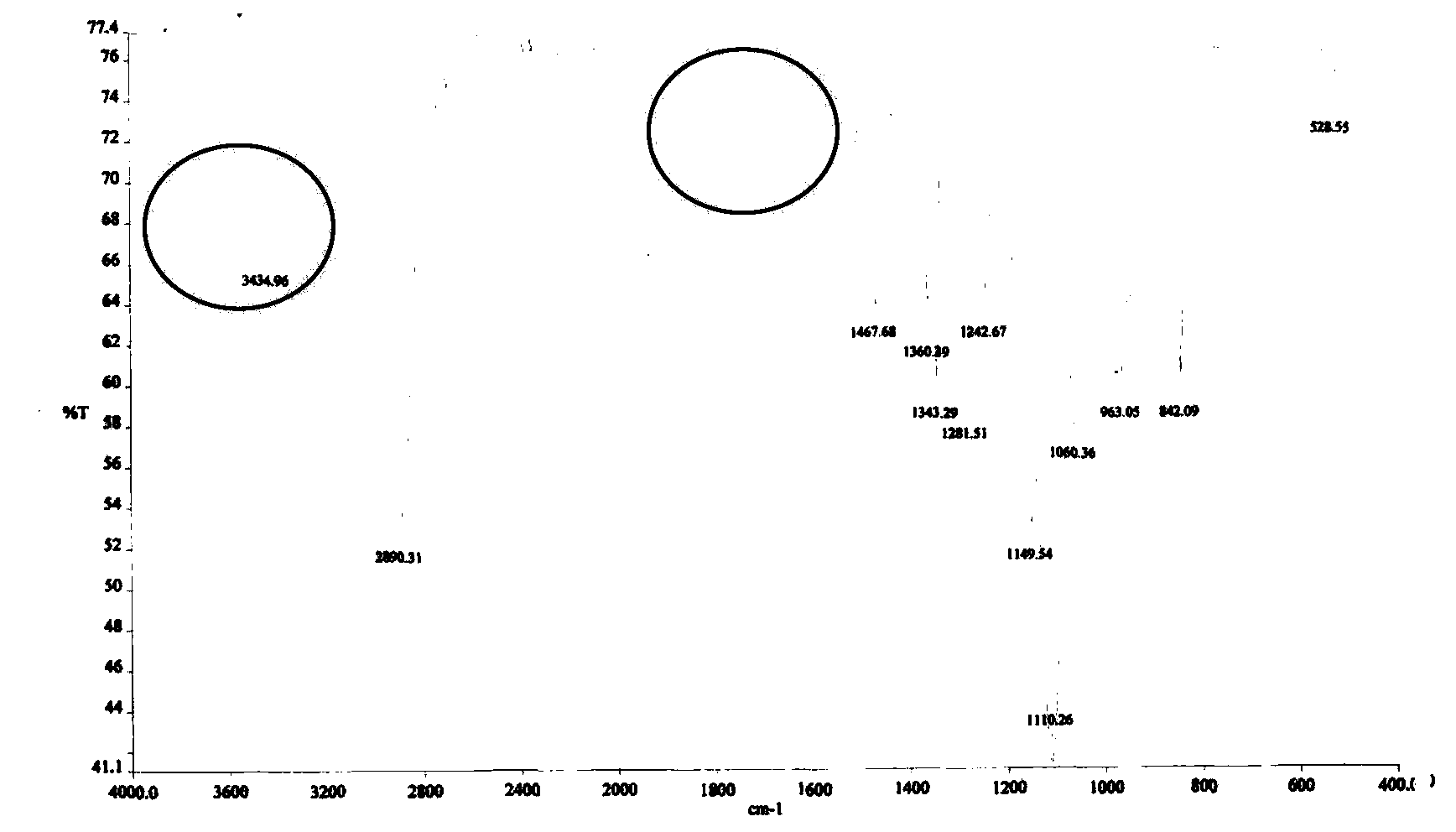

[0085] Add 10g of PEG (molecular weight 3350, sigma, product number P3640) into 150mL of dichloromethane, protect it with argon for 20min, in a water bath at 30°C, add 0.5g of sodium metal, react for 4h to complete the PEG reaction, add 3mL of 25% acrylamide, Reacted for 12 hours, added 0.1 g of β-phenylnaphthylamine, and dried in vacuum for 24 hours to obtain 11.7 g of PEGDA product. The purity of PEGDA was 95.8% by dialysis, see figure 1 , 2 , 3, 4, 5.

[0086] Weigh 2.0g hyaluronic acid (100,000, injection grade, bio-fermentation) into 200mL sterile three-distilled water, stir until dissolved, add 4.0g 2,2'-dithiodiamide, and then use 1.0mol / L HCl Adjust the pH to 3.0, add 1.5g EDC and stir for 2h, then adjust the pH to 7.0 with 1.0mol / L NaOH, add 5g of β-mercaptoethanol, adjust the pH to 8.0 with 1.0mol / L NaOH, stir for 12h, and use 1.0mol / L Adjust the pH to 2.0 with HCl, put it into a dialysis bag of Mw3500Da, dialyze in 0.01mol / L HCl (pH, 2.0) of 5gNaCl for 1 day, dia...

Embodiment 2

[0089] Add 10g of PEG (molecular weight: 3500) into 150mL of dichloromethane, protect it with argon for 20min, put in a water bath at 30°C, add 0.5g of sodium metal, react for 4h, add 3mL of 25% acrylamide, react for 12h, add β-phenylnaphthalene 0.1 g of amine was added to 400 mL of ether for extraction, the ether layer was removed, and the water layer was vacuum-dried for 24 hours. According to the method of Example 1, the yield and purity were detected respectively, and 10.2 g of PEGDA product was finally detected, and the purity of PEGDA was 96.5% after detection.

[0090] Weigh 2.0g of hyaluronic acid (500,000, injection grade, biological fermentation) into 250mL sterile three-distilled water, stir until dissolved, add 2.5g of 4,4'-dithiodiacetamide, and then adjust with 1.0N HCl pH to 4.0, add 2.5g EDC and stir for 2h, then adjust the pH to 7.0 with 1.0mol / L NaOH, add 15g of β-mercaptoethanol, adjust the pH to 8.5 with 1.0mol / L NaOH, stir for 12h, use 1.0mol / L Adjust the...

Embodiment 3

[0093] Add 12g of PEG (molecular weight: 6000) into 250mL of dichloromethane, protect with argon for 20min, magnetically stir at 200rpm, put in a water bath at 40°C, add 0.5g of metal potassium, react for 4h, add 6mL of 20% acrylamide, react for 12h, add benzene 0.05 g of quinone phenothiazine was added to 650 mL of ether for extraction, the ether layer was removed, and the water layer was vacuum-dried for 24 hours. According to the method of Example 1, the yield and purity were detected respectively, and 10.5 g of PEGDA product was finally detected, and the purity of PEGDA was 95.4% after detection.

[0094] Weigh 2.0g of hyaluronic acid (800,000, injection grade, bio-fermentation) into 300mL sterile three-distilled water, stir until dissolved, add 3.0g of 2,2'-dithiodiacetylhydrazide, and then add 1.0mol / L HCl to adjust the pH to 4.5, add 3.0g EDC and stir for 2h, then use 1.0mol / L NaOH to adjust the pH to 7.4, add 20g of β-mercaptoethanol, use 1.0mol / L NaOH to adjust the pH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com