Photo-curable resin composition

a technology of photocurable resins and compositions, applied in the field of selected stereolithographic resins, can solve problems such as excessive color development and part distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

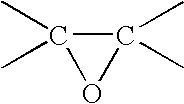

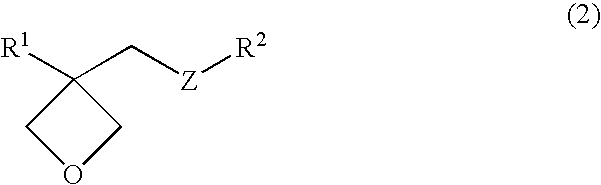

Method used

Image

Examples

examples

[0107]The present invention is further illustrated with a number of examples, which should not be regarded as limiting the scope of the present invention.

[0108]Radiation curable liquid compositions were prepared by weighing all the ingredients into a container under mechanical stirring either at room temperature or up to 50° C. until homogeneous resin mixtures were obtained. Each liquid mixture was then filtered off into a vat of stereolithography apparatus using a medium paint filter before fabrication of parts.

[0109]Compositions were prepared by mixing the components listed in Table 2 (Examples) and Table 3 (Comparative Examples, which are not Examples of the invention) for epoxy and acrylate dual cure or hybrid resins, with amounts of the components being listed in parts by weight. The thus prepared compositions were subsequently analyzed in accordance with the Test Methods described below. The test results are also listed in Tables 2-3.

Test Methods

[0110](a) Energy E10, Depth of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Time | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com