Ordered gas diffusion electrode and preparation and application thereof

A gas diffusion electrode and gas diffusion layer technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of catalytic layer stability and poor material transfer performance, and improve the oxygen reduction capacity and mass transfer performance per unit mass. Good and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of gas diffusion layer:

[0039] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE loading is about 15% (the mass of carbon paper after hydrophobization treatment). Mix Vulcan XC-72 carbon powder with 20% PTFE aqueous solution at a mass concentration of 10% relative to the mass of carbon powder and PTFE, and dilute with ethanol 20 times the mass of carbon powder, disperse under ultrasonic conditions for 20 minutes, and stir well . The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

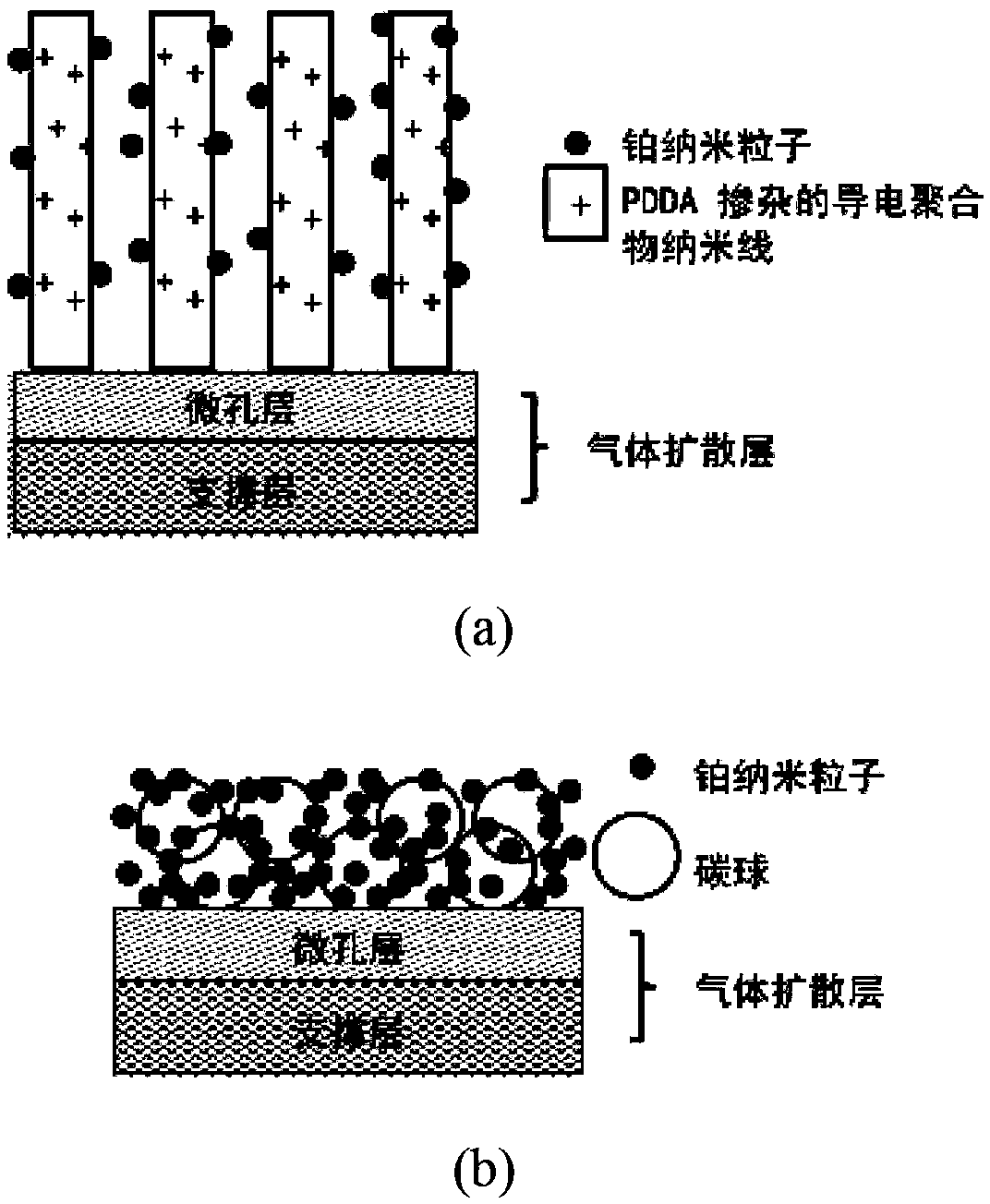

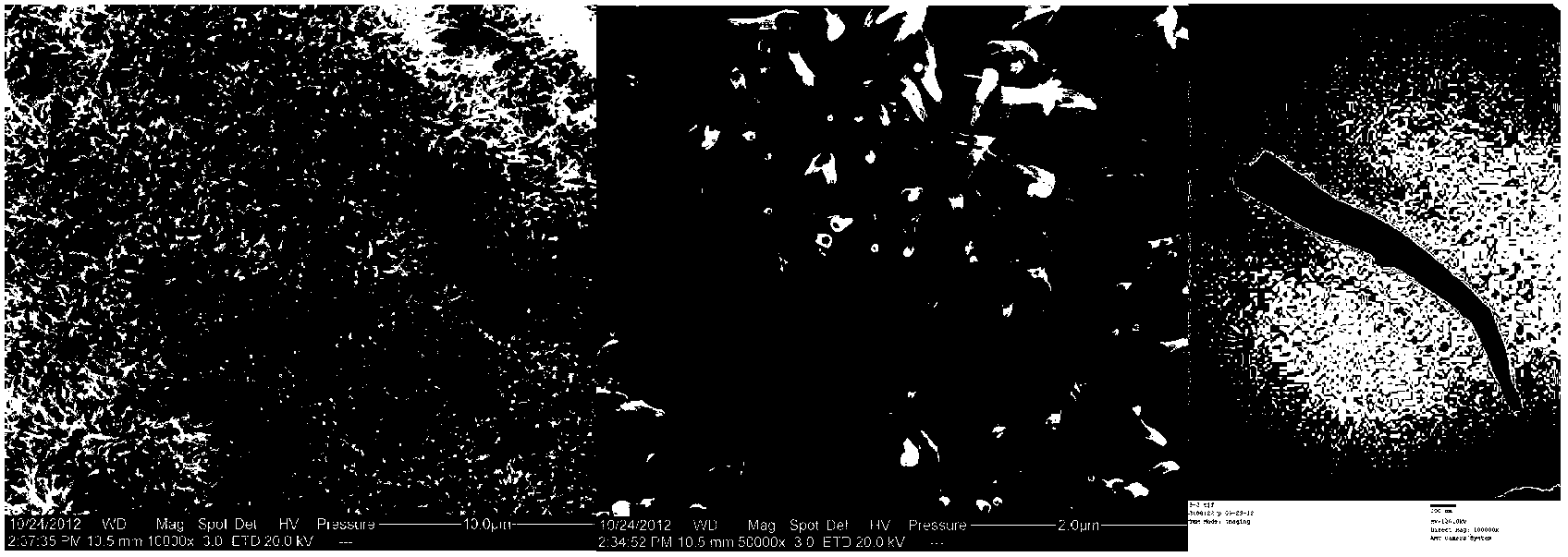

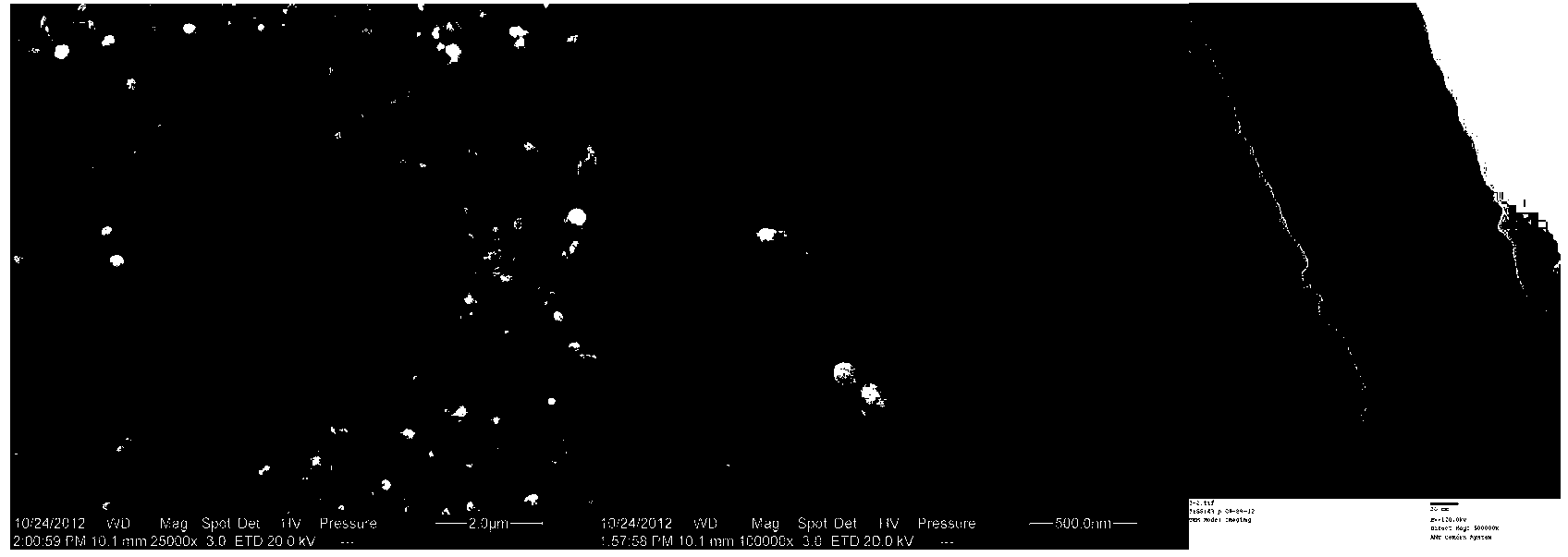

[0040] 2) Preparation of ordered gas diffusion electrodes:

[0041] a. Preparation of surface-modified ordered nanowire array structure

[0042] The gas di...

Embodiment 2

[0046] 1) Preparation of gas diffusion layer:

[0047] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE loading is about 15% (the mass of carbon paper after hydrophobization treatment). Mix Vulcan XC-72 carbon powder with 20% PTFE aqueous solution at a mass concentration of 10% relative to the mass of carbon powder and PTFE, and dilute with ethanol 20 times the mass of carbon powder, disperse under ultrasonic conditions for 20 minutes, and stir well . The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

[0048] The graphene powder prepared by the thermal expansion method was ultrasonically dispersed in an ethanol solution, and the slurry was loaded on the sur...

Embodiment 3

[0055] 1) Preparation of gas diffusion layer:

[0056] Soak Toray carbon paper in 20% PTFE aqueous solution, take it out and air dry after fully soaking, and weigh it. Repeat the above steps until the PTFE loading is about 15% (the mass of carbon paper after hydrophobization treatment). Mix Vulcan XC-72 carbon powder with 20% PTFE aqueous solution at a mass concentration of 10% relative to the mass of carbon powder and PTFE, and dilute with ethanol 20 times the mass of carbon powder, disperse under ultrasonic conditions for 20 minutes, and stir well . The above-mentioned hydrophobized carbon paper was placed on a glass plate and fixed, and the above-mentioned slurry was scraped on the surface of the carbon paper and weighed until the carbon powder loading was 1 mg cm -2 , that is, the gas diffusion layer is obtained.

[0057] The multi-walled carbon nanotube powder prepared by the chemical vapor deposition method was ultrasonically dispersed in an ethanol solution, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com