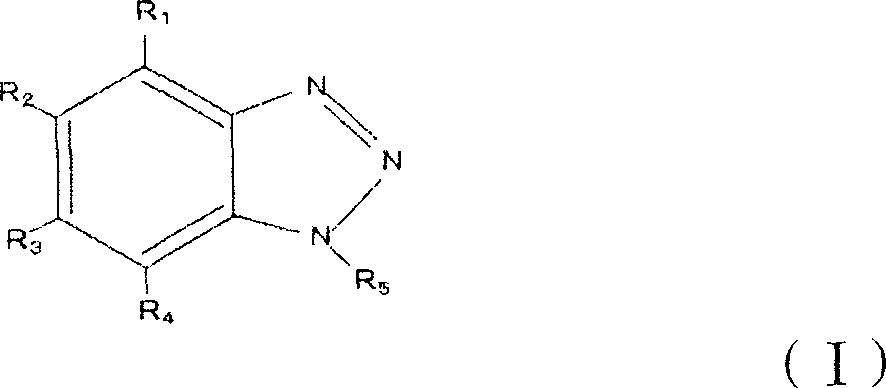

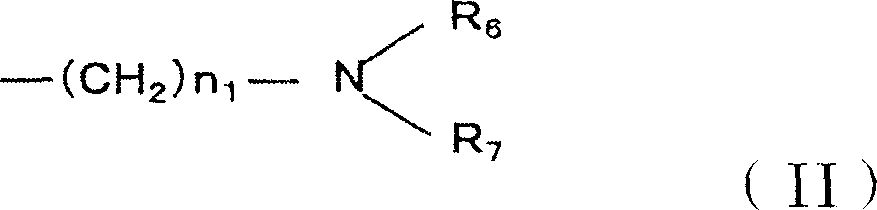

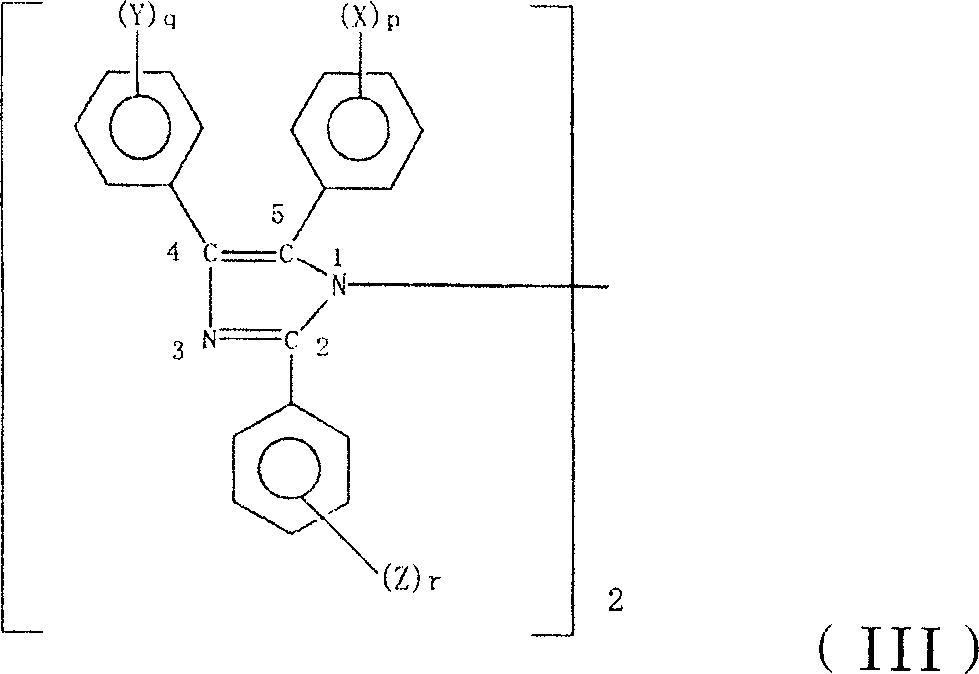

Laminated board comprising photopolymer

A photosensitive resin and laminate technology, applied in the field of laminates, can solve the problems of insufficient storage stability, resist pattern formation and conductor pattern formation, and achieve stable conductor pattern formation, high adhesion, high The effect of resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1

[0127]

[0128] Stir and mix the photosensitive resin composition shown in Table 1 well, and apply it to a flexible substrate (copper foil thickness 9 μm, long side length 10 m, industrial spanex Nippon Steel Co., Ltd.) using a bar coater. Chemical production) on the surface, it was dried in a dryer at 95° C. for 1 minute to form a photosensitive resin layer. The thickness of the photosensitive resin layer was 10 μm.

[0129] Next, a polyethylene terephthalate film with a thickness of 16 μm was pasted as a protective layer on the surface of the photosensitive resin layer on which the flexible substrate was not laminated to obtain a long strip-shaped photosensitive resin-attached laminate.

[0130] The obtained laminate with a photosensitive resin was wound up on a cylindrical core with a diameter of 10 cm and a length of 20 cm made of ABS to obtain a roll-shaped photosensitive resin laminate.

[0131]

[0132] Place the mask required in the evaluation of the photosensitiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com