Polyester resin for antifouling coating materials, method for producing same, antifouling coating material composition, antifouling coating film, and antifouling base

A technology of antifouling coatings and polyester resins, applied in antifouling/underwater coatings, polyester coatings, rosin coatings, etc., can solve problems such as increased surface roughness, obstacles to cooling water supply and drainage circulation, and reduced speed. Achieve excellent curability, excellent long-term antifouling properties, and excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

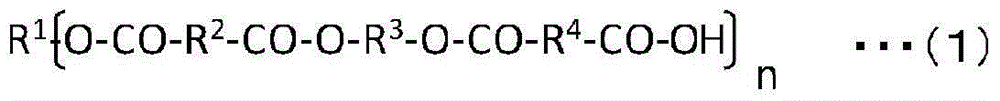

[0149] (Example 1: Manufacture of polyester resin solution (a-1))

[0150] In a reaction vessel with a stirrer, a condenser, and a thermometer, 92 parts of glycerol as (a) a tribasic or higher alcohol, 444 parts of phthalic anhydride as (b) a dibasic acid or an anhydride thereof, and 444 parts as (c) 228 parts of dihydric alcohol propylene glycol and 0.05 part of tetrabutyl titanate as a catalyst were subjected to an esterification reaction from 140° C. to 190° C. over 4 hours. Then, the pressure in the system was gradually reduced to 100 mmHg over 2 hours, and polycondensation reaction was performed at 190°C for 20 hours. During the reaction, the generated water is removed by reflux dehydration, and the acid value measurement by KOH titration method and the hydroxyl value measurement by acetylation method are carried out. When the acid value of the solid component reaches less than or equal to 1mgKOH / g, cool to 120°C and add (d) 439 parts of hexahydrophthalic anhydrides whic...

Embodiment 2~7、26~31

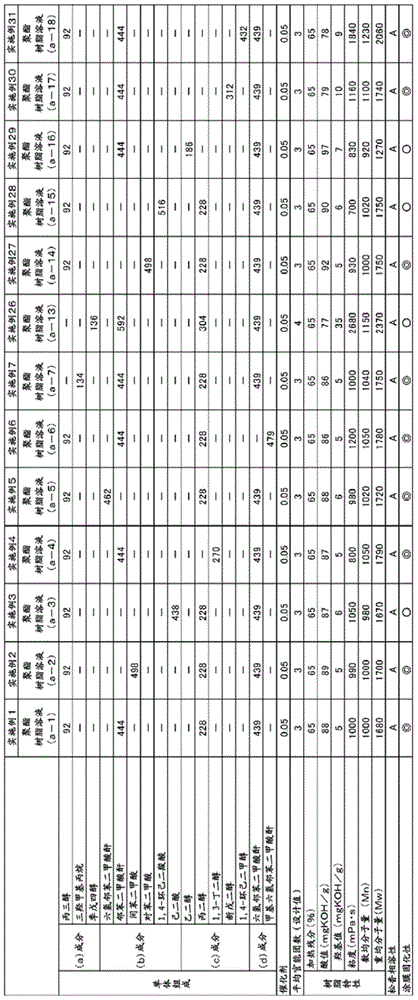

[0151] (Examples 2-7, 26-31: Manufacture of polyester resin solutions (a-2)-(a-7), (a-13)-(a-18))

[0152] Except for changing the types and amounts of raw materials as shown in Table 1, polyester resin solutions (a-2) to (a-7), (a-13) to (a) were obtained in the same manner as in Production Example 1. -18).

Embodiment 8

[0203] An antifouling paint composition was prepared as follows.

[0204] First mix xylene (10.5 parts), methyl isobutyl ketone (2 parts), WW rosin (5.5 parts), TCP (5 parts), polyester resin solution (a-1) ( 8 parts), BYK-101 (0.3 parts), ethyl silicate 28 (0.3 parts), stirred with a pigment shaker until uniformly dissolved.

[0205] Then, with TTK talc (4 parts), zinc oxide (6 parts), NOVAPERM RED F5RK (0.6 parts), cuprous oxide NC-803 (48 parts), 2-methylthio-4-tert-butylamino-6 - Cyclopropylamino-s-triazine (2.5 parts), Iron Oxide Red 404 (2.3 parts), Titanium White R-5N (2 parts), Calcined Plaster (1 part), Disperlon 603-20X (2 parts), Add glass microspheres (200 parts), and disperse for 1 hour.

[0206] Filtrate with an 80-mesh filter to prepare an antifouling paint composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com