Heat conduction paste

A thermal conductivity, acrylate technology, applied in the field of thermal conductivity paste, can solve the problem of physical property degradation, achieve low viscosity, excellent storage stability, and excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

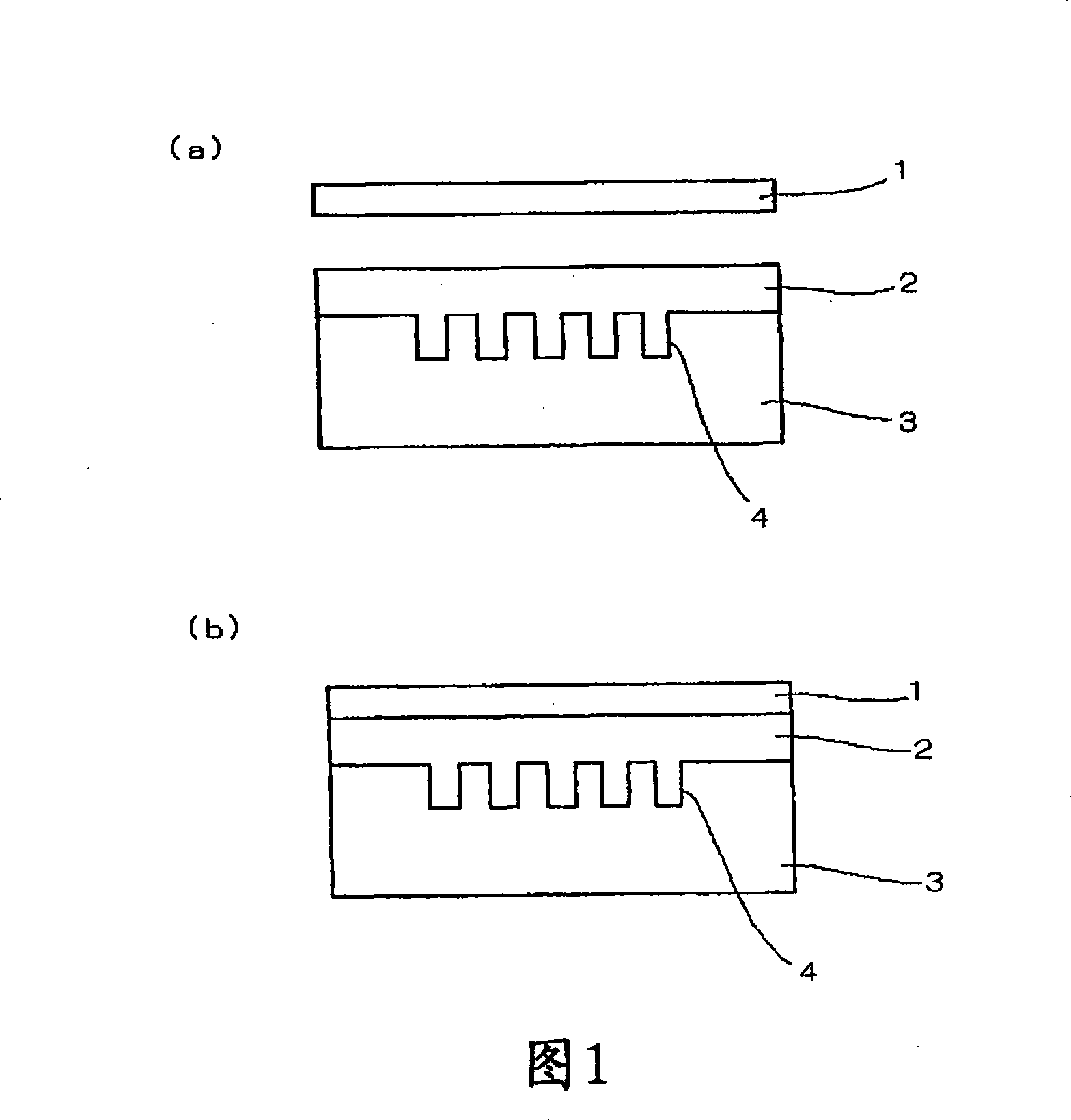

Image

Examples

Embodiment

[0058] Examples of the present invention are shown below, but the present invention is not limited to the following examples.

[0059] [Example]

[0060] The components shown in Table 1 were mixed in the ratio (weight ratio) shown in Table 1 to prepare liquid A and liquid B, respectively. In addition, the details of each component are as follows.

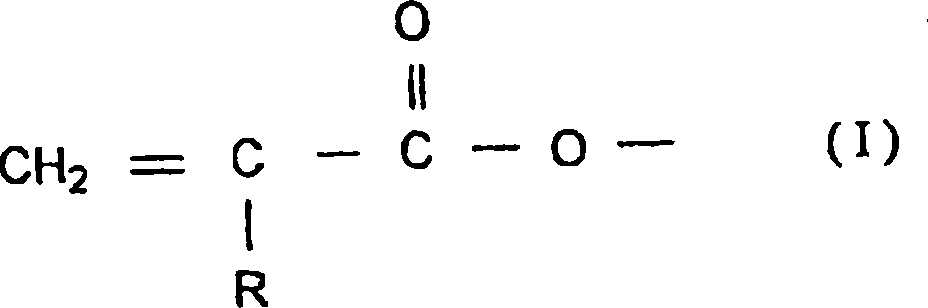

[0061] Acrylate resin: 2-hydroxy-3-acryloyloxypropyl methacrylate (80% by weight), triethylene glycol diacrylate (20% by weight)

[0062] Epoxy resin: Epoxy resin EP-4901E (manufactured by Asahi Denka Co., Ltd.) (80% by weight), ED-529 (manufactured by Asahi Denka Kogyo Co., Ltd.) (20% by weight)

[0063] Alkyd resin: EZ-3020-60-S (manufactured by Dainippon Ink & Chemicals Co., Ltd.)

[0064] Melamine resin: L-121-60 (manufactured by Dainippon Ink Chemical Industry Co., Ltd.)

[0065] Xylene resin: Nikanol PR-1540 (manufactured by Nippon Gas Chemical Co., Ltd.)

[0066] Silica powder: FB-24 (manufactured by Denki Kagaku Kogyo C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com