Monodisperse polystyrene microsphere, and preparation method and application thereof

A polystyrene microsphere, monodisperse technology, applied in the field of emulsion polymerization, can solve the problems of wide particle size distribution, precipitation, and poor storage stability of polymer emulsions, and achieve high production costs, good dispersion, and stable storage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for preparing monodisperse polystyrene microspheres in this embodiment comprises the following steps:

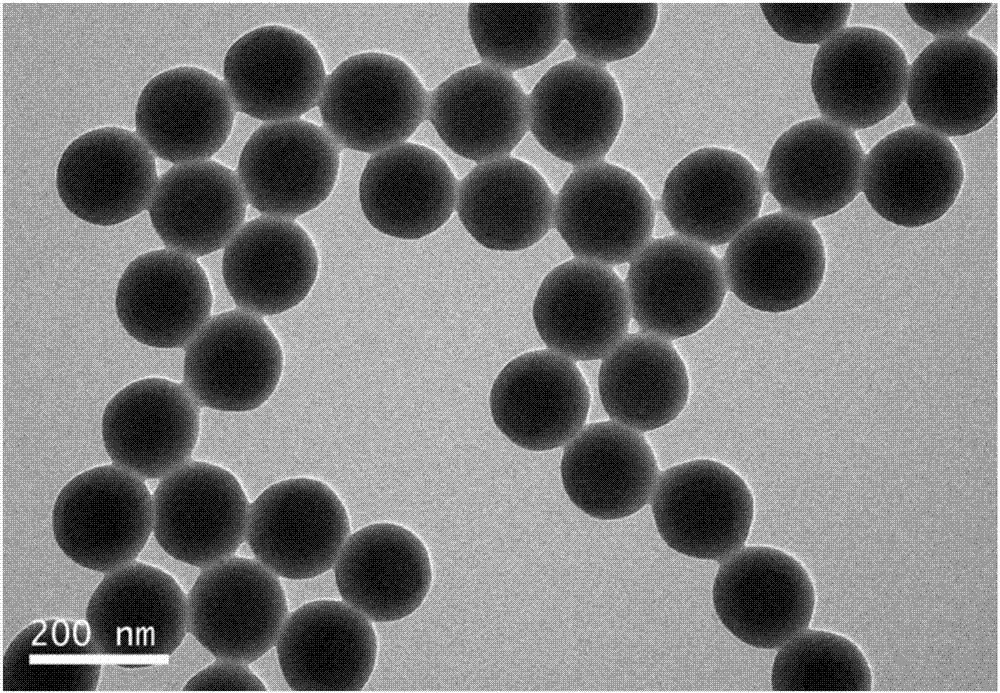

[0042] Add 300 mg of N-isopropylacrylamide, 30 μL of 1-vinylimidazole, and 4 mL of styrene into 50 mL of deionized water, and blow nitrogen gas for 20 minutes while stirring, during which time the temperature is raised to 75°C. After stabilizing for 5 minutes at 75° C., 50 mg of azobisisobutylamidine hydrochloride was added to initiate polymerization. The stirring speed was maintained at 750-1250 rpm, and the reaction was carried out for at least 12 hours. The polystyrene microspheres prepared in this embodiment are as follows: figure 1 shown. Its monodispersity and storage stability are shown in Table 1.

Embodiment 2

[0044] The method for preparing monodisperse polystyrene microspheres in this embodiment comprises the following steps:

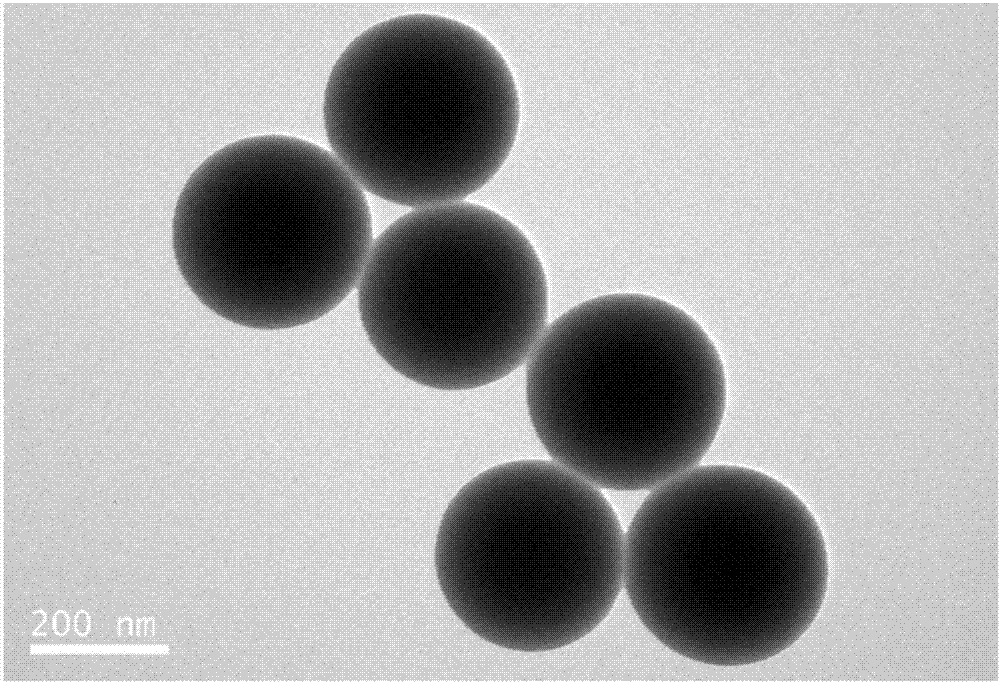

[0045] Add 300 mg of N-isopropylacrylamide, 100 μL of 4-vinylpyridine, and 12 mL of styrene into 100 mL of deionized water, and blow nitrogen gas for 20 minutes while stirring, during which time the temperature is raised to 70°C. After stabilizing for 5 minutes at 70° C., 120 mg of azobisisobutylamidine hydrochloride was added to initiate polymerization. The stirring speed was maintained at 750-1250 rpm, and the reaction was carried out for at least 24 hours. The polystyrene microspheres prepared in this embodiment are as follows: figure 2 shown. Its monodispersity and storage stability are shown in Table 1.

Embodiment 3

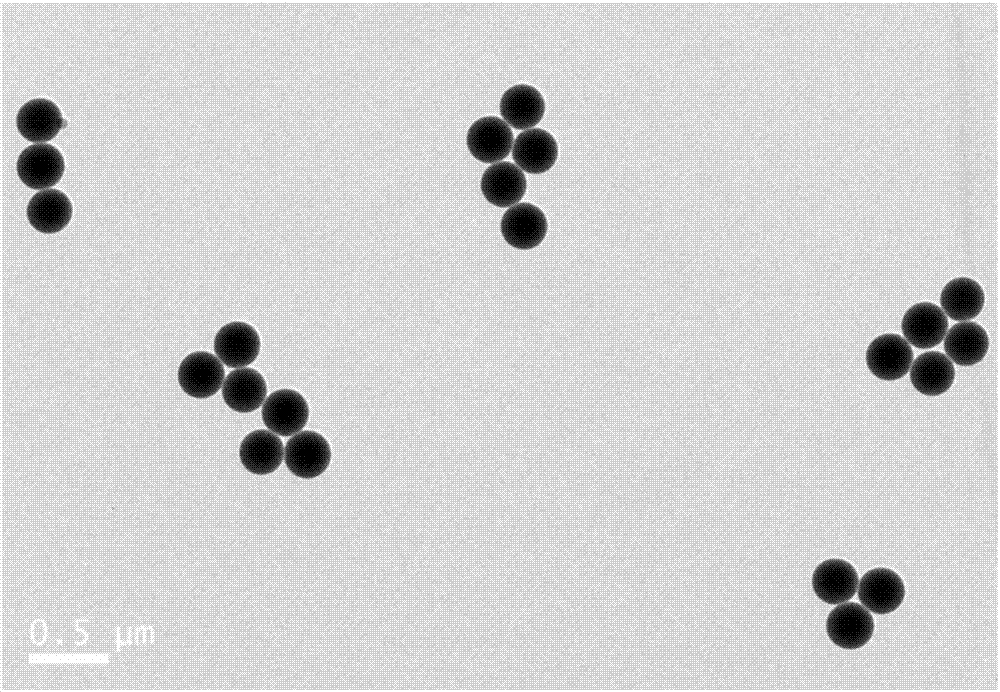

[0047] Add 300mg of N-isopropylacrylamide, 100μL of 2-vinylpyridine, and 12mL of styrene into 100mL of deionized water, blow nitrogen gas for 20 minutes while stirring, and raise the temperature to 70°C during this time. After stabilizing for 5 minutes at 70° C., 120 mg of azobisisobutylamidine hydrochloride was added to initiate polymerization. The stirring speed was maintained at 750-1250 rpm, and the reaction was carried out for at least 24 hours. The polystyrene microspheres prepared in this embodiment are as follows: image 3 shown. Its monodispersity and storage stability are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com