Oil-based gel cosmetic

A gel-like, cosmetic technology, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve problems such as difficulty in obtaining smoothness, inability to maintain volatile oils, and impaired use feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] Preparation of the cosmetic base includes a method of mixing the above-mentioned (A) component, (B) component, (C) component, and optionally (D) component, powder component, and other components.

[0077] The mixing can be performed, for example, by mixing the oily components ((A) component, (B) component, (C) component, if necessary (D) component, and other oil agents) while heating. a step of mixing; and a step of mixing powder ingredients and other ingredients into the resulting mixture.

[0078] Mixing can be performed using, for example, a three-roll mill, a disperser, a homomixer, and the like.

[0079] The gelation of the cosmetic base can be performed by, for example, a method of cooling the filled cosmetic base to room temperature.

[0080] Examples of the predetermined container include stretchable containers, bottles, tubes, cans, bag containers, and the like.

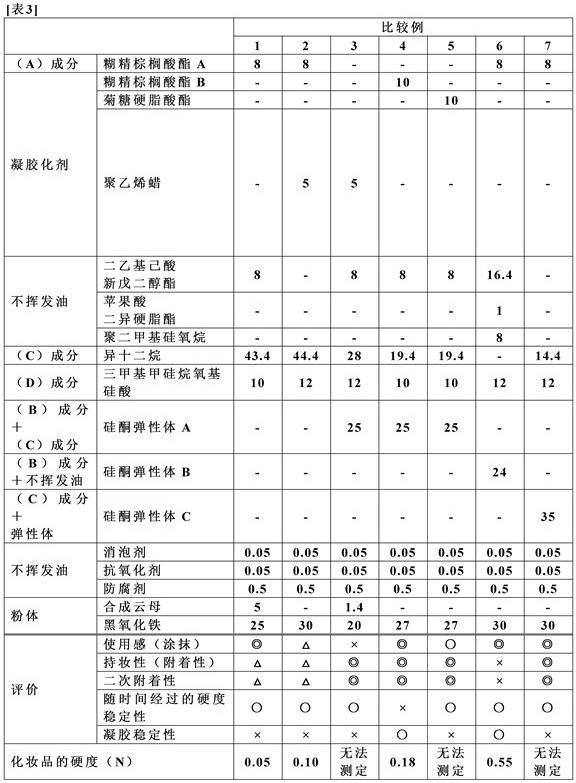

Embodiment 1~12 and comparative example 1~7

[0120] (Examples 1-12 and Comparative Examples 1-7: eyeliner)

[0121] Eyeliner pens with the compositions shown in Tables 1 to 3 were prepared by the following manufacturing method, and filled into a stretchable container. The above-mentioned evaluation was carried out. The results are shown in Tables 1 to 3 together.

[0122]

[0123]Components other than powder components were heated to 100° C. to dissolve and mix. A powder component is added to this mixture and dispersed uniformly to obtain a cosmetic base. The obtained cosmetic base material was filled in a stretchable container, and cooled to room temperature to obtain a gel-like eyeliner.

[0124]

[0125]

[0126]

[0127] In Tables 1 to 3 and Table 4 shown in subsequent paragraphs, the details of each component are as follows.

[0128] Dextrin palmitate A: Rheopearl KL2 (degree of acyl substitution: 2.2) (manufactured by Chiba Flour Milling Co., Ltd., product name)

[0129] Dextrin palmitate B: Rheopea...

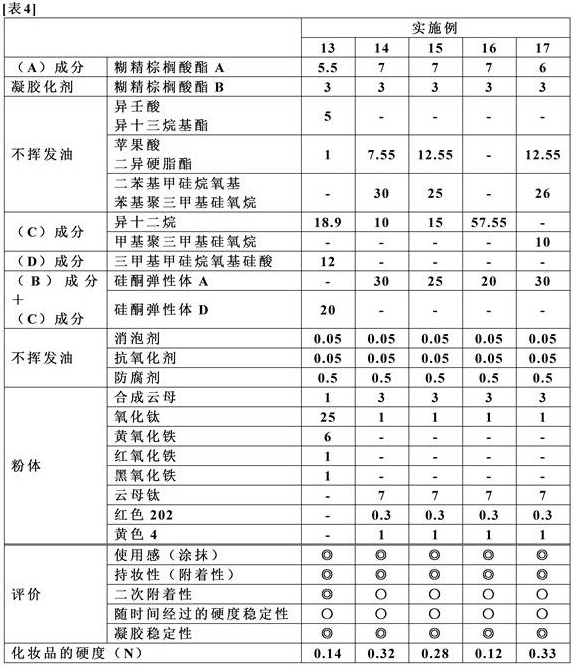

Embodiment 13~17

[0137] (Example 13~17: Concealer or lipstick)

[0138] The concealer (Example 13) and lipstick (Examples 14-17) of the composition shown in Table 4 were prepared by the following manufacturing method. It should be noted that the concealer and the lipsticks of Examples 14 to 16 were filled into the bottle. The lipstick of Example 17 is filled into tubes. Table 4 shows the results of the above evaluations together.

[0139]

[0140] Components other than powder components were heated to 100° C. to dissolve and mix. Powder components are added to this mixture and dispersed uniformly to obtain a cosmetic base. The obtained cosmetic base material was filled in a container and cooled to room temperature to obtain a gel-like concealer or lipstick.

[0141]

[0142] As shown in Table 4, it can be confirmed that the oil-based gel cosmetics obtained in Examples 13 to 17 have good feeling of use (smearing), long-lasting properties (adhesiveness), hardness stability over time, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com