Aqueous ink composition

A technology of ink composition and water-based ink, applied in the direction of ink, printing, copying/marking methods, etc., which can solve the problems of ink composition that cannot obtain the desired printing quality, printing surface removal or peeling, ink unevenness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

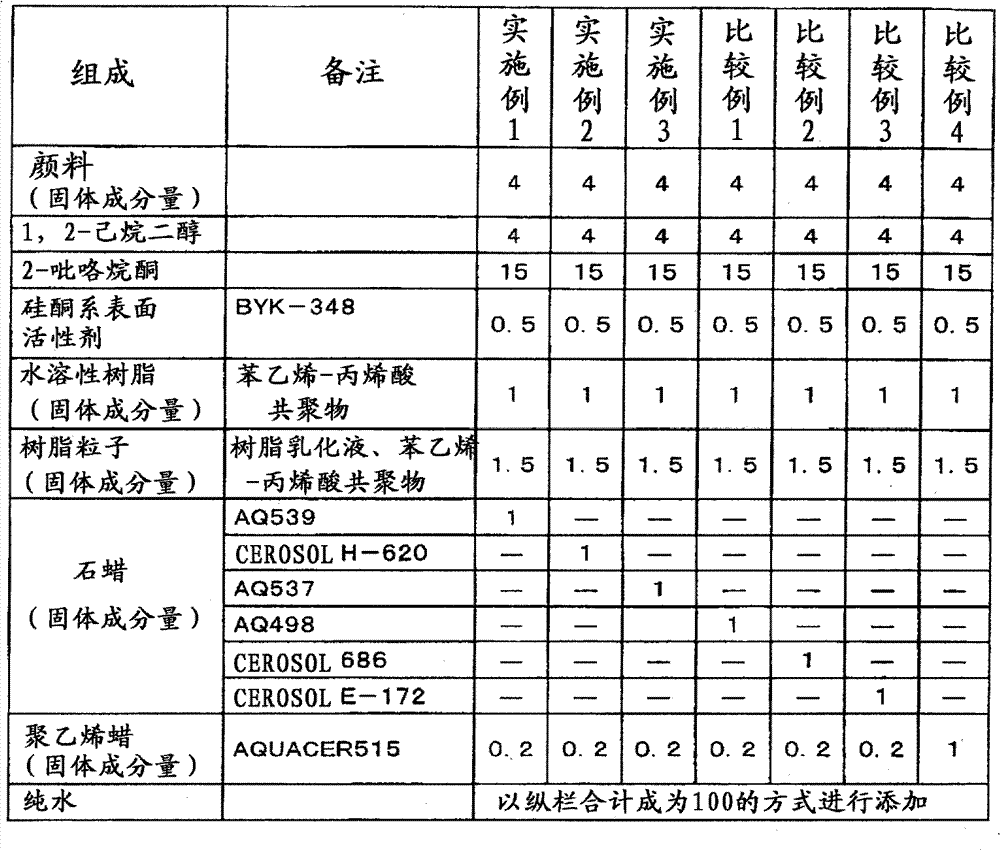

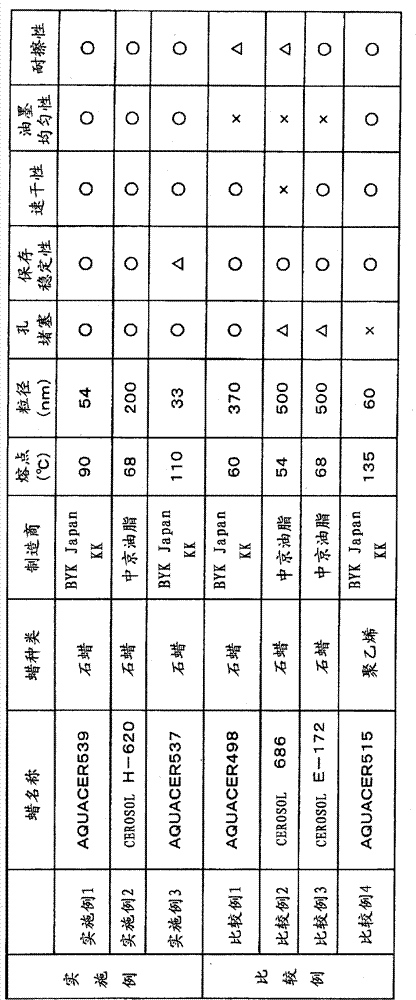

[0141] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these.

[0142] 1. Preparation of Pigment Dispersion

[0143] The water-based ink composition used in this example uses a water-insoluble pigment as a colorant. When adding a pigment to an aqueous ink composition, a resin-dispersed pigment obtained by dispersing the pigment with a resin dispersant in advance is used. Pigment dispersions were prepared as follows.

[0144] 40 parts by mass of polymer dispersant (copolymerized according to the mass ratio of methacrylic acid / butyl acrylate / styrene / hydroxyethyl acrylate=25 / 50 / 15 / 10, with a weight average molecular weight of 12000) was added to hydrogen In a mixed solution of 7 parts by mass of potassium oxide, 23 parts by mass of water, and 30 parts by mass of triethylene glycol mono-n-butyl ether, polymerization was carried out by heating and stirring at 80° C. to prepare a polymer dispersant paint.

[0145] 33.0 kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com