Water-dispersible carbon black pigment and process for producing aqueous dispersion thereof

A water-based dispersion and water-based pigment technology, applied in the direction of pigment slurry, fibrous filler, ink, etc., can solve the problem of insufficient dispersion of carbon black agglomerates, and achieve excellent filterability, excellent paper fixing concentration, good gloss degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

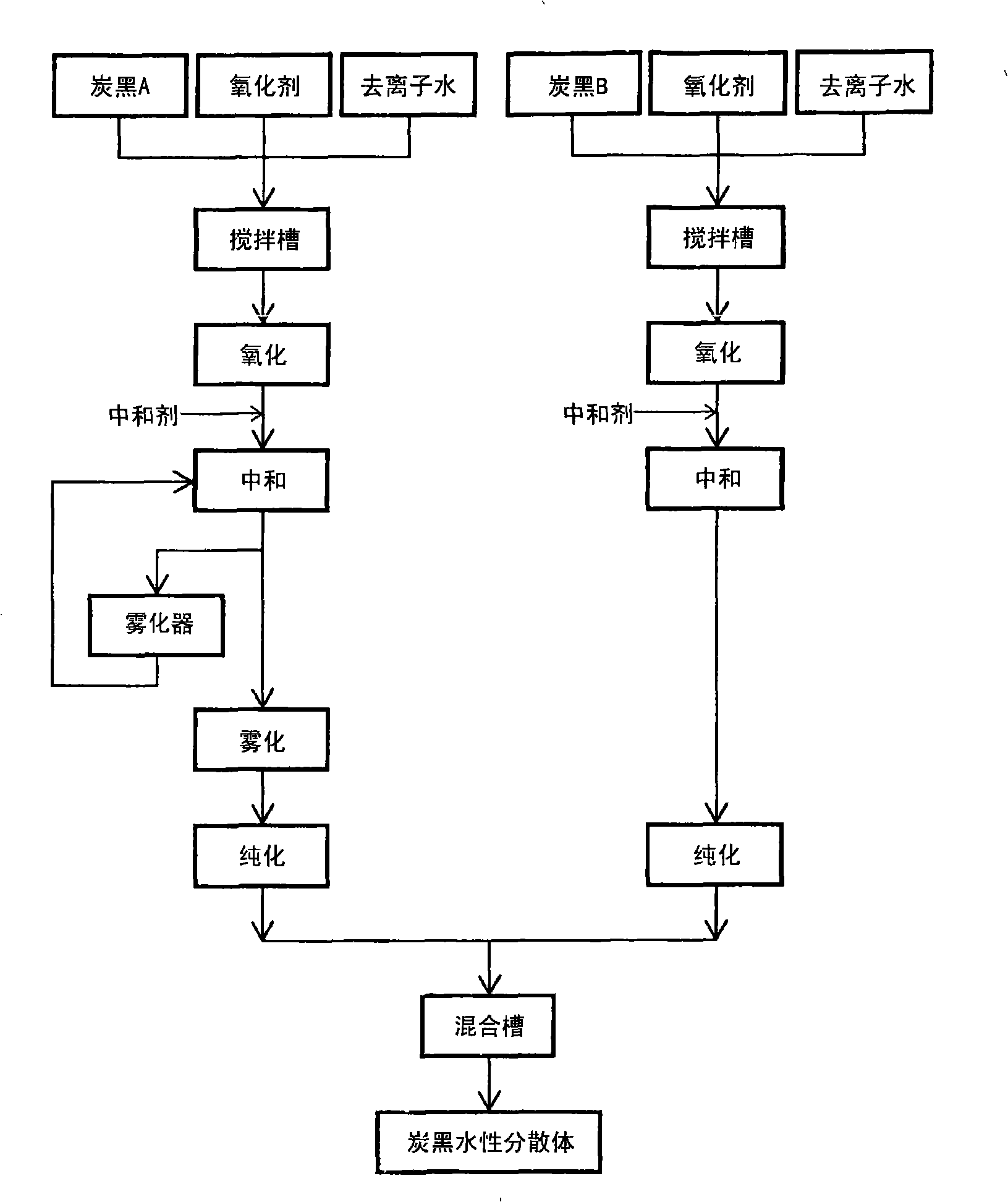

Method used

Image

Examples

Embodiment 1

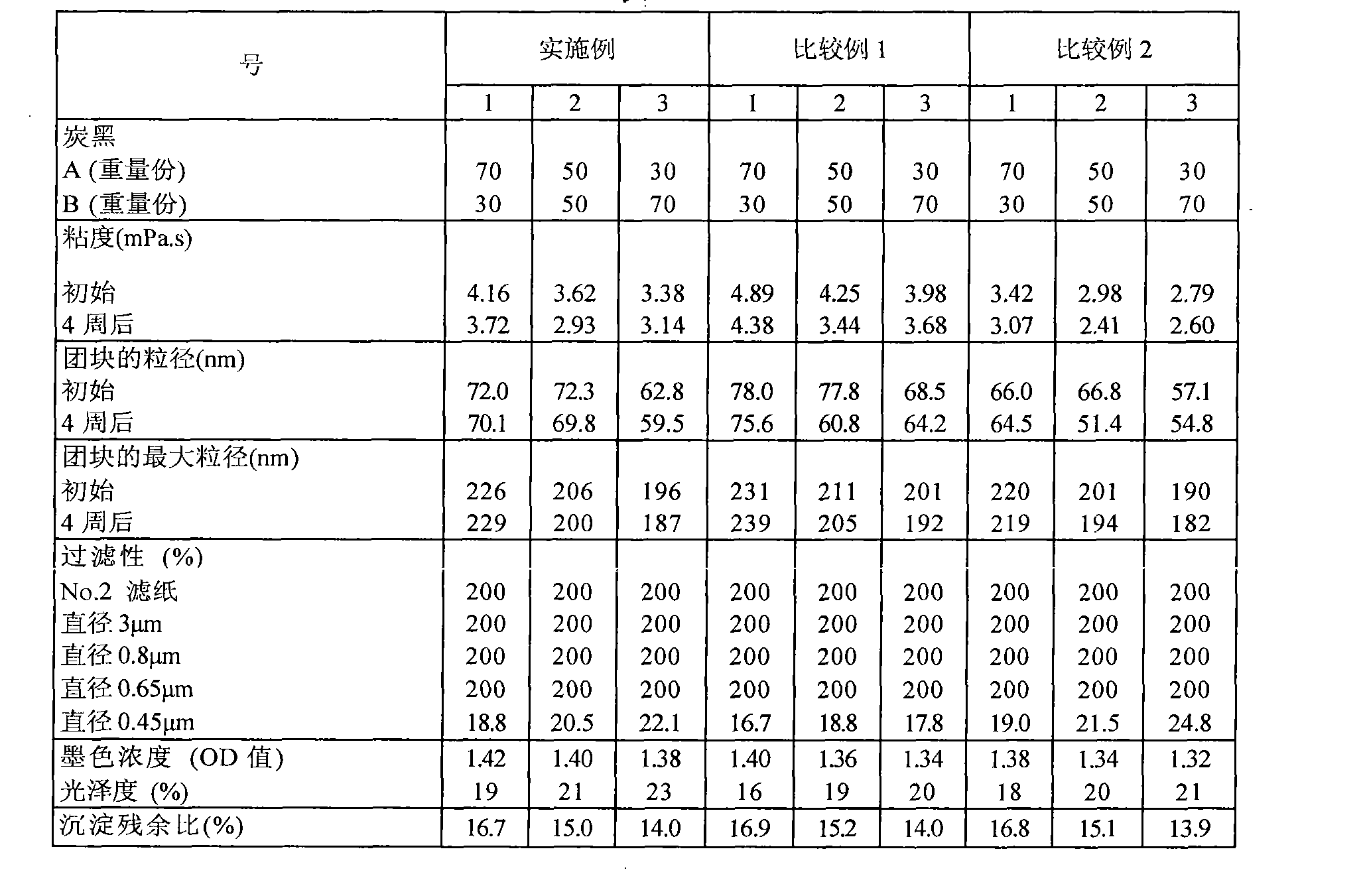

[0047] Carbon black A and carbon black B with the characteristics shown in Table 1 were used

[0048] Table 1

[0049] A

B

N 2 SA(m 2 / g)

DBP (cm 3 / 100g)

Tint(%)

290

98

156

135

56

145

[0050] Carbon black A: Tokablack #8500 (manufactured by Tokai Carbon Co., Ltd.)

[0051] Carbon black B: Tokablack #7550F (manufactured by Tokai Carbon Co., Ltd.)

[0052] Carbon Black A and Carbon Black B were oxidized separately using the following methods.

[0053] 3000 ml of 2.0N sodium peroxodisulfate (aqueous oxidant solution) and 150 g of carbon black were put into the stirring tank. The carbon black was oxidized with stirring to prepare a carbon black slurry. The carbon black was oxidized at 60° C. for 10 hours with a stirring speed of 300 rpm.

[0054] After oxidation the carbon black is filtered from the slurry and neutralized with sodium hydroxide. The resulting product was place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com