Latent curing agent composition and one-part curable epoxy resin composition

A hardener composition and compound technology are applied in the fields of latent hardener compositions and one-liquid hardening epoxy resin compositions, which can solve the problems of lack of storage stability and latent hardeners, etc. Excellent curability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

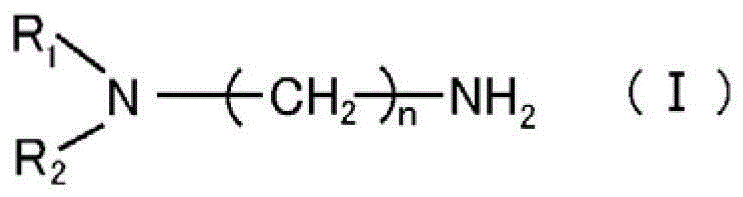

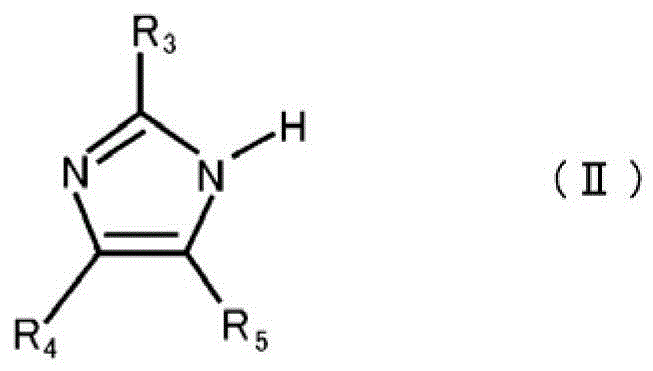

Method used

Image

Examples

manufacture example 1~6

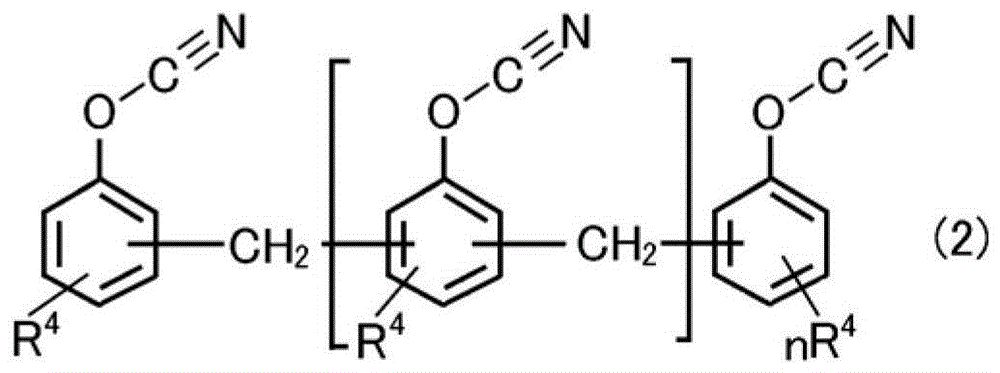

[0076] Manufacture of phenolic resin (PR1~PR6)

[0077] In a four-necked separable flask equipped with a thermometer, a stirring device, a dropping device, and a cooling tube, add phenol, 50% formalin aqueous solution, and oxalic acid, heat, and react at reflux temperature for 4 hours. After the reflux reaction, heat it up to 160°C under normal pressure and concentrate it for 3 hours, then keep it at 160°C and reduce the pressure to 20-30 torr, and concentrate under reduced pressure until the distillate no longer comes out , and yellow-brown phenol resins (PR1 to PR6) having a molecular weight distribution shown in the following [Table 1] were obtained.

[0078] After dissolving 0.01 g of each of the obtained samples in 10 g of THF, gel permeation chromatography (gel permeation chromatography) (Shodex GPC-101 manufactured by Showa Denko Co., Ltd.) was used. Shodex KF-802 was used as the sample column for measurement, Shodex KF-800RH manufactured by Showa Denko Co., Ltd. was u...

Embodiment 1

[0083] In a flask equipped with a thermometer, a cooling device, a stirring device, a dropping device and a dehydration device, add 300 g of propylene glycol monomethyl ether and 100 g of N,N-diethylaminopropylamine, and raise the temperature of the reaction system to 70-75 °C, 213 g of Adeka Resin EP-4100E (trade name of ADEKA Co., Ltd.: Bisphenol A type epoxy resin, epoxy equivalent 190) was added dropwise. After the dripping is completed, mature at 110-130°C for 1 hour, and spend 1 hour at 110-130°C under normal pressure, and spend 1 hour at 175-185°C at 20-30 Torr to remove the solvent. Then, 210 g of phenolic resin PR1 was added in batches at 175 to 185° C., while dissolving the phenolic resin. Furthermore, it degassed under reduced pressure at 180-190 degreeC, 20-30 torr for 1 hour, and obtained the hardening|curing agent composition (HC-1). The obtained curing agent composition was ground in a mortar, and the melting point was 85° C. when measured using a melting point...

Embodiment 2

[0085] Except having used 74 g of 1,2-diaminopropane instead of 100 g of N,N-diethylaminopropylamine, it reacted and processed similarly to Example 1, and obtained the hardening|curing agent composition (HCH-1). The obtained curing agent composition was ground in a mortar, and the melting point was 91° C. when measured using a melting point measuring device manufactured by Yanaco Corporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com