Anisotropic conductive film

An anisotropic, conductive connection technology, applied in the direction of conductive adhesive connection, conductive coating, conductive layer on the insulating carrier, etc., can solve the problems of reduced storage stability and connection reliability, and achieve excellent connection reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

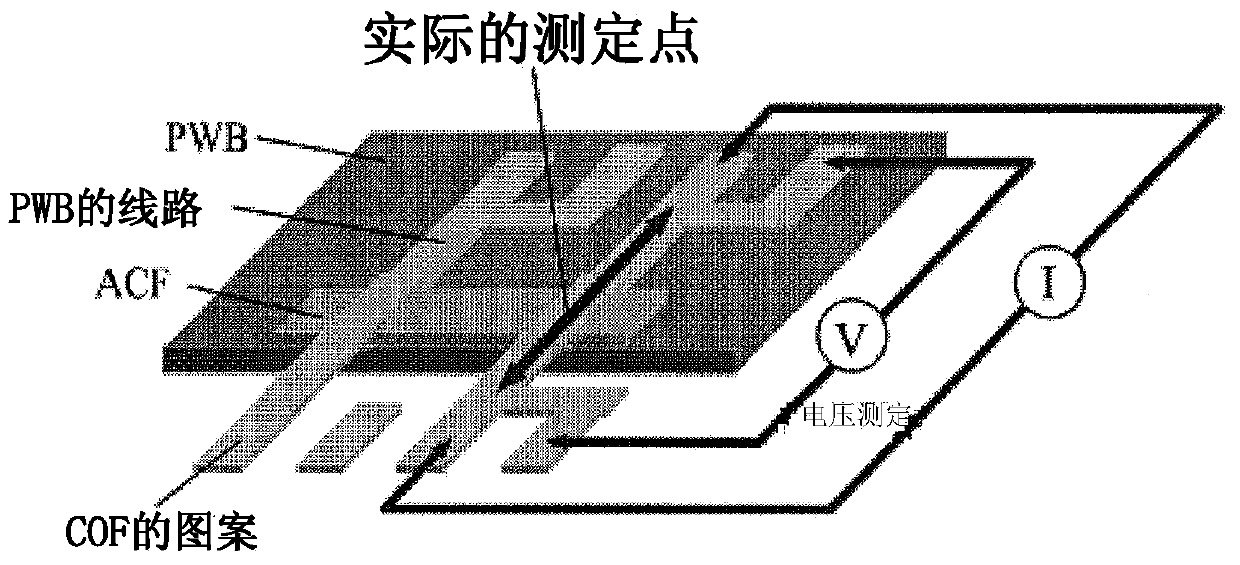

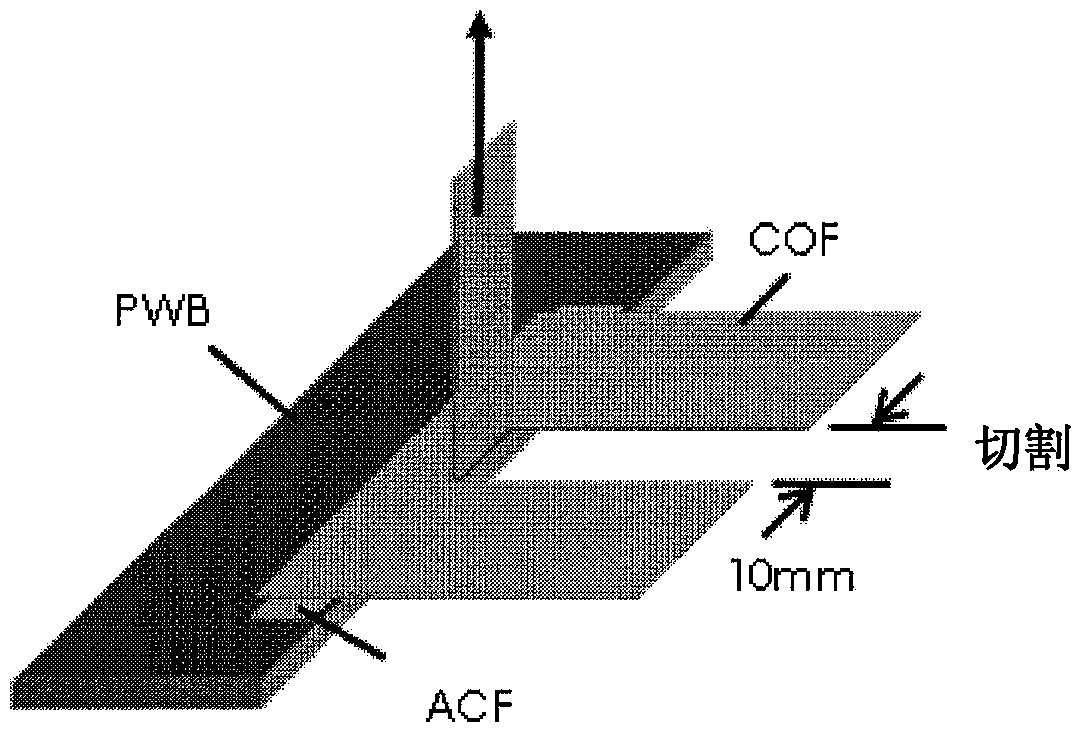

Image

Examples

Embodiment 1

[0133]

[0134] -Formation of conductive particle-containing layer-

[0135] 40 parts by mass of phenoxy resin (trade name: YP50, manufactured by Nippon Steel Chemical Co., Ltd.), bifunctional acrylic monomer (polyethylene glycol) Alcohol #200 diacrylate, brand name: A-200, manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) 30 parts by mass, urethane acrylate (trade name: U-2PPA, manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) 20 parts by mass, Phosphate-type acrylate (trade name: PM-2, manufactured by Nippon Kayaku Co., Ltd.) 2 parts by mass, organic peroxide (dilauroyl peroxide) 3 parts by mass, and conductive particles (Cu particles, average particle diameter 5 μm ) 5 parts by mass are uniformly mixed. The mixed complex was coated on silicone-treated PET (polyethylene terephthalate) in such a way that the average thickness after drying was 17 μm, and dried at 70°C for 5 minutes to produce a conductive Sexual particle layer.

[0136] -Production of in...

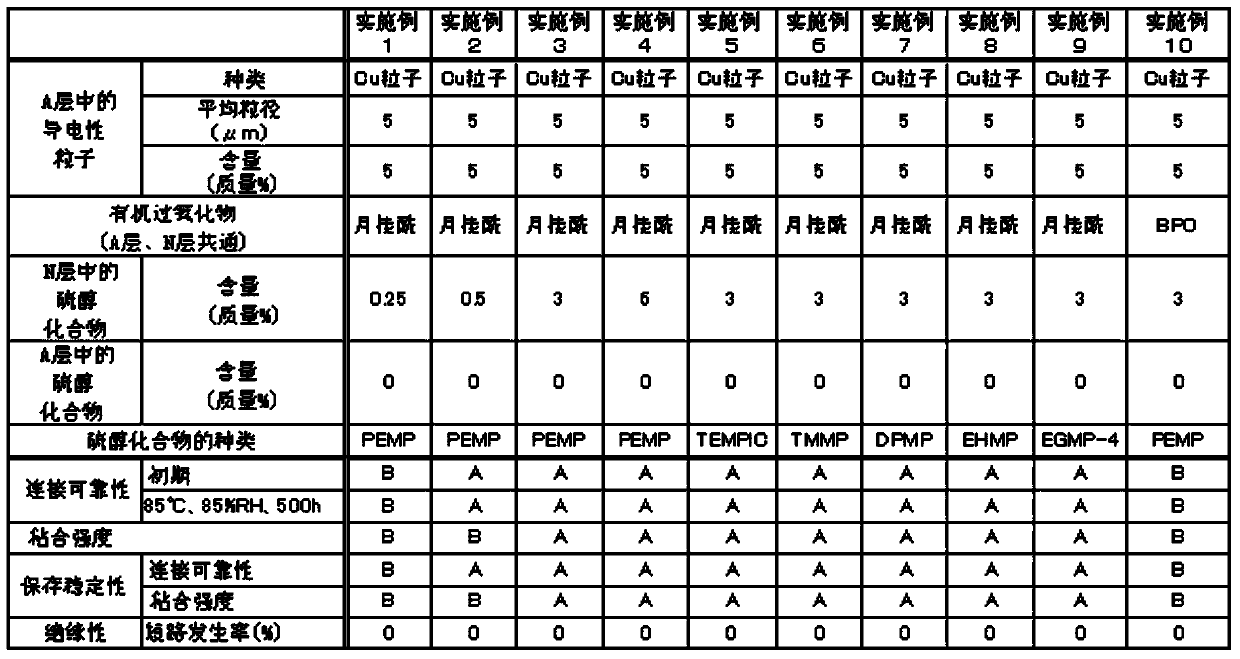

Embodiment 2~20、 and comparative example 1~5

[0164] In Example 1, except for the type and content of the conductive particles in the conductive particle-containing layer (A layer), the type and content of the thiol compound in the conductive particle-containing layer, and the insulating adhesive layer (N layer) ) and the type and content of the thiol compound, and the type of organic peroxide in the conductive particle-containing layer and the insulating adhesive layer were changed to the conductive particles in the conductive particle-containing layer shown in Table 1 to Table 3 The type and content of the thiol compound in the conductive particle-containing layer, the type and content of the thiol compound in the insulating adhesive layer, and the organic compound in the conductive particle-containing layer and the insulating adhesive layer. Except the kind of peroxide, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0165] Using the obtained anisotropic conductive film, it produc...

Embodiment 20

[0174] The "resin particles" in Example 20 are copper-plated resin particles obtained by performing electroless copper plating on benzoguanamine resin particles with an average particle diameter of 4.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com