One-component adhesive and preparation method thereof

A one-component, adhesive technology, used in adhesives, adhesive additives, epoxy resin adhesives, etc., can solve the problems of unstable product performance, poor high temperature resistance, high product defect rate, and achieve good connection reliability. , good fluidity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

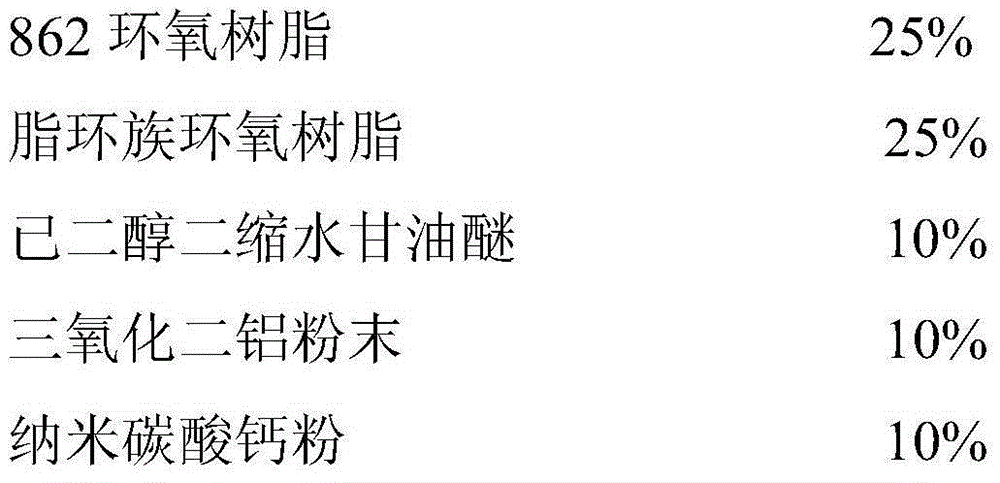

[0032] The adhesive of this embodiment is configured from the following raw materials in weight percentages:

[0033]

[0034]

[0035] The specific configuration steps can be:

[0036] First mix the 862 epoxy resin, cycloaliphatic epoxy resin and black pigment uniformly, then add the N-copper salt of imidazole, aluminum oxide, nano calcium carbonate and electroplated nickel, mix under cooling and drying conditions, and control by cold water bath At 25°C, the mixture is uniformly mixed and vacuumed for 25 minutes. When the above materials are uniformly mixed, hexanediol diglycidyl ether is added and mixed, and vacuum is vacuumed for 60 minutes to obtain sample S1.

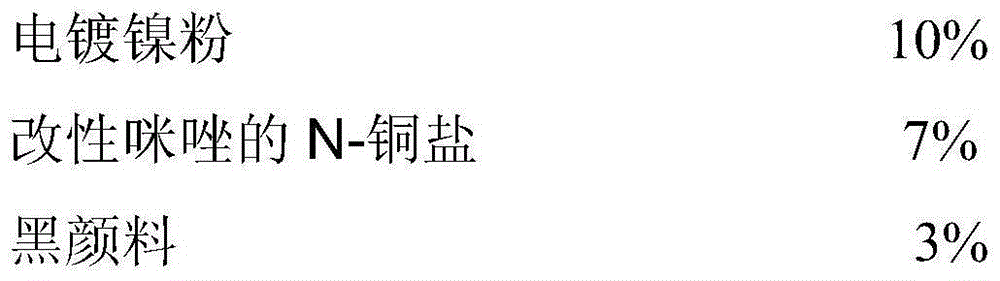

Embodiment 2

[0038]

[0039] The specific configuration steps can be:

[0040] First mix 862 epoxy resin, cycloaliphatic epoxy resin and black pigment uniformly, then add the N-copper salt of imidazole, organic bentonite, aluminum oxide, nano calcium carbonate and electroplated nickel, and mix under cooling and drying conditions. The cold water bath is controlled at 25°C, and the mixture is uniformly mixed and vacuumed for 25 minutes. When the above materials are uniformly mixed, hexanediol diglycidyl ether is added and mixed, and vacuum is vacuumed for 60 minutes to obtain sample S2.

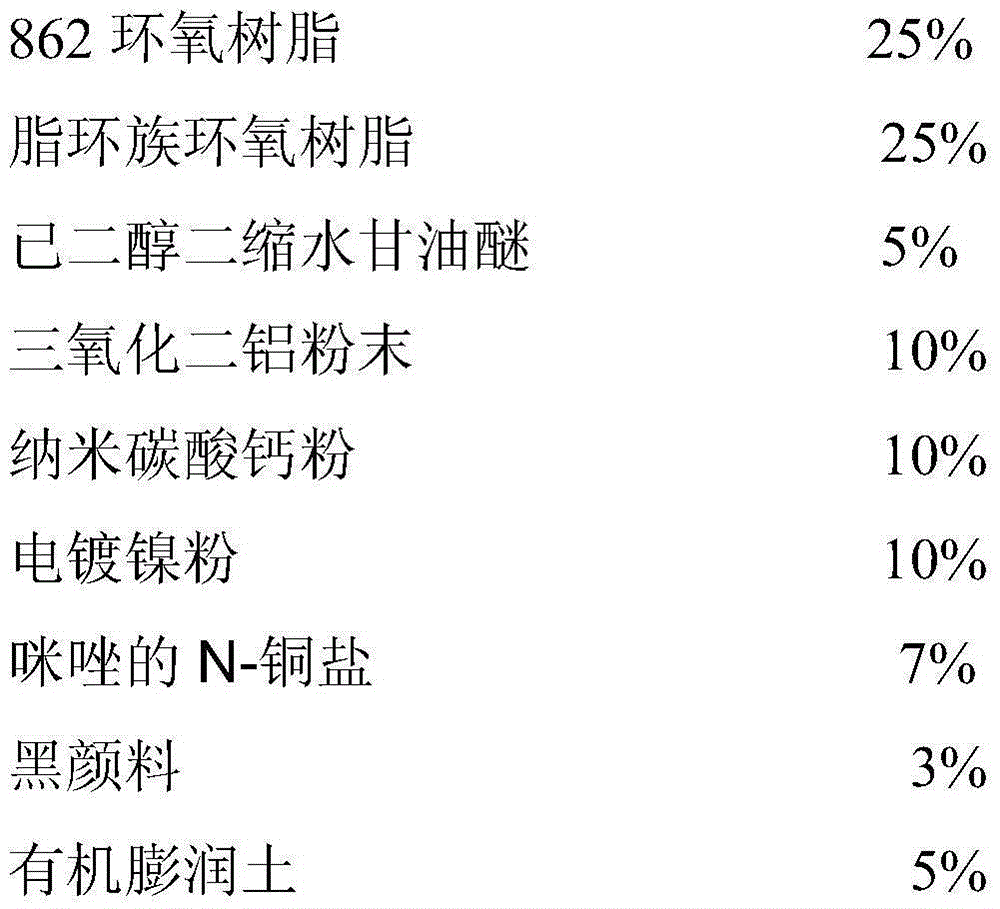

Embodiment 3

[0042] The adhesive was prepared using the same method and steps as in Example 1, except that the following raw materials were used in weight percentages:

[0043]

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com