Hollow lathe body base of large-breadth cutting and welding equipment

A large-format, equipment technology, used in metal processing equipment, other manufacturing equipment/tools, clamping and other directions, can solve the problems of deformation degree of ring frame extrusion, cutting and welding equipment failure, energy accumulation and deformation, etc. Service life, improve heat dissipation, avoid deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be further described in detail below. It should be understood that the description of the embodiments of the present invention here is not intended to limit the protection scope of the present invention.

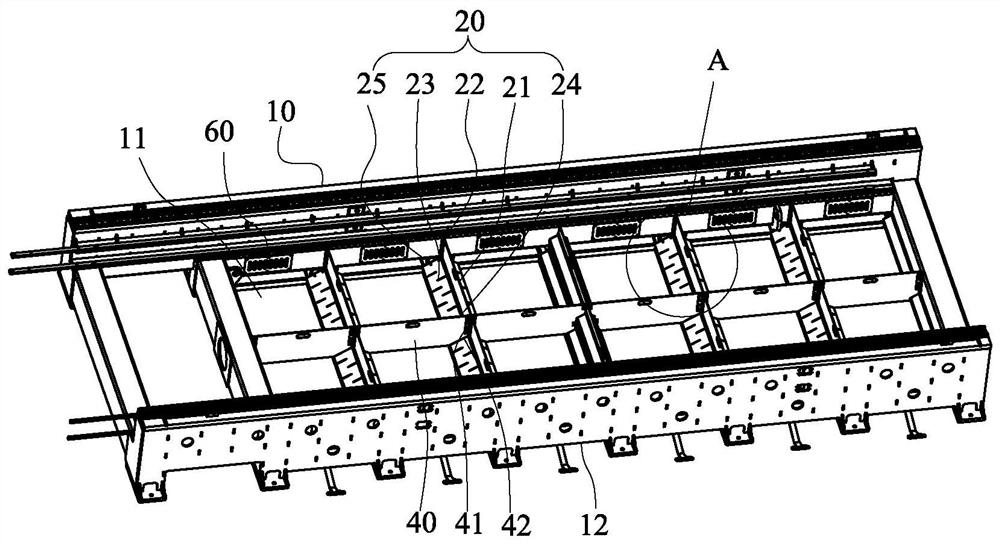

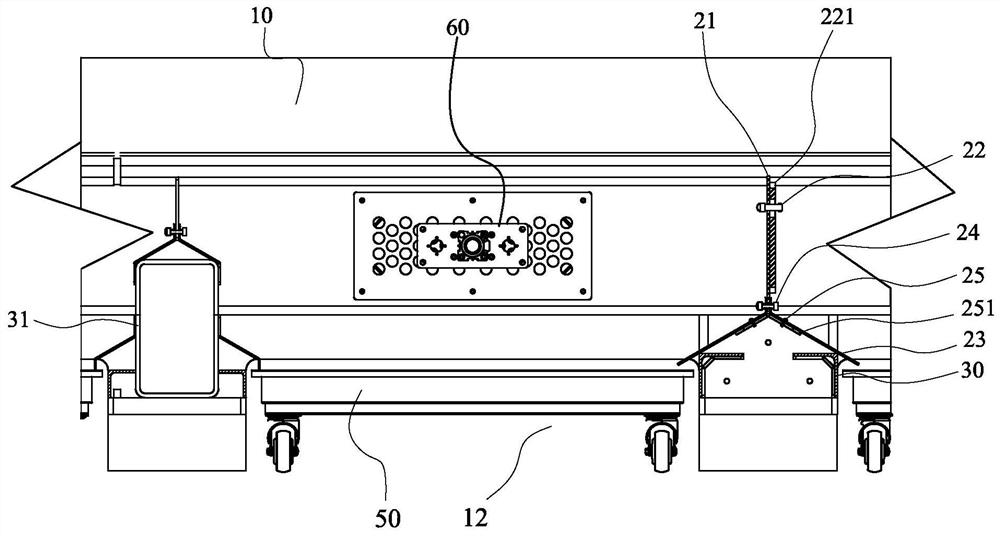

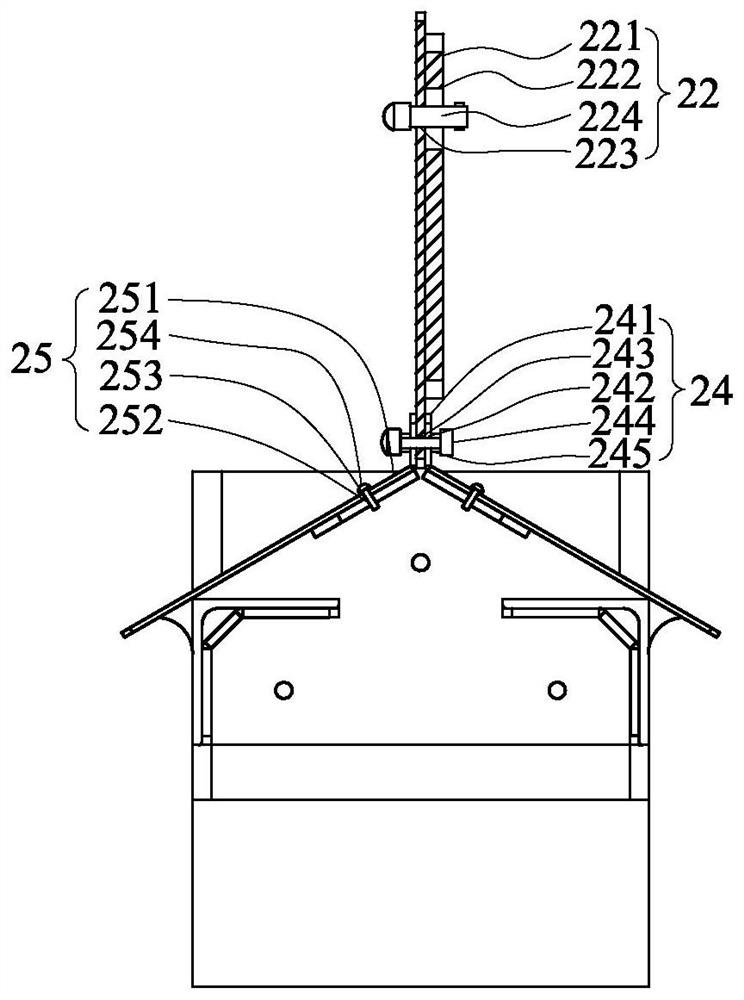

[0023] see Figure 1 to Figure 5 , which is a structural schematic diagram of a hollow body-passing base of a large-format cutting and welding equipment provided by the present invention. A hollow base for large-scale cutting and welding equipment, including a ring-shaped main body 10, the ring-shaped main body 10 is the body of the laser cutting and welding equipment, and is also the main body installation frame of the equipment. The inner side of the annular body 10 is provided with an installation cavity 11, and at least one split beam 20 is arranged in the installation cavity 11. The installation cavity 11 is divided into several smaller chambers by the split beam 20, and each small chamber is equipped with Ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com