Oil-in-water emulsion composition and use of same

An oil-in-water emulsion and composition technology, which can be used in cosmetic preparations, pharmaceutical formulas, cosmetic preparations, etc., can solve the problems of phase separation, increase in turbidity, and impaired transparency, and achieve the maintenance of storage stability and The effect of transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

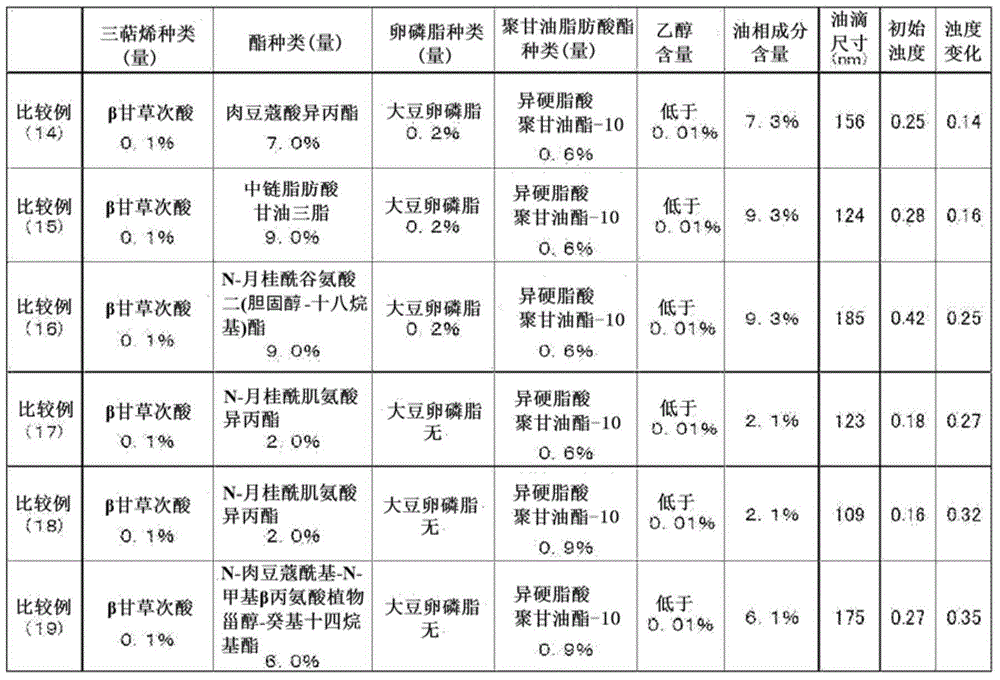

Examples

Embodiment

[0213] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following Example unless the summary is exceeded.

Embodiment (1

[0215] (Preparation of oil-in-water emulsion composition)

[0216] β-glycyrrhetinic acid (manufactured by Maruzen Pharmaceutical Co., Ltd.) 1.00 g, N-lauroyl sarcosine isopropyl ester (manufactured by Ajinomoto, ELDEW SL-205) 20.00 g, high-purity soybean lecithin (manufactured by Tsuji Oil Co., Ltd., SLP- White) 2.00 g was mixed and dissolved while stirring at 70° C., and this was used as an oil phase composition.

[0217] On the other hand, 6.00 g of polyglyceryl isostearate-10 (HLB=12) (manufactured by Nikko Chemical Industry Co., Ltd.) was dissolved in a mixed solution of 100.00 g of glycerin (manufactured by Wako Pure Chemical Industries) and purified water at 70° C., and the It acts as an aqueous phase composition. The amount of purified water is properly adjusted so that the total mass of the prepared emulsion composition reaches 200 g.

[0218] The water-phase composition and the oil-phase composition dissolved respectively were roughly emulsified at 60° C. at 500 rpm...

Embodiment (2

[0229] Except that in the above example (1), the amount of β-glycyrrhetinic acid in the oil phase composition is 2.00 g, the amount of N-lauroyl sarcosinate isopropyl ester is 4.00 g, and the amount of high-purity soybean lecithin is 4.00 g. g. Except that the amount of polyglyceryl isostearate-10 in the aqueous phase composition is 9.00 g, the emulsion and the subsequent skin external composition are prepared in the same way as in Example (1), which is used as the skin external composition ( 2).

[0230] In addition, the evaluation of the oil droplet size and turbidity was performed in exactly the same manner as in Example (1).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com