Preparation method and application of corn juice

A technology of corn juice and corn, which is applied in the field of plant protein beverages, can solve the problems of unhealthy product ingredients, poor product stability, and bad taste, and achieve the effects of improving product color, reducing product quality decline, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] The invention provides a method for preparing corn juice, which is especially suitable for preparing prepackaged, heated and ready-to-eat corn juice.

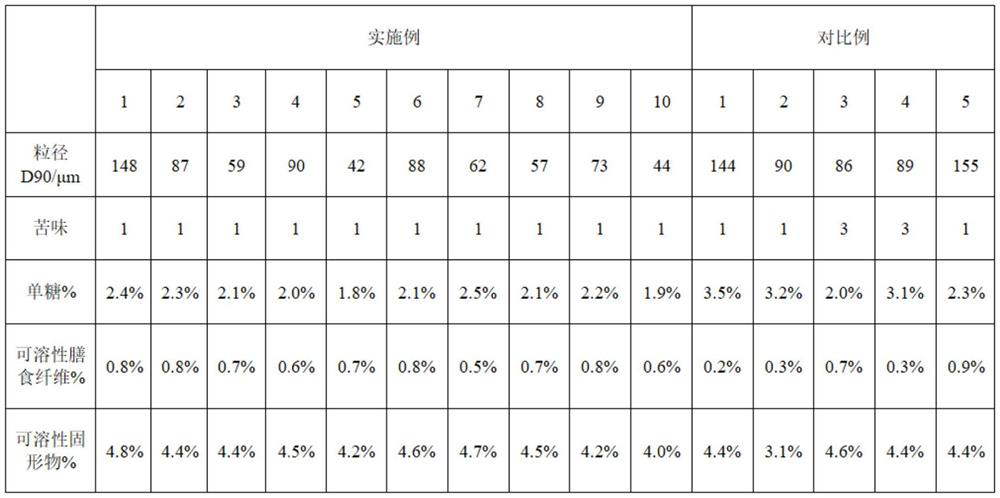

[0058] The method of the present invention mainly includes performing two enzyme treatments on the pulverized corn components, during the two enzyme treatments, the nutritional components of the corn components are fully degraded, and the oligosaccharide / dietary fiber components in the final product are improved , and avoid the bitter taste caused by the use of traditional protease, and also improve the storage stability of corn juice.

[0059] The method of the present invention will be specifically described below.

[0060] (initial raw material)

[0061] The preparation method of the corn juice of the present invention mainly uses corn as the initial raw material.

[0062] In some specific embodiments of the present invention, there is no special limitation on the variety of corn, for example, sweet corn, waxy corn ...

Embodiment 1

[0113] In this example, fresh black waxy corn was used as raw material, and different amylases were added step by step in one enzyme treatment for enzymolysis, and no protease was added in one enzyme treatment. Specifically include the following steps:

[0114] Step one, pre-processing. Use fresh black waxy corn as the raw material for threshing, take 1000g corn kernels, and heat them in microwave for 25 minutes at 90°C; use a shearing grinder with a grinding material water ratio of 1:3, and grind twice; and use a high-pressure homogenizer , homogenized once at 60MPa high pressure; the crude protein content in the obtained grinding mixture was detected to be 1%, and the carbohydrate content was 8%.

[0115] Step 2, an enzyme treatment. Adjust the temperature of the grinding mixture obtained in step 1 to 70°C, add α-amylase at 0.5% and add pullulanase at 0.5% of the carbohydrate mass fraction measured in step 1, perform enzymatic hydrolysis for 0.5h, and lower the temperature...

Embodiment 2

[0122] In this example, fresh sweet corn was used as raw material, and amylase and protease were added step by step in one enzyme treatment for enzymatic hydrolysis. Specifically include the following steps:

[0123] Step one, pre-processing. Fresh sweet corn was used as raw material for threshing, and 1000g corn kernels were heated at 90°C for 15 minutes by direct steam injection; a shearing grinder was used, and the ratio of grinding material to water was 1:1.5. Grind twice, and use a high-pressure homogenizer to homogenize twice under 60MPa high pressure. The ground mixture was tested for 1.2% crude protein and 9% carbohydrates.

[0124] Step 2, an enzyme treatment, adjust the temperature of the grinding mixture in step 1 to 70°C, add α-amylase according to 1% of the mass fraction of carbohydrates in the grinding mixture measured in step 1, enzymolyze for 0.5h, cool down to 60°C, follow the steps Add glucoamylase to 1% of the measured carbohydrate mass fraction, add acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com