A kind of cemented artificial sandstone material and its preparation method

An artificial sand and gelling technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of lack of adaptability and achieve the effect of loose source requirements and simple treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] A dam project is built with cemented artificial sand and gravel materials, and the preparation of the dam building materials has the following steps:

[0051] 1. Carry out exploration and sampling test on the material source of the project site;

[0052] 2. According to the exploration and test results, determine the aggregate crushing process of gelled artificial sandstone, which is crushed by a jaw crusher. Generally, one or two jaw crushers can be used for the aggregate crushing process of gelled artificial sand. The crushed aggregate does not need to be sieved, and only the particles with a particle size larger than 150mm are removed by sieving once.

[0053] 3. According to the aggregate production process determined in step 2, the project site starts to produce artificial sand and gravel aggregates.

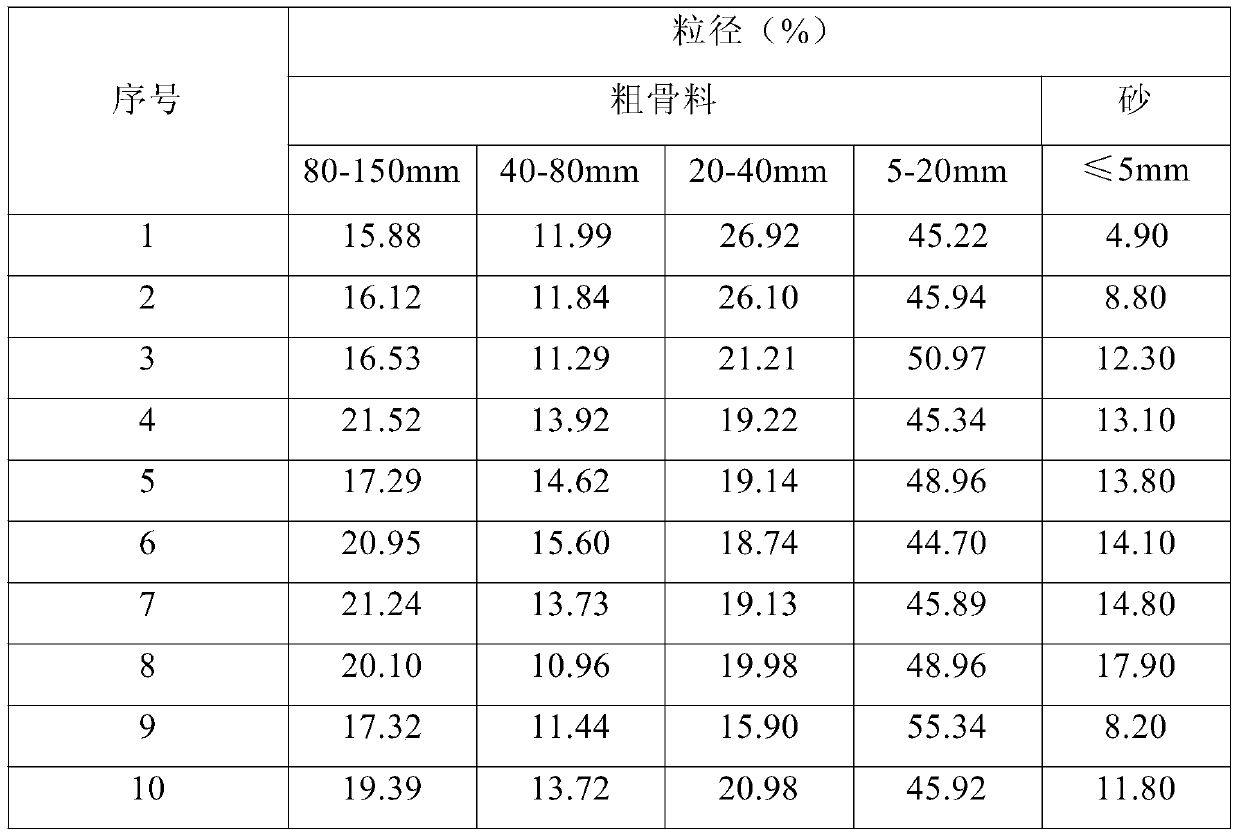

[0054] In the space of the stockyard (that is, the site where the produced aggregates are stacked), more than 10 positions are evenly selected in the prepared aggr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com