Self-adaptive intelligent waste heat boiler

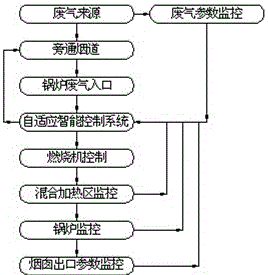

A waste heat boiler, an intelligent technology, applied in the field of waste heat boilers, can solve problems such as affecting the amount of steam and steam quality, very high requirements for waste heat sources, unstable working conditions of waste heat boilers, etc., to achieve stable steam output and reduce exhaust gas sources. Requirements, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing:

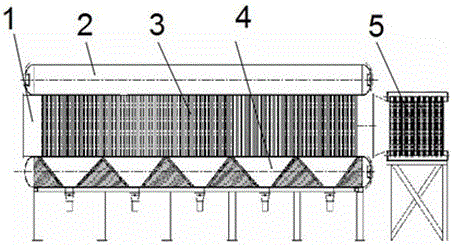

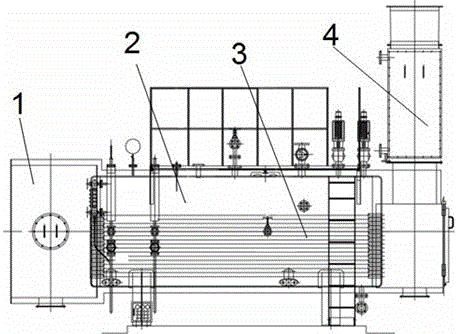

[0019] Such as image 3 Shown: Adaptive intelligent waste heat boiler, including the upper front smoke box 1, the upper drum 2 and the upper rear smoke box 4 which are connected in sequence. The waste heat flue gas inlet is located on the upper front smoke box 1 and located on the upper drum 2. The upper convection pipe 3 is arranged inside, and the waste heat flue gas outlet is arranged on the upper rear smoke box 4 . The upper part of the upper drum 2 is provided with a liquid inlet, a liquid level controller, a pressure display instrument, an exhaust port and a safety valve; the middle part of the upper drum 2 is provided with a sampling port and a surface sewage outlet. A lower drum 7 is arranged outside the upper drum 2 , and the lower drum 7 is connected to the upper drum 2 through a connecting pipe 9 . The lower drum 7 is provided with a supplementary combustion mechanism for h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com