Patents

Literature

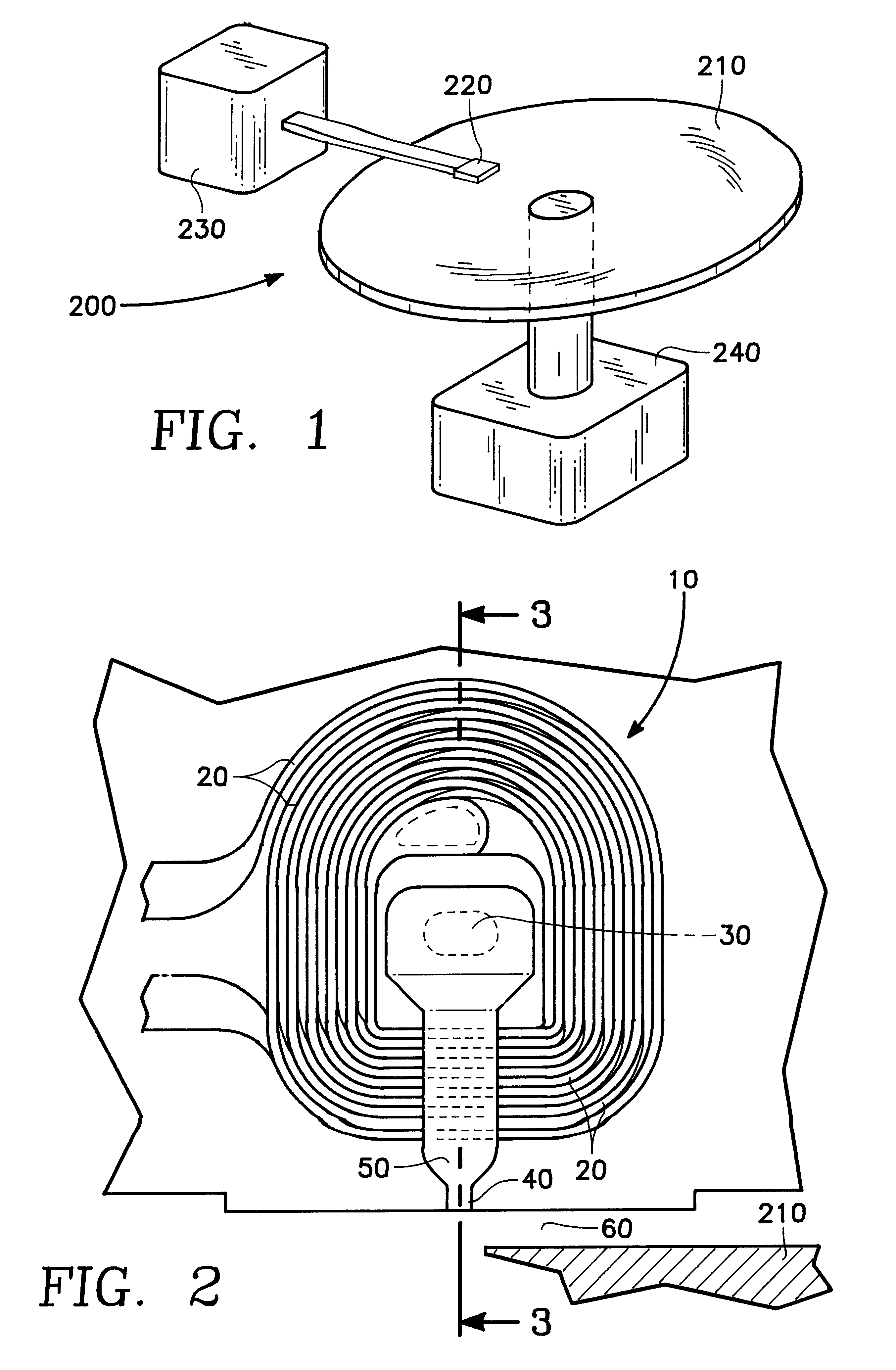

890results about "Heads with metal sheet cores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin film write head with interlaced coil winding and method of fabrication

InactiveUS6466401B1Increase working frequencySeparationConstruction of head windingsHeads using thin filmsResistConductive materials

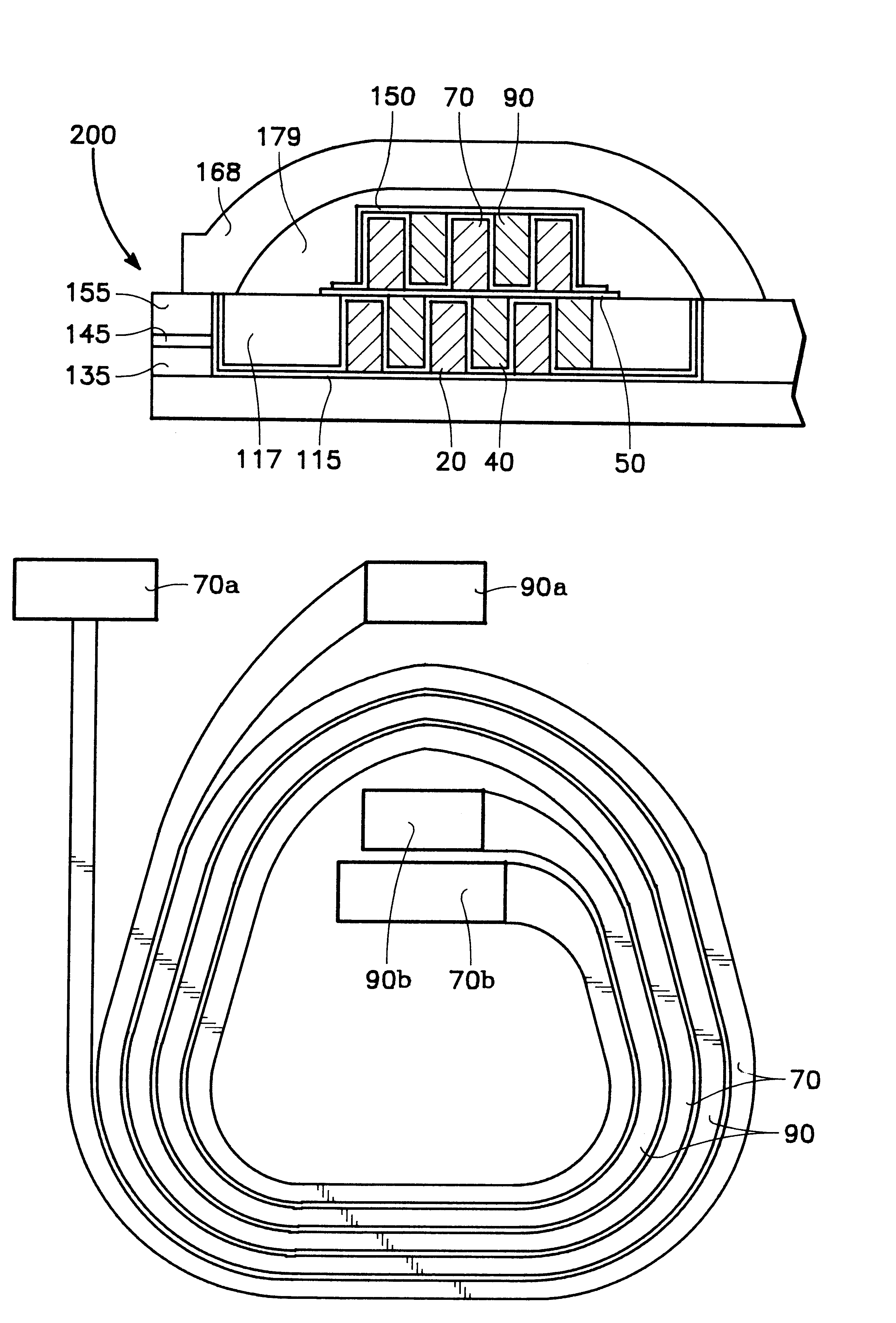

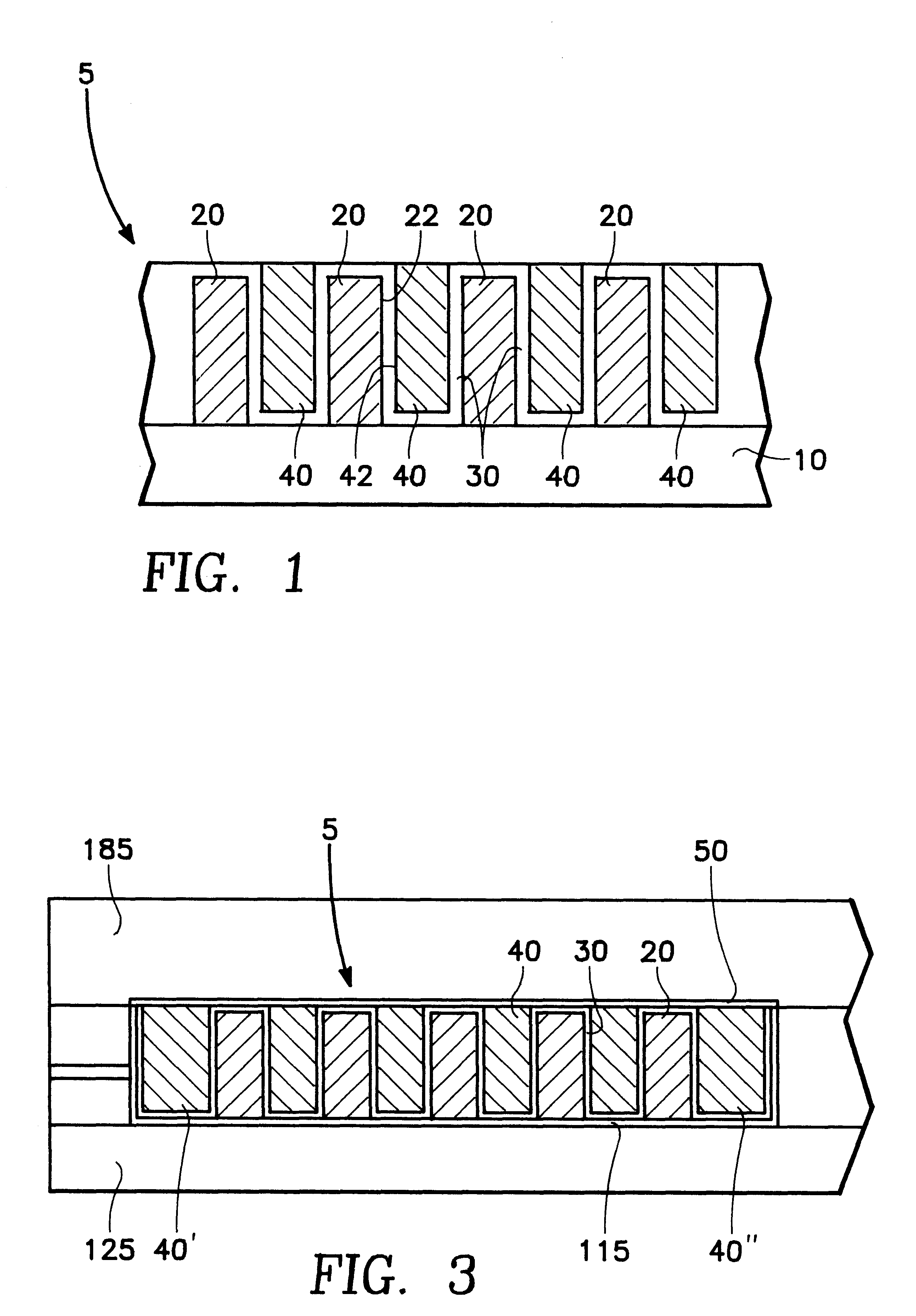

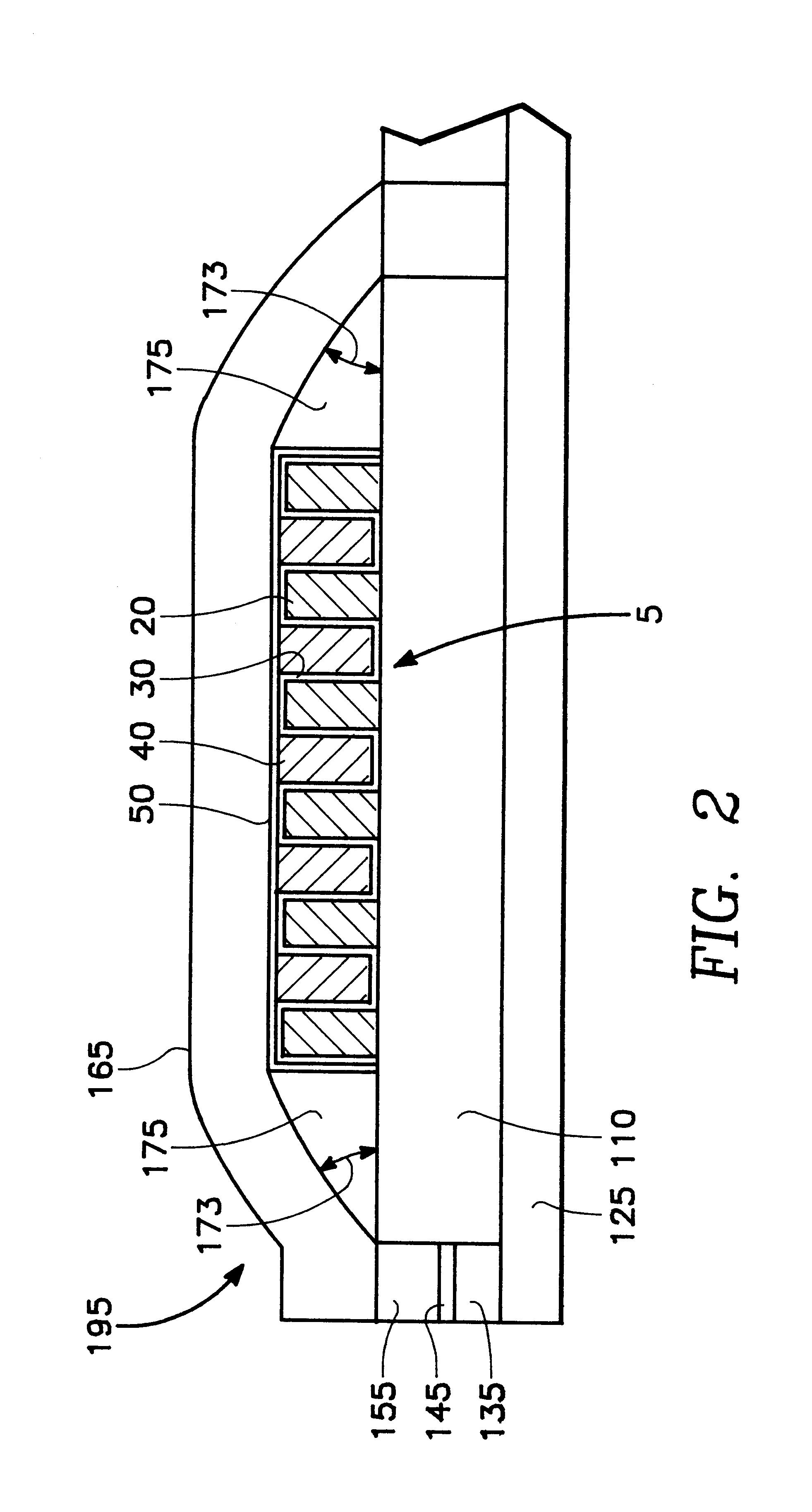

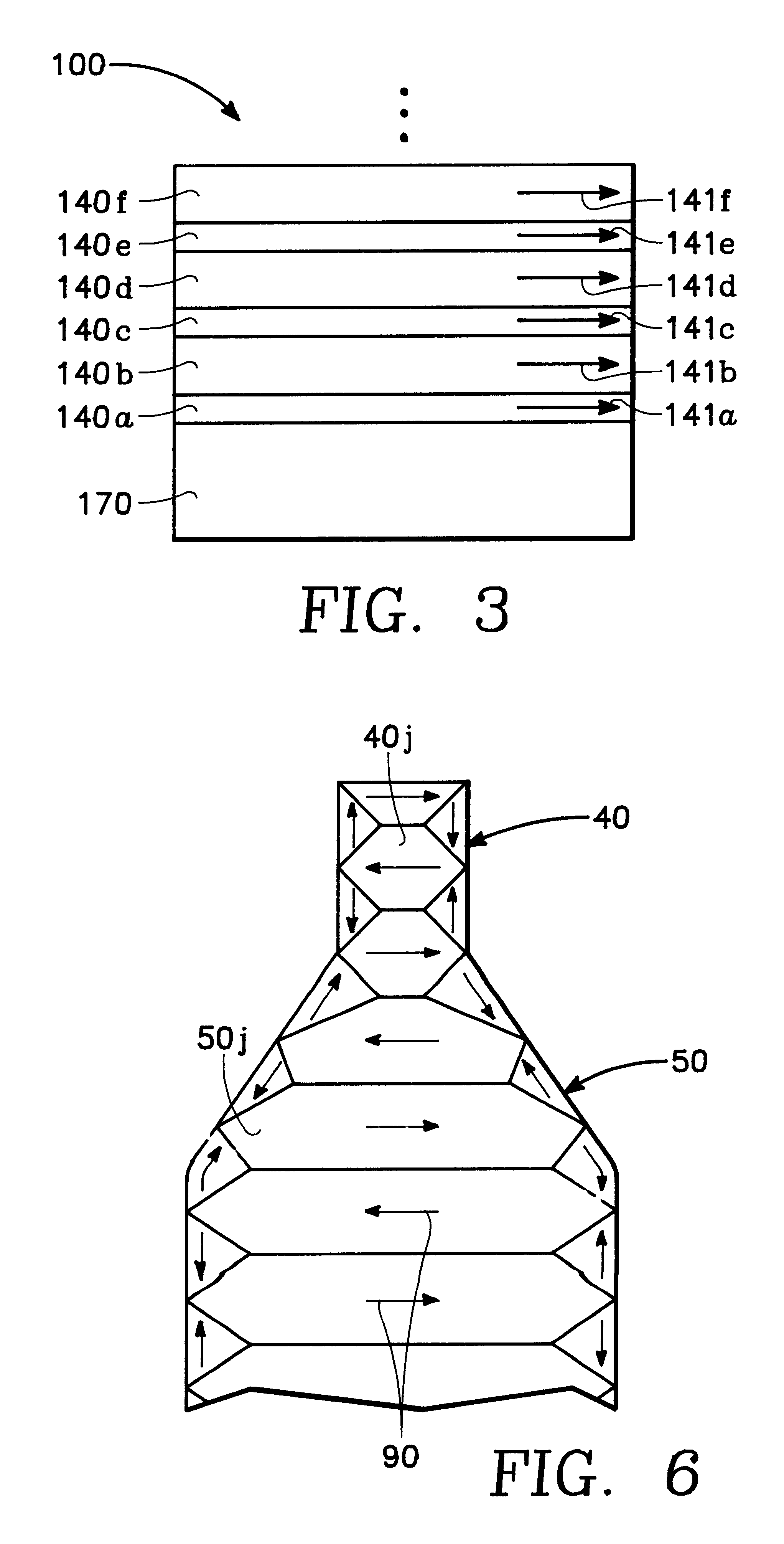

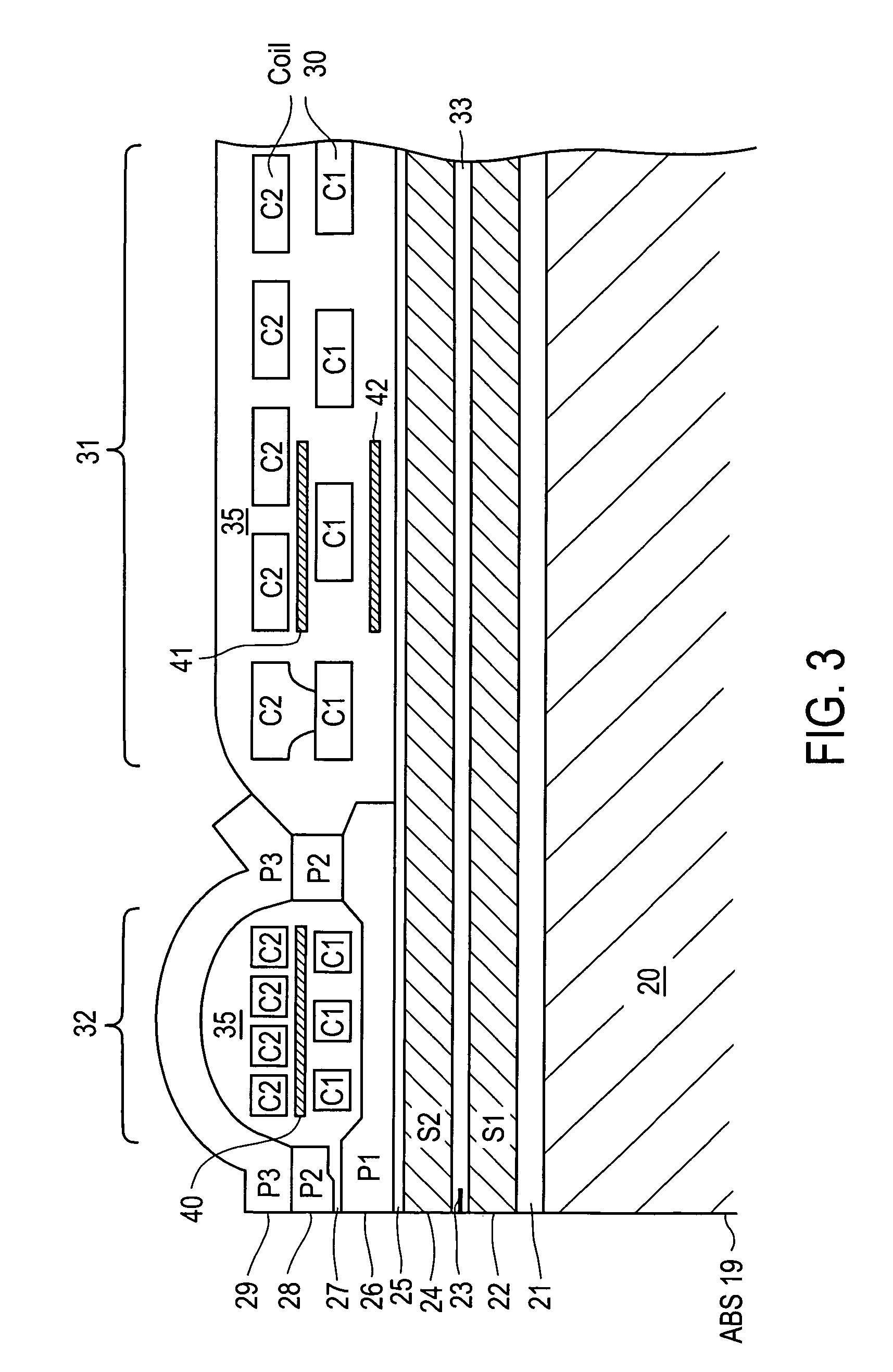

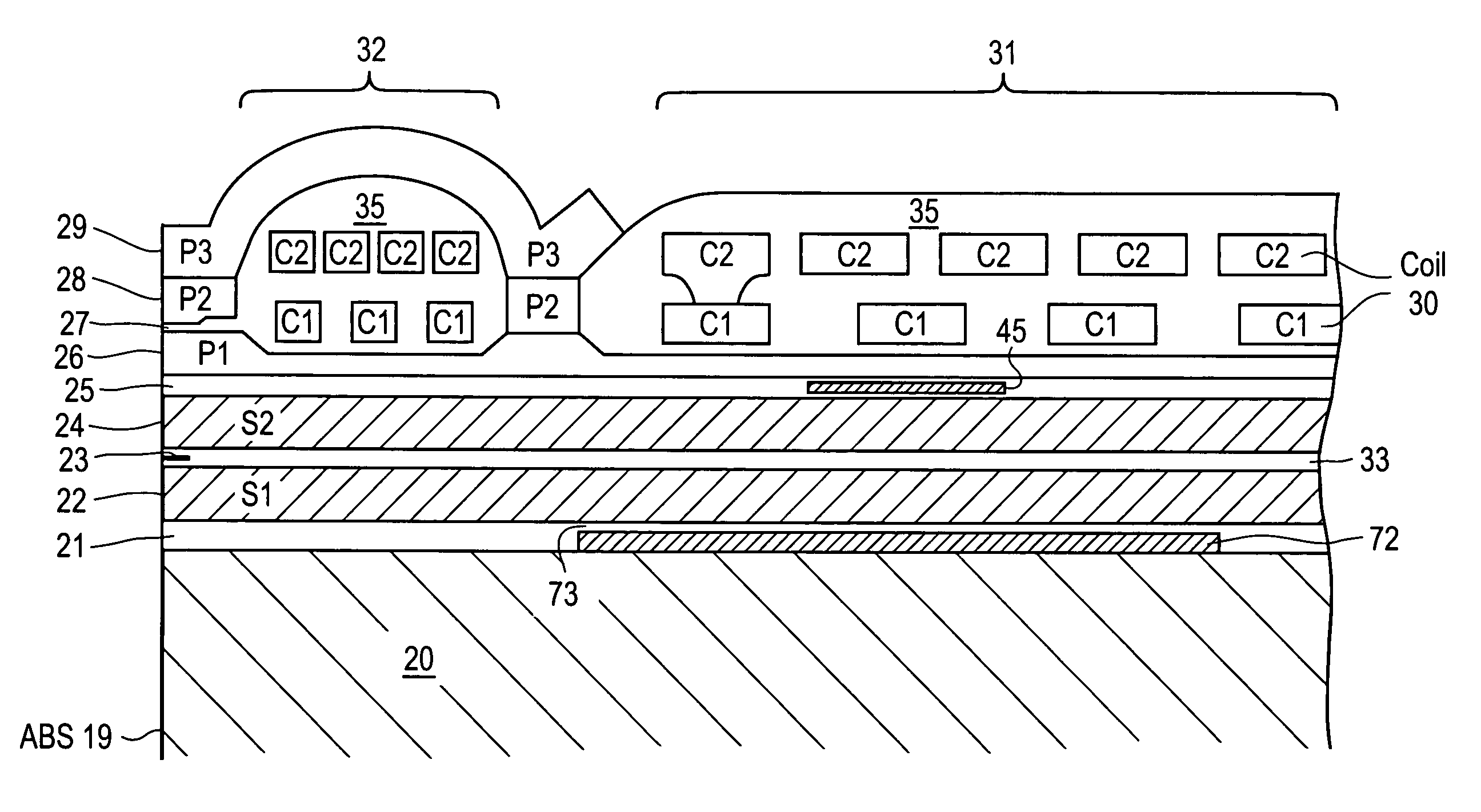

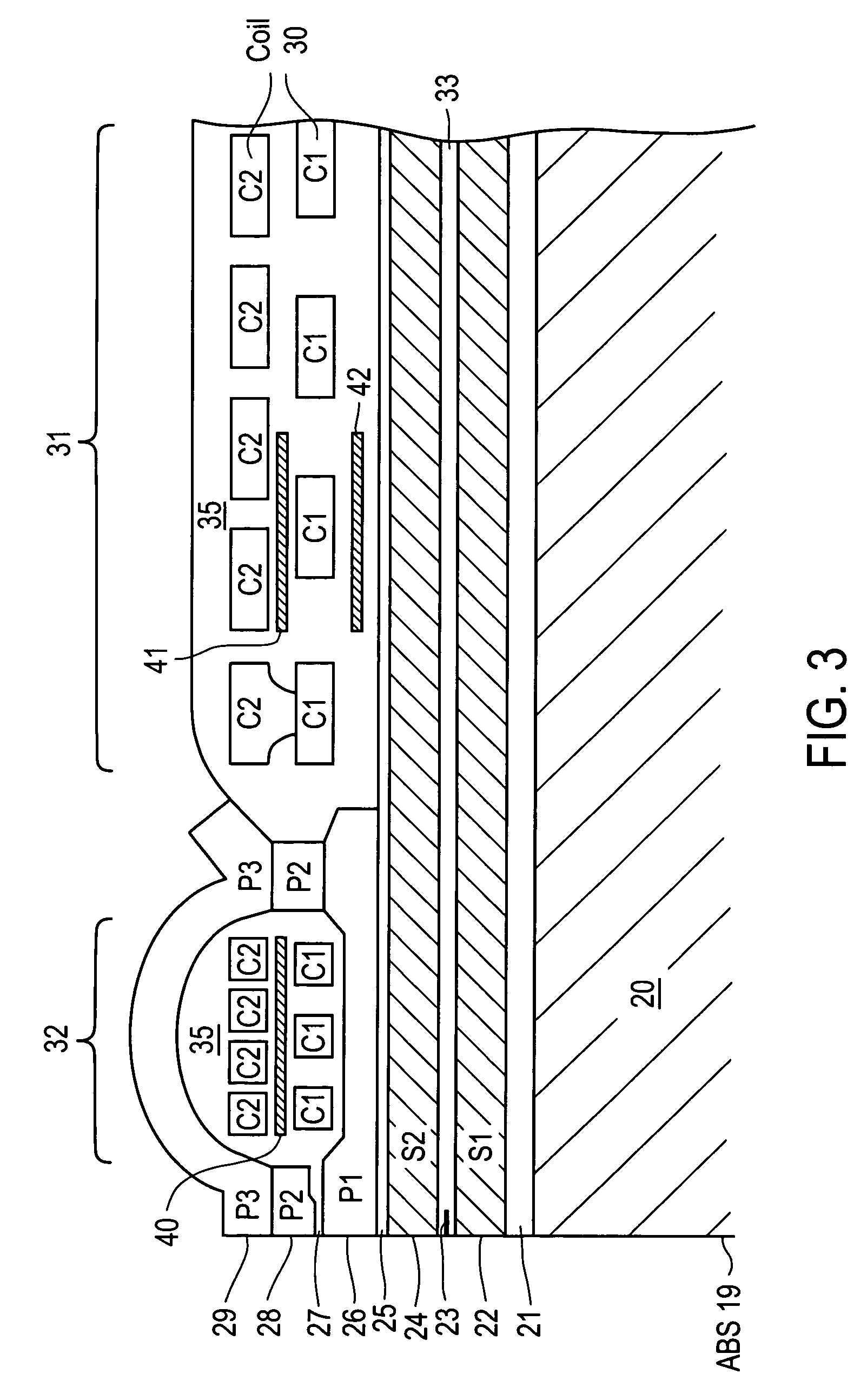

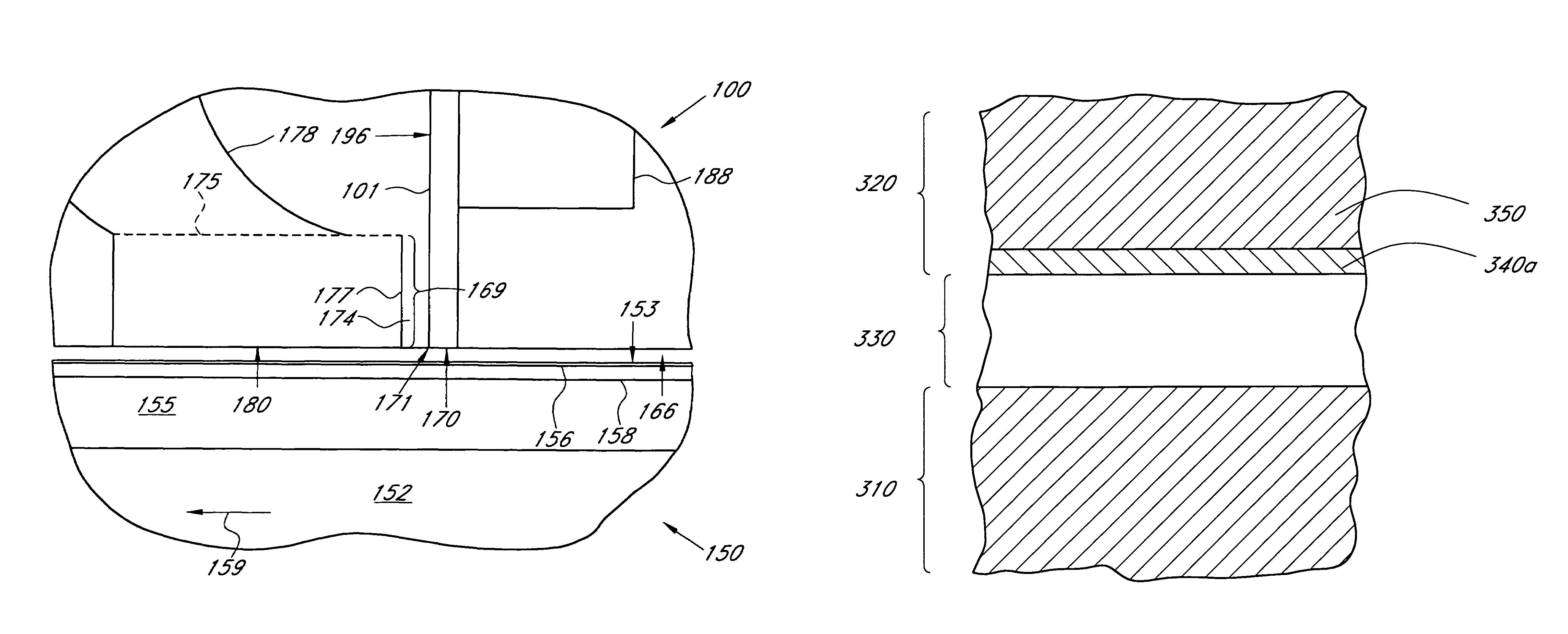

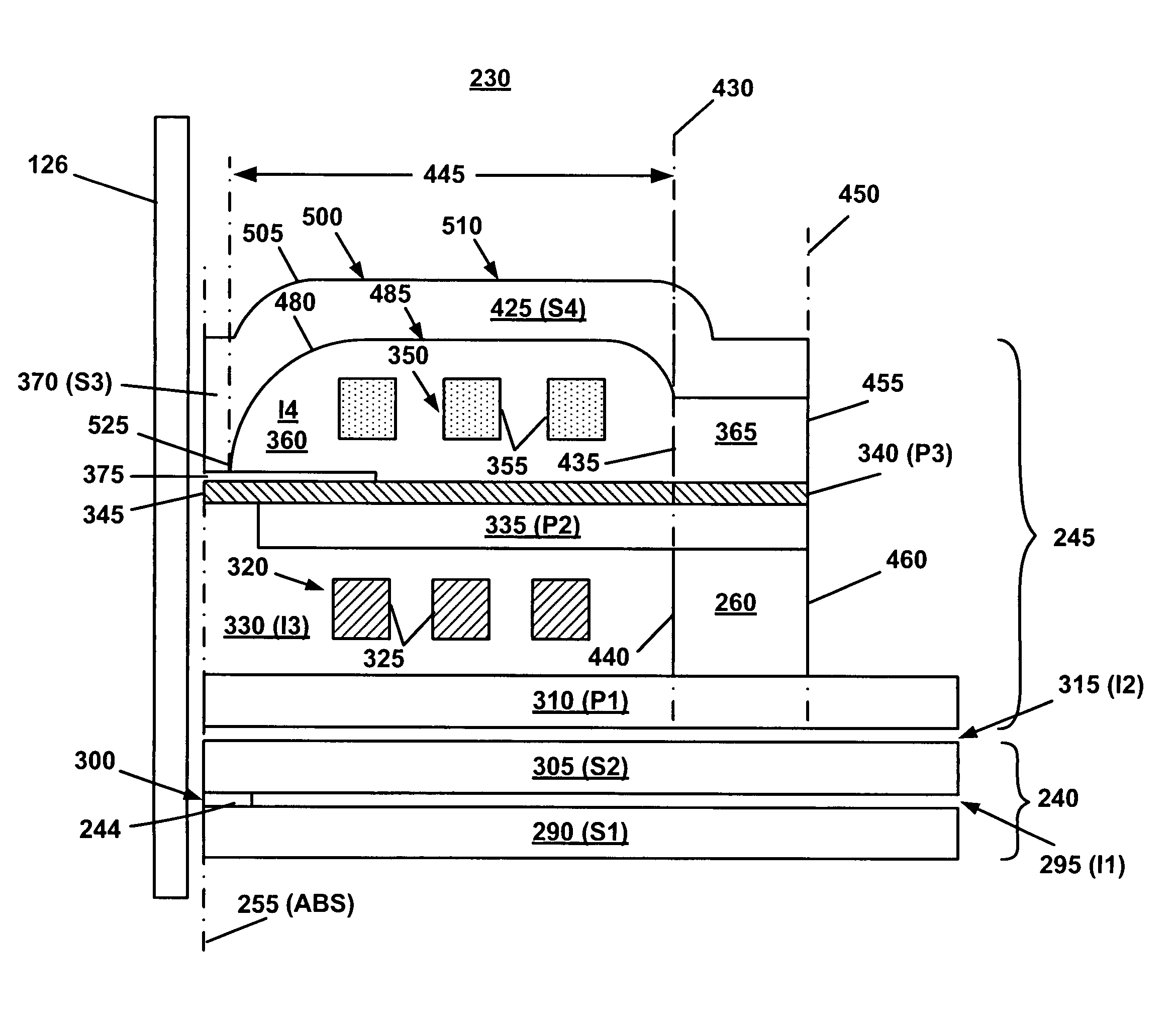

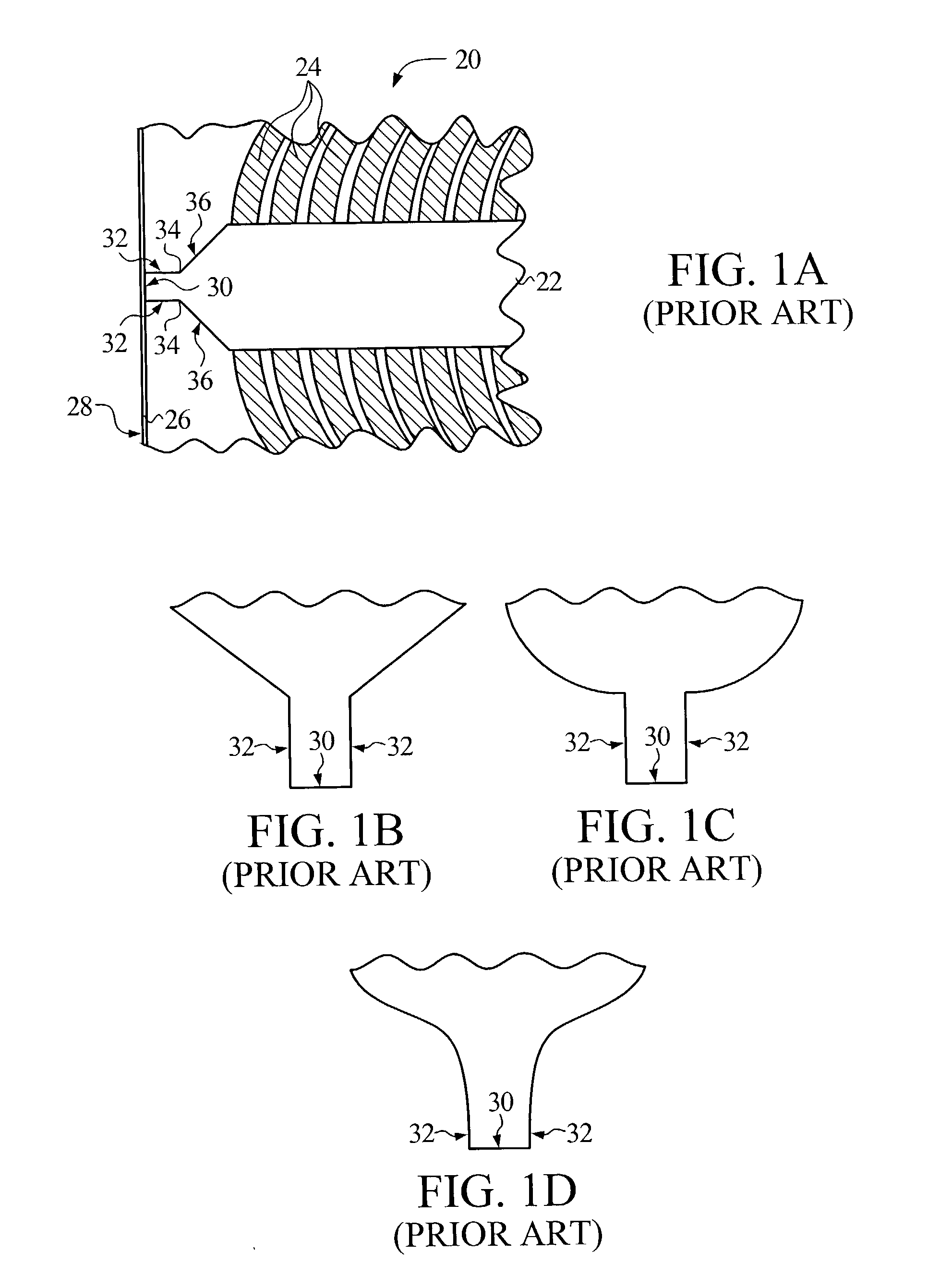

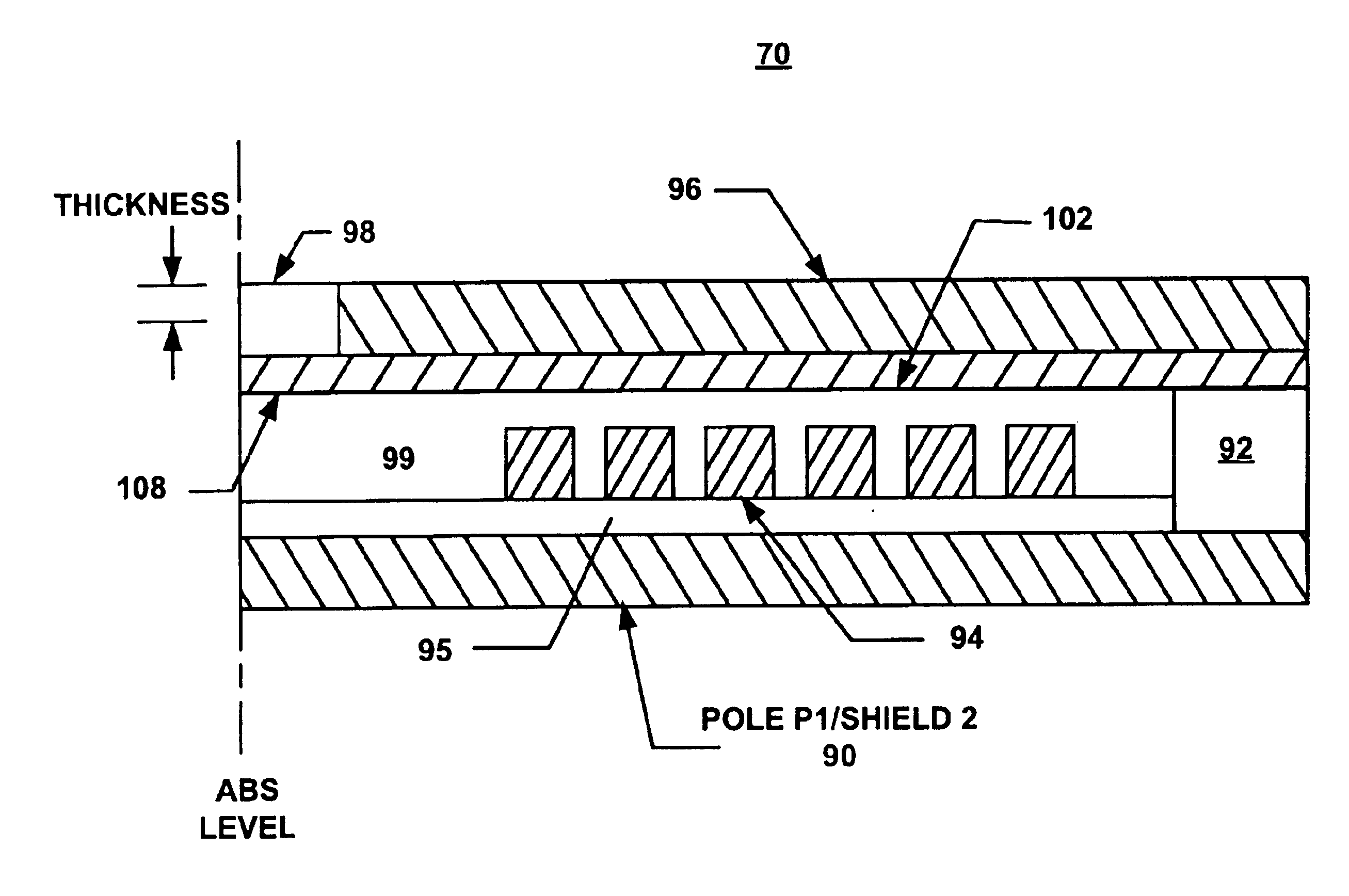

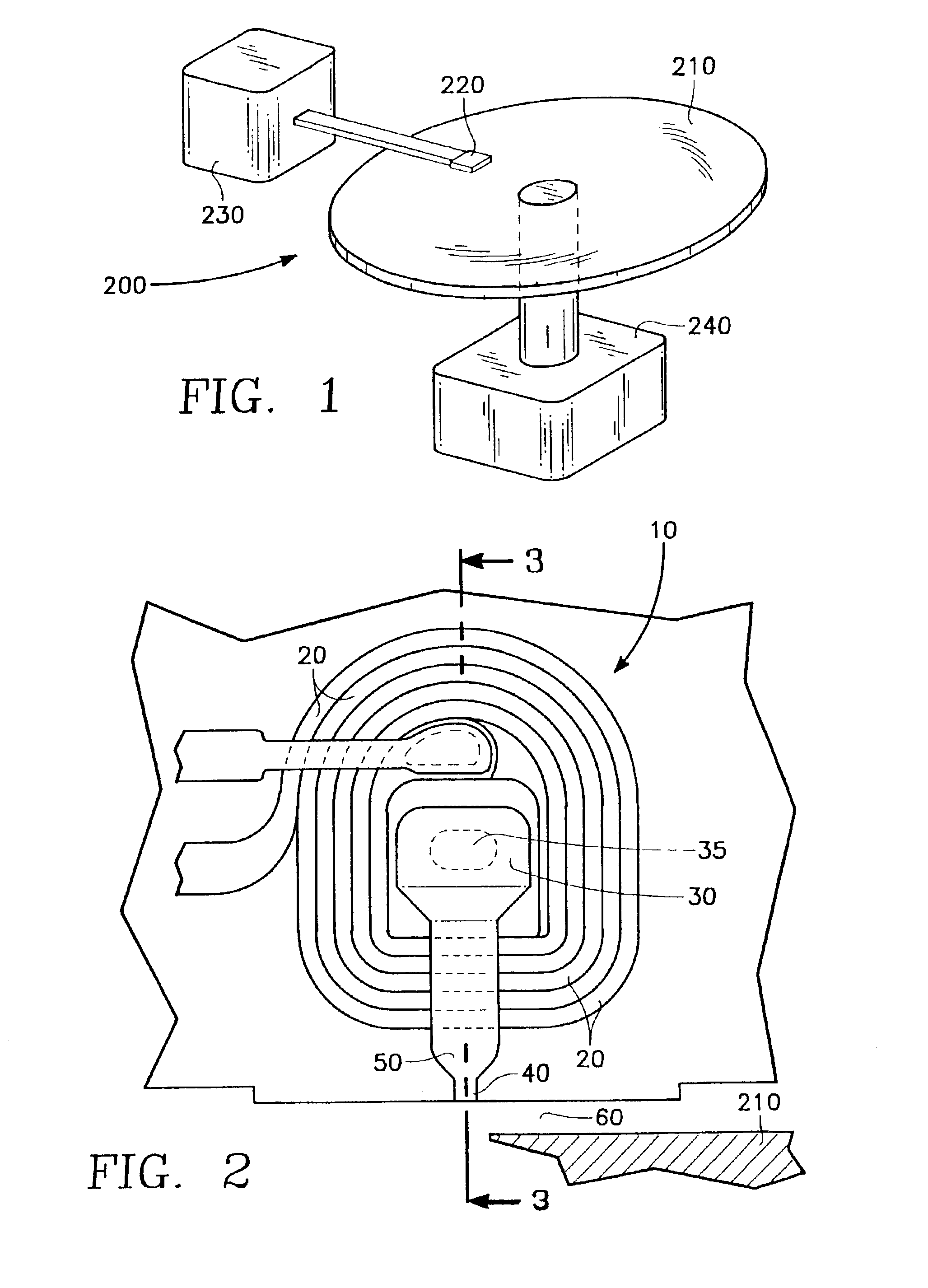

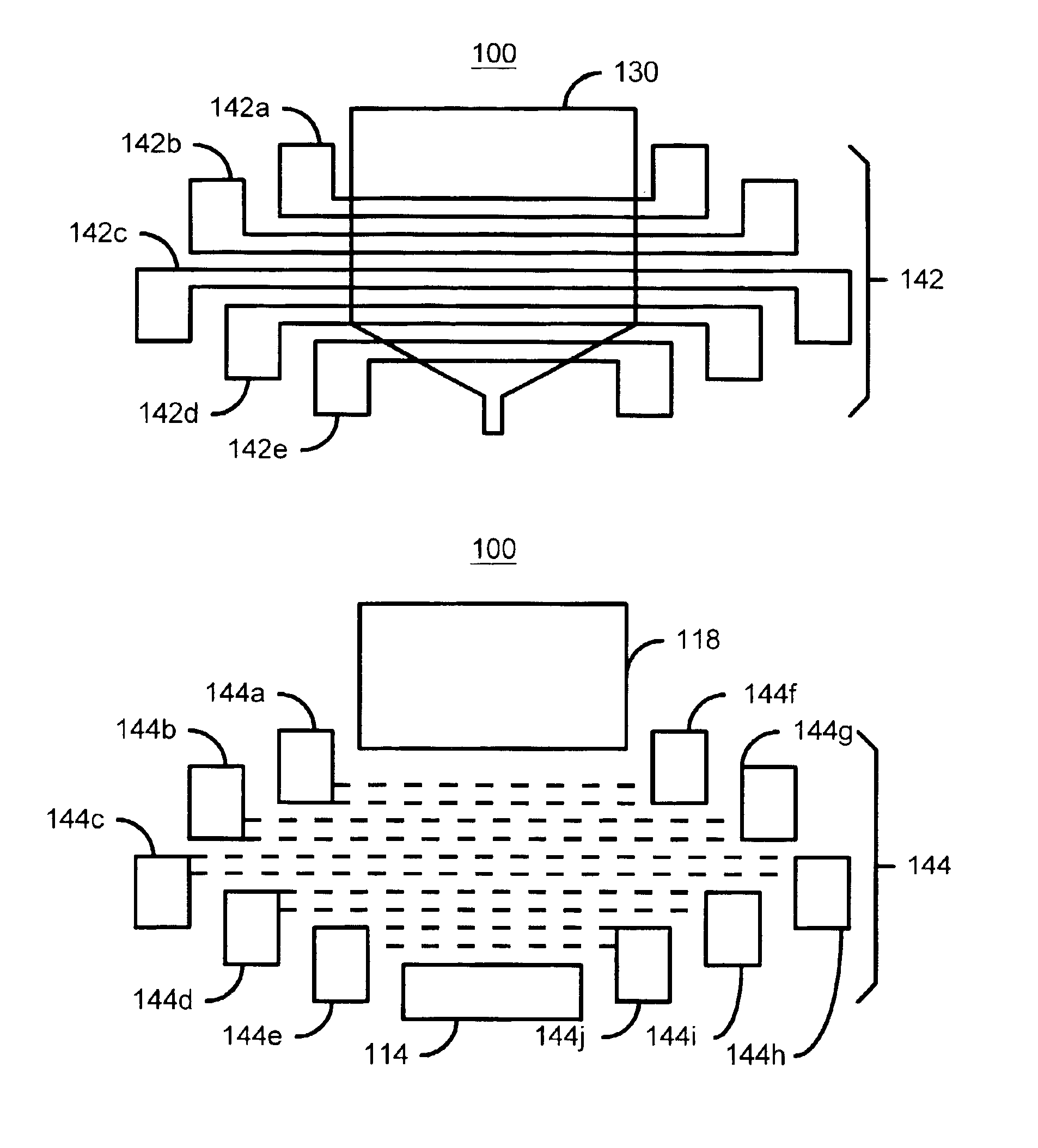

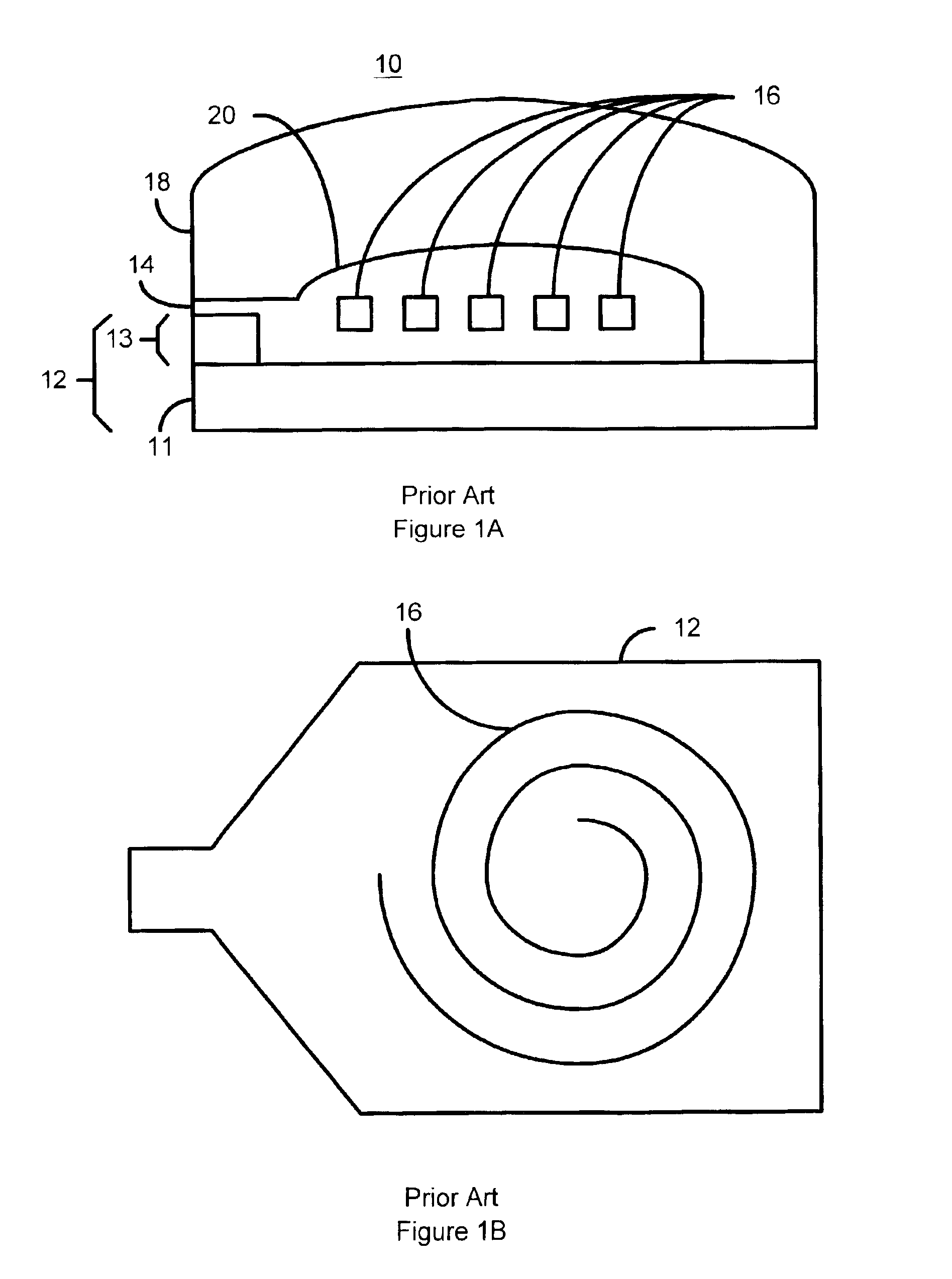

The preferred embodiment of the present invention provides a write head having an interlaced conductor coil winding and method of fabrication. The interlaced winding of the present invention may have alternating turns of a first and a second coil. In the preferred embodiment, the side walls of successive coil turns are separated by an ultra thin inorganic insulation which defines the distance between successive turns of the first and second coil. In one method of fabrication, a conductive seed layer is deposited on a generally planar insulative surface, a resist mask is formed on the seed layer, and a conductive material deposited on the exposed seed layer to form the turns of the first coil. The masked portions of the seed layer are removed, after resist mask removal, to electrically isolate the turns of the first coil. The inorganic insulation may be formed in a layer conformal with the first coil. The second coil is formed between the turns of the first coil. A seed layer and mask may be used to facilitate second coil deposition. Etching, or planarization, may be used to electrically isolate the turns of the second coil. A capping layer may be formed over any exposed conductor material to insulate the winding from an upper pole structure or other overlying structure. Embodiments of the present invention may have multiple layers of conductor winding having some conventional, or all interlaced coil structure.

Owner:WESTERN DIGITAL TECH INC

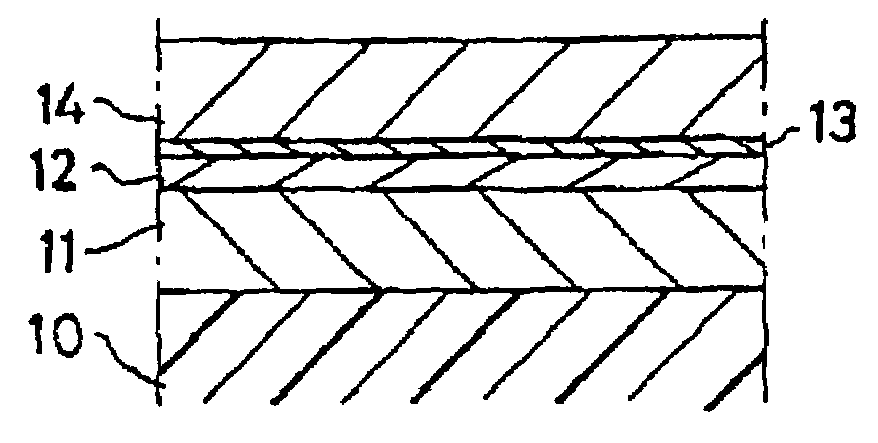

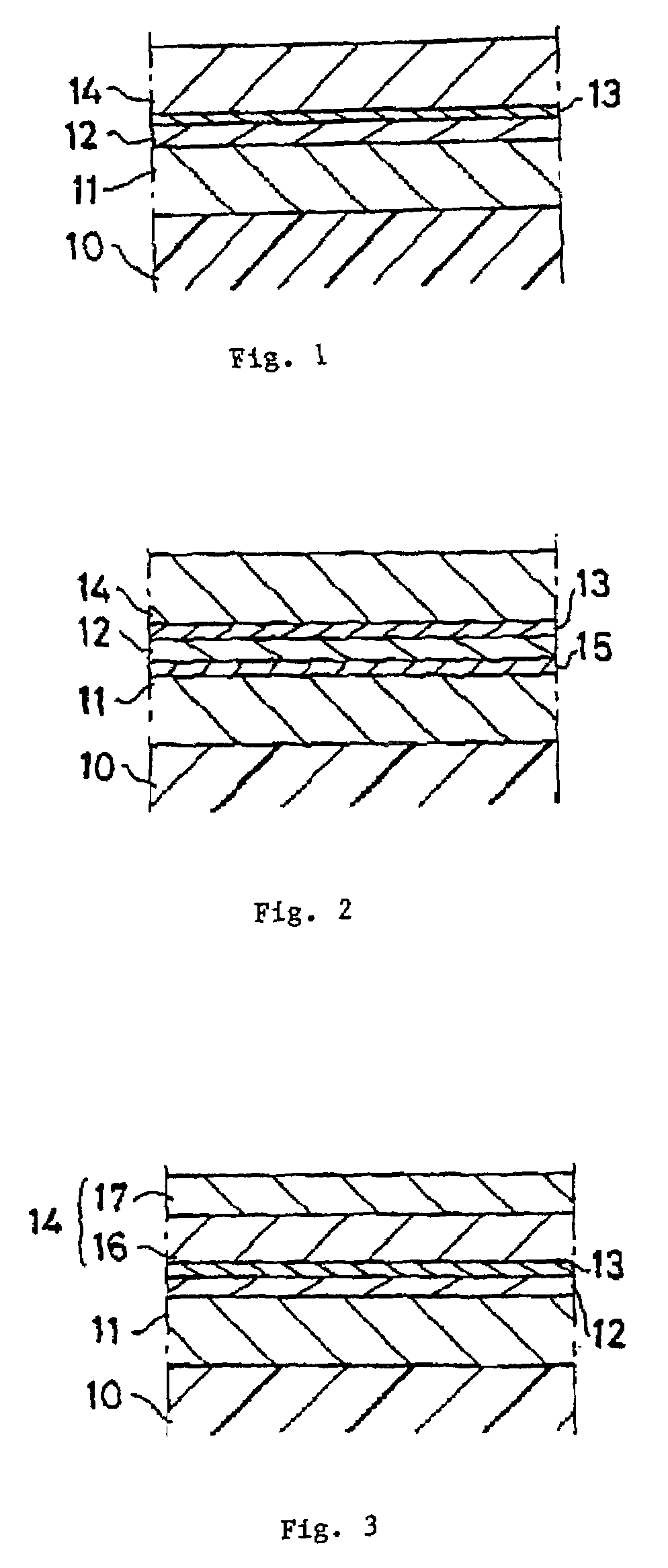

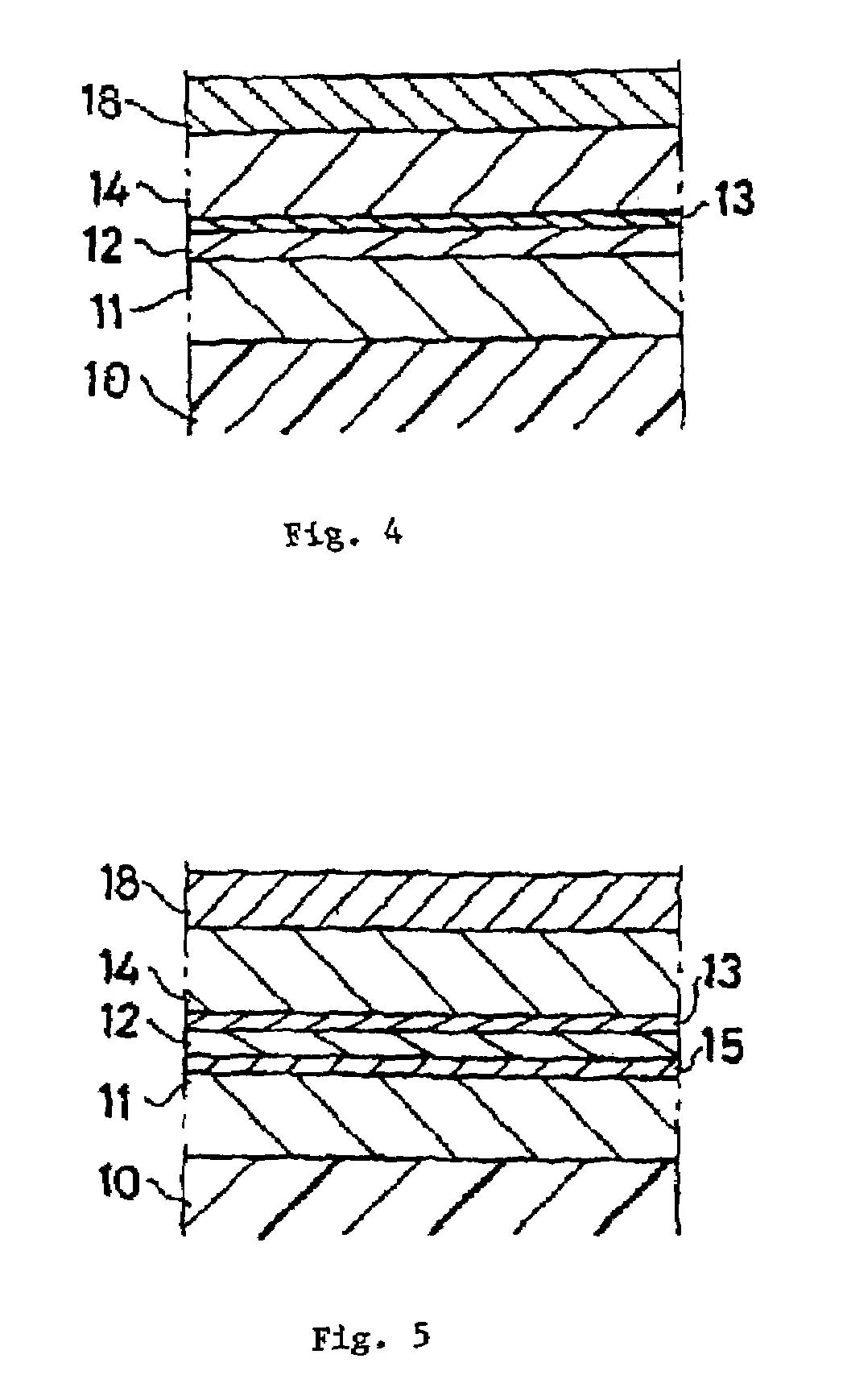

Thin film write head with improved laminated flux carrying structure and method of fabrication

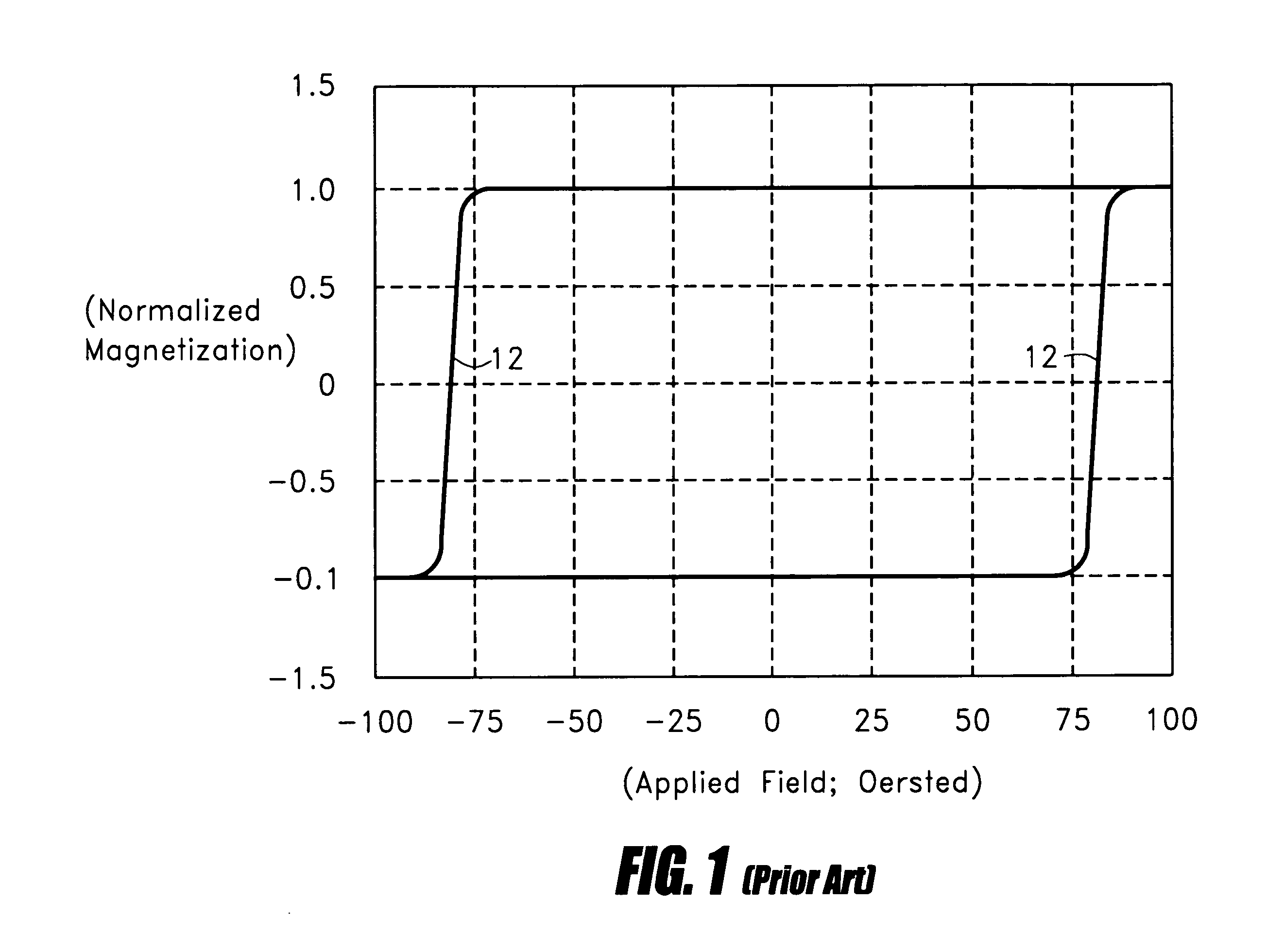

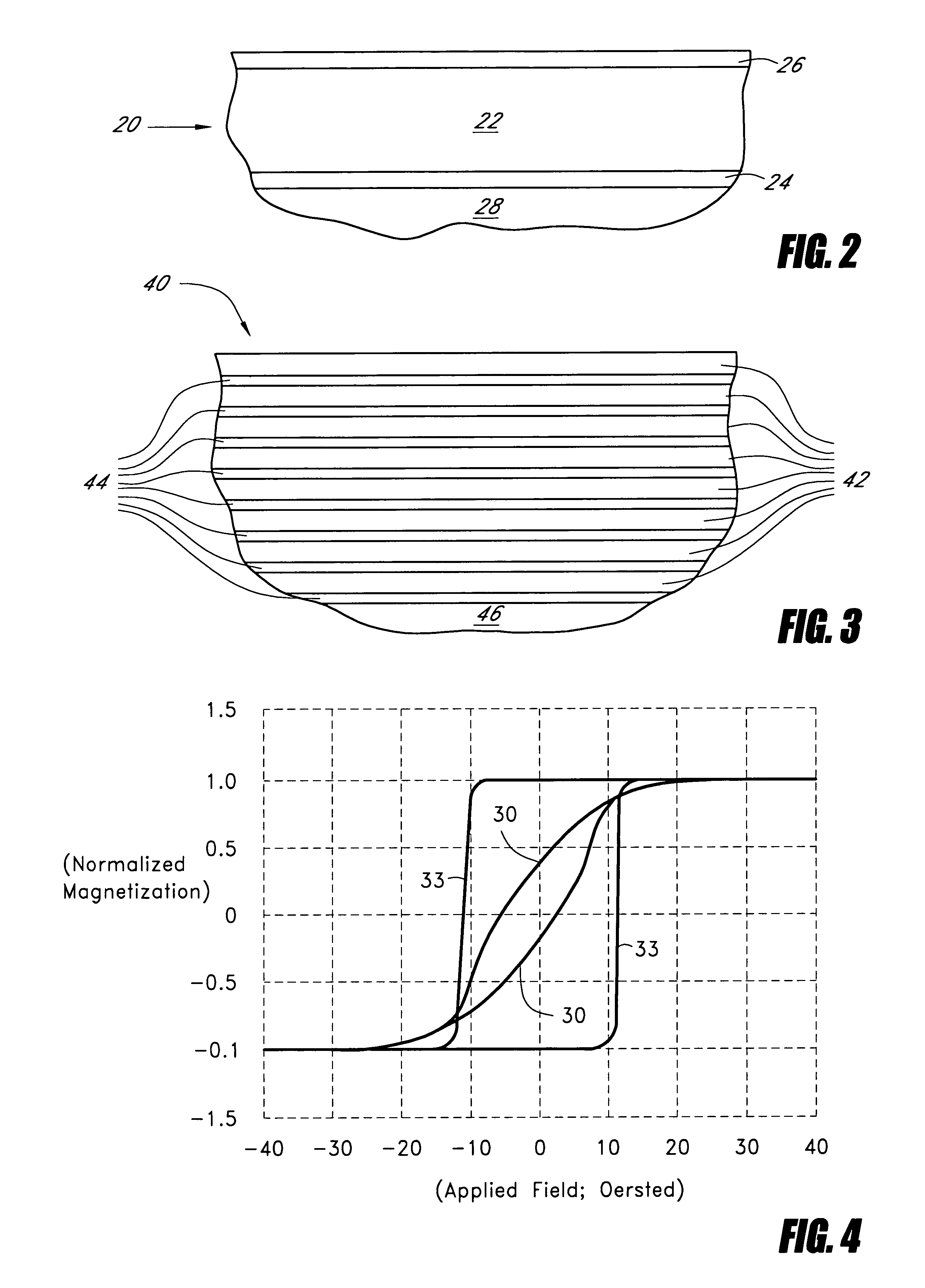

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

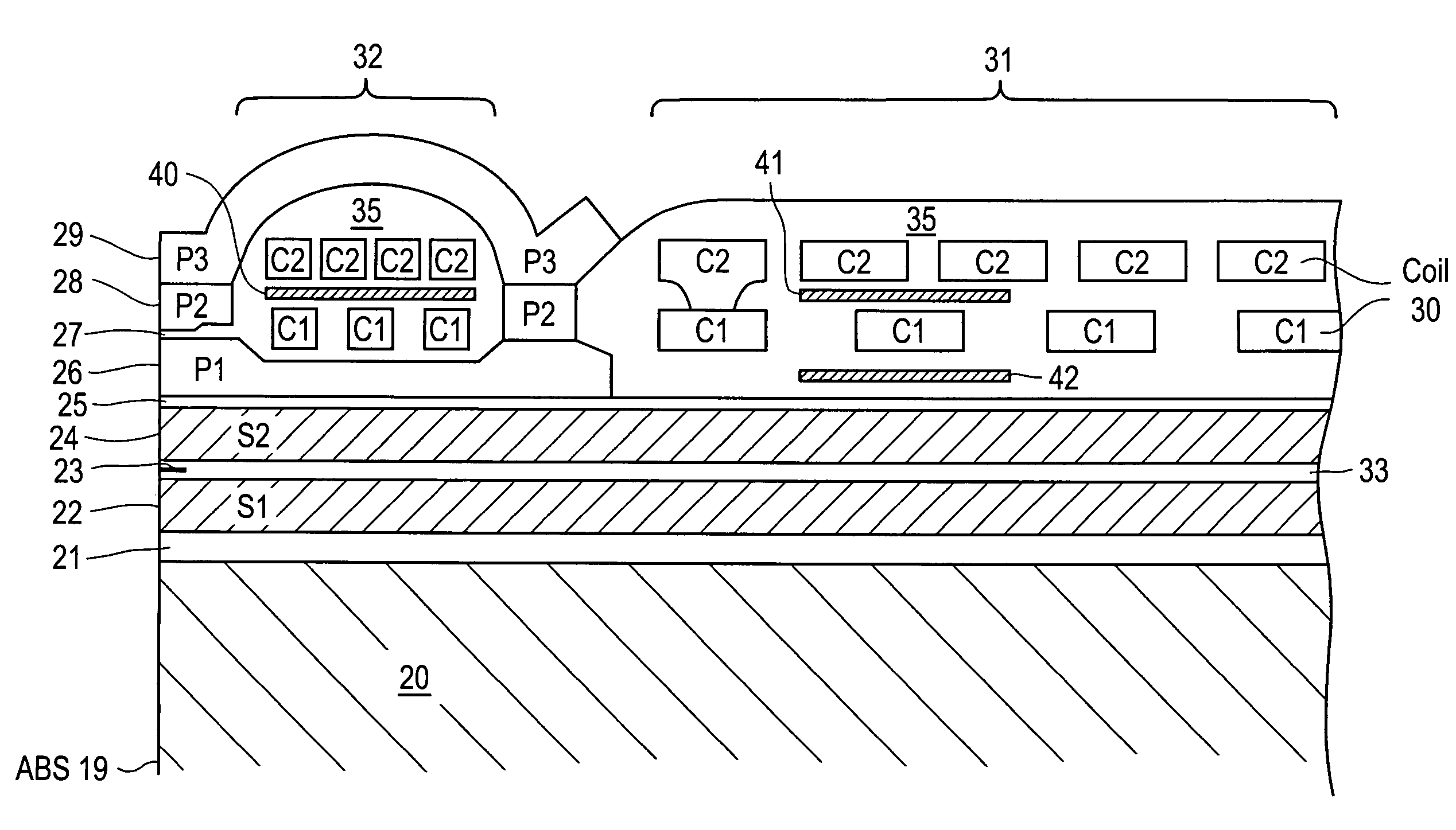

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

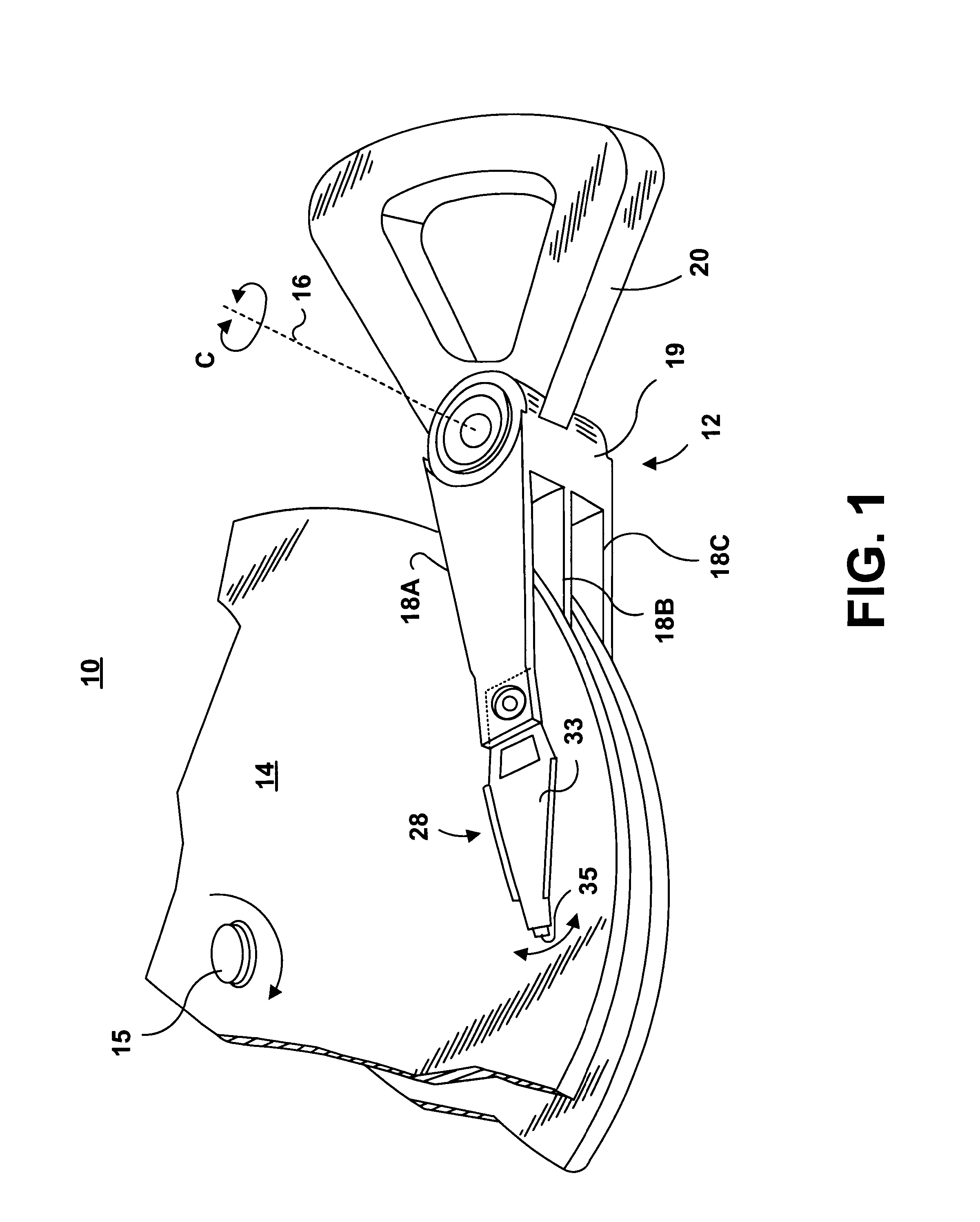

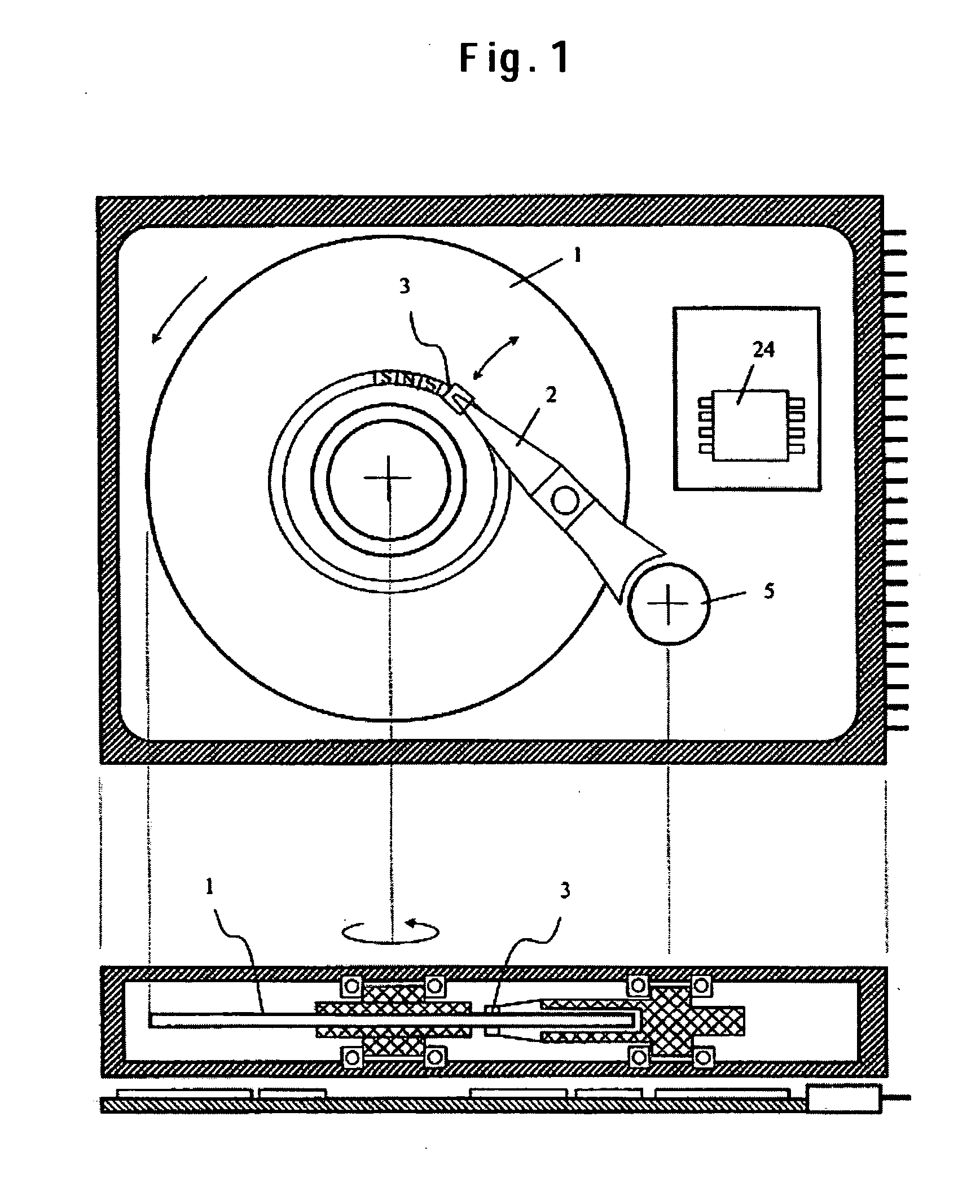

Magnetic recording head with resistive heating element located near the write coil

InactiveUS7372665B1Disposition/mounting of recording headsRecord information storageTransducerTrailing edge

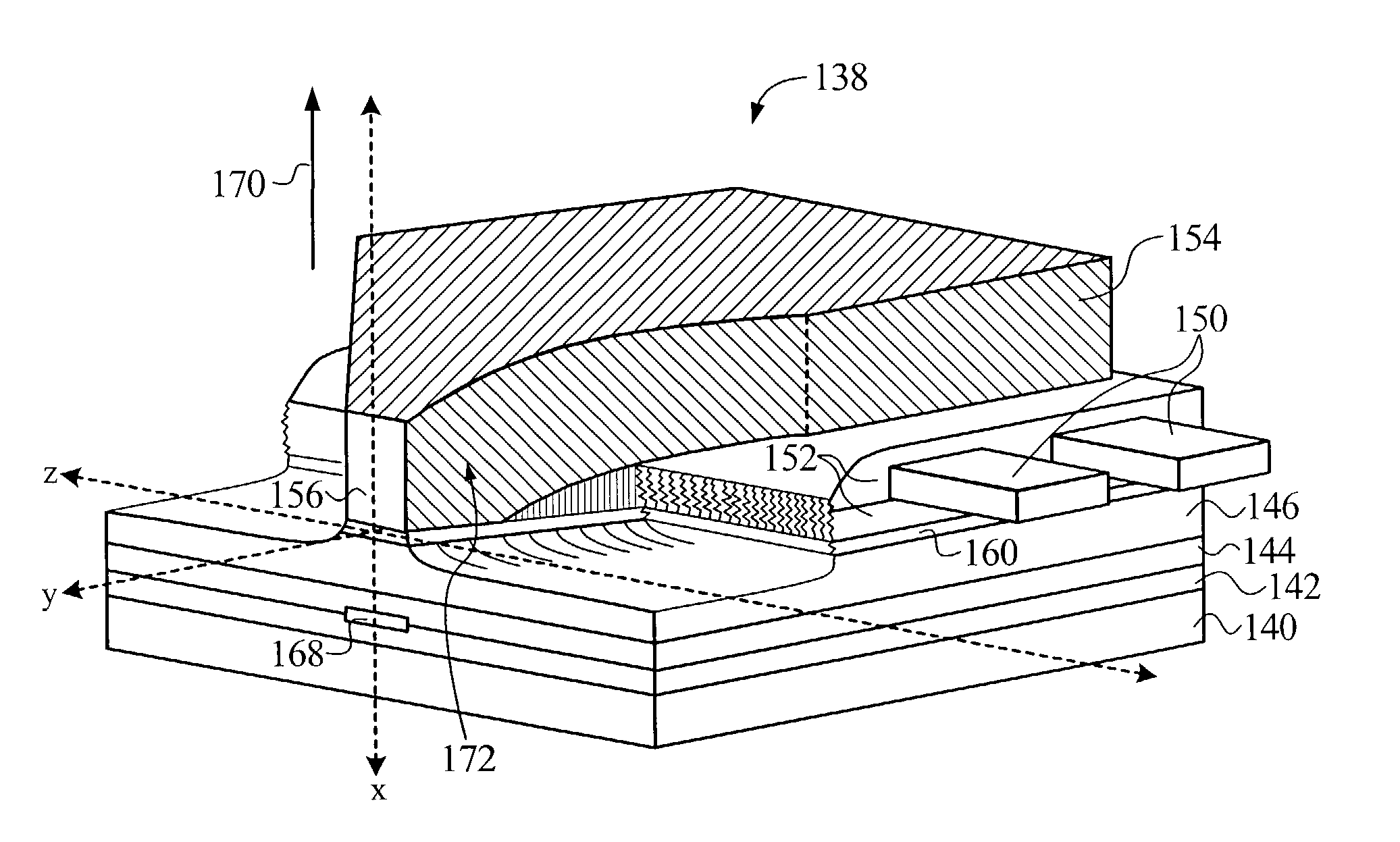

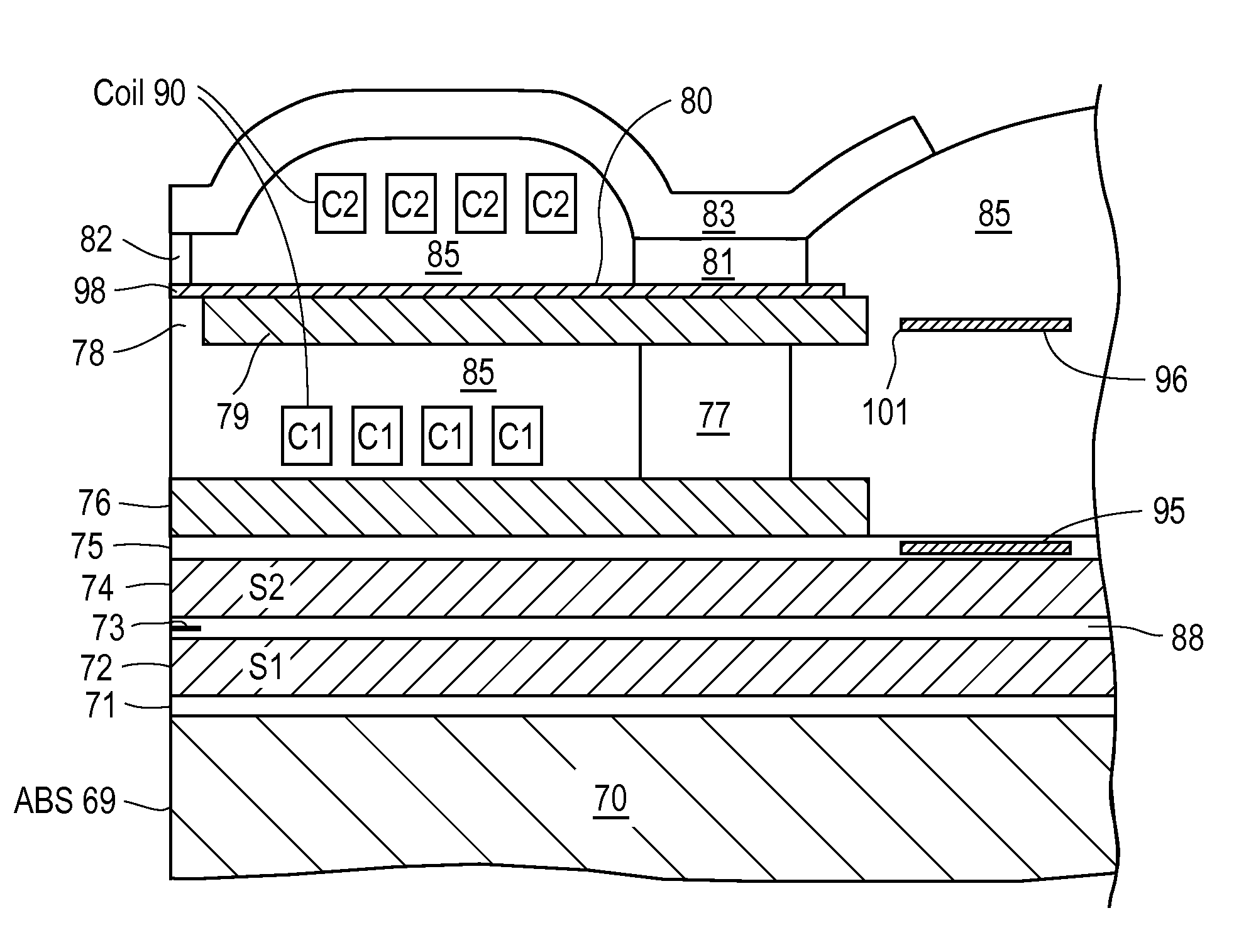

A magnetic head includes a slider body having a trailing surface meeting an air-bearing surface at a trailing edge, with a thin-film transducer disposed on the trailing surface of the slider body near the trailing edge. The thin-film transducer includes a coil embedded between first and second poles. A resistive heating element is disposed adjacent and electrically insulated from, the coil. Application of power to the resistive heating element causes expansion of at least the first and second poles.

Owner:WESTERN DIGITAL TECH INC

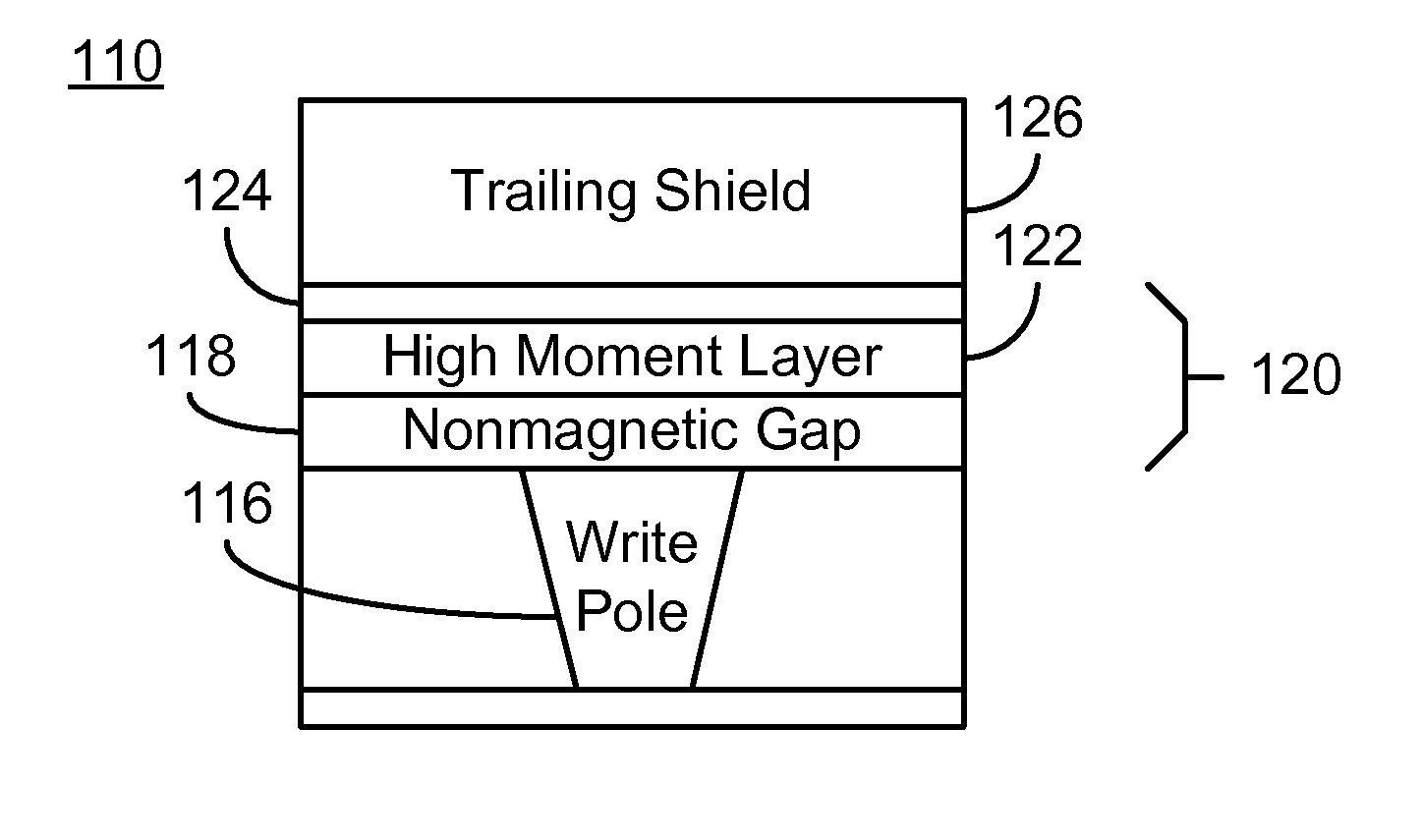

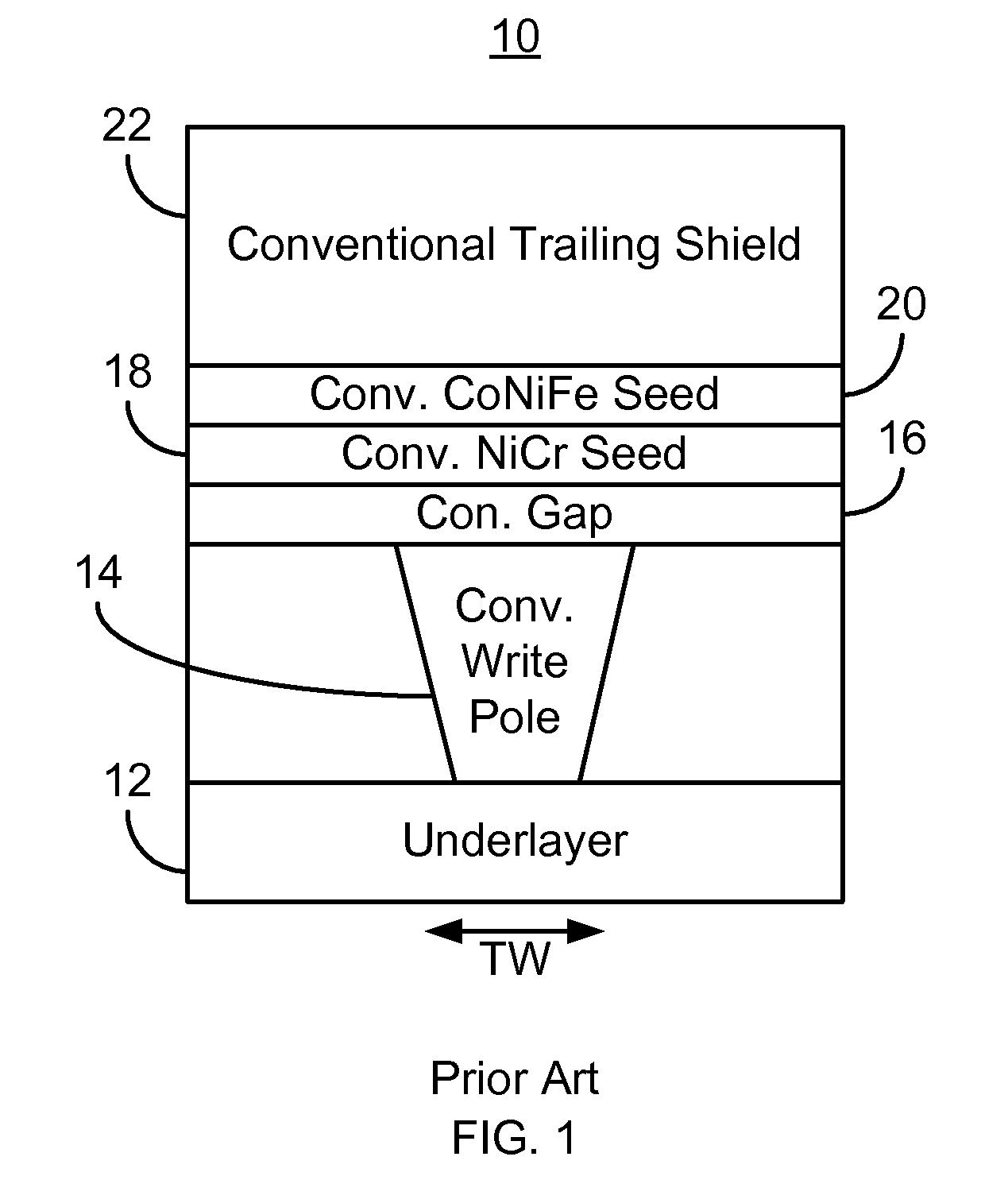

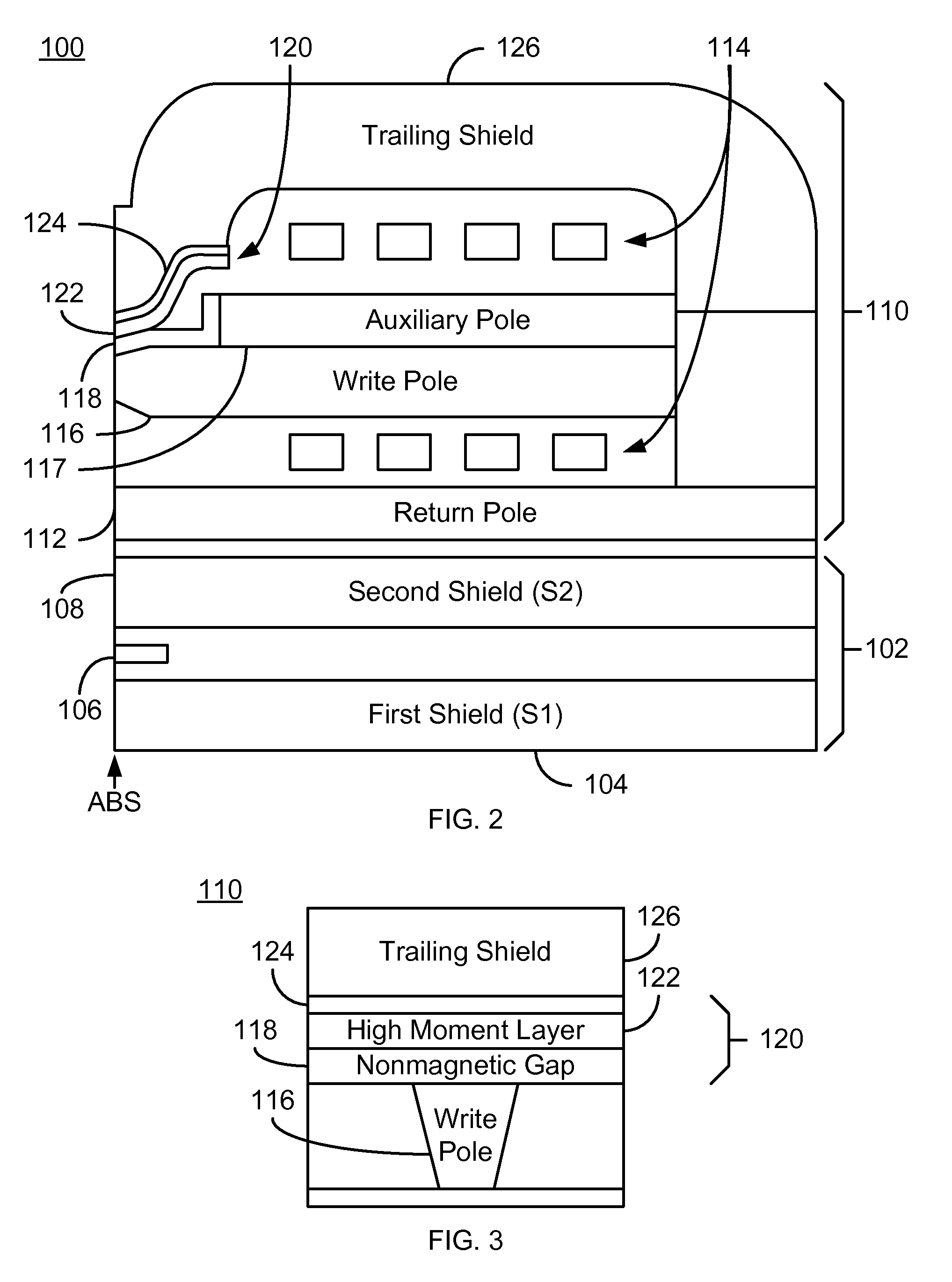

Method and system for providing a magnetic transducer having a high moment bilayer magnetic seed layer for a trailing shield

ActiveUS8582241B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersMagnetization

A method and system for providing a magnetic read transducer is described. The magnetic recording transducer includes a write pole, a nonmagnetic gap, a magnetic seed layer, a trailing shield and coil(s) that energize the write pole. The write pole is configured to write to a media. The nonmagnetic gap is between the write pole and the magnetic seed layer. The magnetic seed layer includes a high moment layer and a magnetic buffer layer. The high moment layer is between the nonmagnetic gap and the magnetic buffer layer. The high moment layer has a saturation magnetization greater than 2.3 T and a first corrosion potential. The magnetic buffer layer has a second corrosion potential less than the first corrosion potential. The magnetic seed layer is between the trailing shield and the nonmagnetic gap layer. The magnetic buffer layer is between the trailing shield and the high moment layer.

Owner:WESTERN DIGITAL TECH INC

Hybrid diffuser for minimizing thermal pole tip protrusion and reader sensor temperature

InactiveUS6859343B1Reduces reader sensor temperatureImprove thermal conductivityManufacture head surfaceRecord information storageInvarInsulation layer

An enchance recording head design provides conduction and mechanical restraint control in order to minimize the pole tip protrusion and the head temperature resulting from the thermal heating of the magnetic recording head during operation. In one embodiment, the recording head includes a hybrid diffuser formed within an insulation layer, at a predetermined distance from the head write section. The hybrid diffuser is comprised of a thermal conduction layer with high thermal conductivity, such as gold or copper, and a mechanical restraint layer having near zero CTE, such as a 60-80% face-centered-cubic NiFe (Invar) material. The hybrid diffuser is recessed from the ABS to prevent the delamination of the hybrid diffuser due to the otherwise displacement incompatibility between the inner insulating layer and the hybrid diffuser at the ABS.

Owner:WESTERN DIGITAL TECH INC

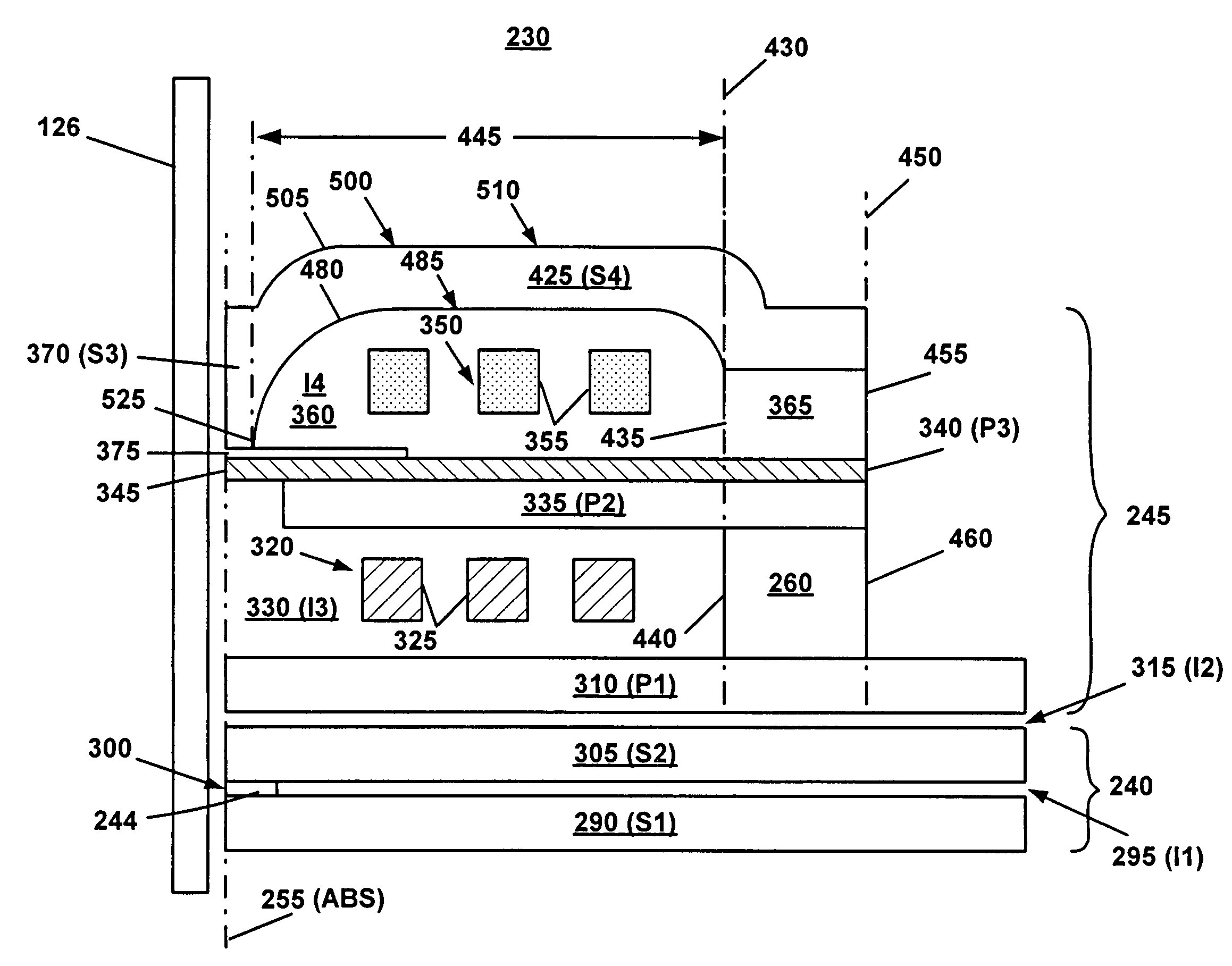

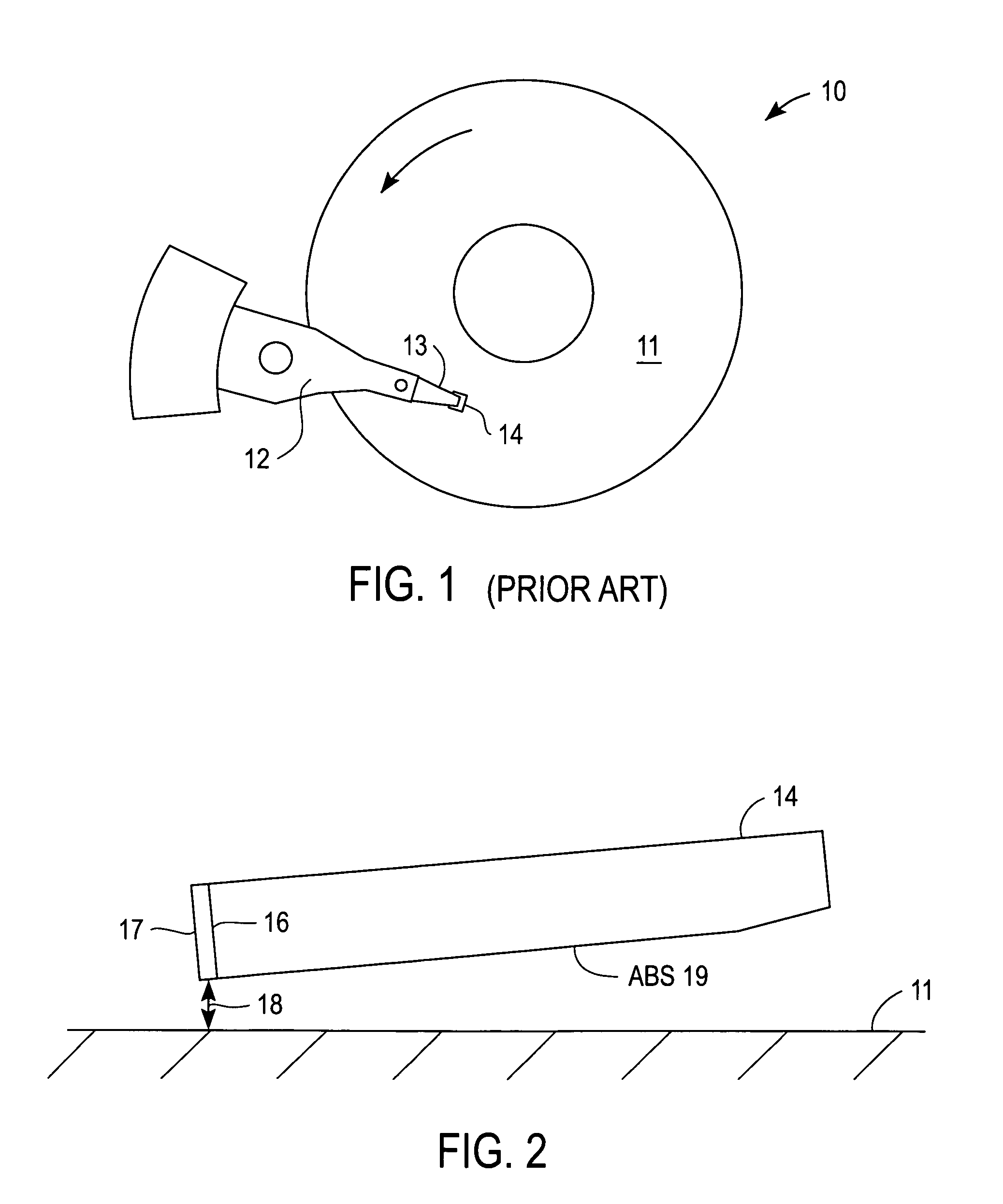

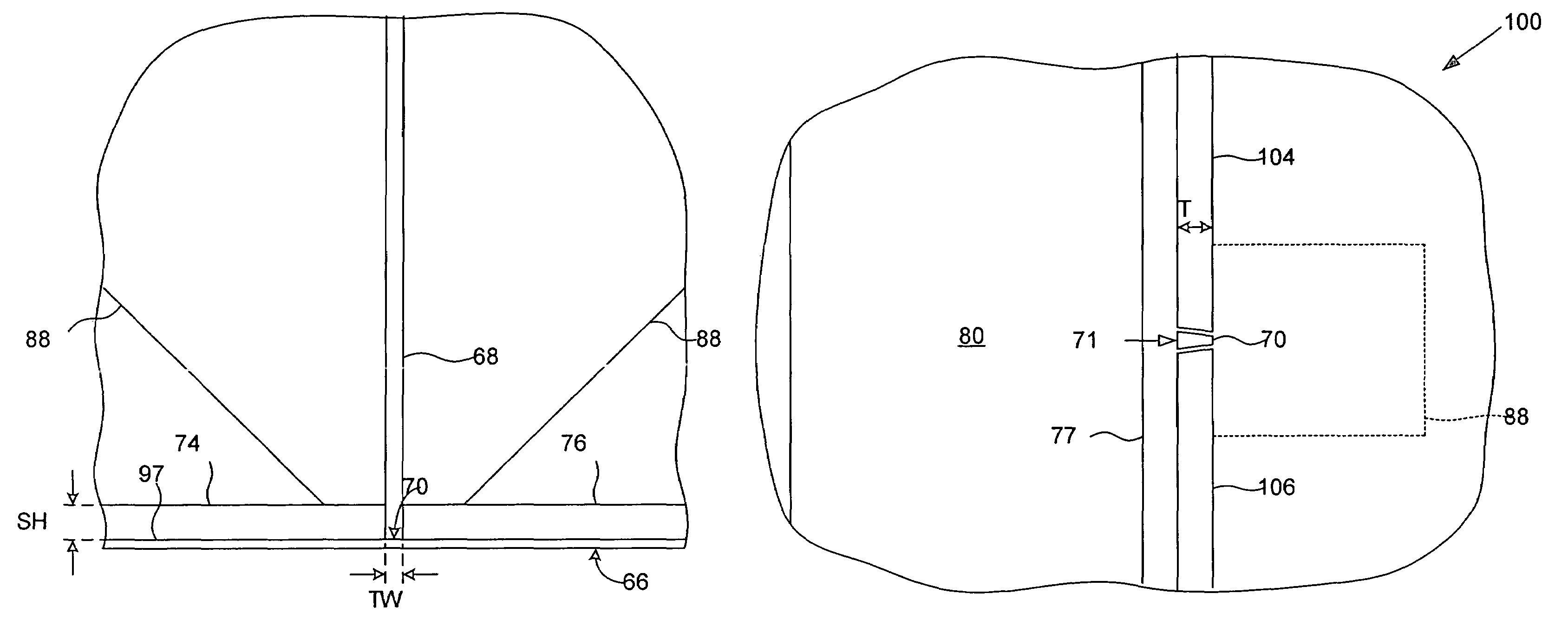

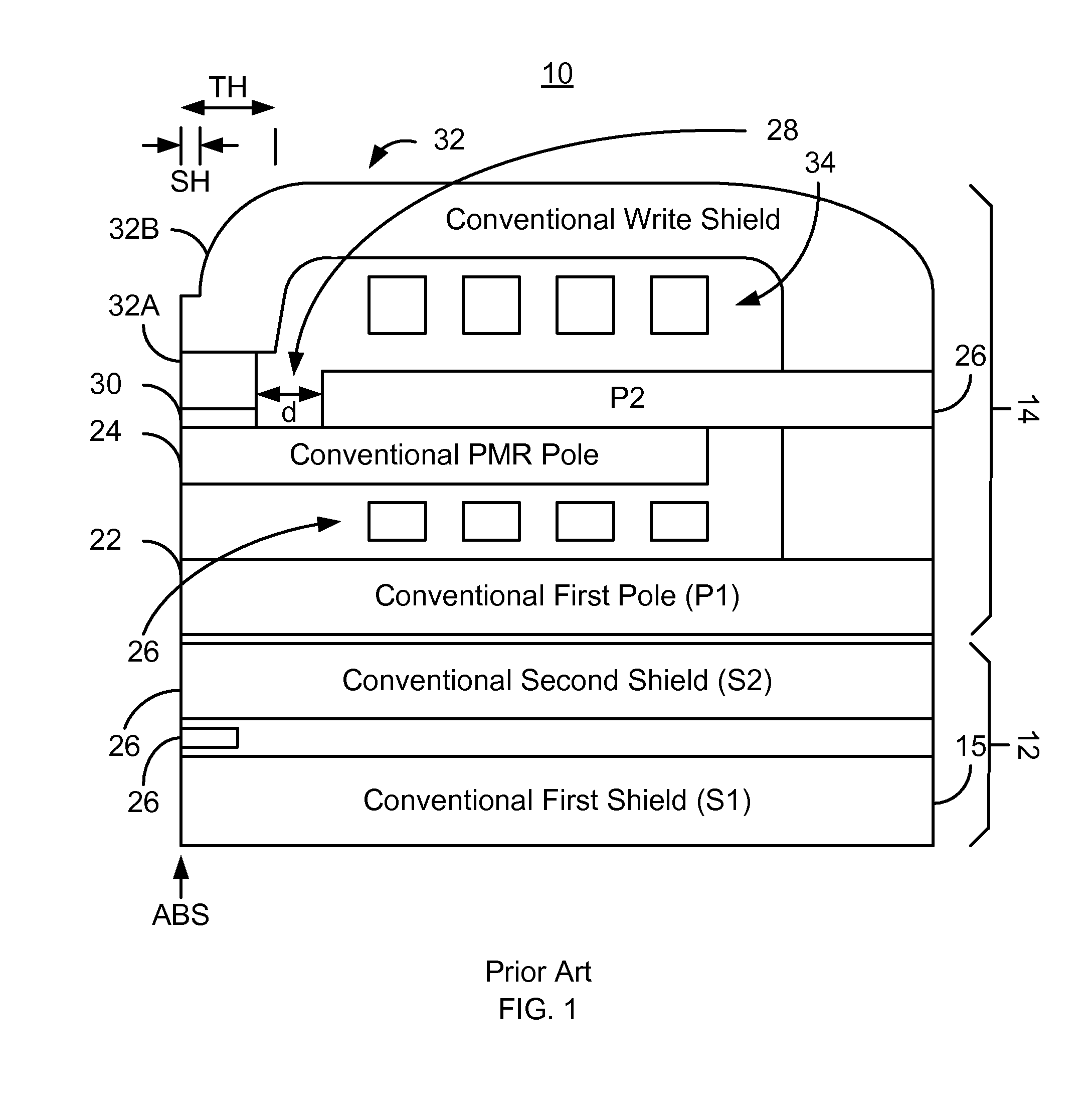

Shielded pole magnetic head for perpendicular recording

A read / write head for use in a perpendicular magnetic recording head in a data storage system. The read / write head includes a write section that is comprised of a first pole layer, a second pole layer, a third pole layer, and a shield layer. The third pole layer defines a write pole tip, and the third pole layer and the shield layer are separated from each other to define a write gap therebetween. At least part of the shield layer has a generally uniform width, and wherein the write pole tip defines a track width that is substantially equal to the uniform width of the shield layer. According to one embodiment the entire shield layer has a generally uniform width that is substantially equal to the track width. According to another embodiment, the shield layer includes a lower section and an upper section, wherein the lower section has a generally uniform width along its entire length, and wherein the upper section is wider than the lower section.

Owner:WESTERN DIGITAL TECH INC

Magnetic recording head with resistive heating element and thermal barrier layer

ActiveUS7428124B1Record information storageProtective measures for recording headsEngineeringTrailing edge

A thin film magnetic head includes a slider body having a trailing surface meeting an air-bearing surface at a trailing edge. A magnetic read and write elements are disposed along the trailing surface near the trailing edge. The magnetic write element includes write poles and a coil. A portion of a heating element is disposed in a first general plane beneath the coil and above the magnetic read element. At least one thermally-insulating layer of material having a thermal conductivity of less than about 2.0 W / m-K extends in a second general plane substantially beneath the heating element.

Owner:WESTERN DIGITAL TECH INC

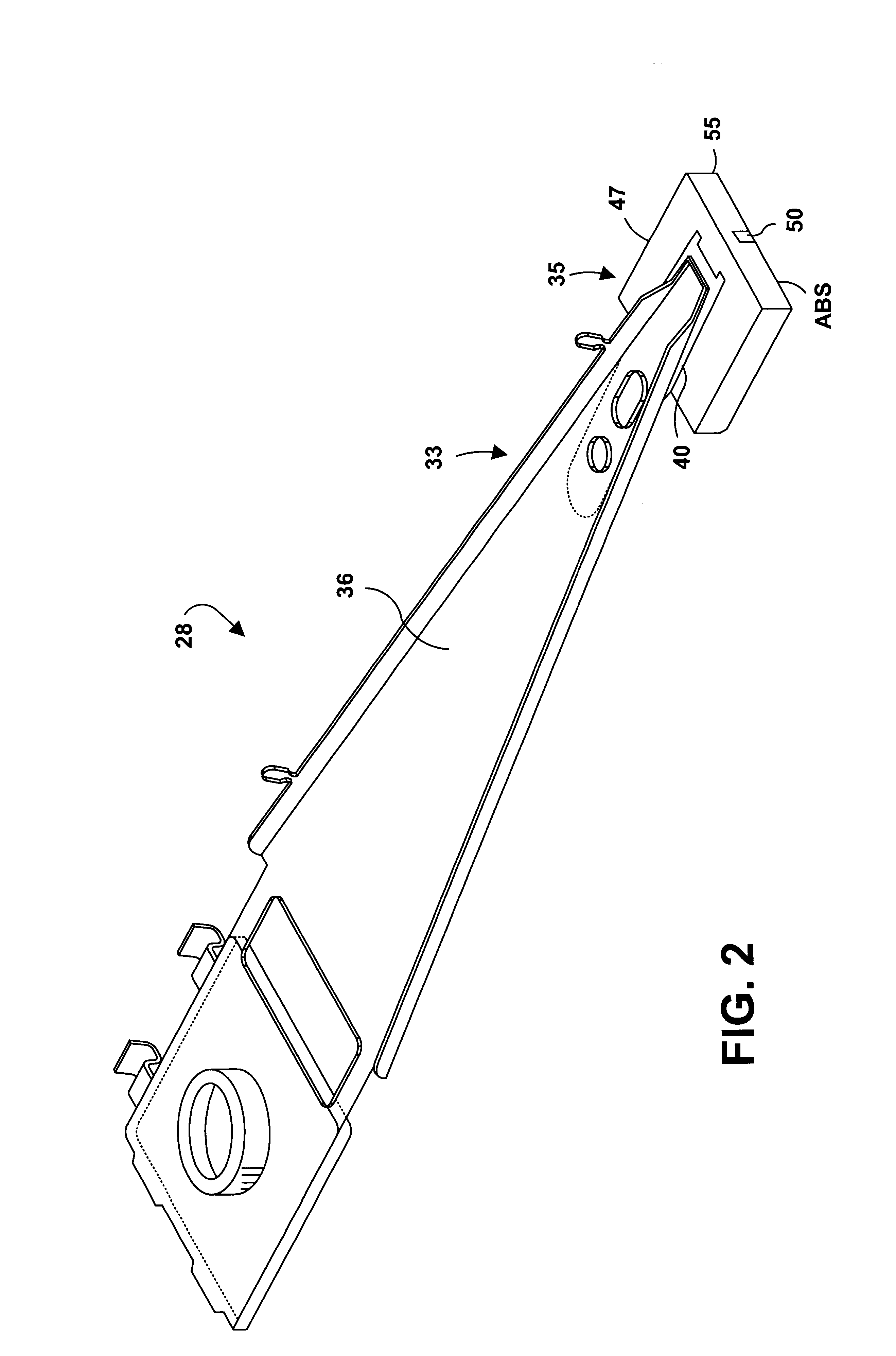

Writer with a hot seed zero throat and substantially flat top pole

InactiveUS6912106B1High-density recordingConstruction of head windingsHeads using thin filmsThroatEngineering

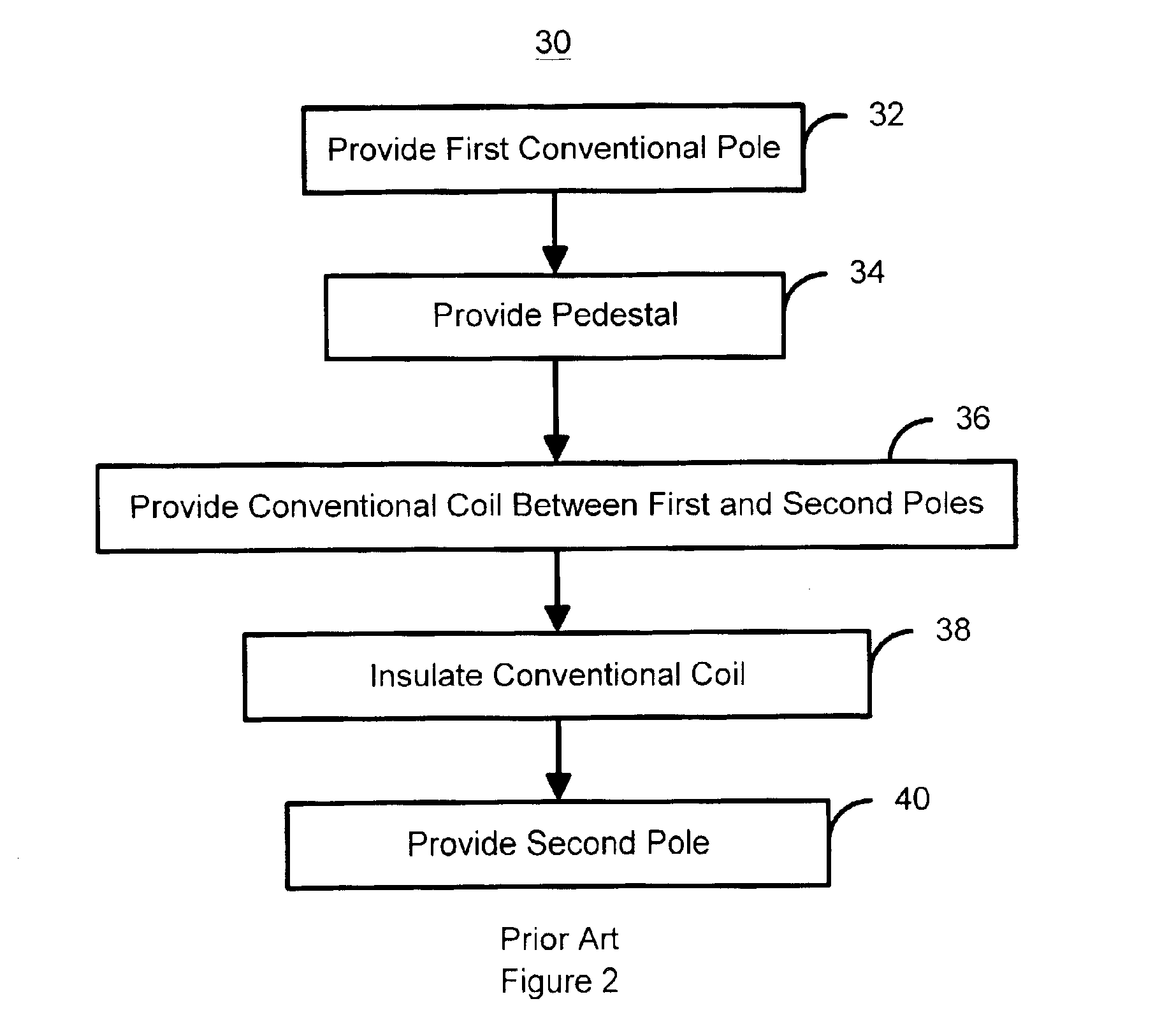

A method and system for providing a recording head is disclosed. The method and system include providing a first pole, a second pole, a write gap and at least one coil. The write cap separates the first pole from the second pole. The coil(s) include a plurality of turns and is between the first and second poles. The first pole includes a pedestal that has a first portion and a second portion. The first portion includes a high moment electroplated material. The second portion includes a hot seed layer that has a high moment sputtered material. The second portion of the first pole is adjacent to the write gap.

Owner:WESTERN DIGITAL TECH INC

Magnetic write head with high moment magnetic thin film formed over seed layer

A magnetic write head includes a seed layer and a magnetic layer on the seed layer. The seed layer includes seed-layer grains having either a face-centered cubic (fcc) crystalline structure with a surface plane substantially oriented in a [111] direction or a hexagonal-close-packed (hcp) crystalline structure with a surface plane substantially oriented in a [0001] direction. The magnetic layer includes magnetic-layer grains having a body-centered-cubic (bcc) crystalline structure with a surface plane substantially oriented in a [110] direction.

Owner:WESTERN DIGITAL TECH INC

Method for manufacturing a shielded pole magnetic head for perpendicular recording

ActiveUS7337530B1Electrical transducersHeads using thin filmsEngineeringElectrical and Electronics engineering

A method of making a perpendicular magnetic recording head for use in a data storage device includes forming a first pole layer, a second pole layer, a third pole layer, and a shield layer of a write section. The first pole layer, second pole layer, third pole layer, and shield layer are formed without using a chemical mechanical polishing process. The method next includes concurrently trimming the shield layer and a write pole that is defined by the third pole layer to a predetermined track width. In the trimming step, the shield layer is used as a mask for the write pole.

Owner:WESTERN DIGITAL TECH INC

Pole tip with sides flared at media-facing surface

InactiveUS7133253B1Record information storageHeads for perpendicular magnetisationsTransducerEngineering

A thin film electromagnetic head has an inductive transducer with a ferromagnetic pole layer terminating adjacent a media-facing surface at a pole tip surface. The pole layer has side surfaces each having an end region that meets the pole tip surface, the end regions increasingly separated with increasing distance from the pole tip surface. Having a pole layer that is tapered to the point at which it meets the pole tip surface channels flux more efficiently for writing on-track as opposed to off-track. Such a tapered pole tip can be formed for a pair of pole layers separated by a submicron nonferromagnetic gap, or for a single perpendicular writing pole layer.

Owner:WESTERN DIGITAL TECH INC

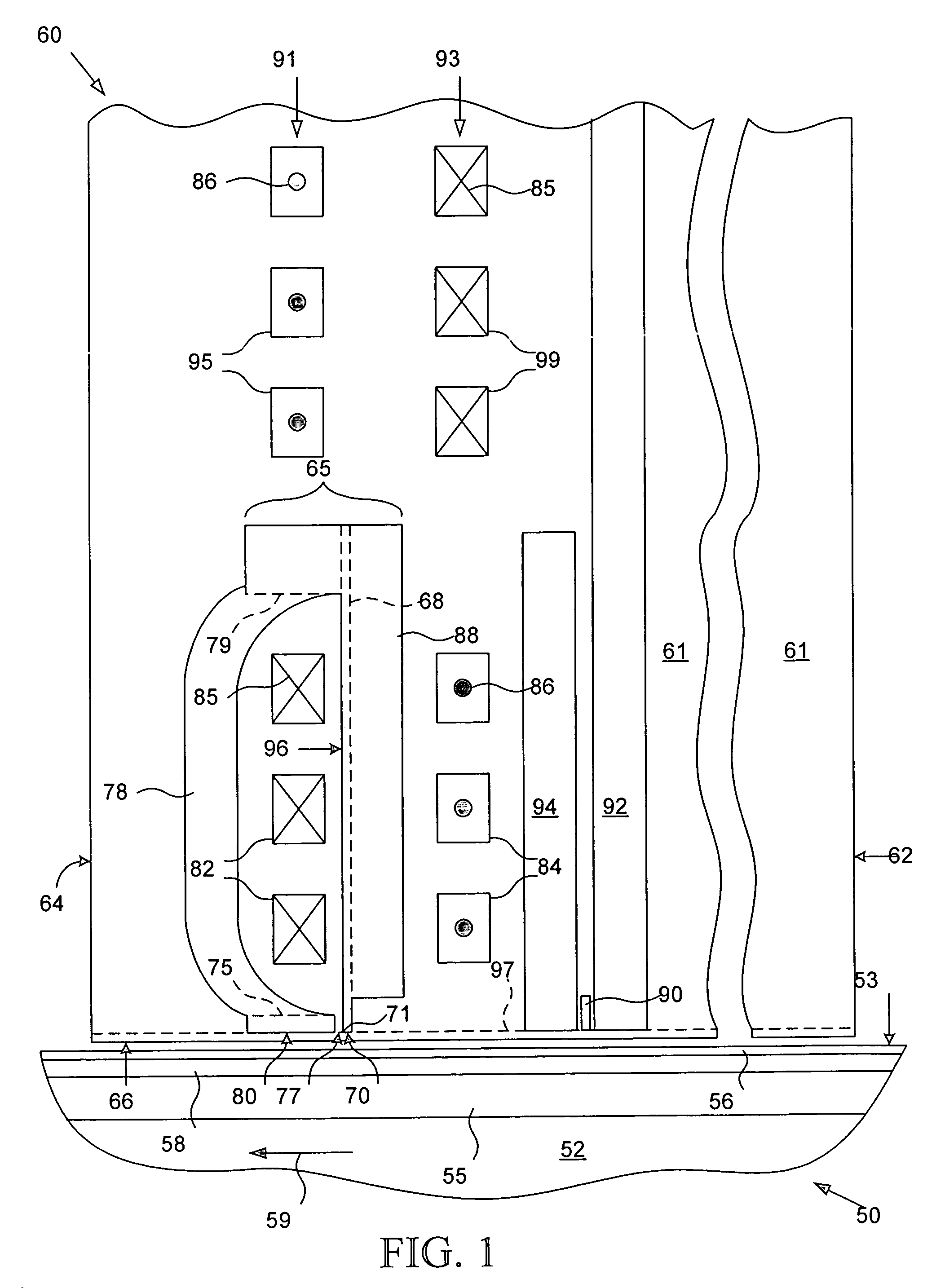

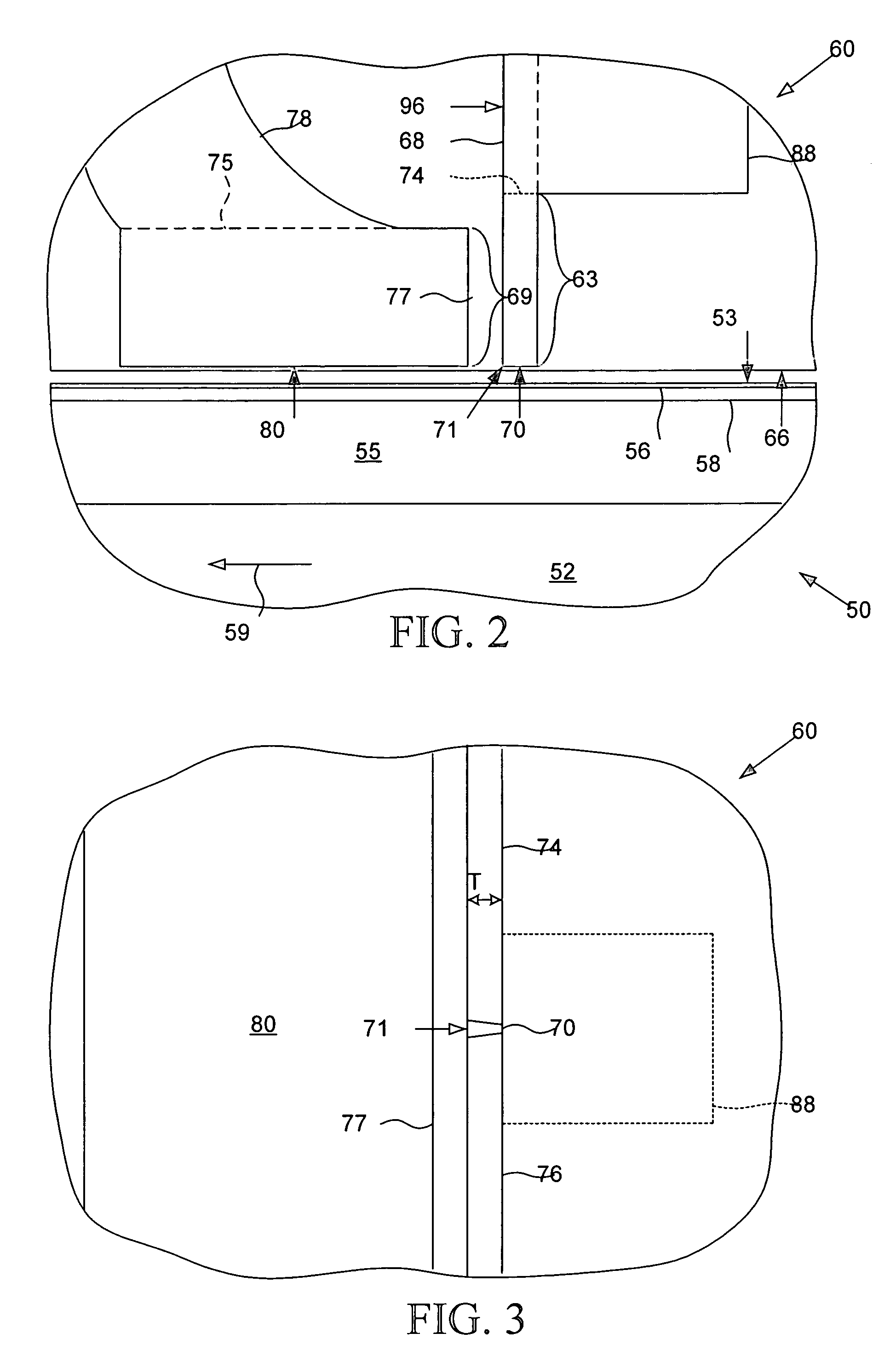

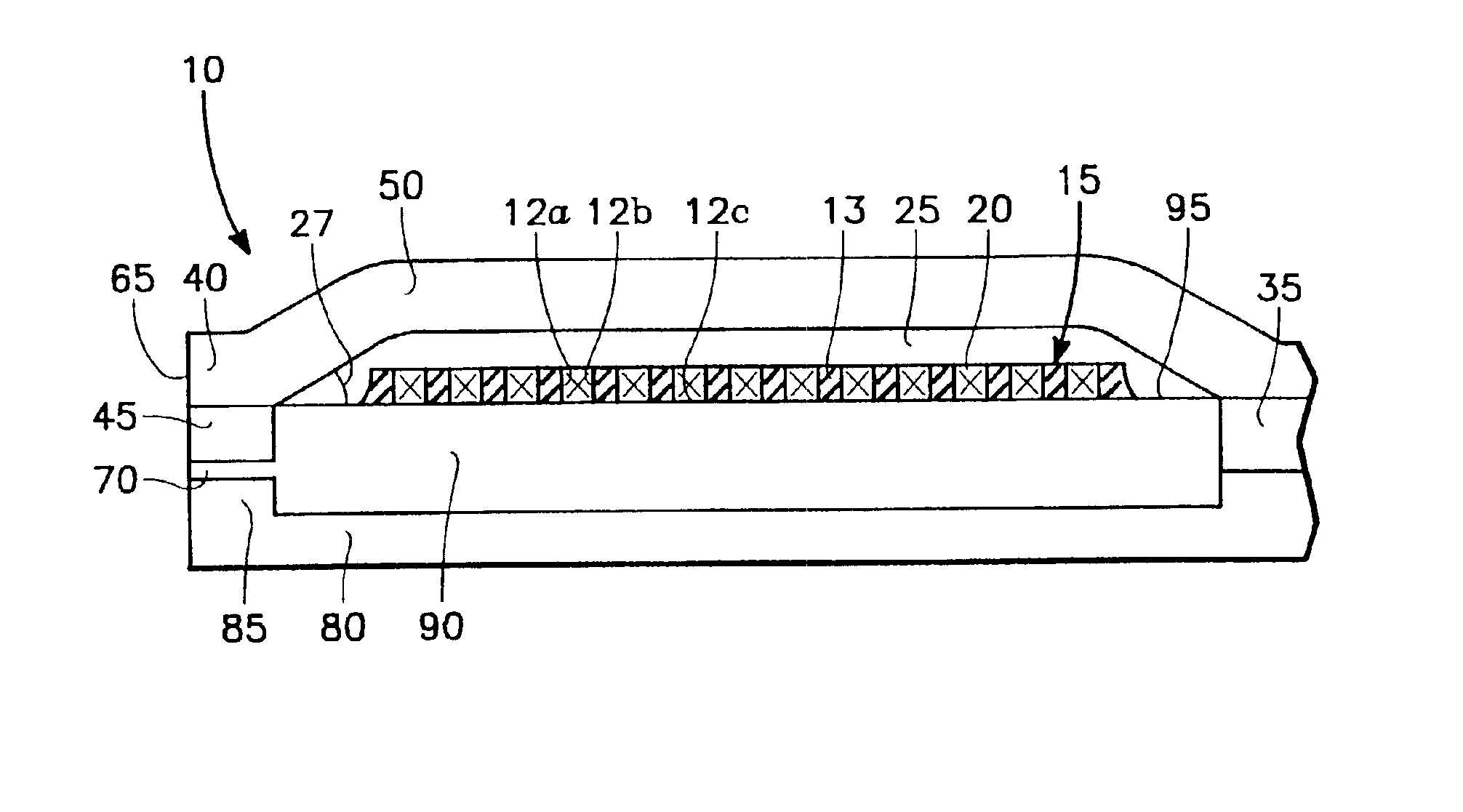

Inductive writer with flat top pole and pedestal defined zero throat

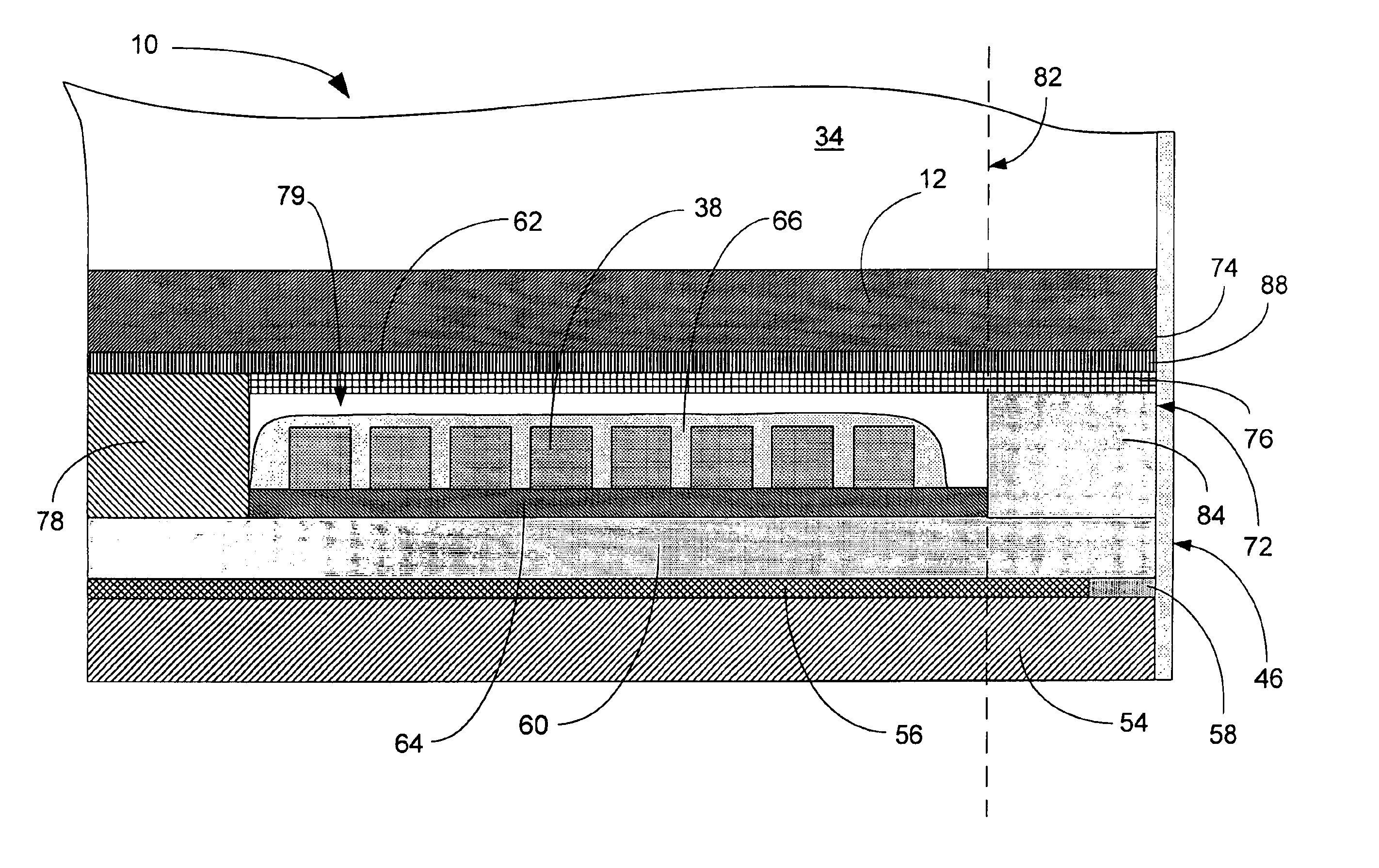

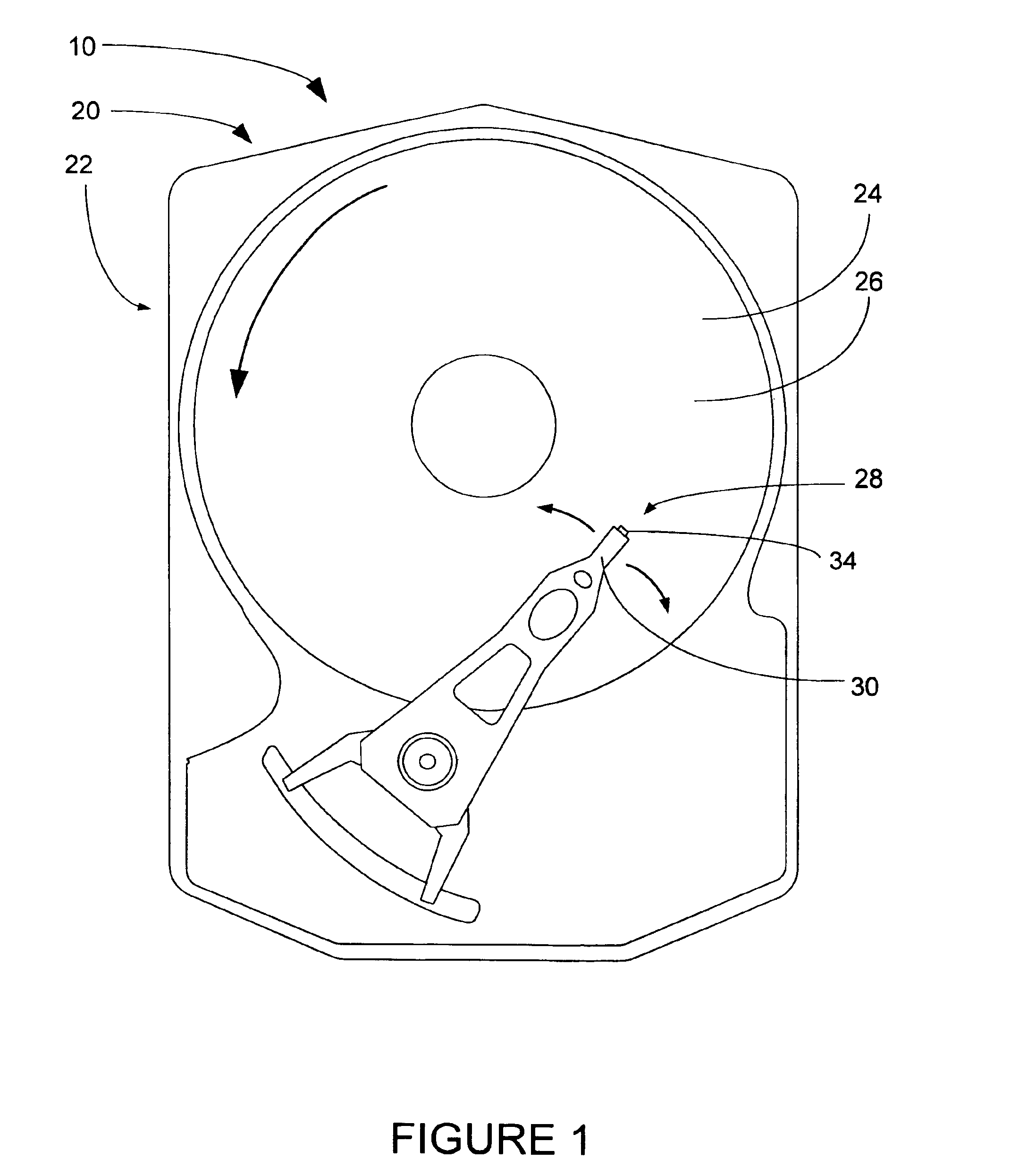

InactiveUS6870712B2Critical dimensions are more easily controlledEasy to controlElectrical transducersHeads using thin filmsEngineeringElectrical and Electronics engineering

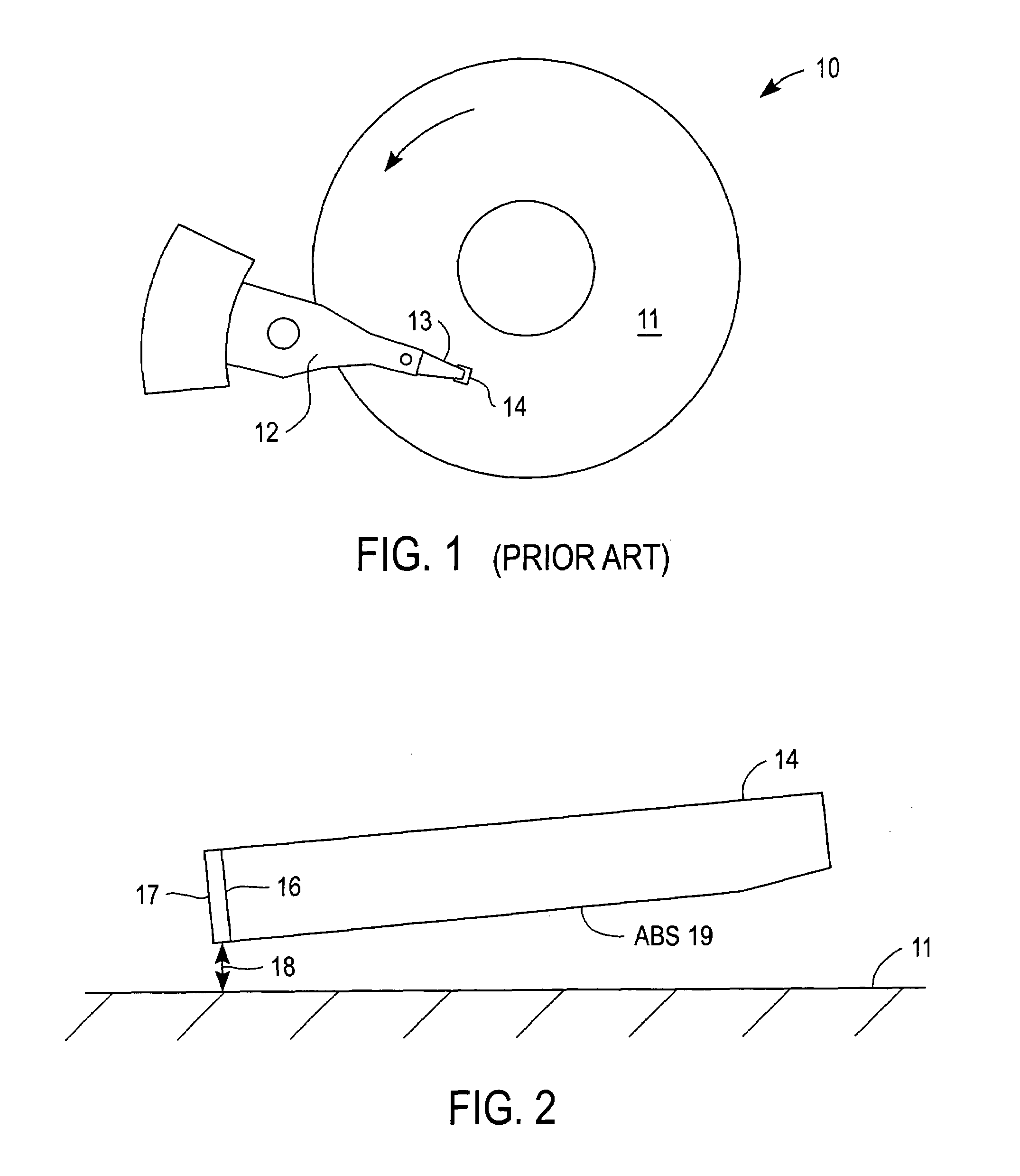

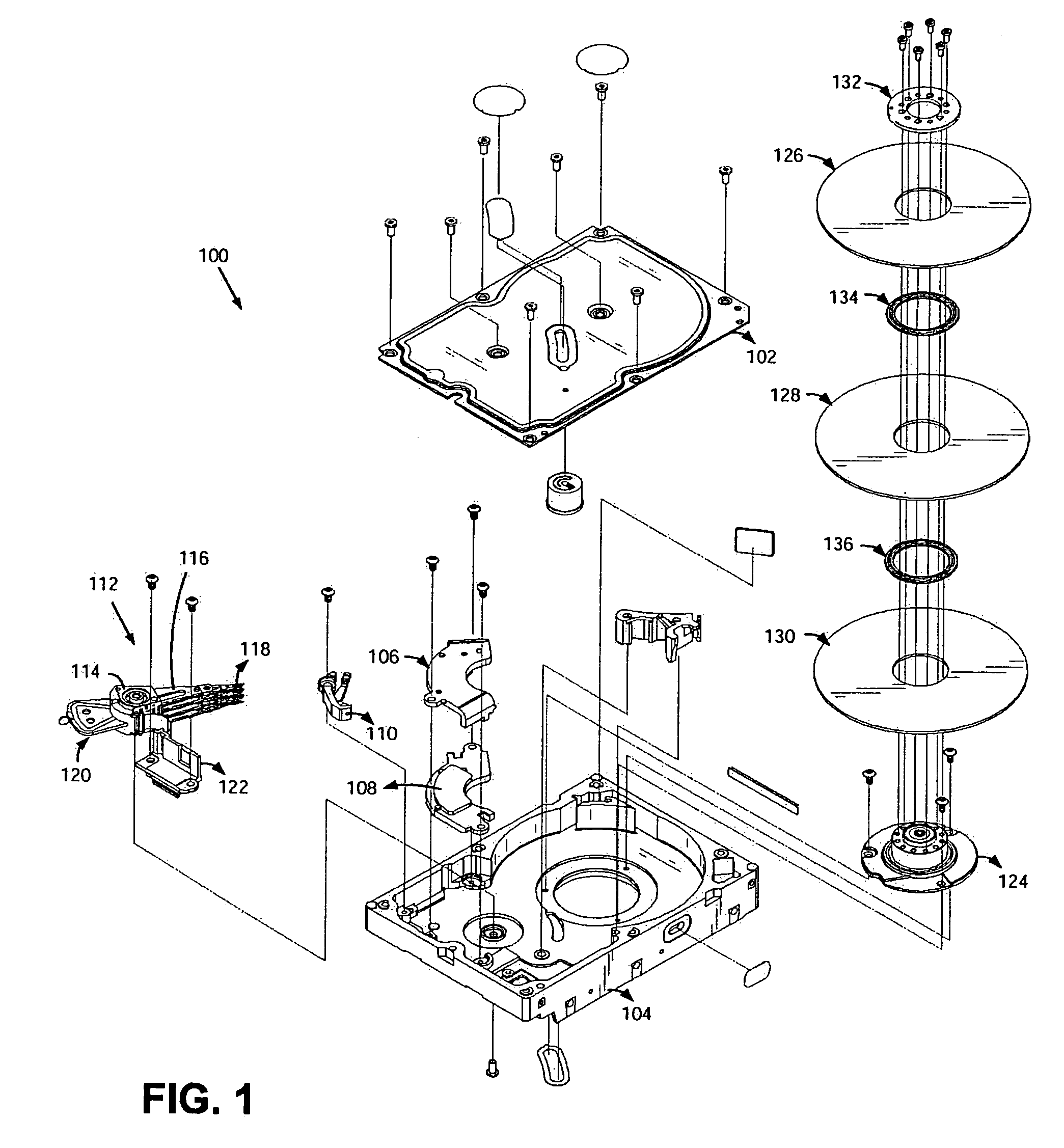

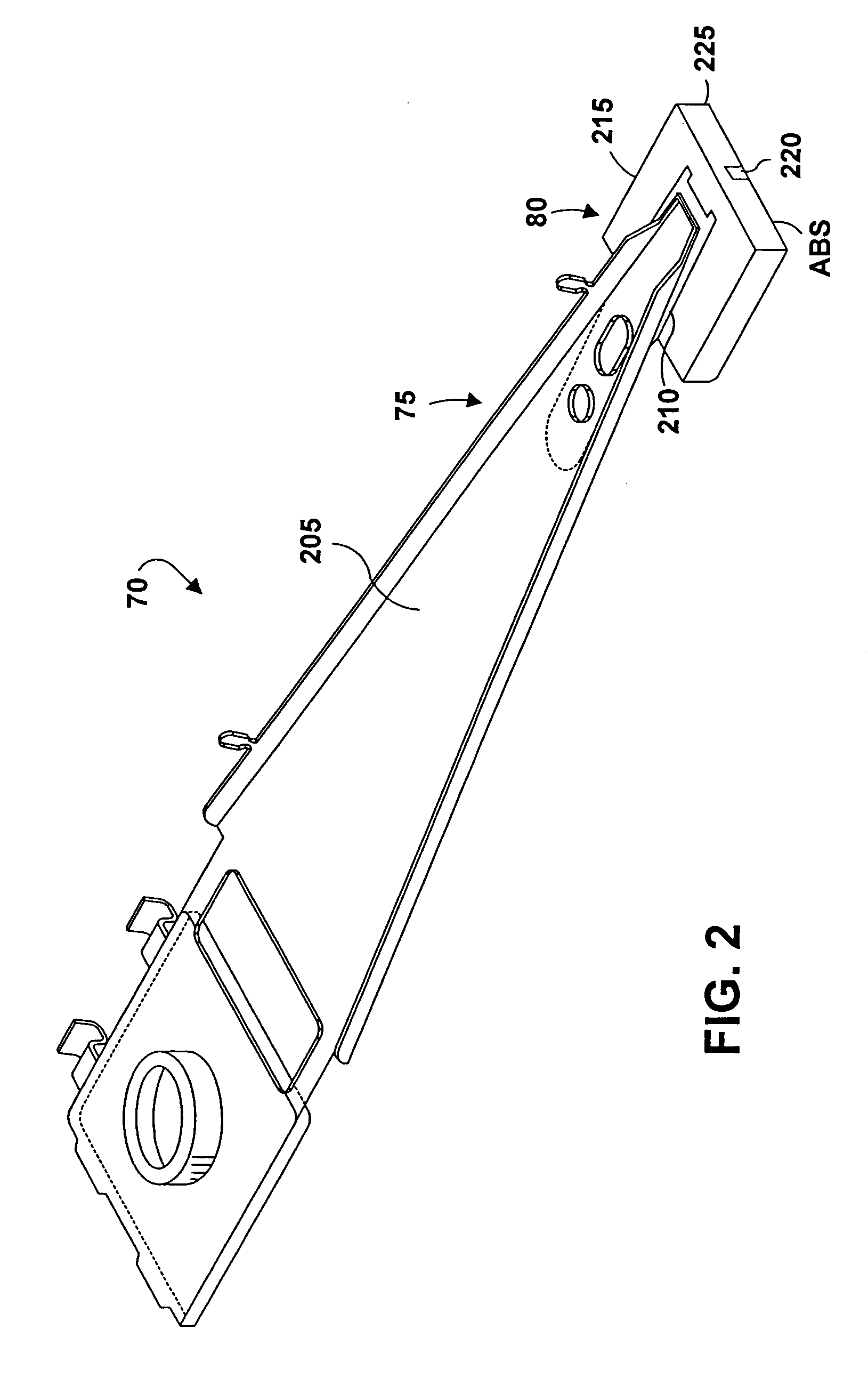

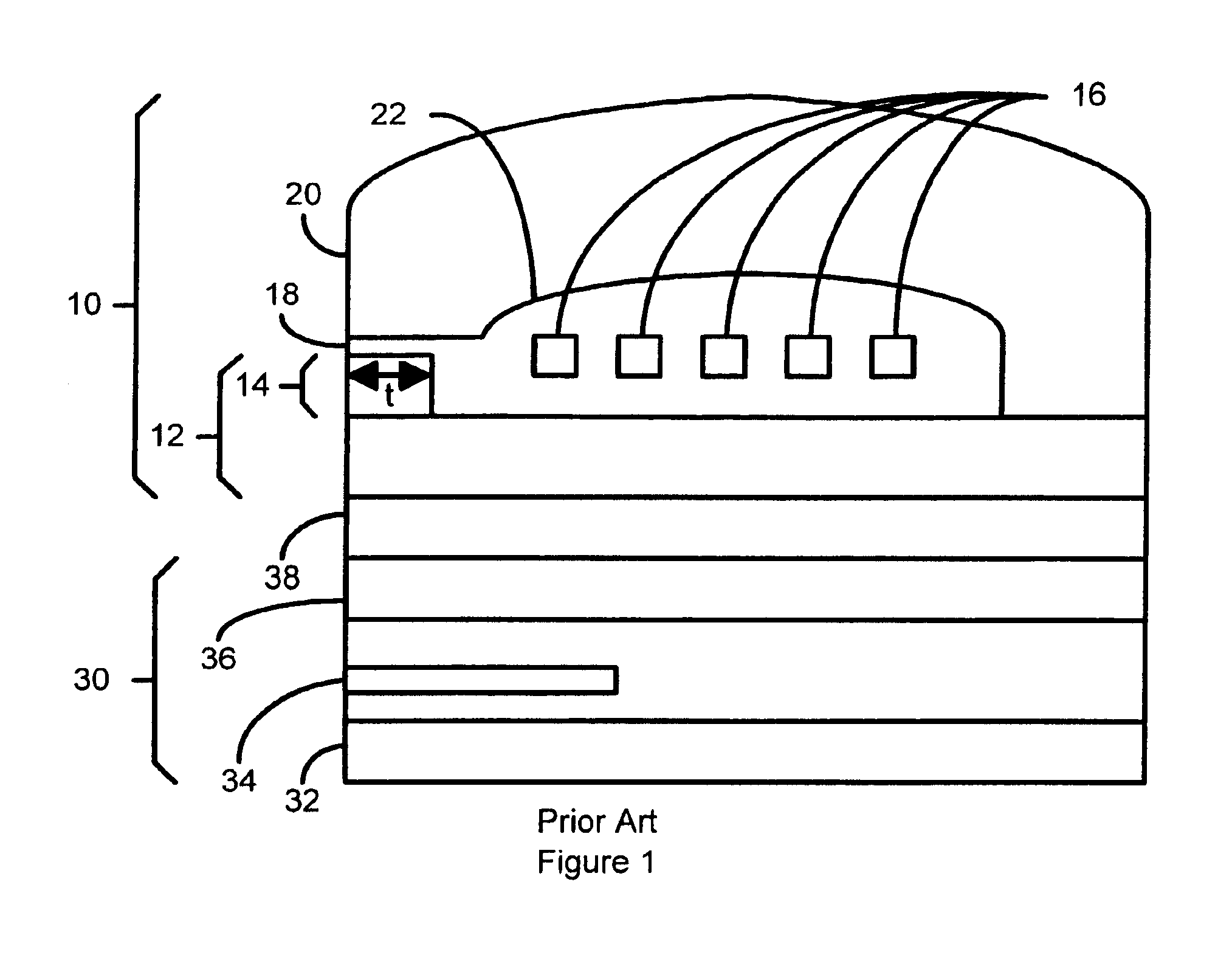

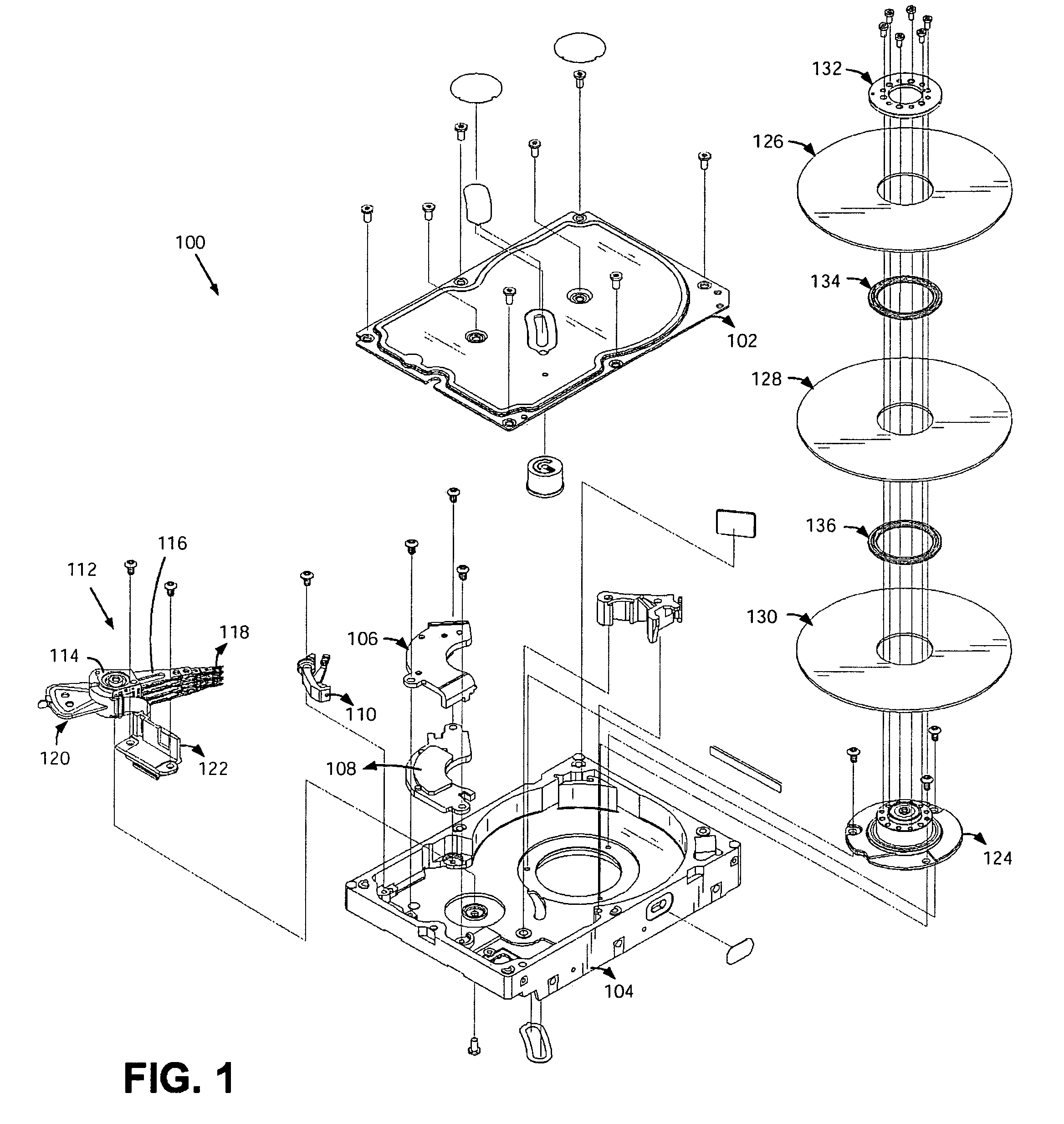

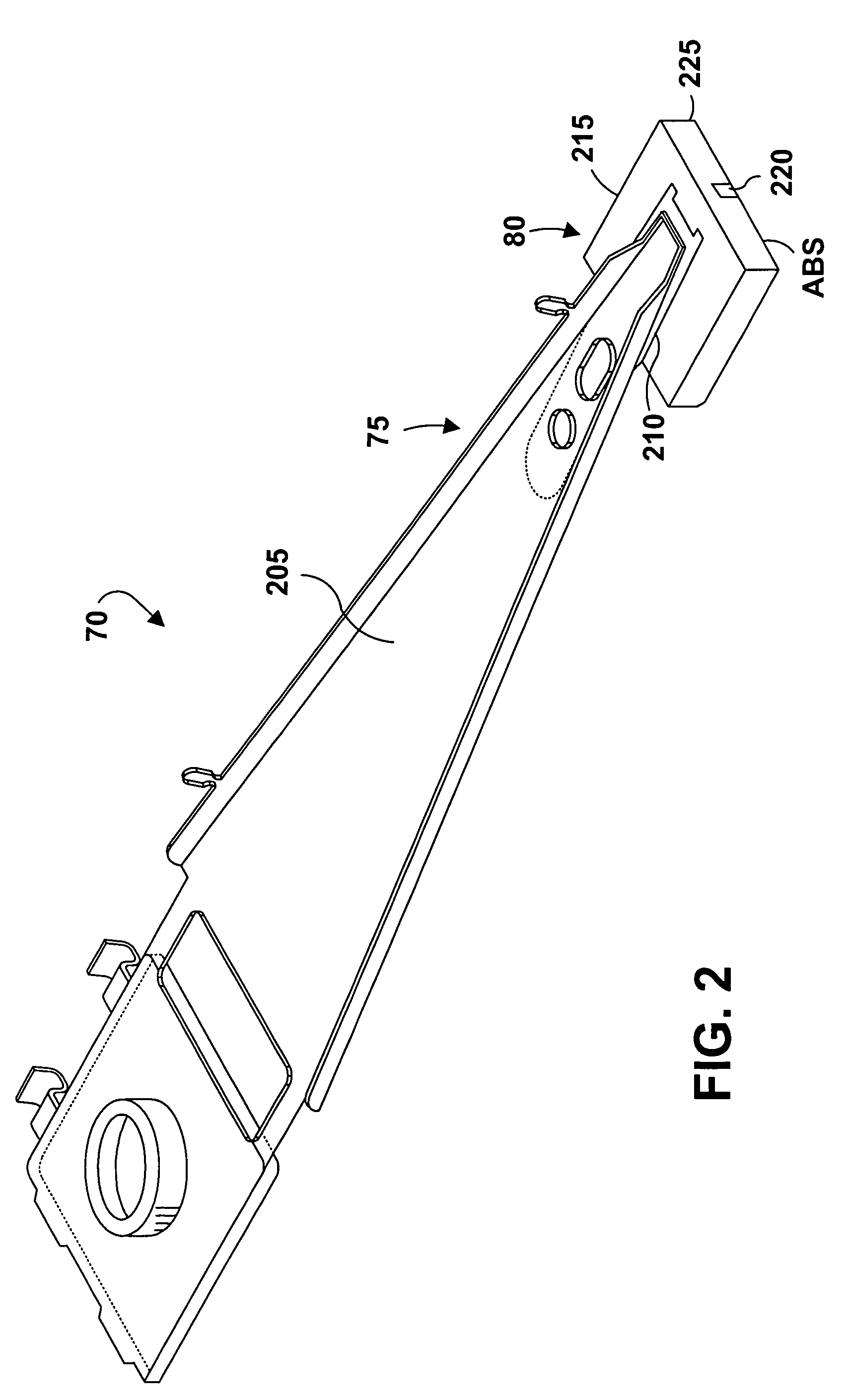

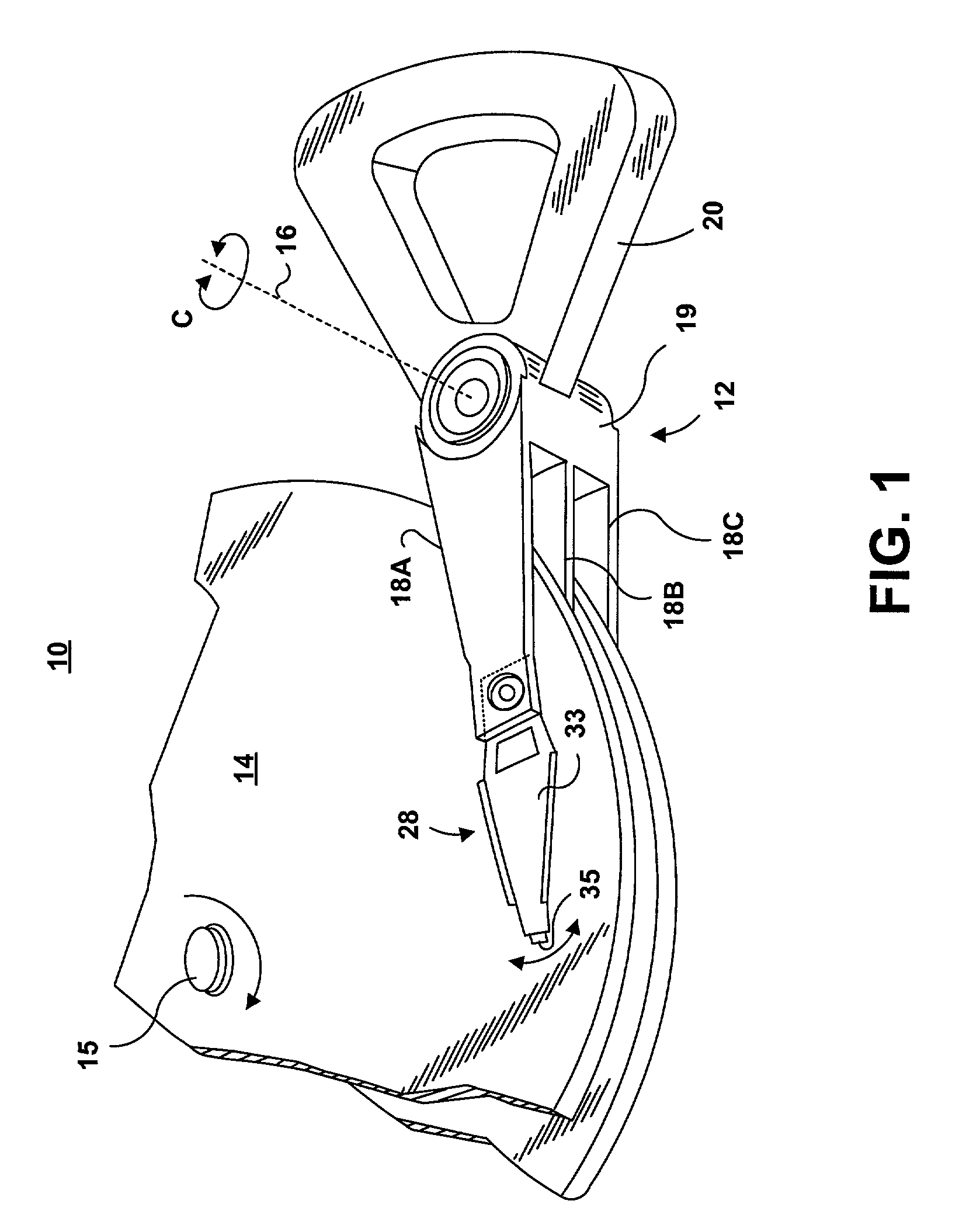

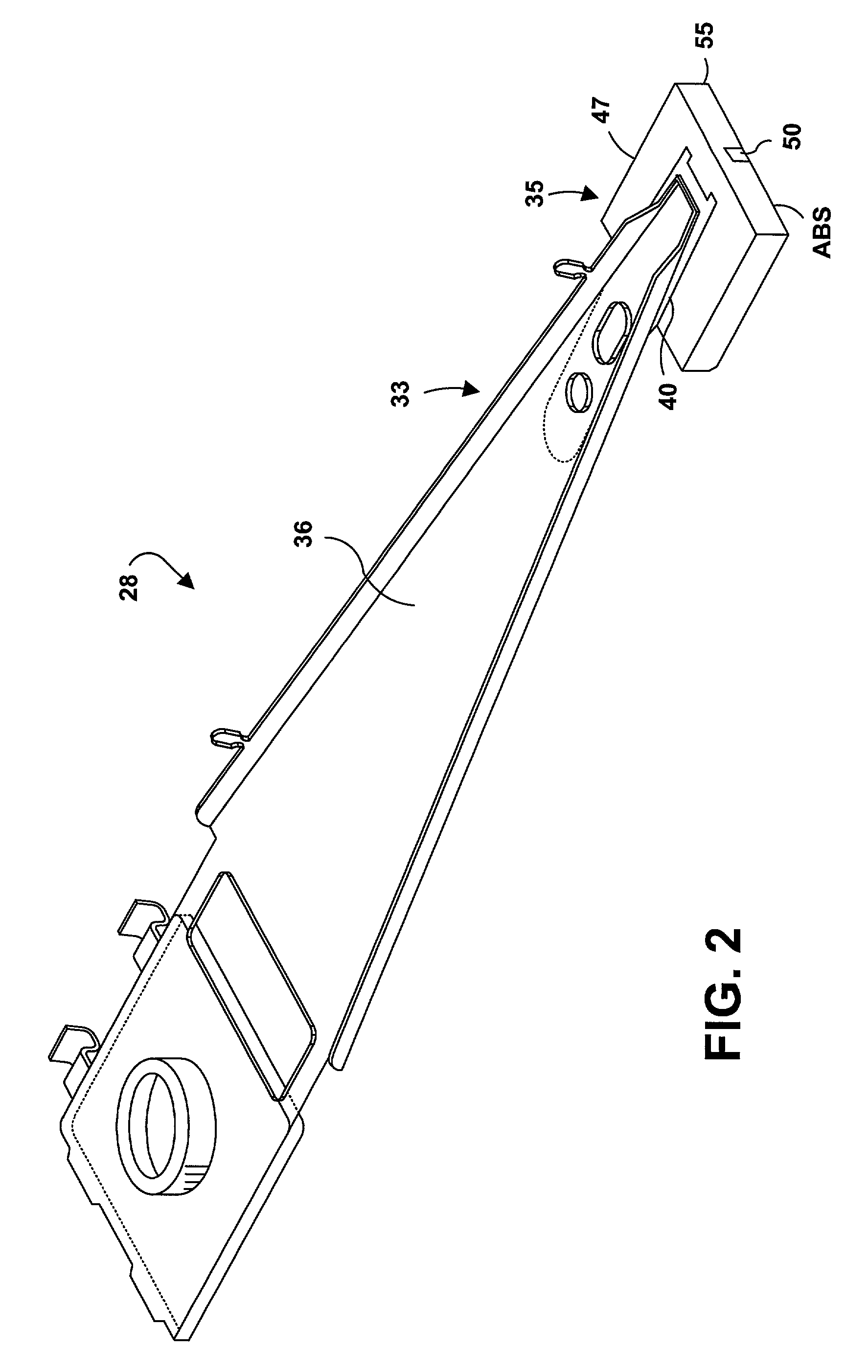

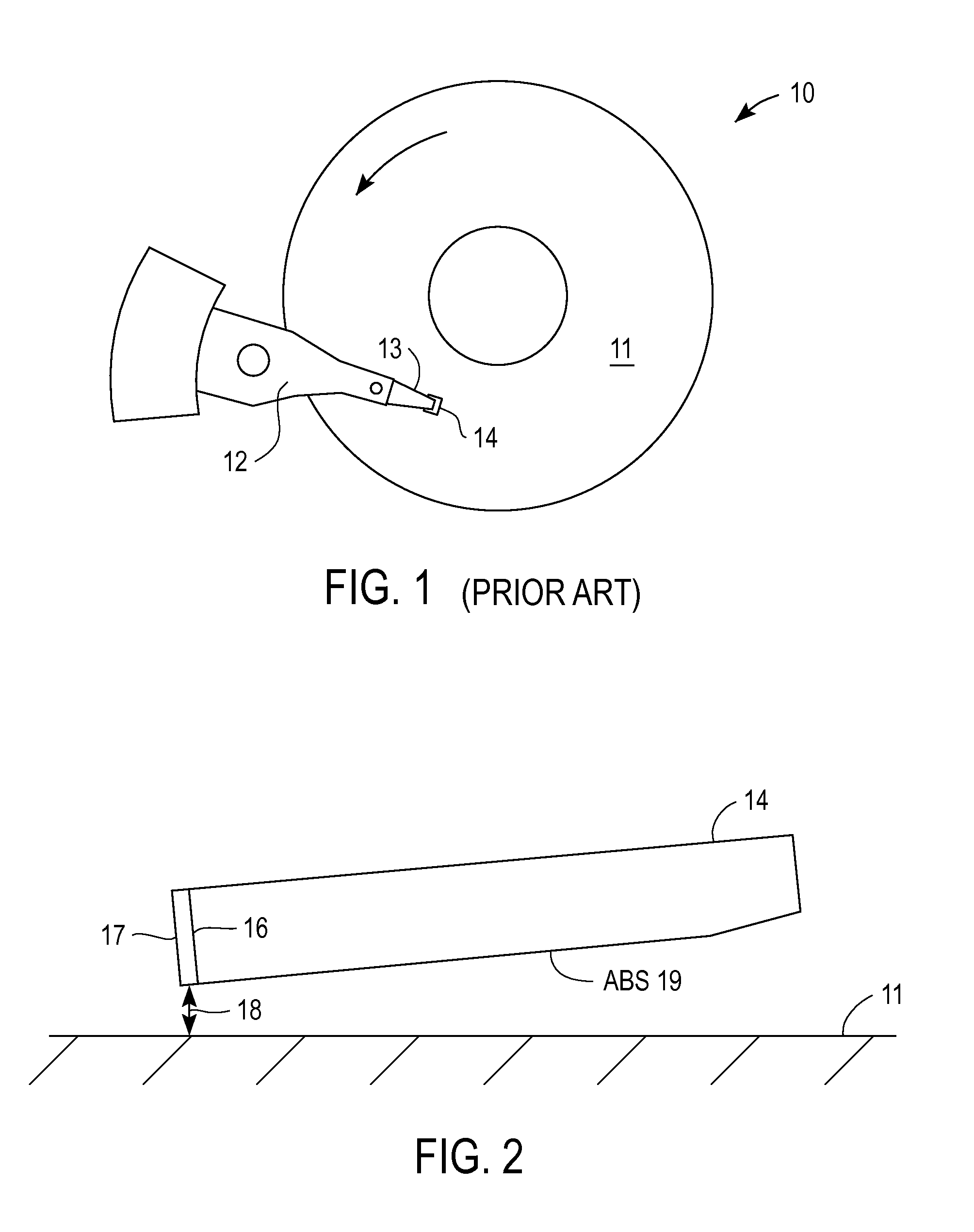

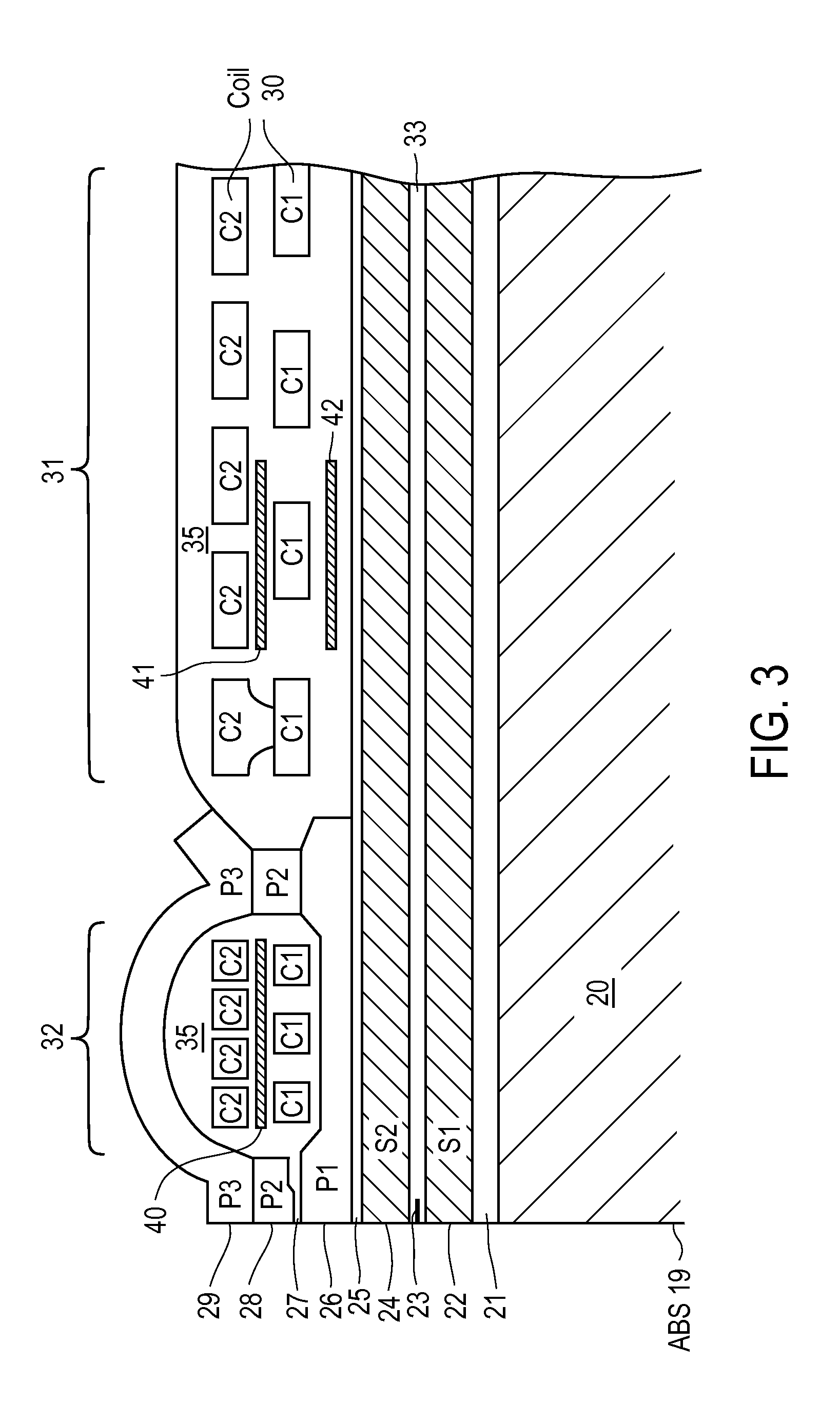

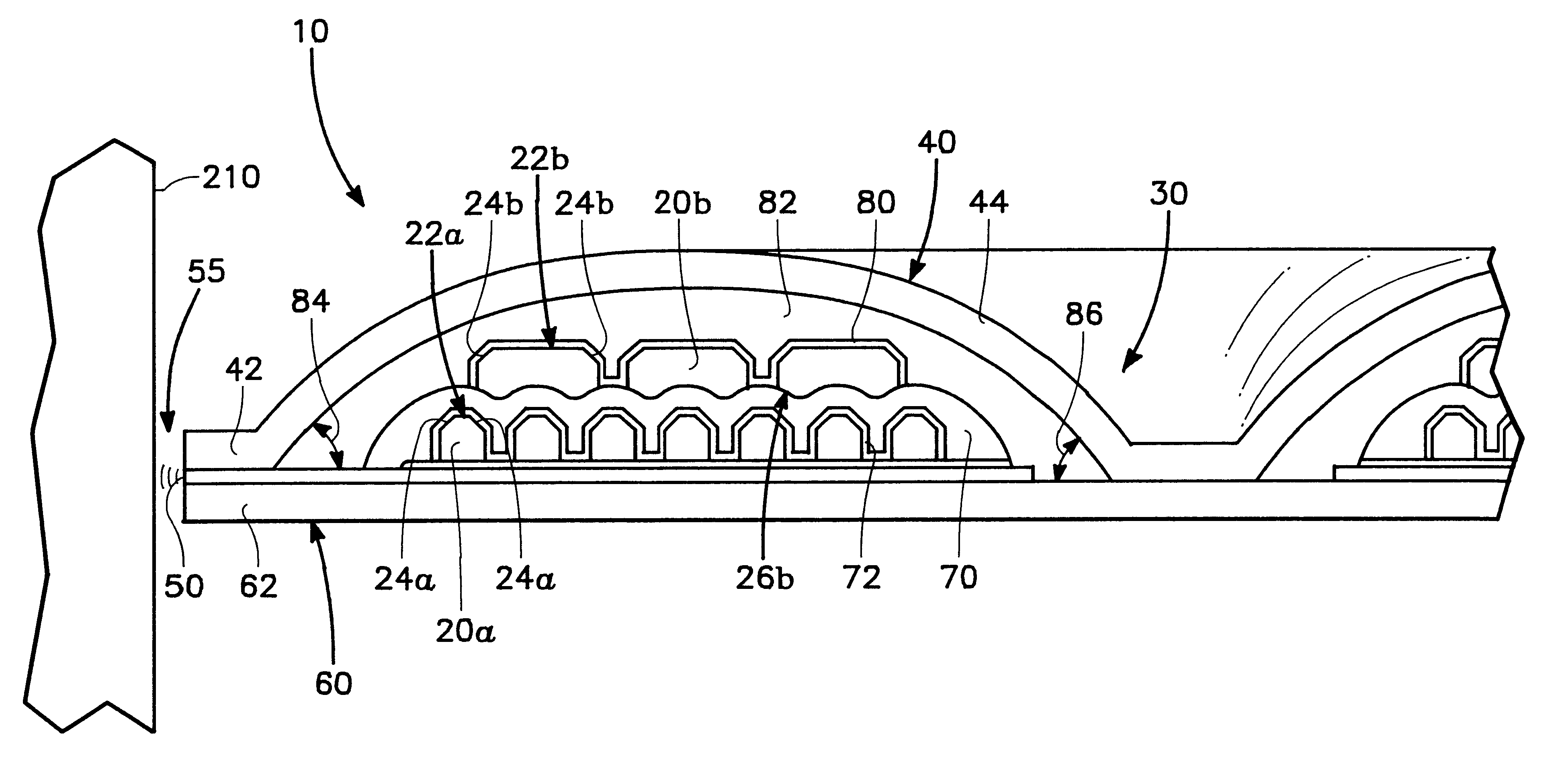

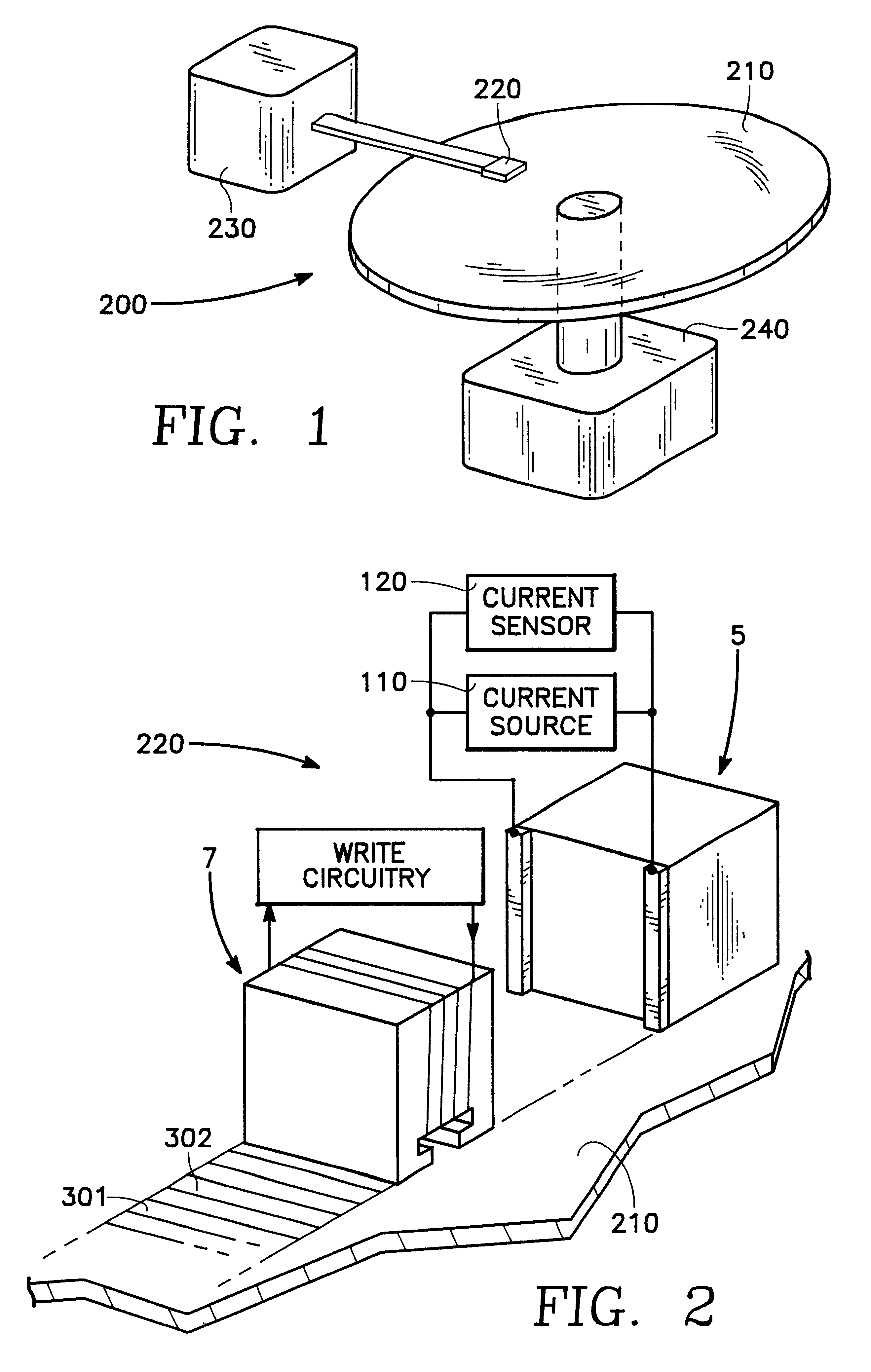

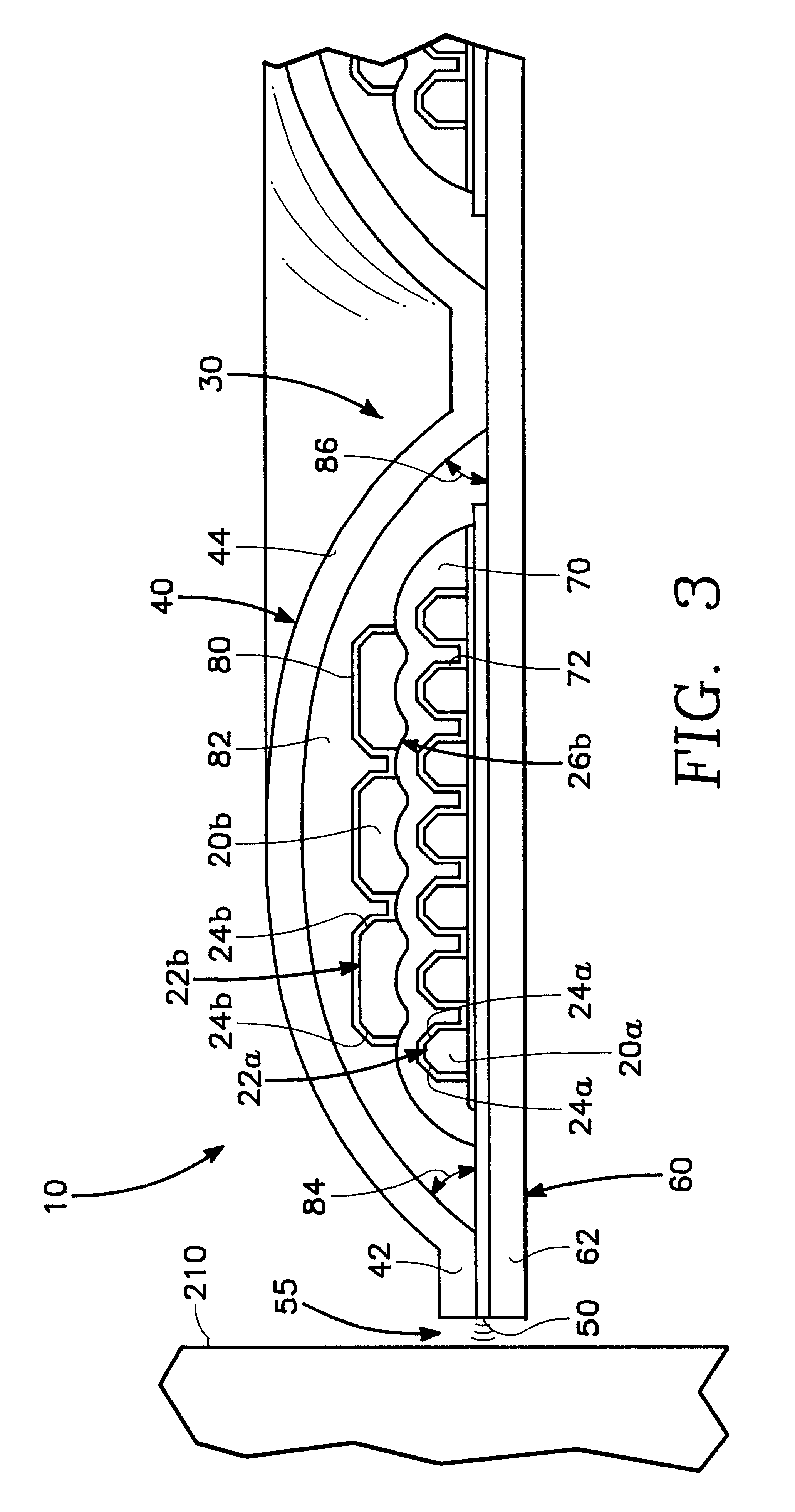

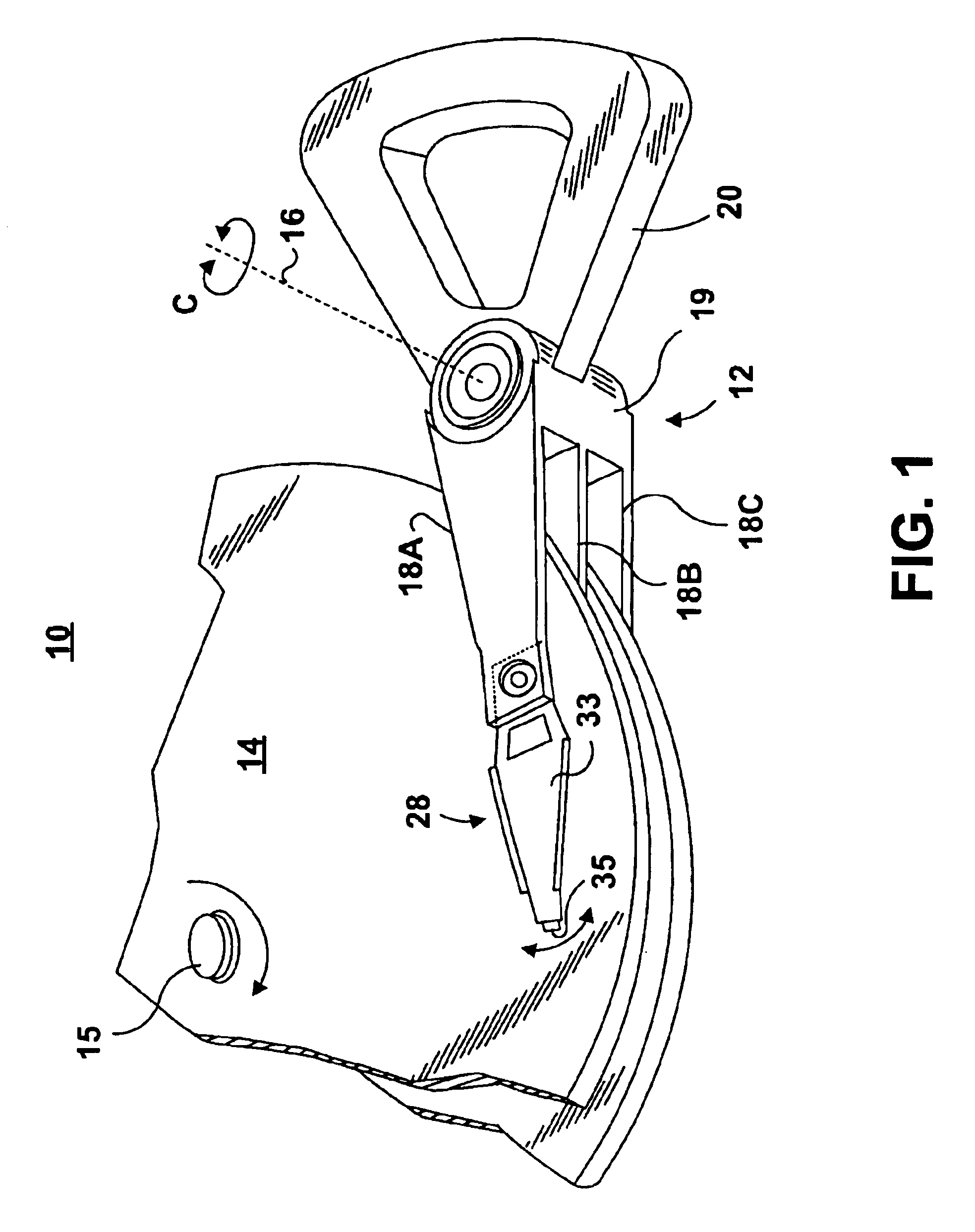

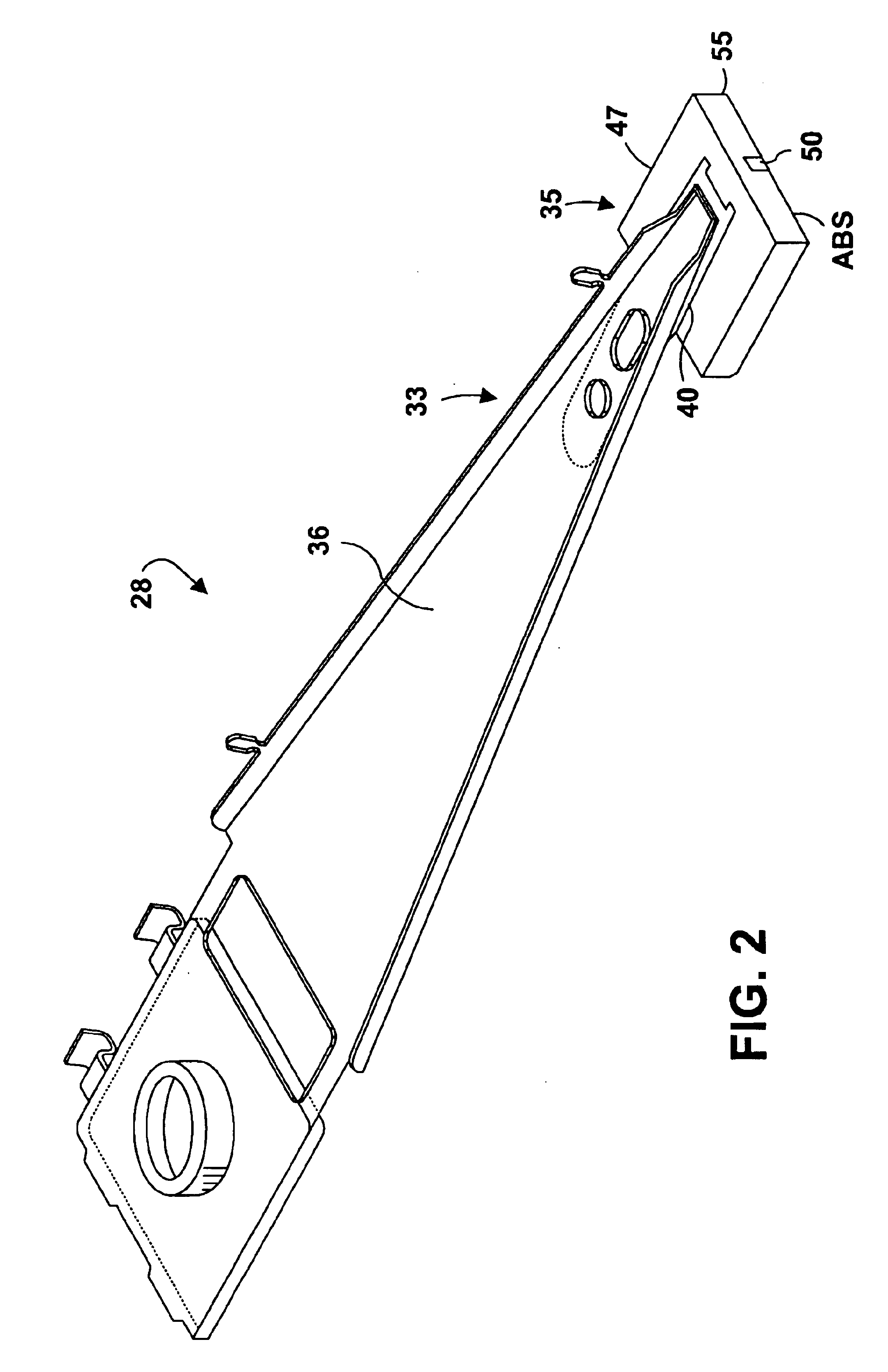

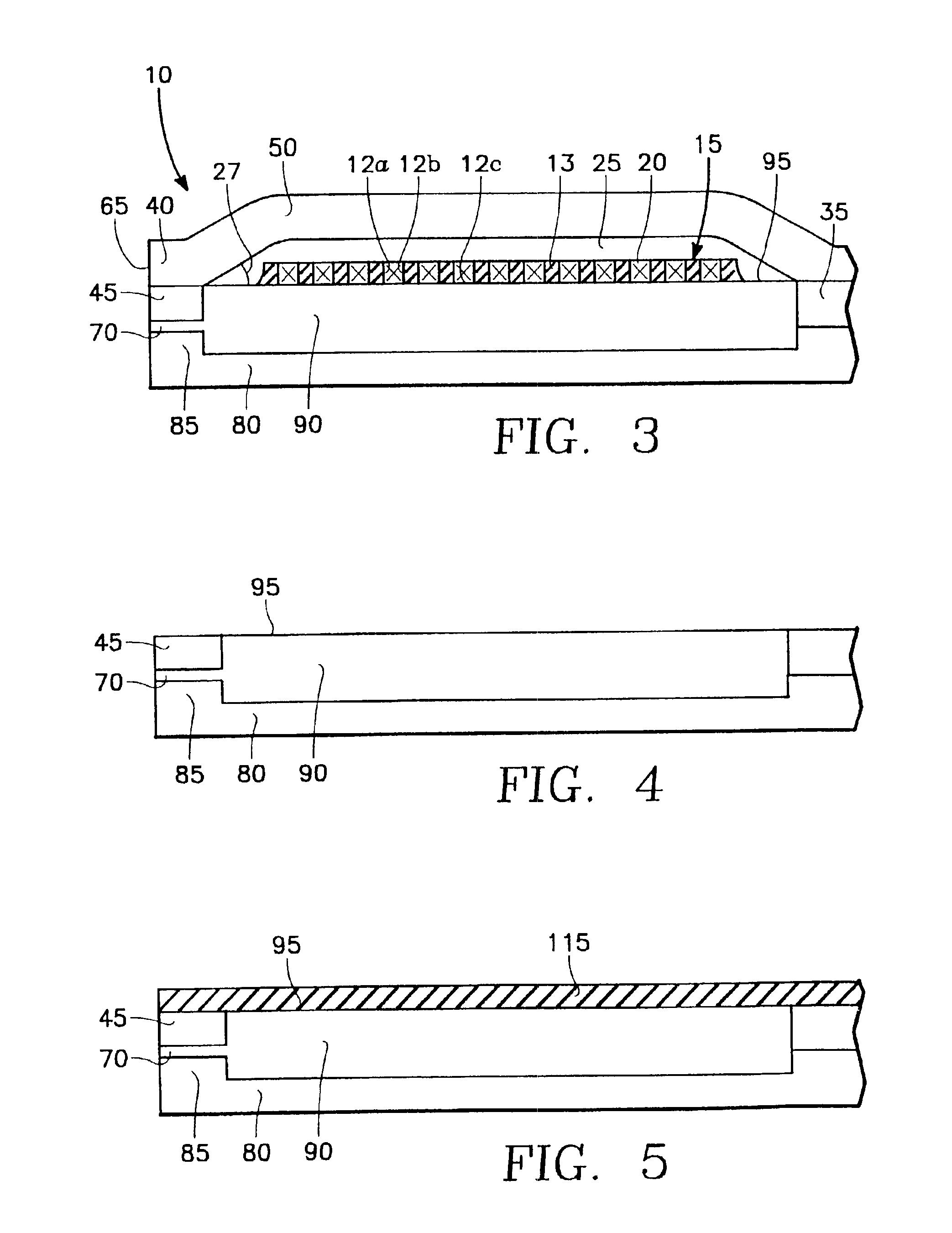

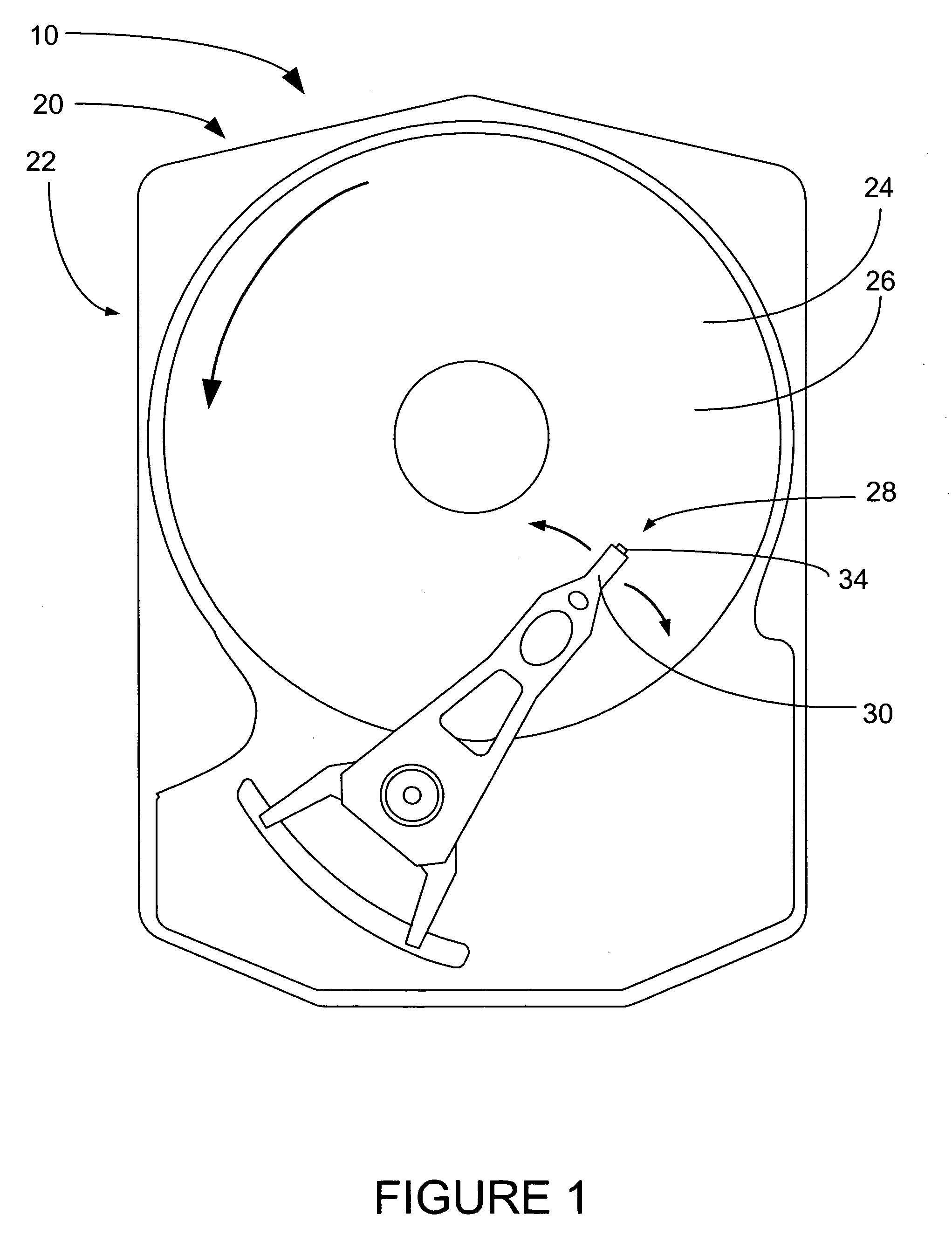

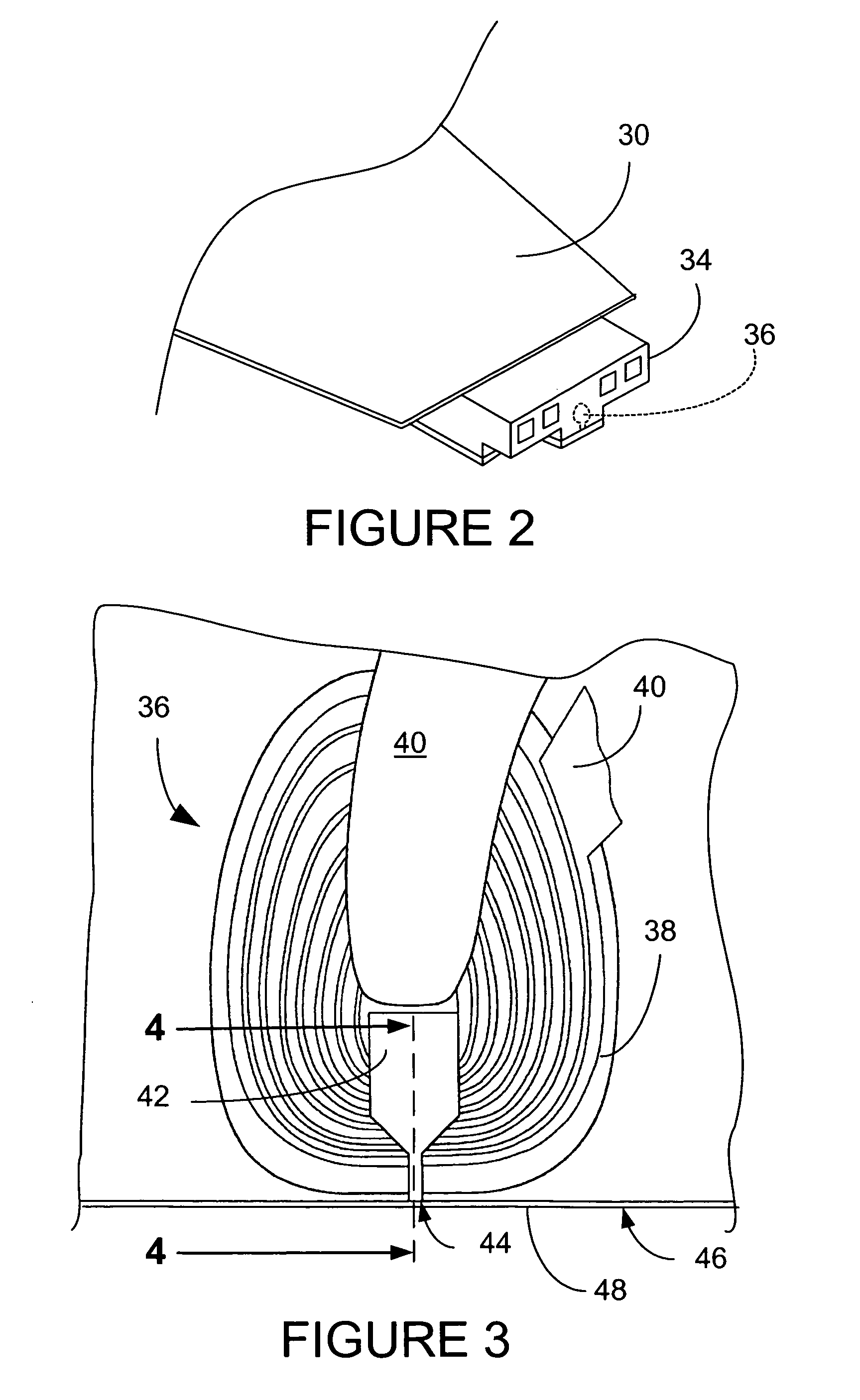

A disk drive write head (10) having a bottom pole (60), a first insulation layer (64) formed on the bottom pole (60), a coil (38) formed on the first insulation layer (64), a second insulation layer (66) formed on the coil (38), a write gap layer (76) formed on the second insulation layer (66), and a top pole (12) formed on the write gap layer (76), where the top pole (12) is substantially flat.A second embodiment (100) is described which is produced by a damascene process.

Owner:WESTERN DIGITAL TECH INC

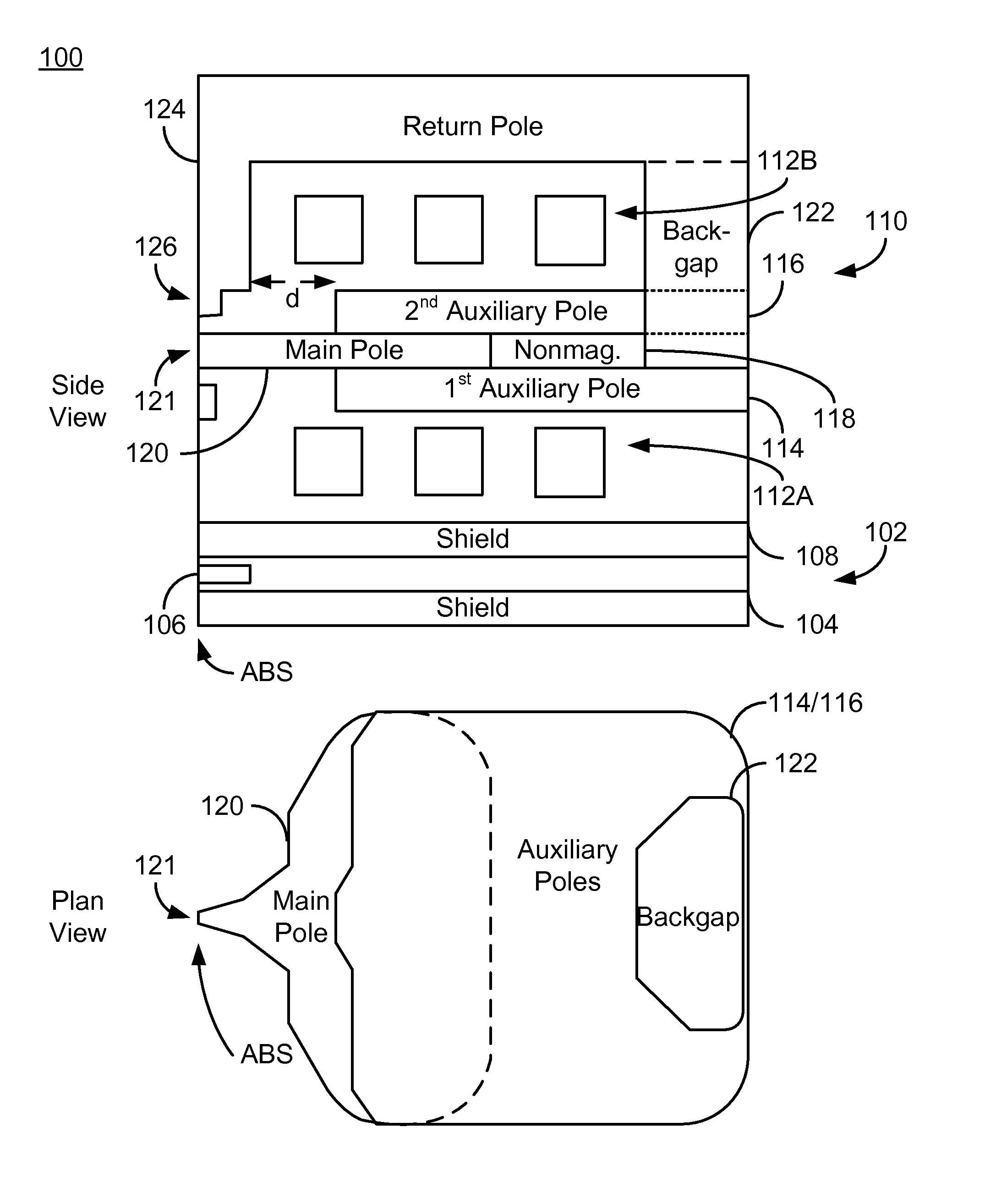

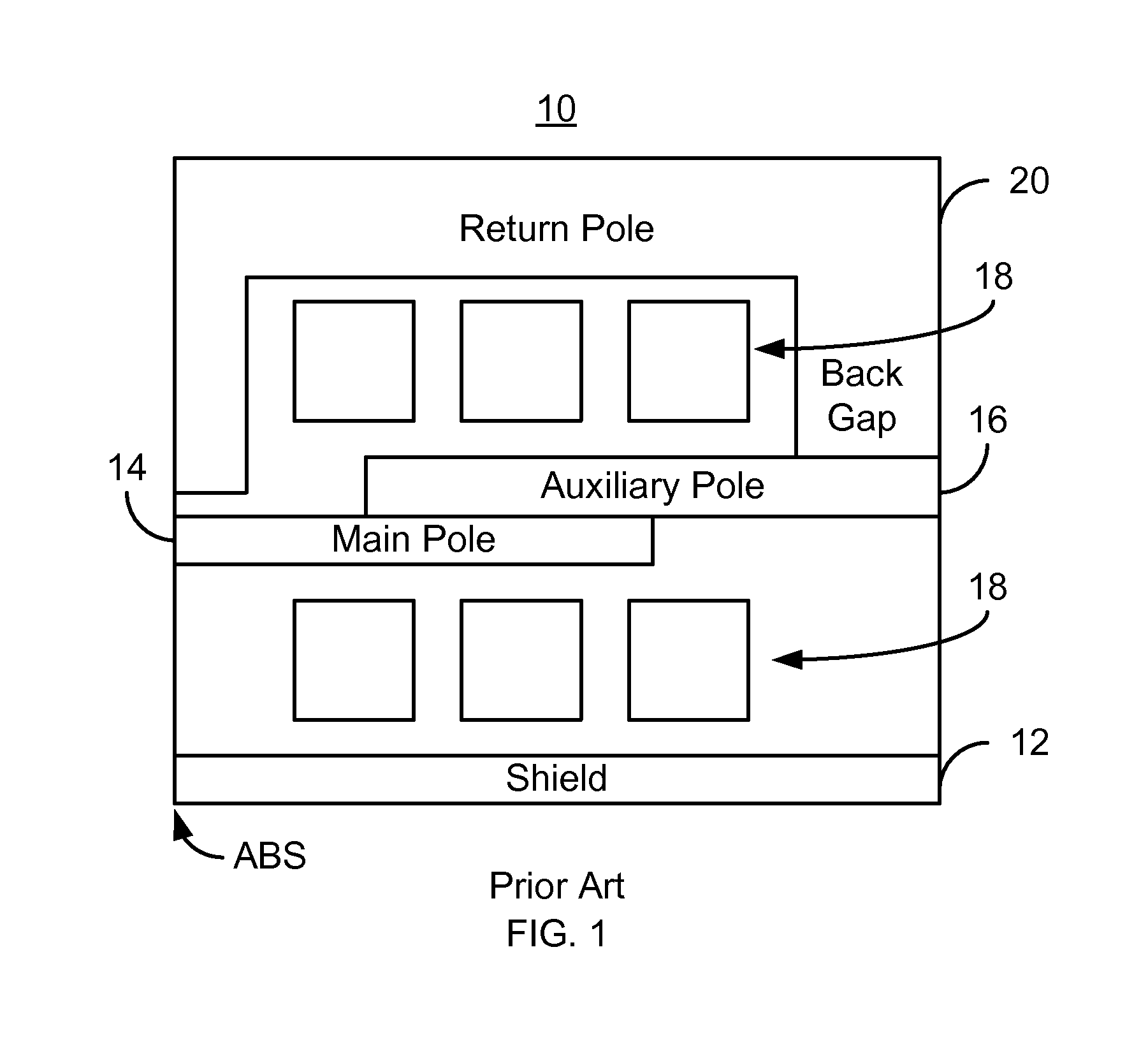

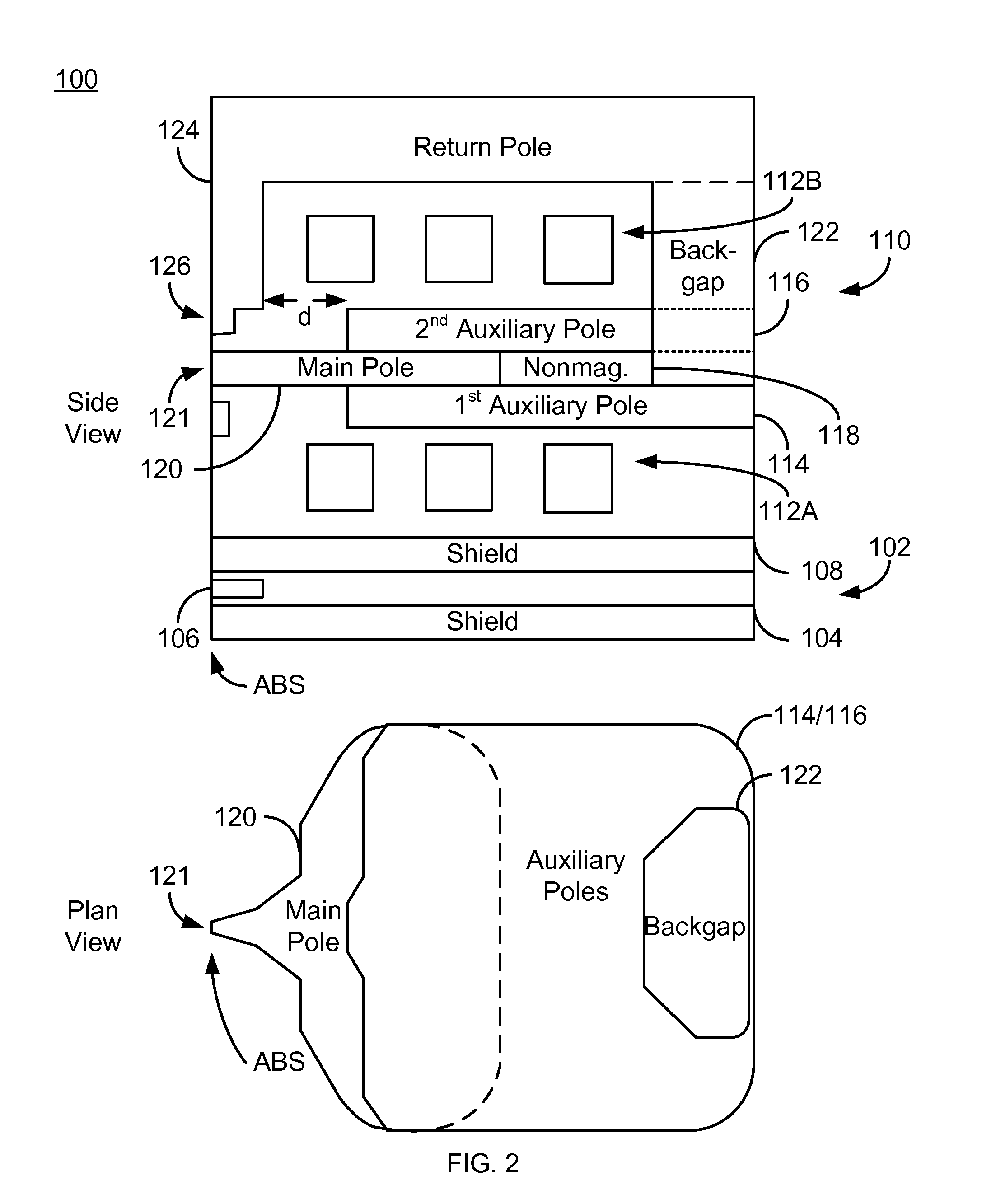

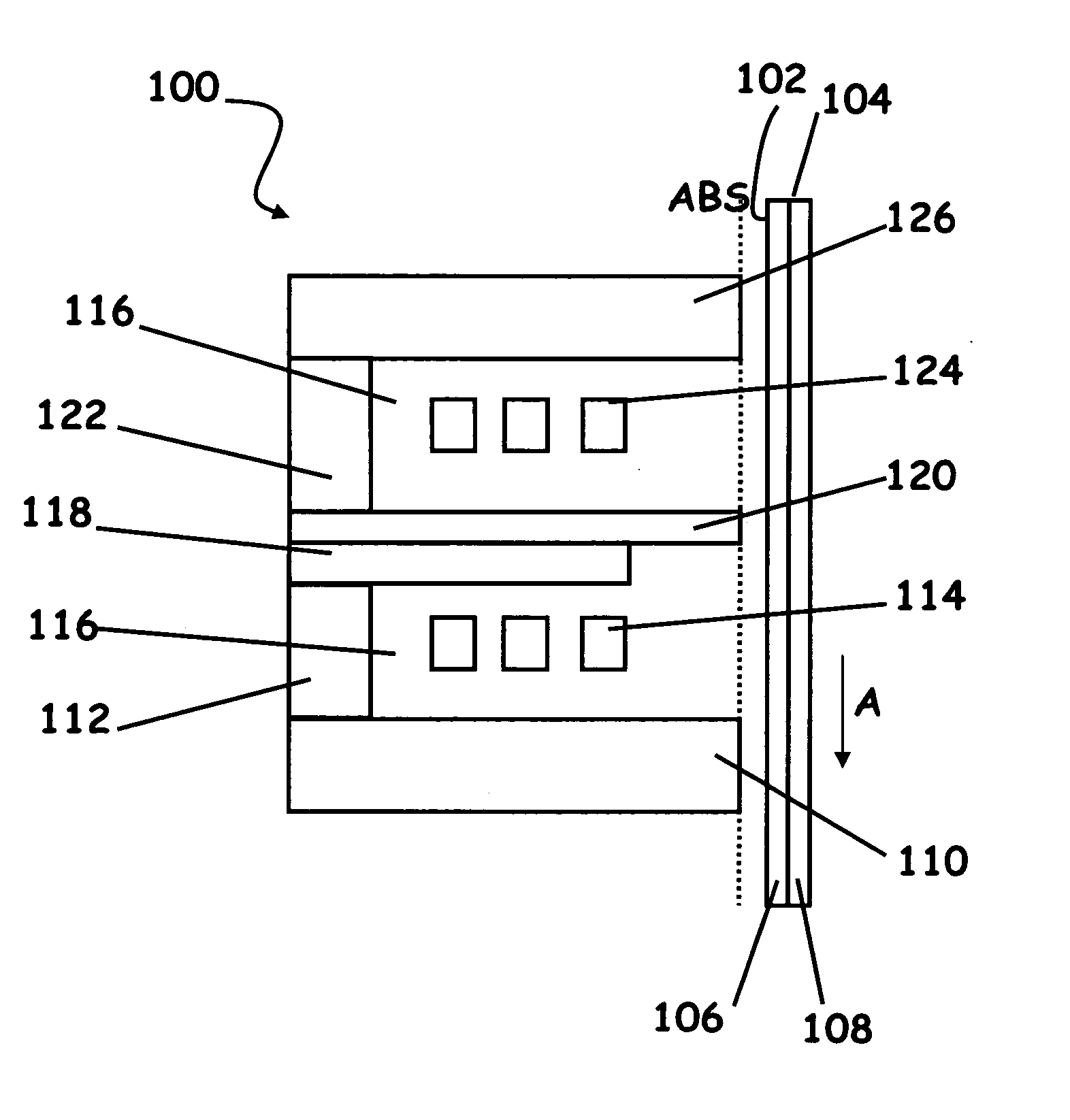

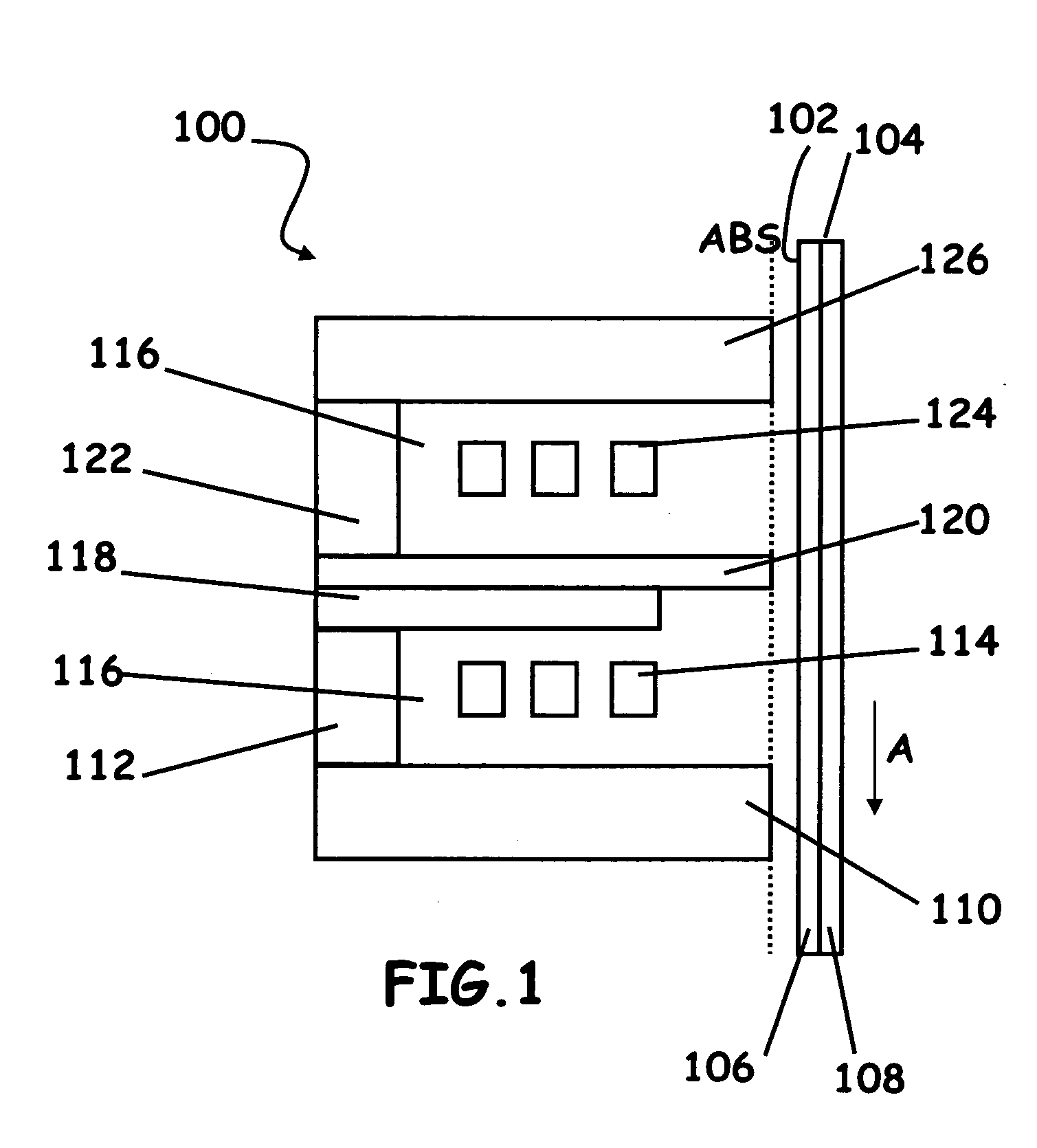

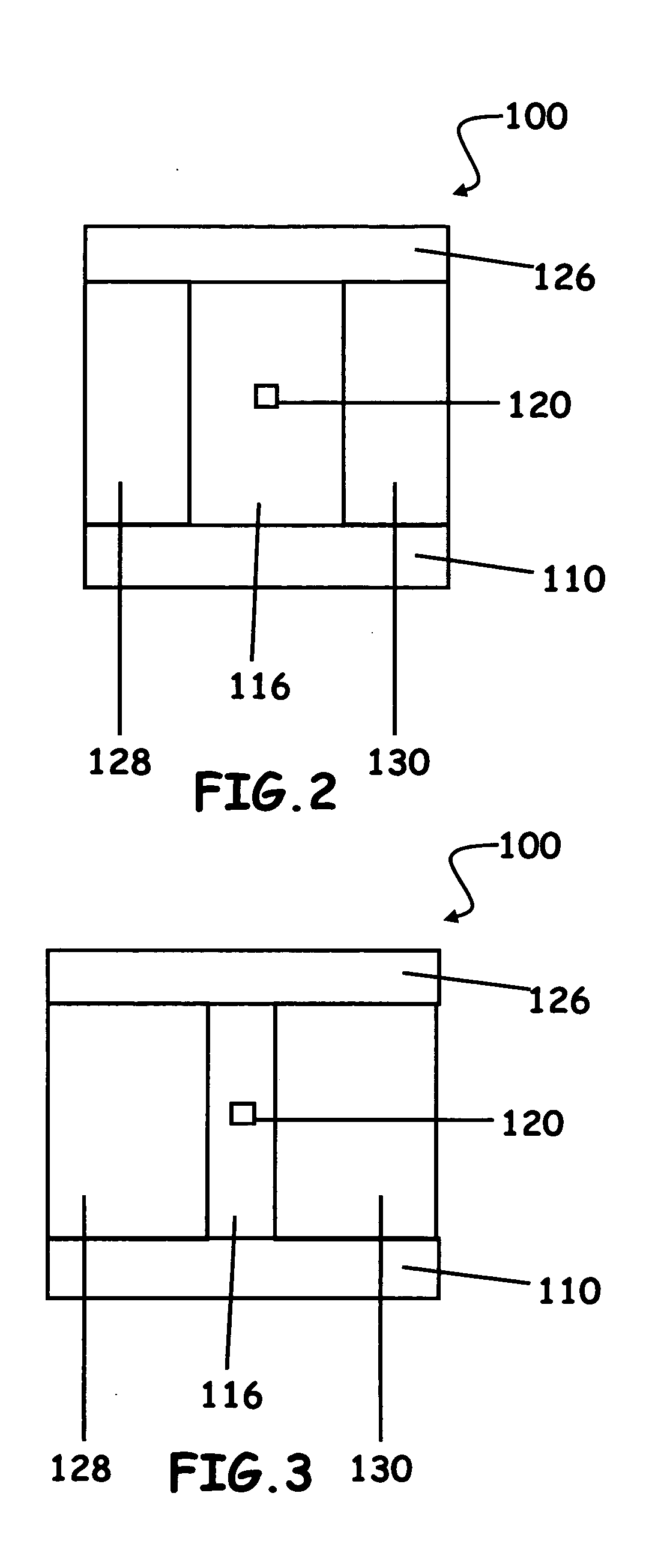

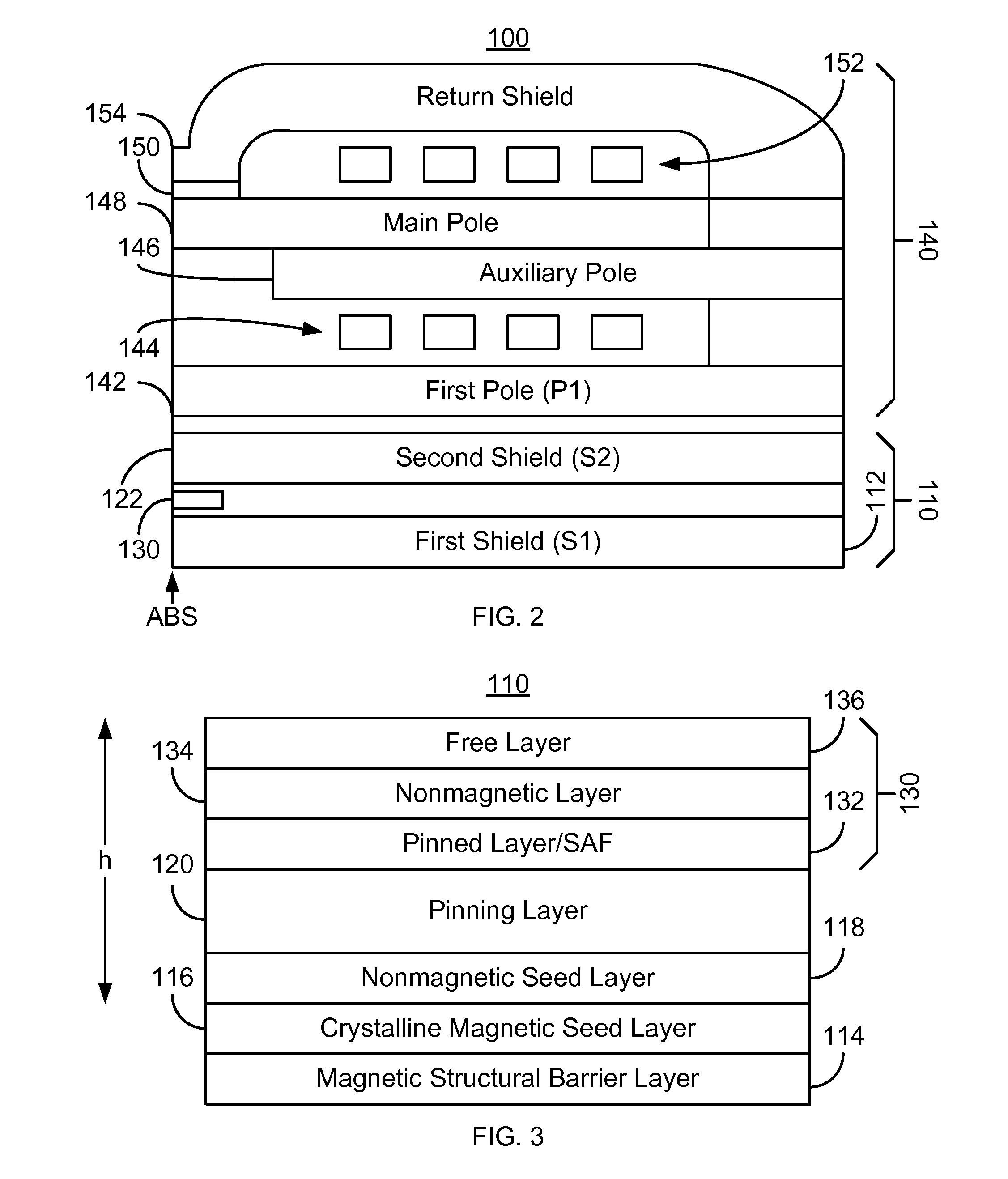

Method and system for providing a transducer having dual, ABS recessed auxiliary poles on opposite sides of a main pole with non-magnetic spacer adjoining back portion of main pole and positioned between auxiliary poles

A method and system for providing a magnetic recording head is described. The magnetic recording head has an ABS configured to reside in proximity to a media during use. The magnetic recording head includes a main pole, first and second auxiliary poles, a backgap, a nonmagnetic spacer, and at least one coil. The main pole includes a pole tip occupying a portion of the ABS and a back edge distal from the ABS. Each auxiliary pole has a front recessed from the ABS and a back portion. A portion of the main pole distal from the ABS resides between the auxiliary poles. The auxiliary poles are magnetically coupled with the main pole. The backgap magnetically couples the back portions of the auxiliary poles. The nonmagnetic spacer adjoins the back edge of the main pole and is between the auxiliary poles. The coil(s) energize the main pole.

Owner:WESTERN DIGITAL TECH INC

System and method for minimizing thermal pole tip protrusion

InactiveUS7035046B1Minimize pole tip protrusionSimple designRecord information storageProtective measures for recording headsInvarDiffusion

An enhanced recording head design provides thermal diffusion and thermal expansion control in order to minimize the pole tip protrusion resulting from the thermal heating of the magnetic recording head during operation. In one embodiment, the recording head a thermal restraint section formed above a write section, and is made of a 60–80% face-centered-cubic NiFe (Invar) material. According to another embodiment, the thermal restraint section is formed under the read section. According to yet another embodiment, one thermal restraint section is formed above the write section, and another thermal restraint section formed under the read section.

Owner:WESTERN DIGITAL TECH INC

Perpendicular magnetic recording head with dynamic flying height heating element disposed below turns of a write coil

ActiveUS7729086B1Disposition/mounting of recording headsRecord information storageTransducerFlying height

Owner:WESTERN DIGITAL TECH INC

Magnetic head for perpendicular recording with hard bias structure for write pole tip

A magnetic head for writing information on a relatively-moving medium is disclosed, the head having a leading end, a trailing end and a medium-facing surface, the head comprising: a soft magnetic write pole that terminates in a pole tip that is disposed adjacent to the medium-facing surface; at least one coil section that is disposed adjacent to the write pole to induce a magnetic flux in the write pole; and a hard magnetic bias structure disposed within one micron of the pole tip to magnetically bias the pole tip.

Owner:WESTERN DIGITAL TECH INC

Low resistance coil structure for high speed writer

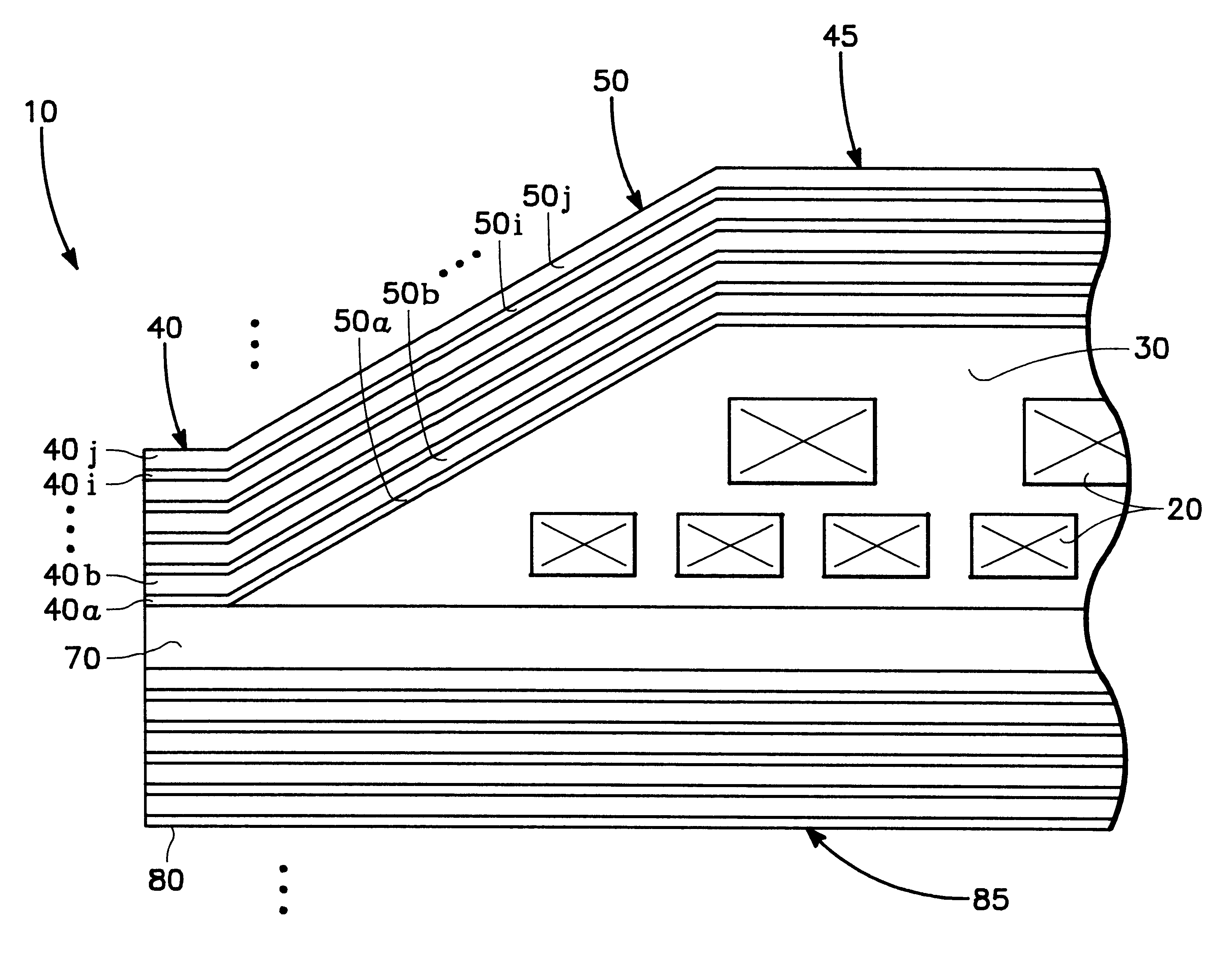

InactiveUS6333830B2Lower coil resistanceReduce dissipationConstruction of head windingsHeads using thin filmsElectrical conductorLower pole

The present invention provides a thin film write head having an upper and lower pole structures and conductor turns forming a winding for generating magnetic flux. The conductor is formed with a non-planar top surface. The winding of the present invention may be formed of lower and upper turns. The upper turns may be formed with a non-planar top surface, a non-planar bottom surface, or both. It is preferred that the bottom surface of the upper conductor turns be coherent with the non-planar top surface of the lower conductor turns. The non-planar top surface may be formed by removing corners formed during deposition between a generally planar top surface and abutting side walls. The corners may be removed by ion milling to form the non-planar top surface. The conductor may be copper with the non-planar top surface having sloping facets. The thin film write head of the present invention may be utilized to provide an improved data storage and retrieval apparatus. The preferred embodiment provides reduced coil resistance thereby reducing Johnson Thermal Noise and power dissipation. It also allows for reduced yoke length and reduced stack height while providing low apex angles to expand and improve yoke material deposition thereby improving head response and operational frequency.

Owner:WESTERN DIGITAL TECH INC

Write head having a recessed, magnetic adjunct pole formed atop a main pole, and method of making the same

InactiveUS6906894B2Enhanced magnetic write fieldEliminate the problemConstruction of head windingsElectrical transducersSputteringEngineering

A read / write head and method of making the same are used in a data storage system, such as a disk drive, for perpendicular magnetic recording of data. The head employs a two-layer pole design with a main pole made of sputtered high moment magnetic material, and an adjunct pole made of electroplated soft magnetic film. The main pole is used to write data onto the medium, and is formed over the write coil. The adjunct pole is substantially recessed from the air bearing surface and is formed over the main pole. The present head design significantly enhances the magnetic write field, and substantially reduces side-writing that result in accidental erasure of data in adjacent tracks on the magnetic recording medium.

Owner:WESTERN DIGITAL TECH INC

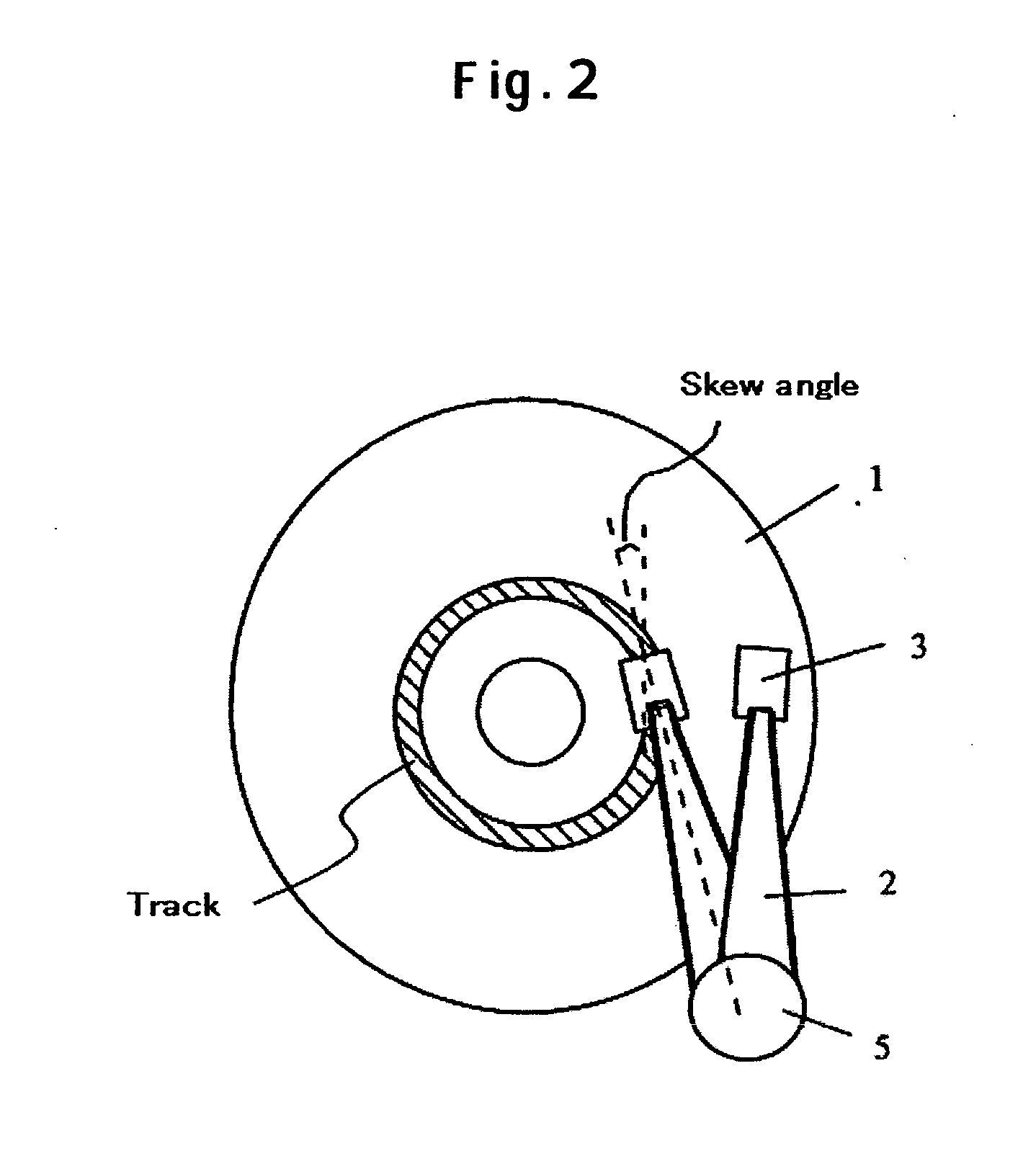

Magnetic recording head for perpendicular recording, fabrication process, and magnetic disk storage apparatus mounting the magnetic head

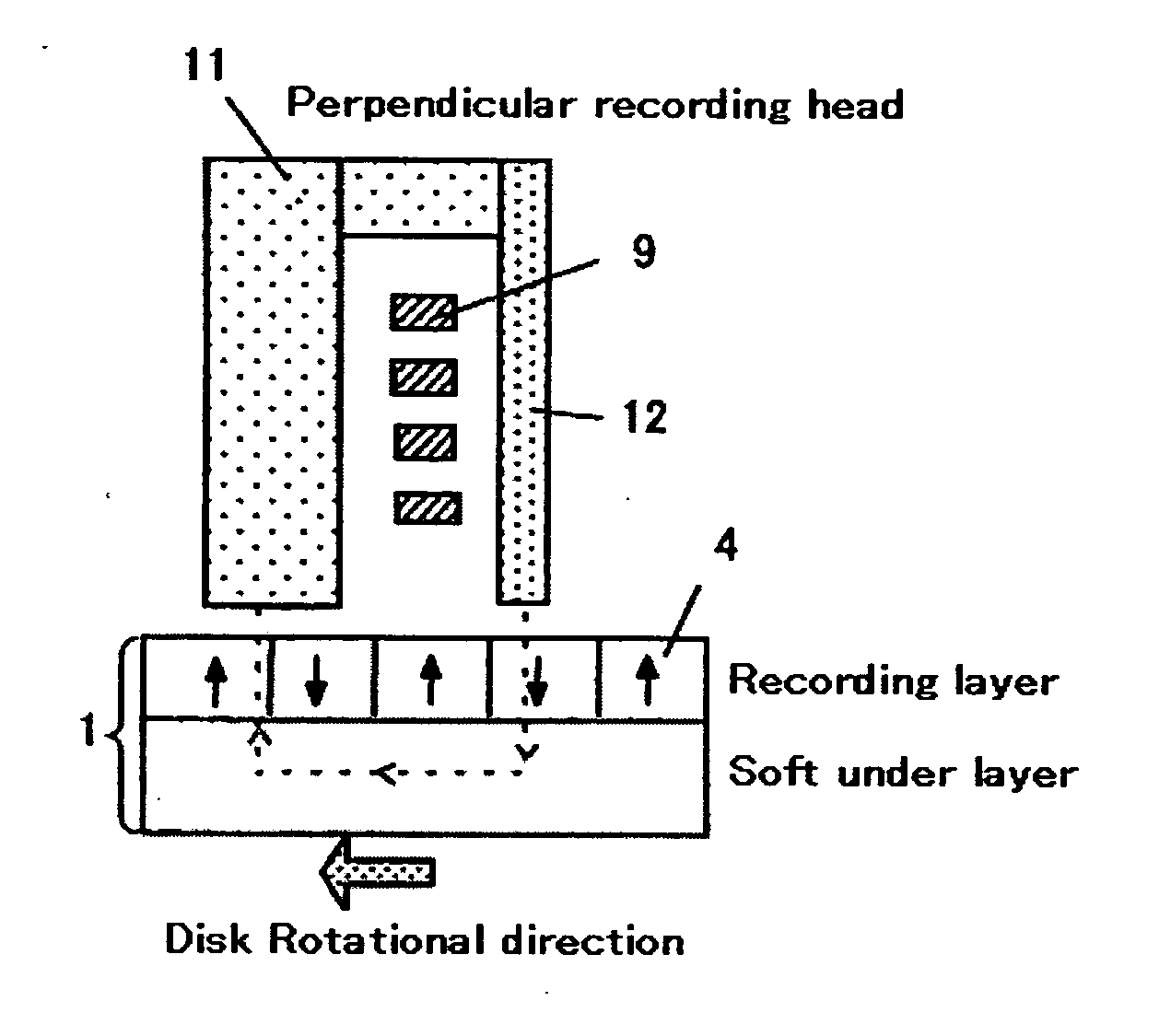

InactiveUS20050141137A1Improving recording magnetic field gradientIncreasing the thicknessManufacture head surfaceHeads using thin filmsMagnetic field gradientMagnetic media

Embodiments of the invention provide a perpendicular magnetic writing head with a suppressed effective track width to be written on a magnetic medium while increasing writing magnetic field gradient. In one embodiment a trailing side shield is disposed by way of a gap film to a main pole of a perpendicular writing magnetic head. A gap distance (Gt) on a trailing side of the main pole and a gap distance (Gs) on a lateral side of the main pole is defined as Gt<Gt, and a thickness (Gd) from an air bearing surface of the shield is made equal to or less than a throat height. Alternatively, the thickness of Gd on the side of the main pole is reduced to less than that on the trailing side of the main pole. Further, for preventing defoliation of the shield upon fabrication of the air bearing surface, a thickness for a portion away from the main pole is increased.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

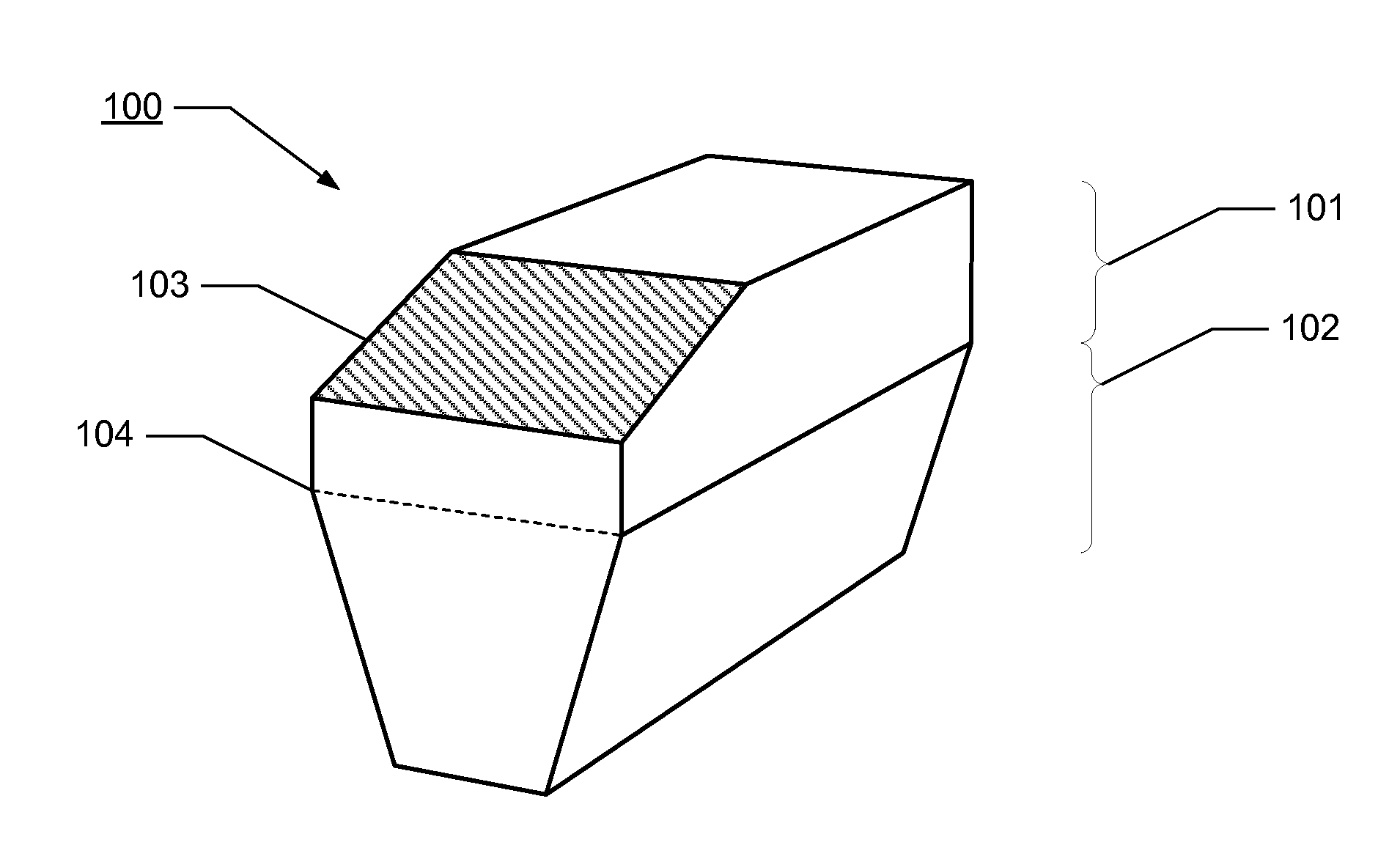

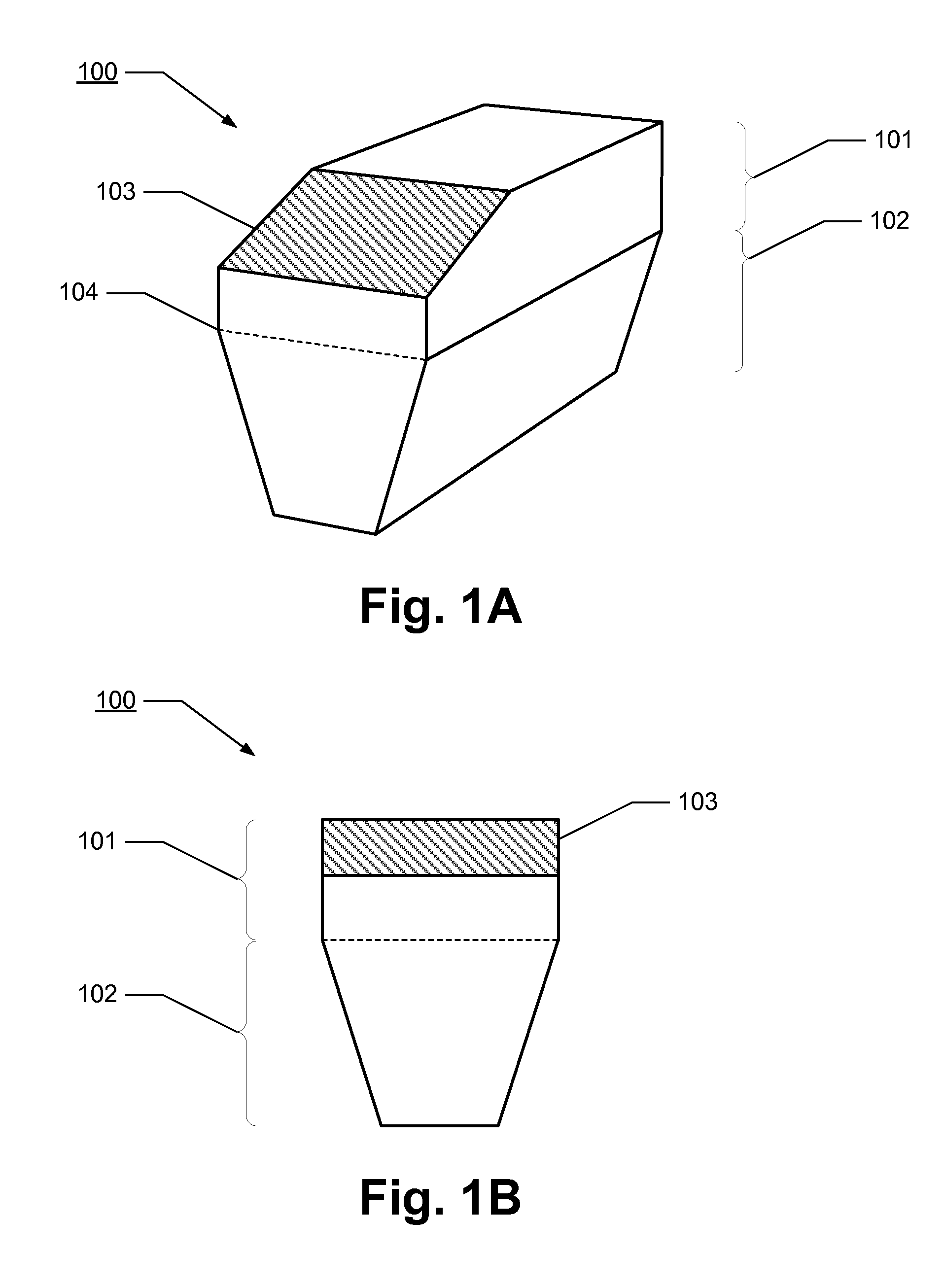

Straight top main pole for PMR bevel writer

ActiveUS8254060B1Record information storageHeads with metal sheet coresEngineeringMechanical engineering

A magnetic recording head includes a write pole comprising a throat region. The throat region includes a lower portion having a substantially trapezoidal cross-section, and an upper portion having a substantially rectangular cross-section. In a beveled region of the write pole, the substantially rectangular cross-section of the upper portion decreases in height towards an air bearing surface of the magnetic recording head.

Owner:WESTERN DIGITAL TECH INC

Head for perpendicular recording with reduced erasure

ActiveUS20050128637A1Reduced erasure fieldReducing erasure fieldHeads using thin filmsRecord information storageEngineeringPerpendicular media

A perpendicular writer of the present invention comprises a main pole connected to two return poles and further includes one or more shorting shields thereby reducing erasure field on double layer perpendicular media. The perpendicular writer may include side shorting shields connecting the first and second return poles thereby modifying the crosstrack field gradient. Additionally, the perpendicular writer may include a top shorting shield modifying the downtrack gradient and may additionally include a bottom shorting shield for further reduction of erasure fields. The distance between the main pole and the shorting shields may be modified to customize the write field gradient.

Owner:SEAGATE TECH LLC

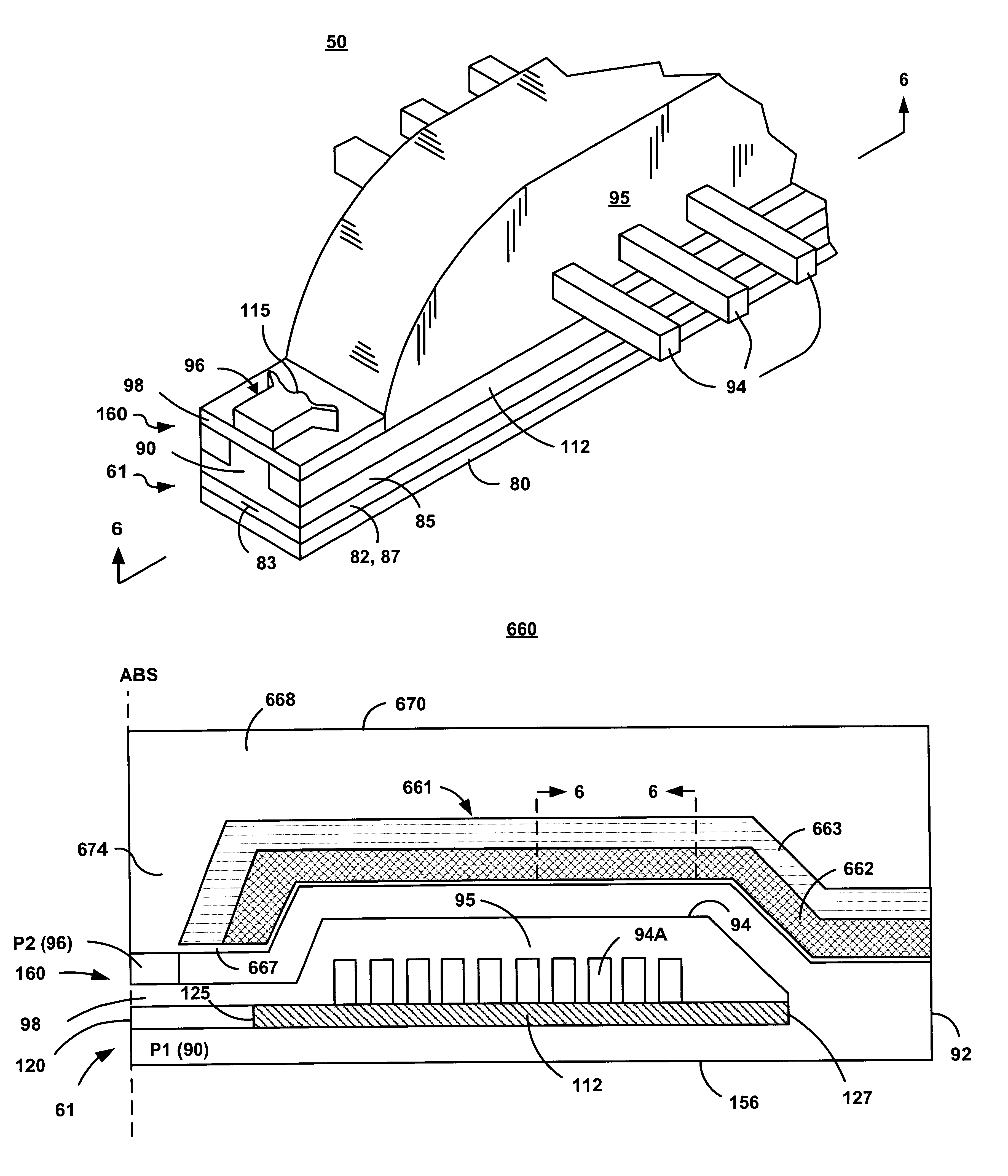

Ultra-short yoke and ultra-low stack height writer and method of fabrication

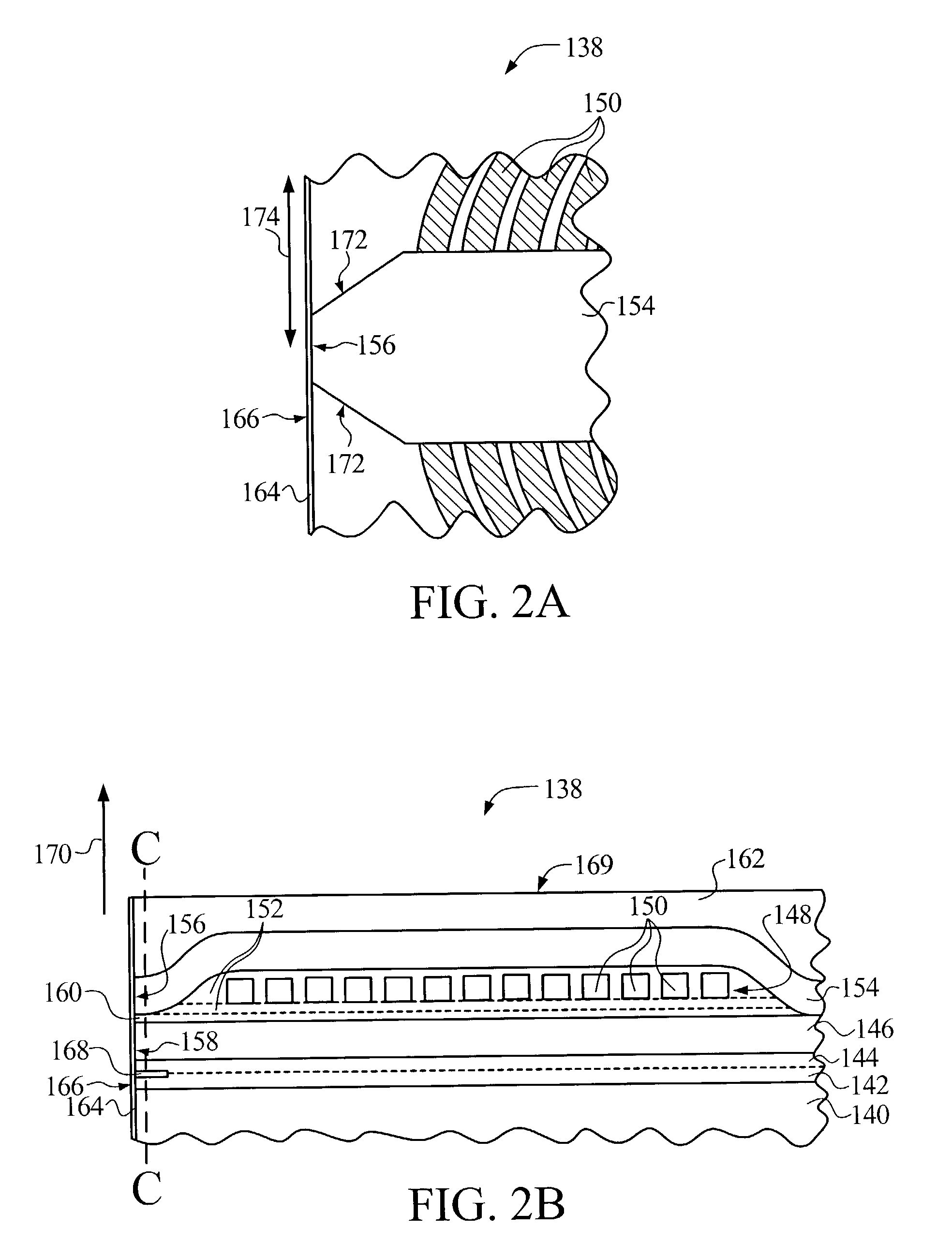

InactiveUS6954332B1Height of stackReduce the overall heightConstruction of head windingsManufacture head surfaceResistElectrical conductor

The present invention provides an improved thin film write head and method of fabrication capable of providing an ultra-short yoke and / or an ultra-low conductor winding stack. The present invention reduces yoke length and stack height by forming the conductor winding in a trench etched from an insulation layer, preferably formed of an inorganic insulation material. A thin resist mask is used to define the width of the trench while the etch process defines the depth. Preferably, the insulation layer is formed on a different inorganic insulation material to control the etch process, thus, the conductor winding may be formed on the underlying layer. The conductor winding preferably is formed by depositing conductor material so that it fills the trench and then planarizing, such as by chemical mechanical polish, to remove conductor material deposited outside the trench. An organic insulation layer, such as cured photoresist, may be deposited on the planarized surface of the conductor winding to insulate it from an overlying yoke. This overlying organic insulation layer may also define the apex angle of the head. The present invention may have multiple layers of conductor winding. The subsequent layers of conductor may be formed similar to the first layer, or may be formed with conventional photoresist processes and structures. The present invention may utilize any known pole structure or material.

Owner:WESTERN DIGITAL TECH INC

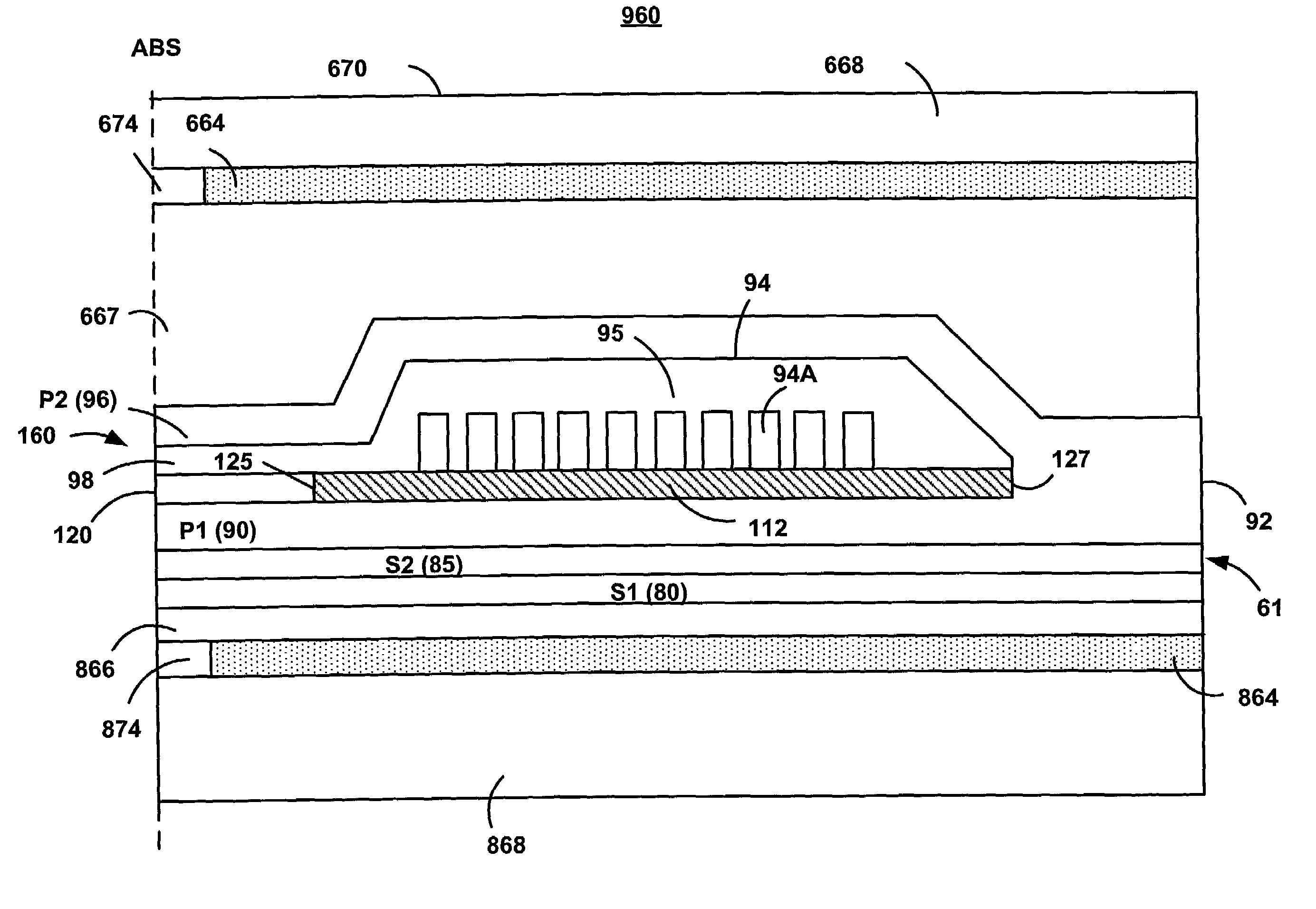

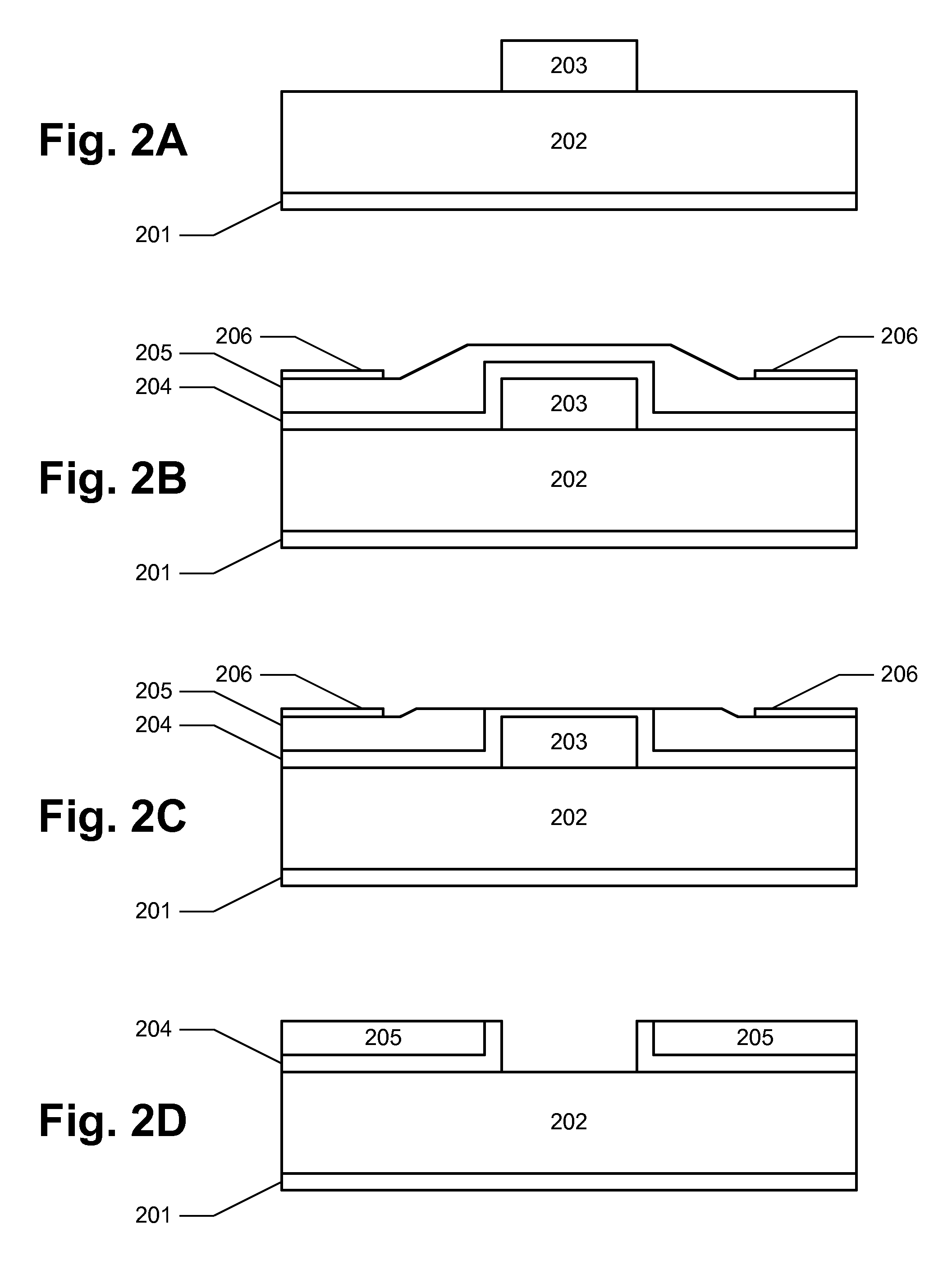

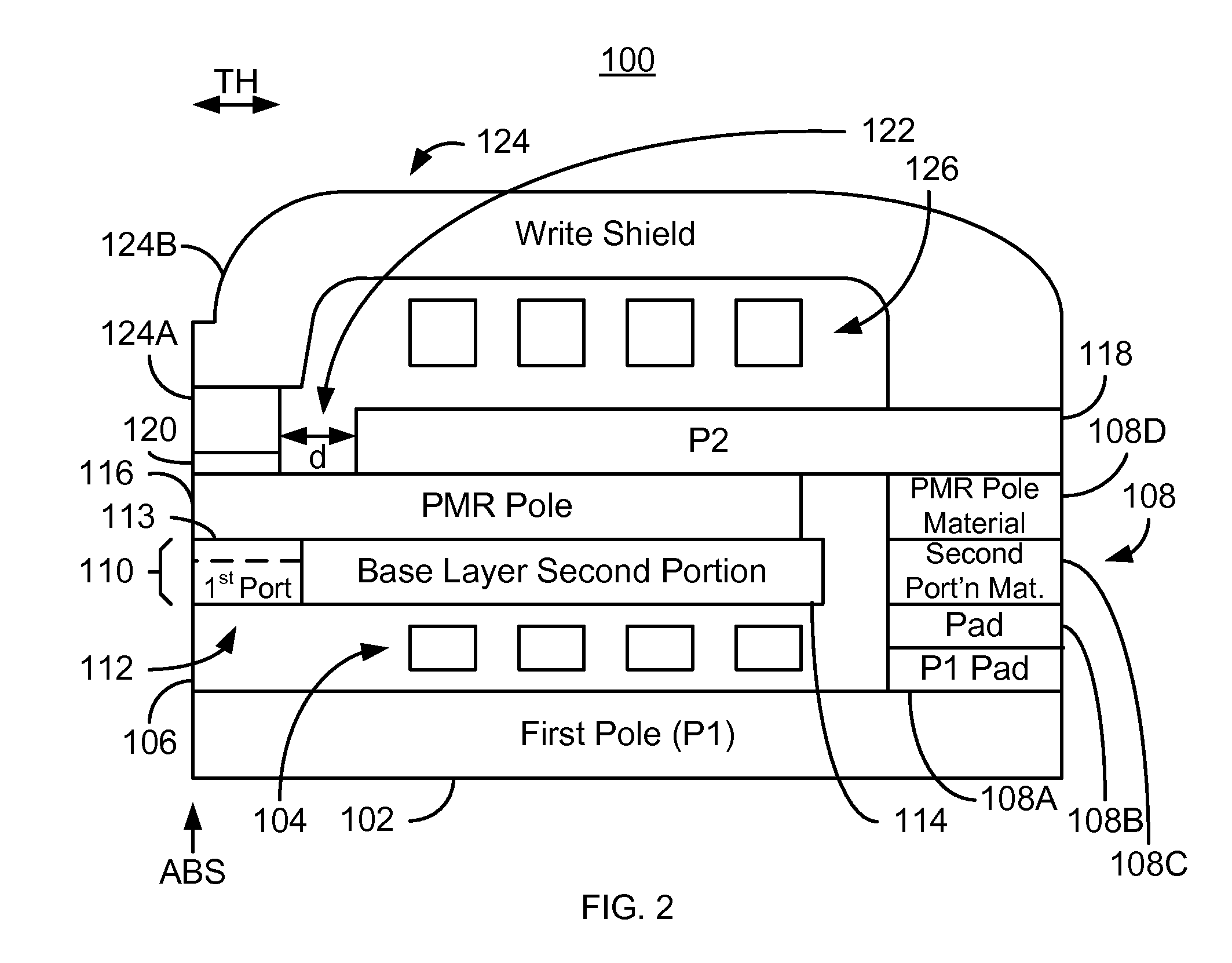

Perpendicular magnetic recording head having a recessed magnetic base layer

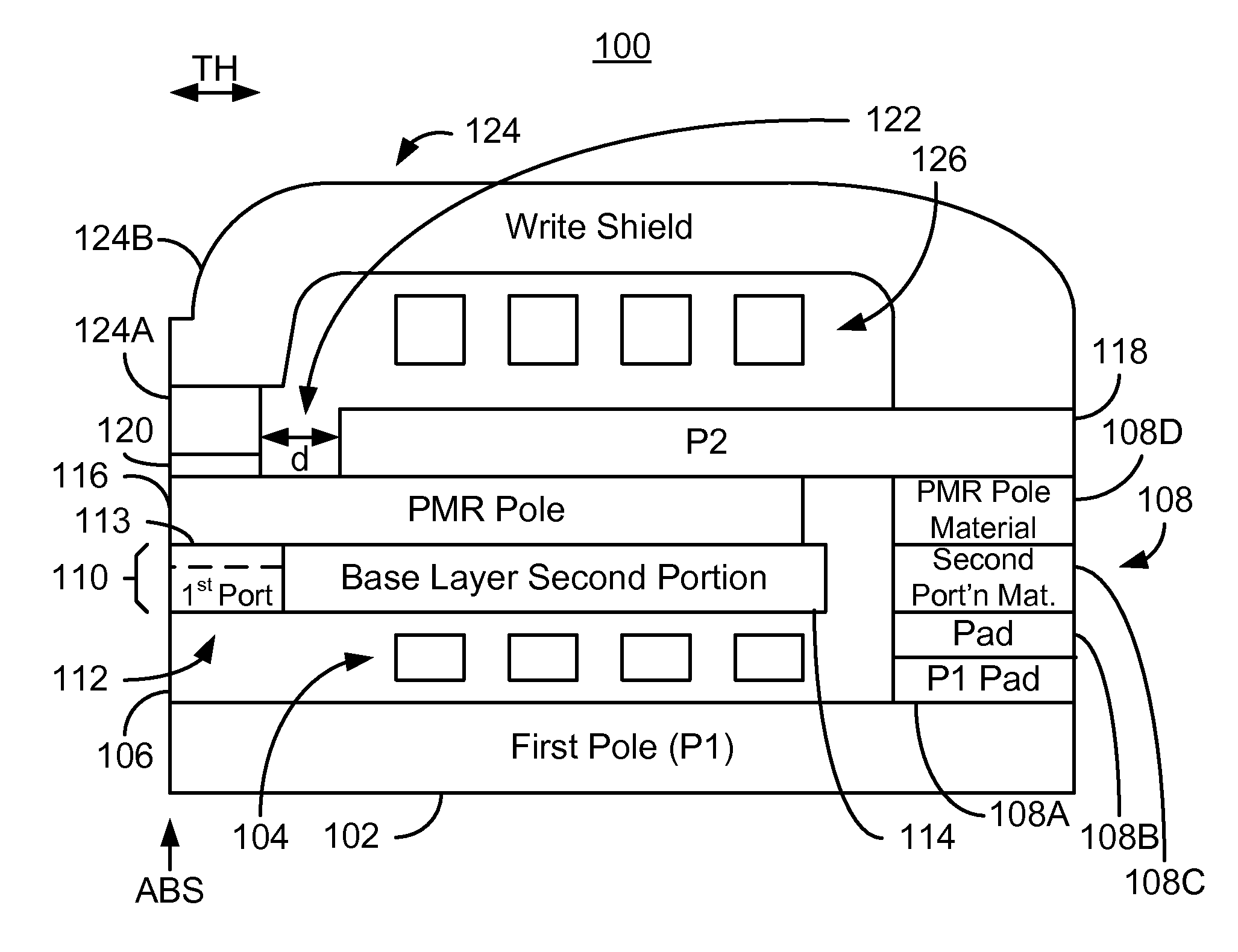

ActiveUS8077434B1Record information storageHeads for perpendicular magnetisationsMagnetic transducersEngineering

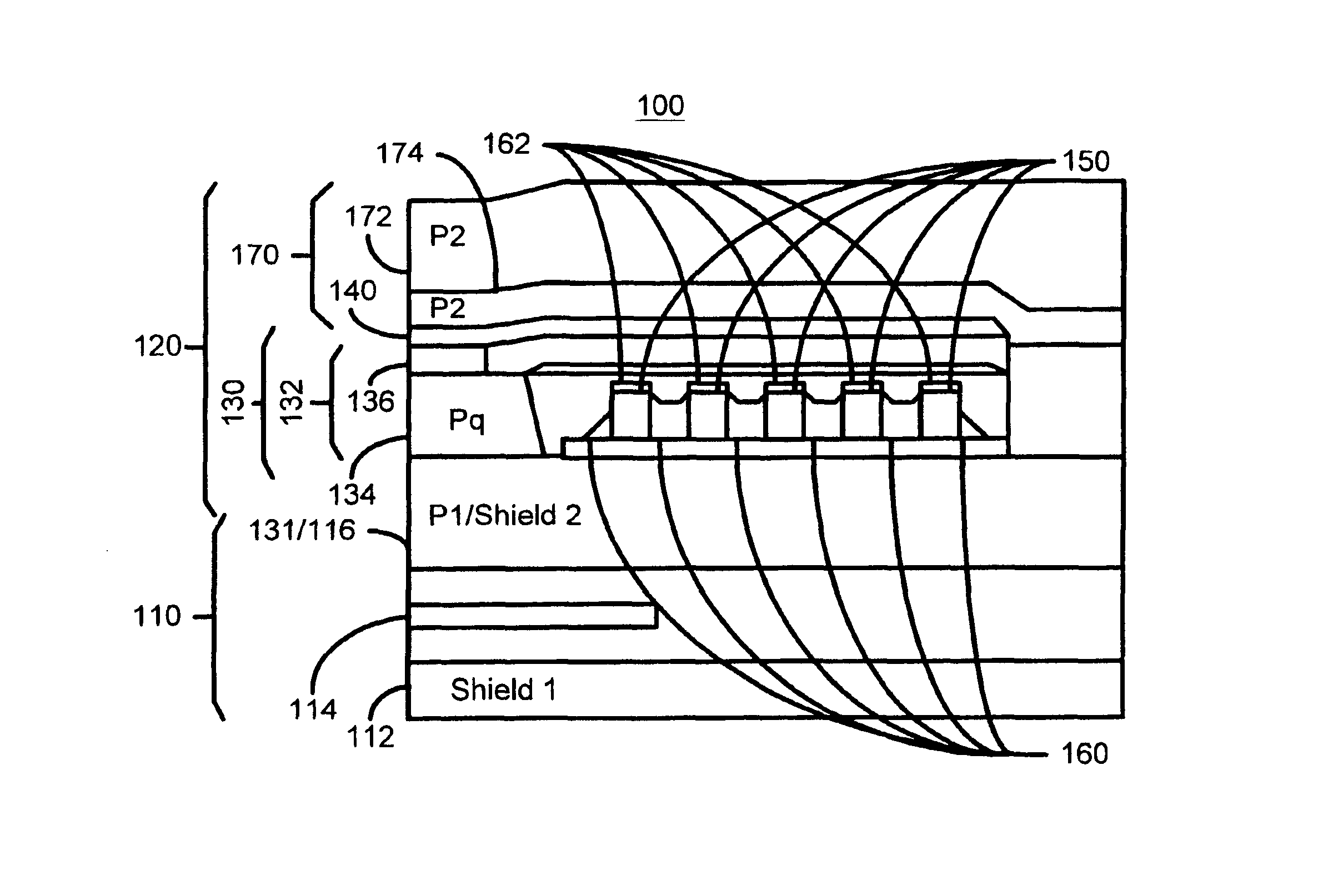

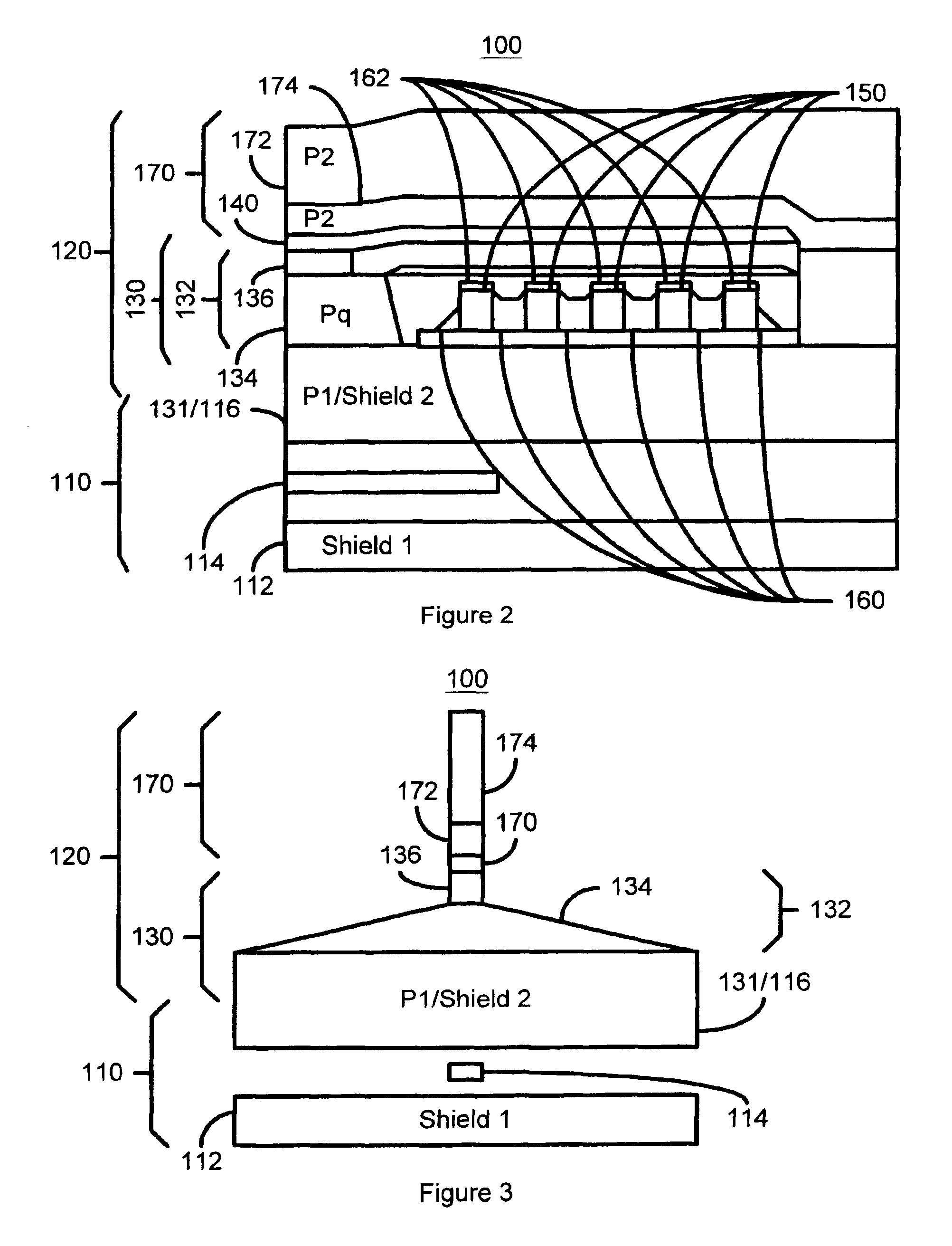

A method and system for providing a magnetic transducer having an air-bearing surface (ABS) are described. The magnetic transducer includes a base layer, a perpendicular magnetic recording (PMR) pole on the base layer, an additional pole, a write shield, a write gap between the PMR pole and a portion of the write shield, and coil(s) that energize at least the additional pole. The base layer includes a first portion proximate to the ABS and a second portion recessed from the ABS. The first portion is nonmagnetic, while the second portion is magnetic. The PMR pole has a first front portion proximate to the ABS. The additional pole has a second front portion recessed from the ABS. At least a portion of the additional pole resides between the PMR pole and write shield. At least a portion of the write gap resides on the front portion of the PMR pole.

Owner:WESTERN DIGITAL TECH INC

Magnetoresistive element and magnetic head

A magnetic transducing element in which a ferromagnetic tunneling junction film, including first and second ferromagnetic layers and an insulating layer are enclosed between the ferromagnetic layers, and a nonmagnetic metal thin film is inserted between the second ferromagnetic layer and the insulating layer, is formed on a substrate.

Owner:WESTERN DIGITAL TECH INC

Coil inductive writer having a low inductance and short yoke length

InactiveUS6940688B2Improve efficiencyIncrease speedConstruction of head windingsHeads using thin filmsLow inductanceElectrical and Electronics engineering

A method and system for providing a thin film recording head are disclosed. The method and system include providing a first pole, providing a second pole and providing a write gap separating the first pole from the second pole. The method and system further include providing at least one coil having a plurality of turns. A portion of each of the plurality of turns is between the first and the second pole. The plurality of turns wind around the second pole.

Owner:WESTERN DIGITAL TECH INC

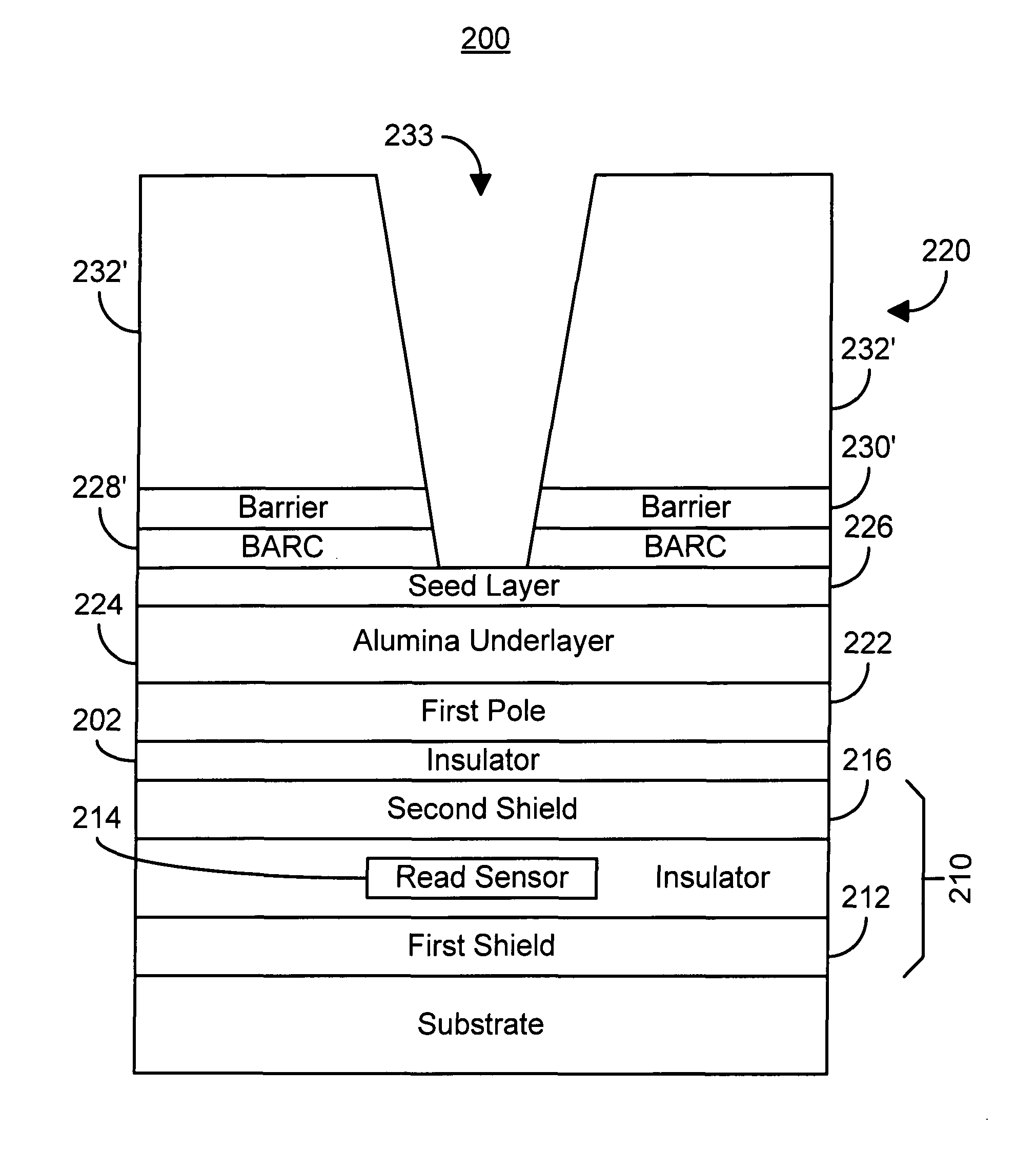

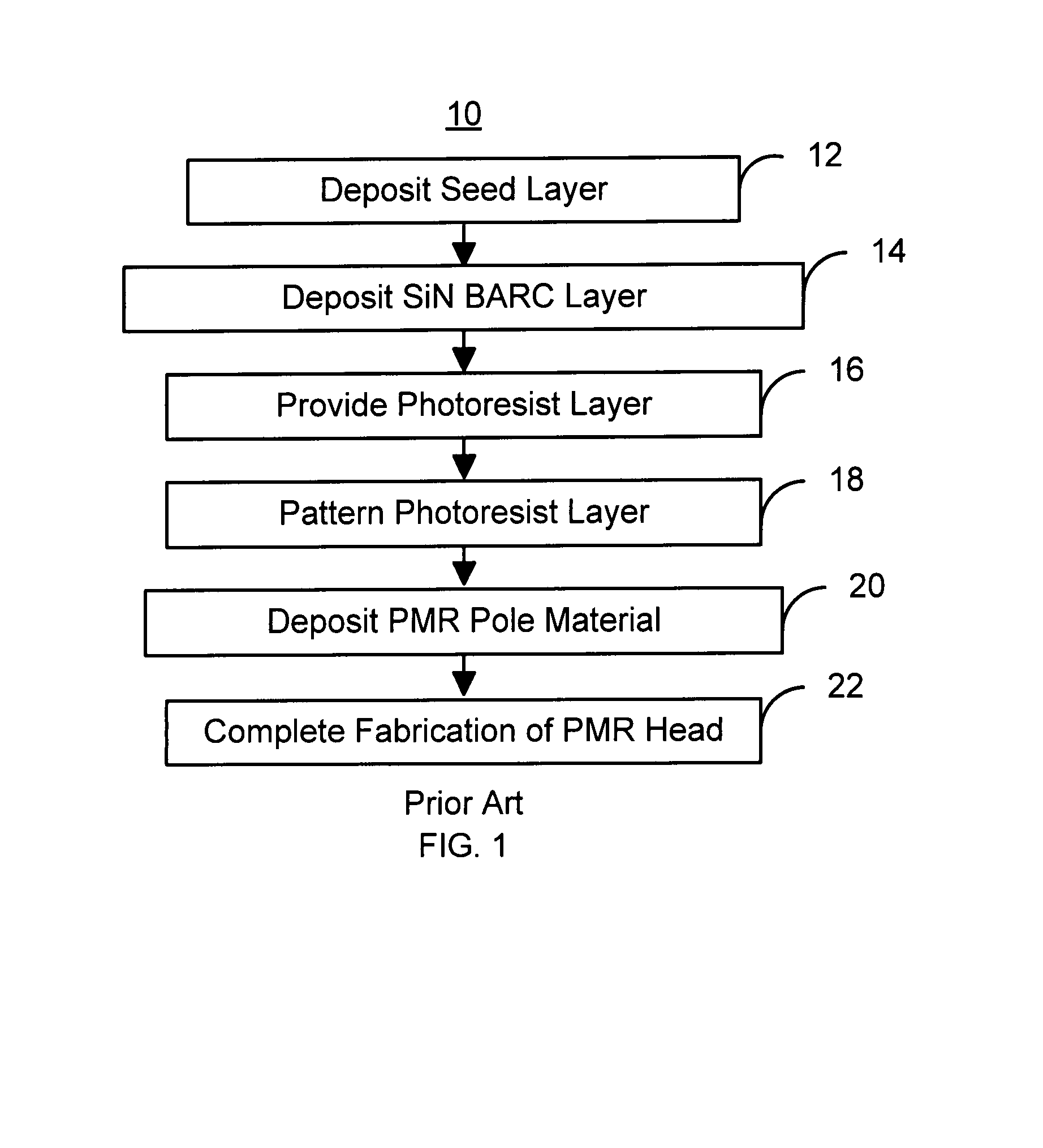

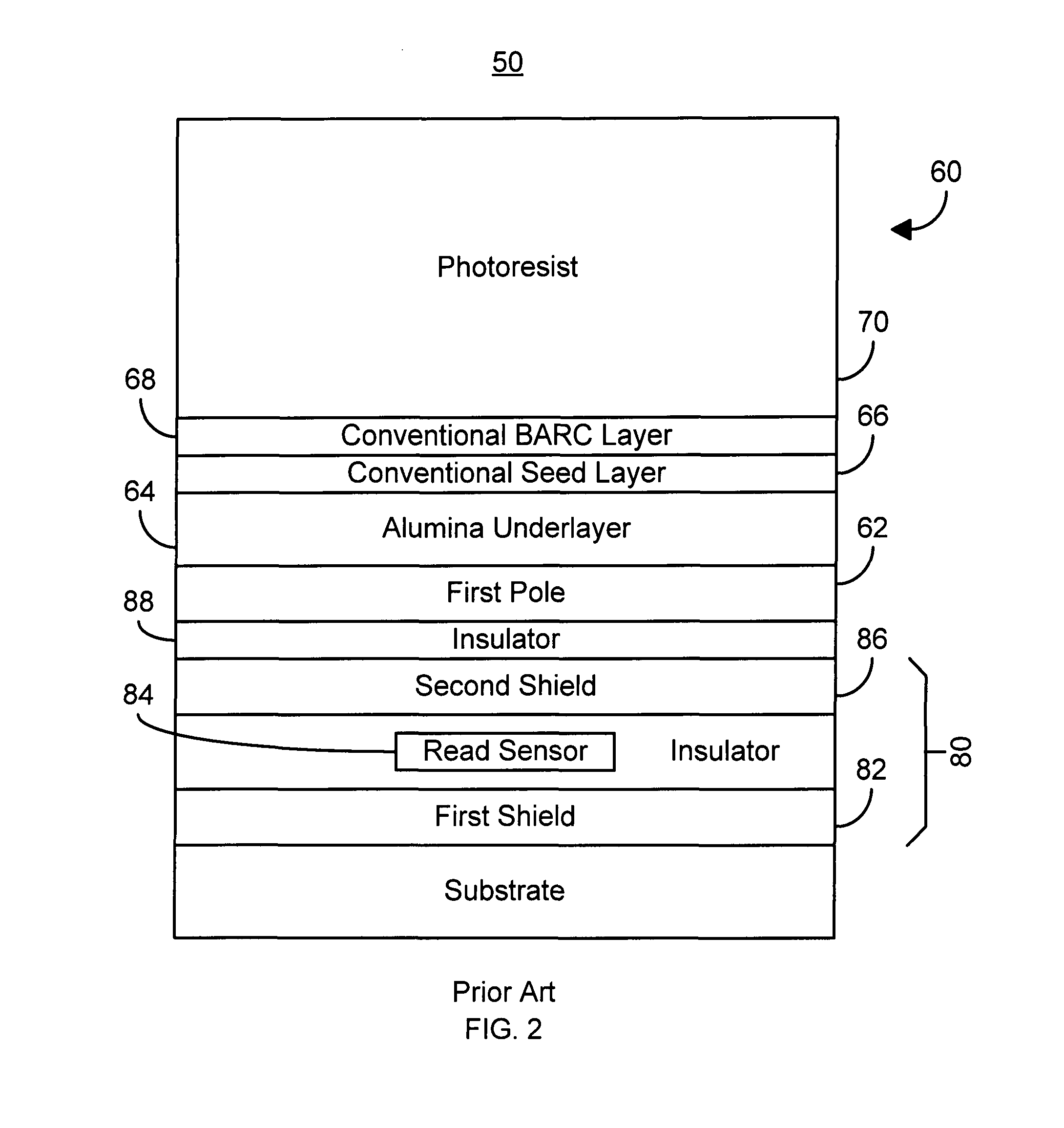

Method and system for providing a magnetic writer using a BARC

ActiveUS8072705B1Reduce reflectivityRecord information storageHeads for perpendicular magnetisationsReflectivityCoating

A method and system for providing a magnetic writer are described. The method and system include providing a bottom antireflective coating (BARC) on a portion of the magnetic writer. The BARC has a low reflectivity. The method and system also include providing a barrier layer on at least a portion of the BAR and providing a mask on at least a portion of the barrier layer. The barrier layer isolates the BARC from the mask.

Owner:WESTERN DIGITAL TECH INC

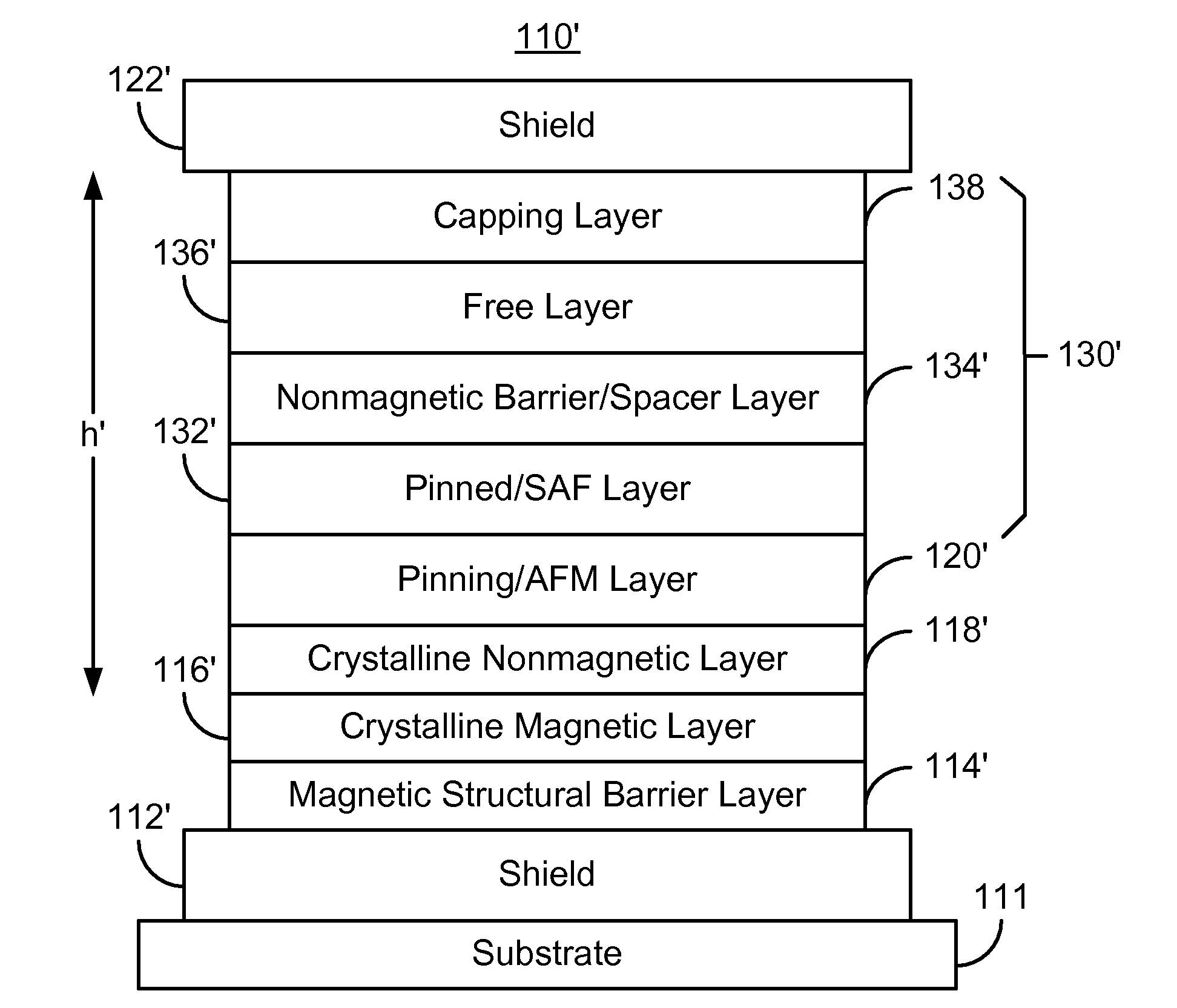

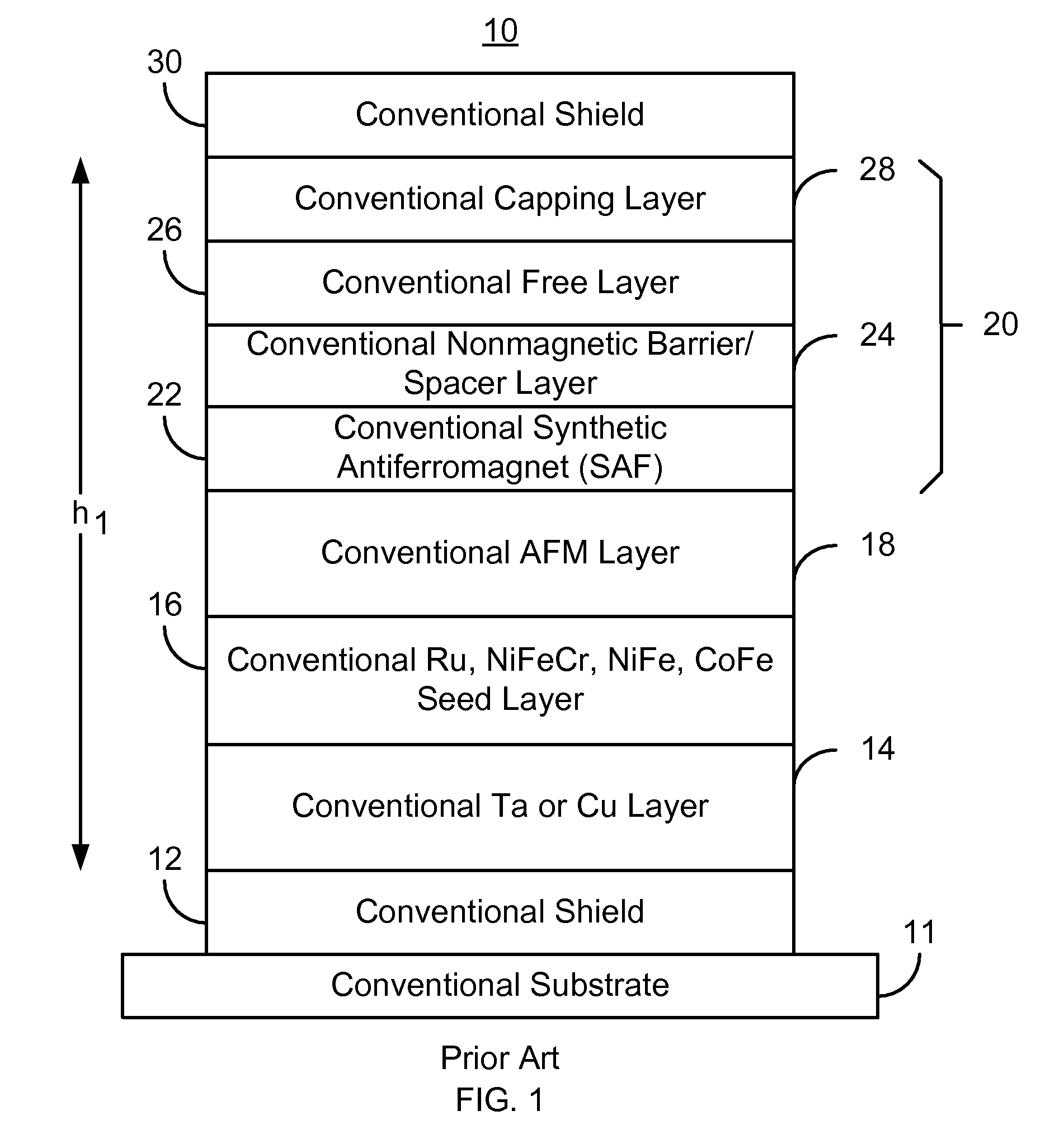

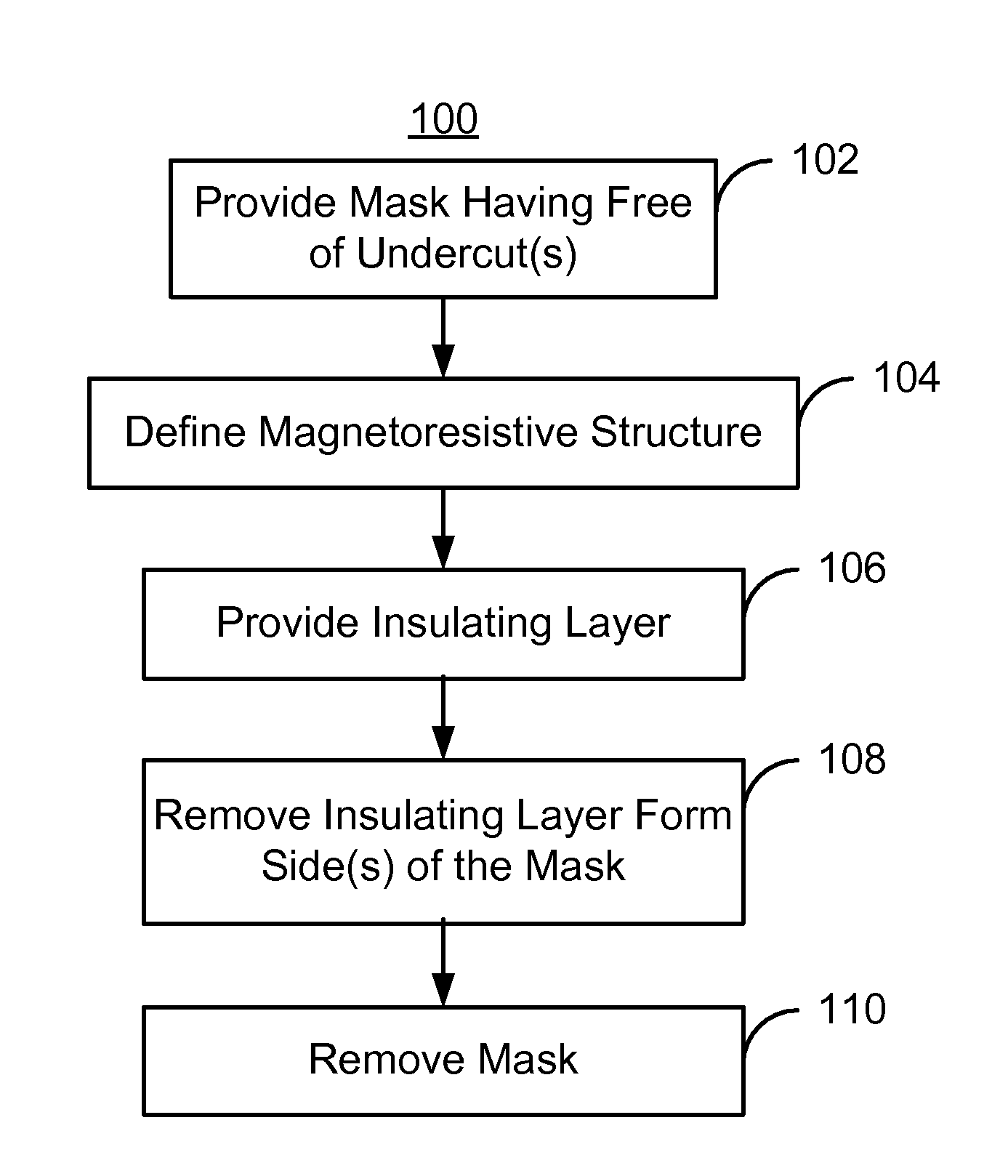

Method and system for providing a magnetic transducer having improved shield-to-shield spacing

InactiveUS8537502B1Magnetic measurementsMagnetic-field-controlled resistorsMagnetic transducersNon magnetic

A method and system for providing a magnetic transducer is described. The method and system include providing a magnetic structural barrier layer and a crystalline magnetic layer on the magnetic structural barrier layer. The magnetic structural barrier layer may reside on a shield. The method and system also include providing a nonmagnetic layer on the crystalline magnetic layer. A pinning layer is provided on the nonmagnetic layer. Similarly, a pinned layer is provided on the pinning layer. The pinning layer is magnetically coupled with the pinned layer. The method and system also include providing a free layer and a nonmagnetic spacer layer between the pinned layer and the free layer.

Owner:WESTERN DIGITAL TECH INC

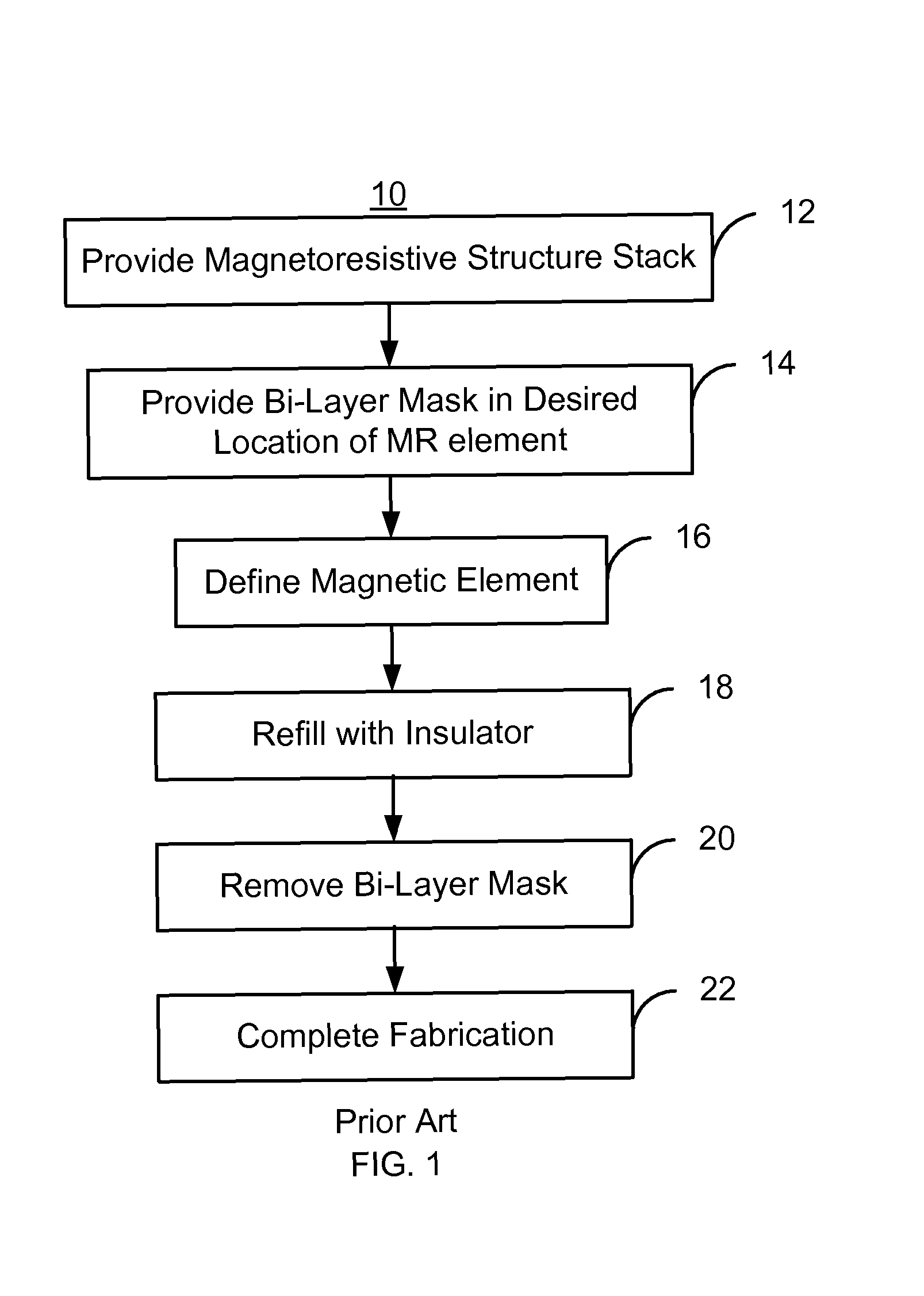

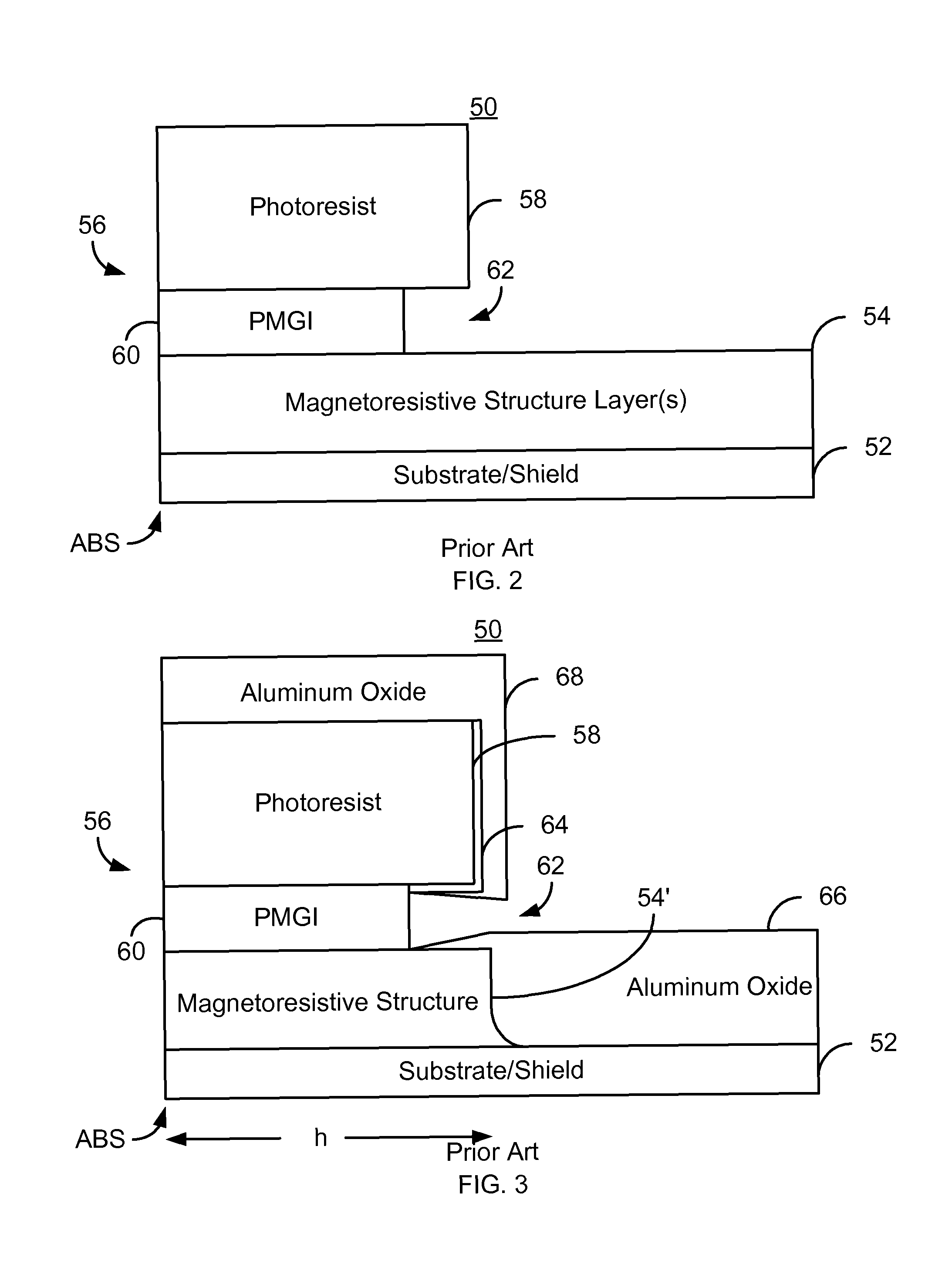

Method and system for providing a magnetoresistive structure using undercut free mask

A method and system provide a magnetoresistive structure from a magnetoresistive stack that includes a plurality of layers. The method and system include providing a mask that exposes a portion of the magnetoresistive stack. The mask has at least one side, a top, and a base at least as wide as the top. The method and system also include removing the portion of the magnetoresistive stack to define the magnetoresistive structure. The method and system further include providing an insulating layer. A portion of the insulating layer resides on the at least one side of the mask. The method and system further include removing the portion of the insulating layer on the at least one side of the mask and removing the mask.

Owner:WESTERN DIGITAL TECH INC

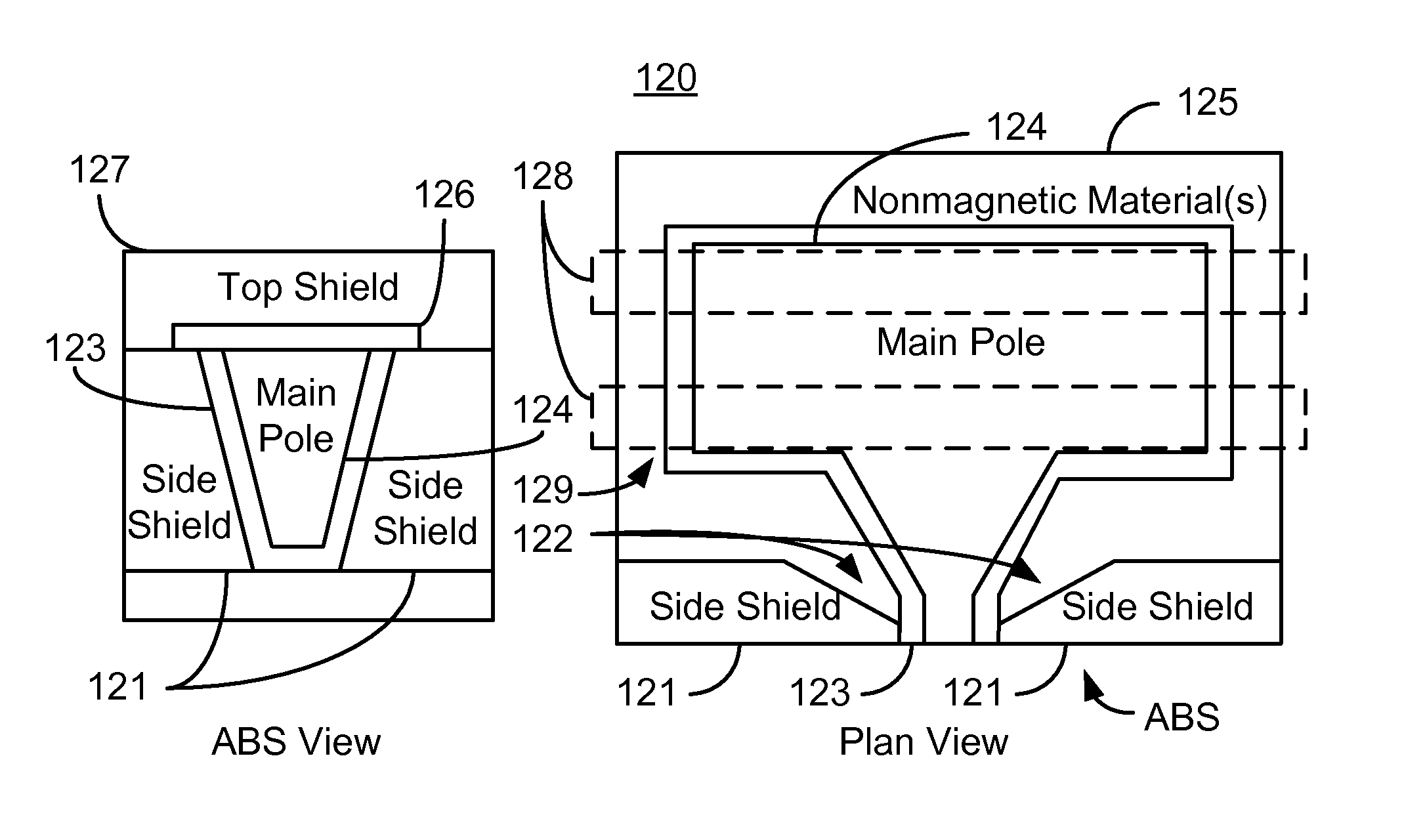

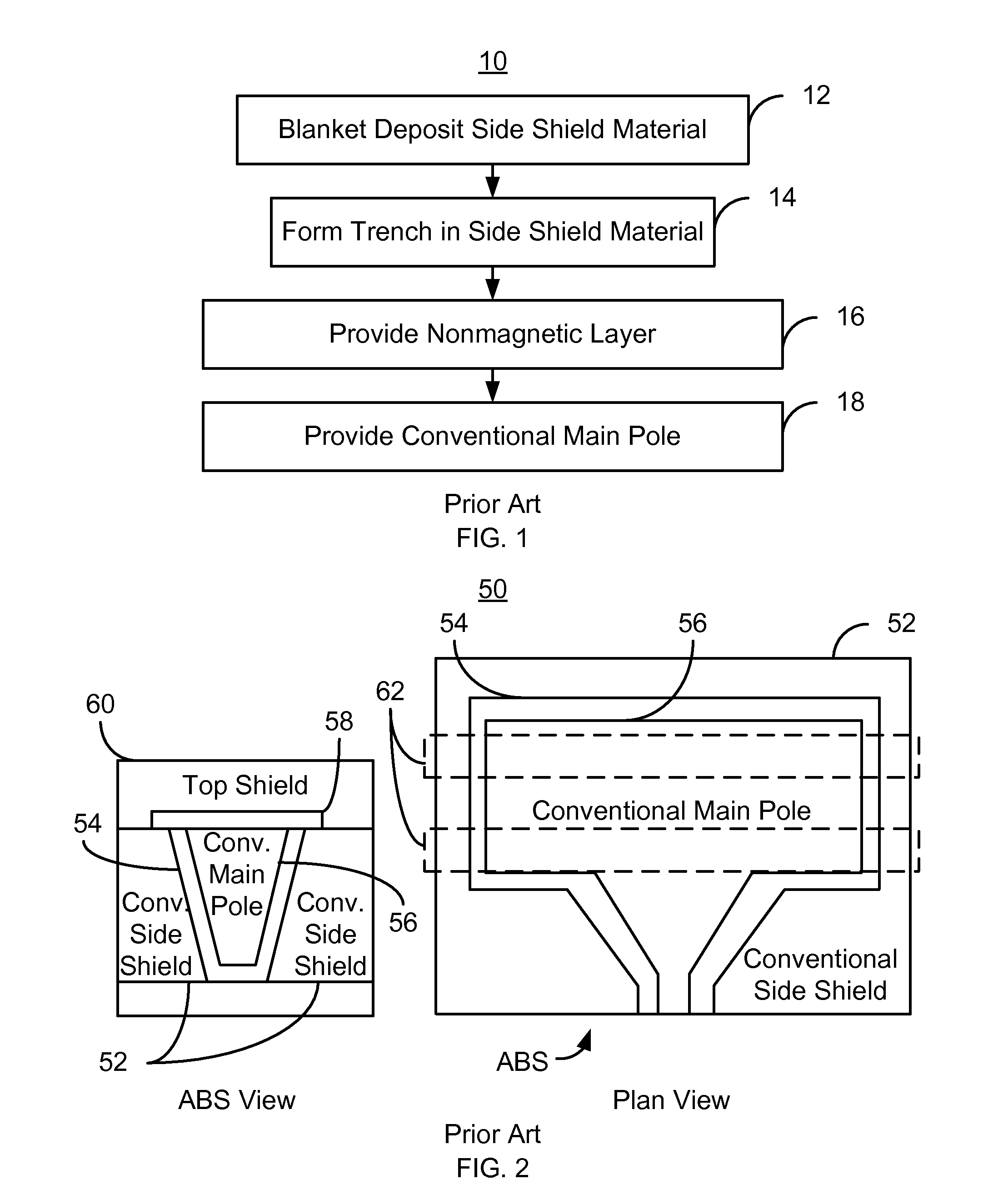

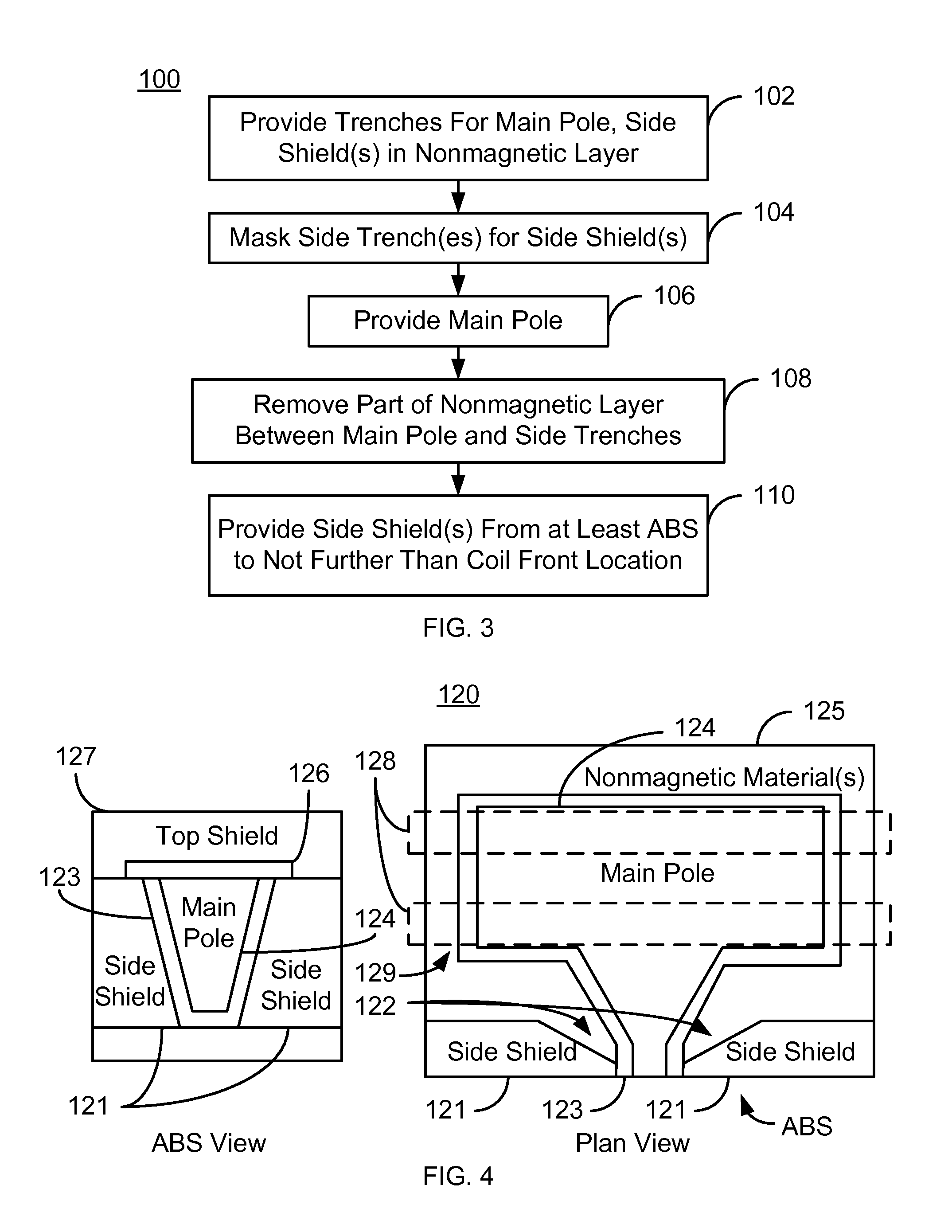

Magnetic recording transducer having side shields

ActiveUS8488272B1Record information storageHeads for perpendicular magnetisationsTransducerEngineering

A magnetic recording transducer includes a main pole including a nose portion, the nose portion terminating at an air-bearing surface (ABS). The magnetic recording transducer further includes at least one coil having a coil front distal from the ABS, and at least one side shield, the at least one side shield extending from at the ABS to not further than the coil front.

Owner:WESTERN DIGITAL TECH INC

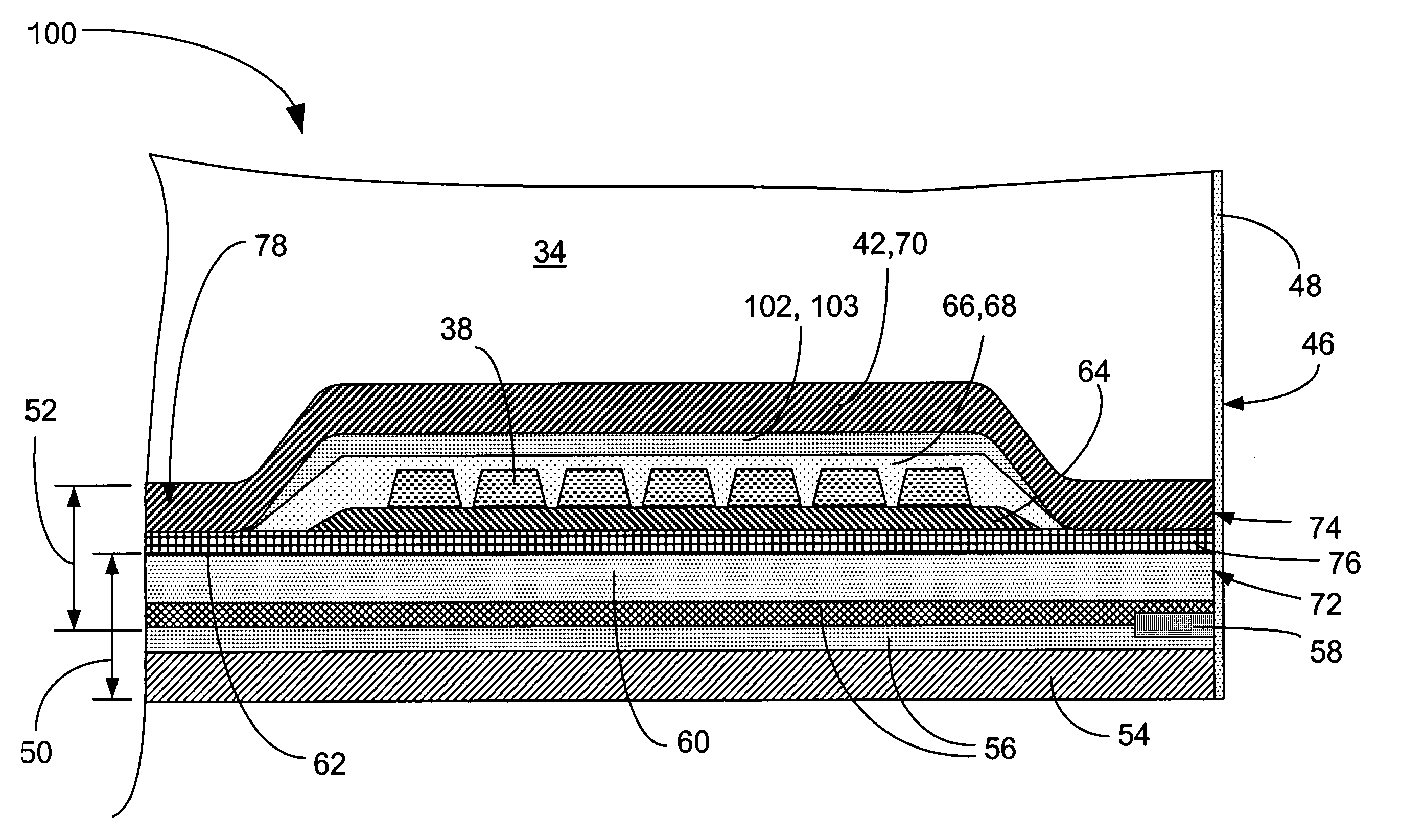

Insulation layer structure for inductive write heads and method of fabrication

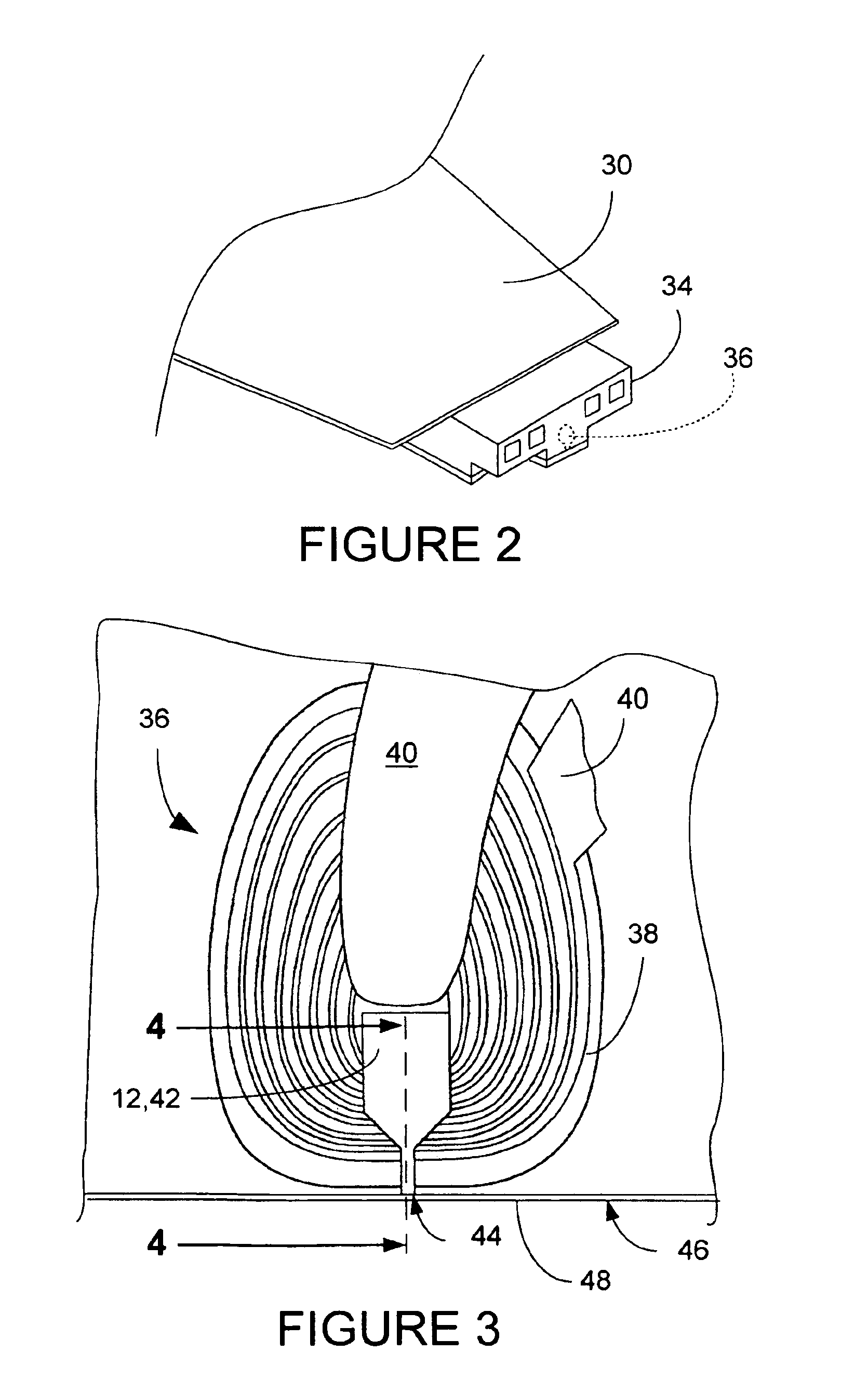

InactiveUS6958885B1Avoid crackingImprove film propertiesConstruction of head windingsElectrical transducersResistInsulation layer

A computer disk drive (22) having a write head (52) which includes a coil (38), a photoresist insulation layer (66) formed on the coil (38), and an insulation shell layer (102) which is formed on the photoresist insulation layer (66). In the first preferred embodiment (100), the top pole (42) of the write head (52) is formed on the insulation shell layer (102).In the second preferred embodiment (200), the disk drive write gap (76) is formed on the insulation shell layer (102) and the top pole (42) of the write head (52) is formed on the write gap (76).The insulation shell layers (102) in both embodiments are preferably made of dielectric materials (103).Methods of fabrication for these embodiments are also disclosed.

Owner:WESTERN DIGITAL TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com