High flexion articular insert

a technology of articular inserts and knees, applied in the field of knee prostheses, can solve the problems of unwanted movement of the femoral component on the tibial component, inability to fully bend the knee, and difficulty in daily living, etc., and achieve the effect of minimizing impingemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

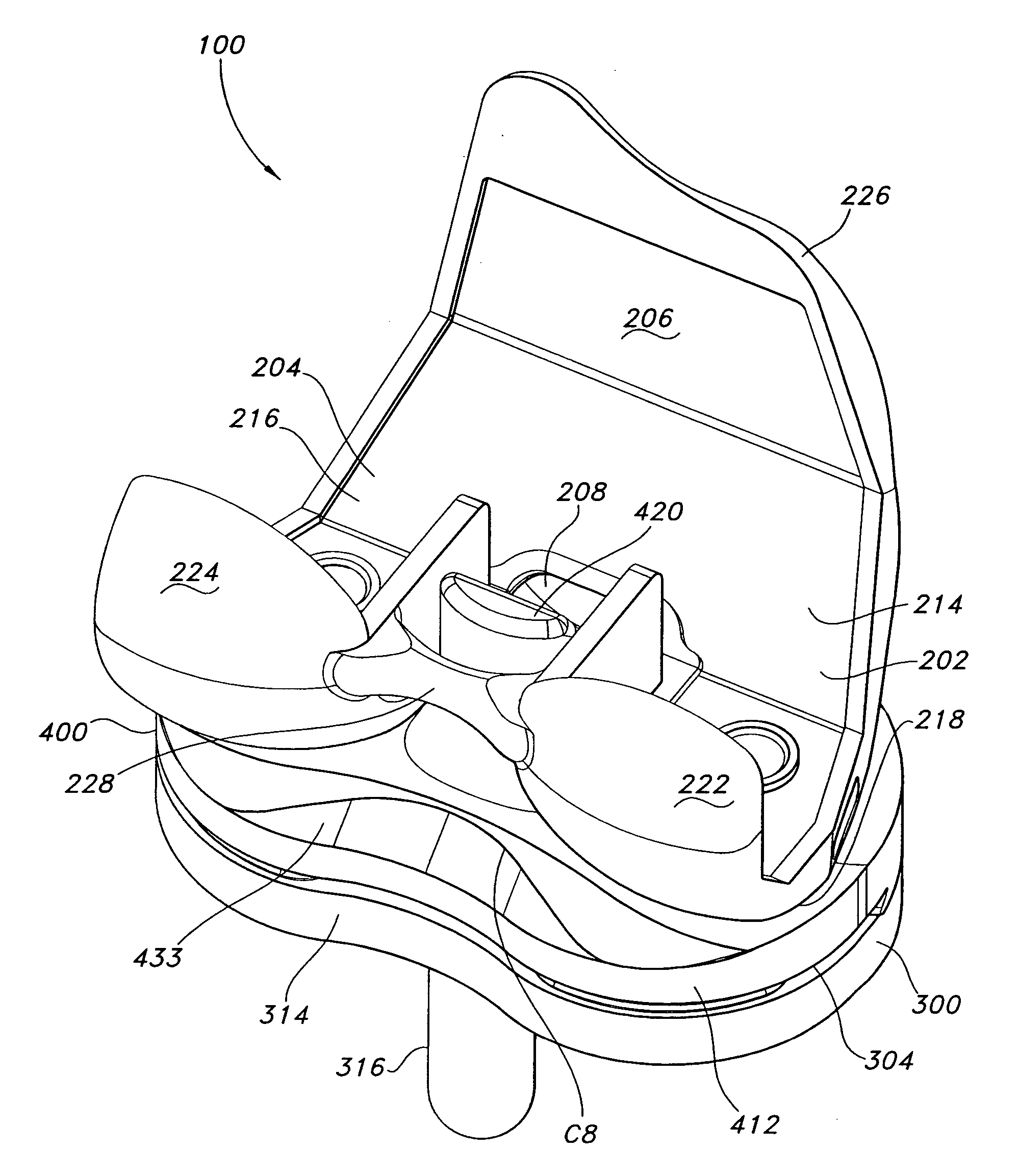

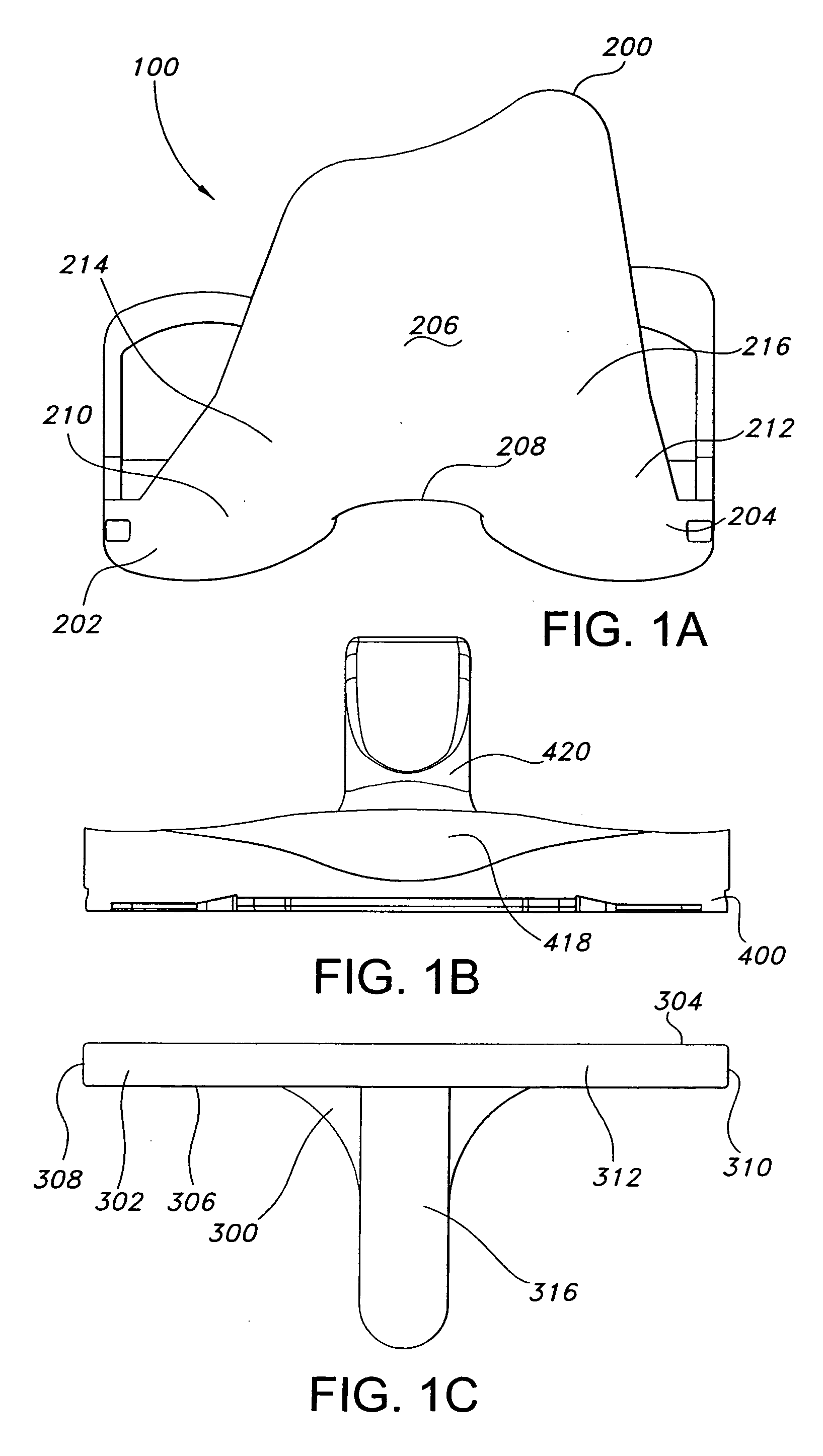

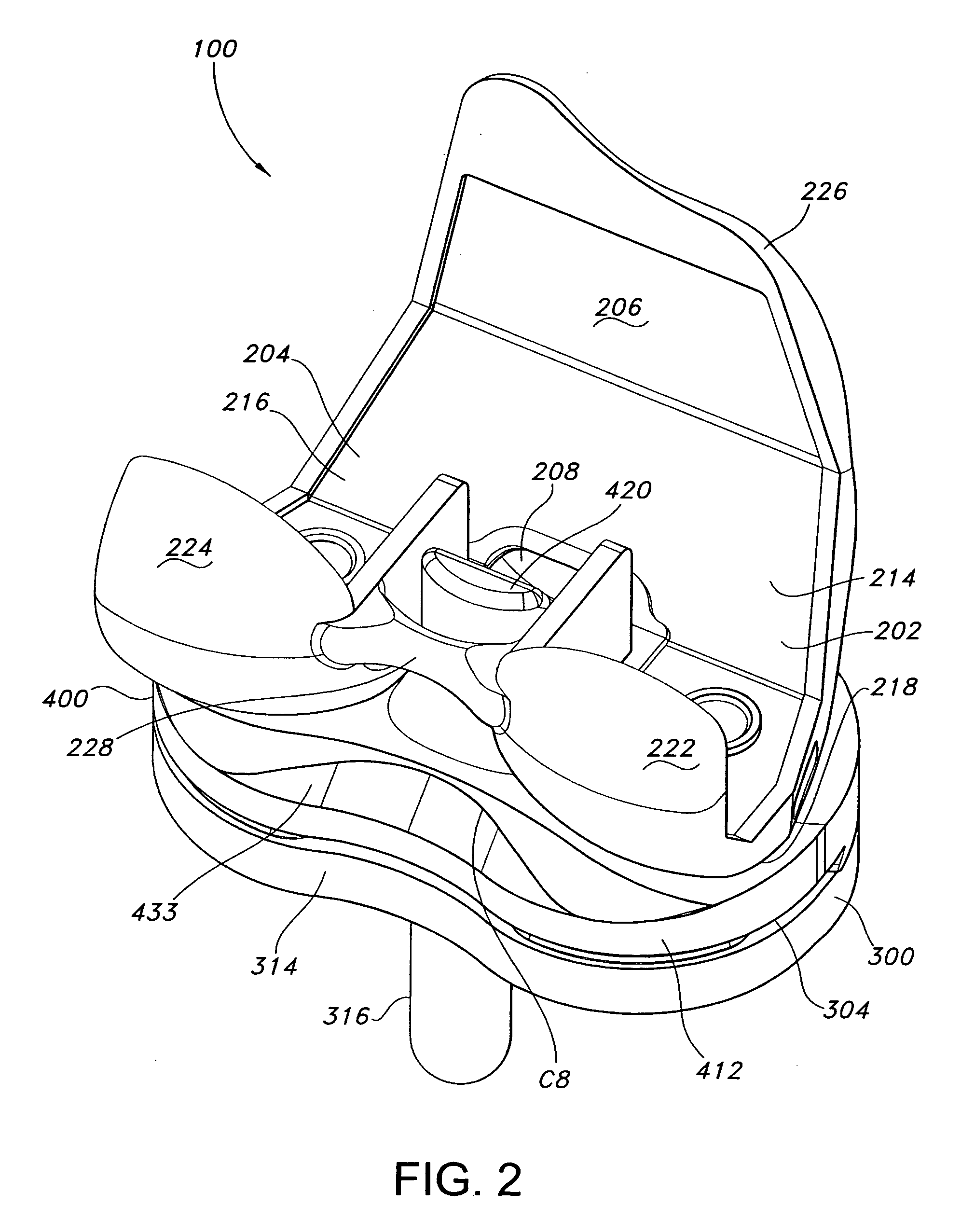

[0032] Various embodiments of the invention provide improved knee prostheses for replacing at least a portion of a knee joint between the distal end of a femur and the proximal end of a tibia.

[0033] As used herein, the following directional definitions apply. Anterior and posterior mean toward the front or toward the back of the body, respectively. Proximal means nearer to a point of reference, as opposed to distal which means farther from a point of reference. For example, the distal femur is part of the knee joint, while the proximal femur is part of the hip joint. Medial means nearer to the middle or center of the body. Lateral means farther from the middle or center of the body. Thus, when referring to the knee, medial would mean the side of the knee that is closest to the other knee and lateral would mean the side of the knee that is farthest from the other knee.

[0034] Knee prostheses according to certain embodiments of the invention advantageously remove material from the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com