Technology for preparing high-purity manganous-manganic oxide with manganous sulfate solution

A technology of manganese sulfate solution and manganese tetraoxide, which is applied in the direction of manganese oxide/manganese hydroxide, can solve the problems of low technical content, high production cost, and small specific surface area, and achieve simple process operation, low production cost, and relatively The effect of large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Hydrolysis and precipitation of manganese sulfate: accurately measure 500ml of feed-grade manganese sulfate solution with a concentration of 0.2mol / L, pour it into a beaker with a capacity of 2L, and use a 500ml volumetric flask to prepare ammonia water with a mass concentration of 10% or 25%. Transfer an appropriate amount of ammonia water into a pipetting funnel or a basic burette with a capacity of 100ml. Move the beaker containing the high-purity manganese sulfate solution into a constant temperature water bath, adjust its temperature to 70°C, and stir the reaction system at 300r / min. During the stirring process, drop ammonia water into the manganese sulfate solution to control the temperature of the ammonia water. The rate of addition is 4ml / min; After the reaction starts, adding 2.5g of ammonium chloride with a concentration of 5g / L is used as a reaction catalyst to accelerate the speed of the manganese ion hydrolysis reaction. During the reaction process, the pH ...

PUM

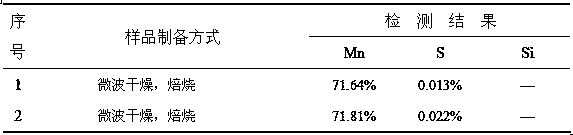

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com