Preparation method of ternary Ni-Co-Mn precursor and ternary Ni-Co lithium manganate material

A technology of nickel-cobalt lithium manganese oxide and precursors, which is applied in the field of lithium-ion battery materials, can solve problems such as irregular shape, poor performance at high and low temperatures, and poor secondary sphericity, and overcome poor electrochemical performance, Reduce condition requirements and overcome the effect of compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

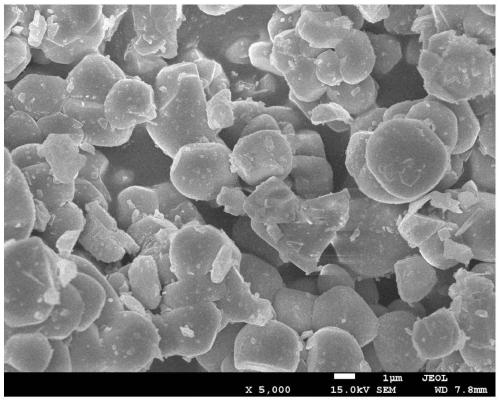

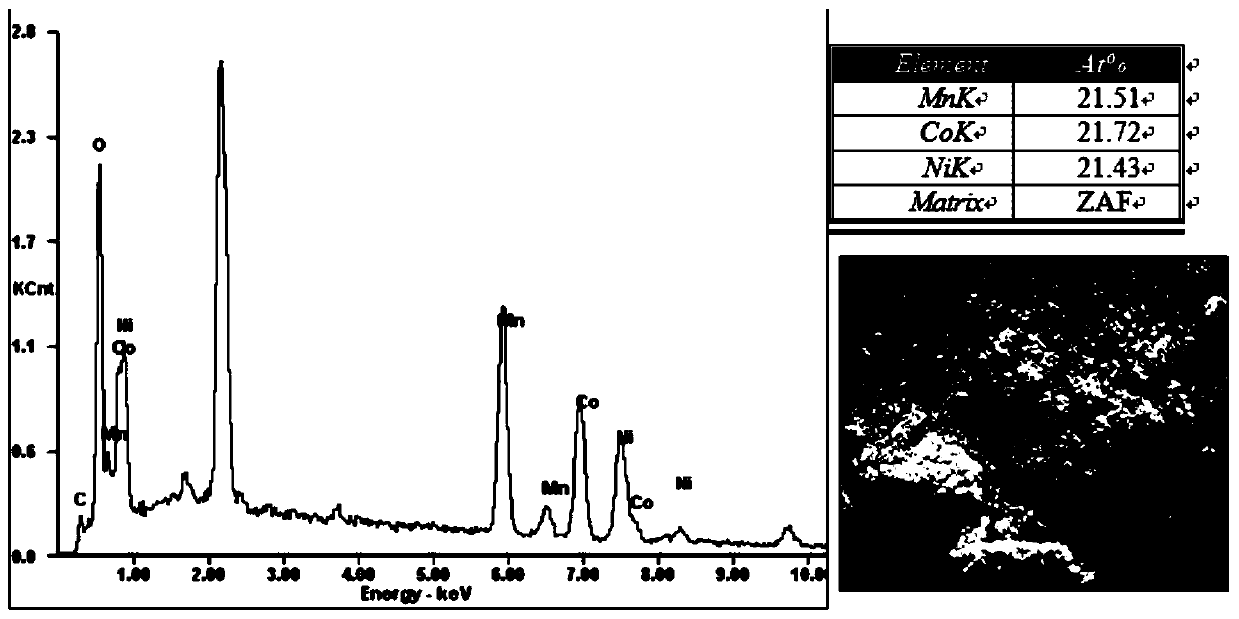

[0034] As an embodiment of the preparation method of a high energy density ternary nickel-cobalt lithium manganese oxide of the present invention, the preparation method of the ternary nickel-cobalt lithium manganate comprises the following steps:

[0035] (1) Get 630mol58% concentrated nitric acid, be dissolved in the stirred tank that 42L deionized water is installed. Take 100mol of manganese carbonate, 100mol of cobalt carbonate, and 100mol of nickel carbonate according to the nickel-cobalt-manganese molar ratio of 1 / 3:1 / 3:1 / 3, slowly add them to the stirring tank, add sodium hydroxide after dissolving to adjust the pH value Increase to 6, filter; take the filtrate and add it to a high-speed stirring tank, add citric acid, keep the citric acid concentration at 0.1mol / L, and keep stirring;

[0036] (2) Take 600 mol of 98% sodium hydroxide and add it to 30 L of deionized water for dissolving as a precipitating agent with a concentration of 20 mol / L. Pump sodium hydroxide int...

Embodiment 2

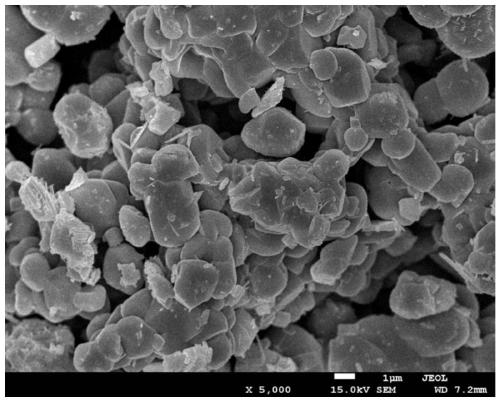

[0043] As an embodiment of the preparation method of a high energy density ternary nickel-cobalt lithium manganese oxide of the present invention, the preparation method of the ternary nickel-cobalt lithium manganate comprises the following steps:

[0044] (1) Weigh 160 mol of nickel sulfate, 20 mol of cobalt sulfate, and 20 mol of manganese sulfate according to the molar ratio of nickel, cobalt, and manganese of 0.8:0.1:0.1, slowly add them to the stirring tank, add water to form a slurry with a solid content of 30%, and dissolve After filtering; get the filtrate and join in the high-speed stirring tank, add 25mol citric acid, keep the citric acid concentration as 2.5mol / L and keep high-speed stirring;

[0045] (2) Weigh 400 mol of 98% sodium hydroxide and add it into 200 L of deionized water to dissolve it as a precipitating agent. Pump the sodium hydroxide into the high-speed stirring tank, and keep stirring for 3 hours after the transfer; press filter, wash the material wi...

Embodiment 3

[0052] As an embodiment of the preparation method of a high energy density ternary nickel-cobalt lithium manganese oxide of the present invention, the preparation method of the ternary nickel-cobalt lithium manganate comprises the following steps:

[0053] (1) Take 120mol of nickel chloride, 40mol of cobalt chloride, and 40mol of manganese chloride in a molar ratio of 0.6:0.2:0.2, slowly add them to the stirring tank, add water to dissolve and filter; take the filtrate and add it to the high-speed stirring tank , add 2.5mol / L citric acid, and keep stirring at high speed;

[0054] (2) Sodium carbonate (200mol) with a total sodium ion concentration of 20mol / L is used as a precipitant. Pump the sodium carbonate solution into the high-speed stirring tank, and keep stirring for 3 hours after the transfer; press filter, and wash the material with deionized water. After washing the material, the filter residue is dried to obtain nickel hydroxide cobalt manganese containing 0.5% of f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Compaction density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com