Preparation method and application of high-capacity high-temperature-resistant lithium manganate

A high-temperature lithium manganate, high-capacity technology, applied in the field of nanomaterials, can solve problems such as environmental pollution, reduced specific capacity, and intensified dissolution of manganese, and achieves the effects of easy control of reaction conditions, simple preparation method, and high charging capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] A preparation method of high-capacity high-temperature-resistant lithium manganate, comprising the following steps:

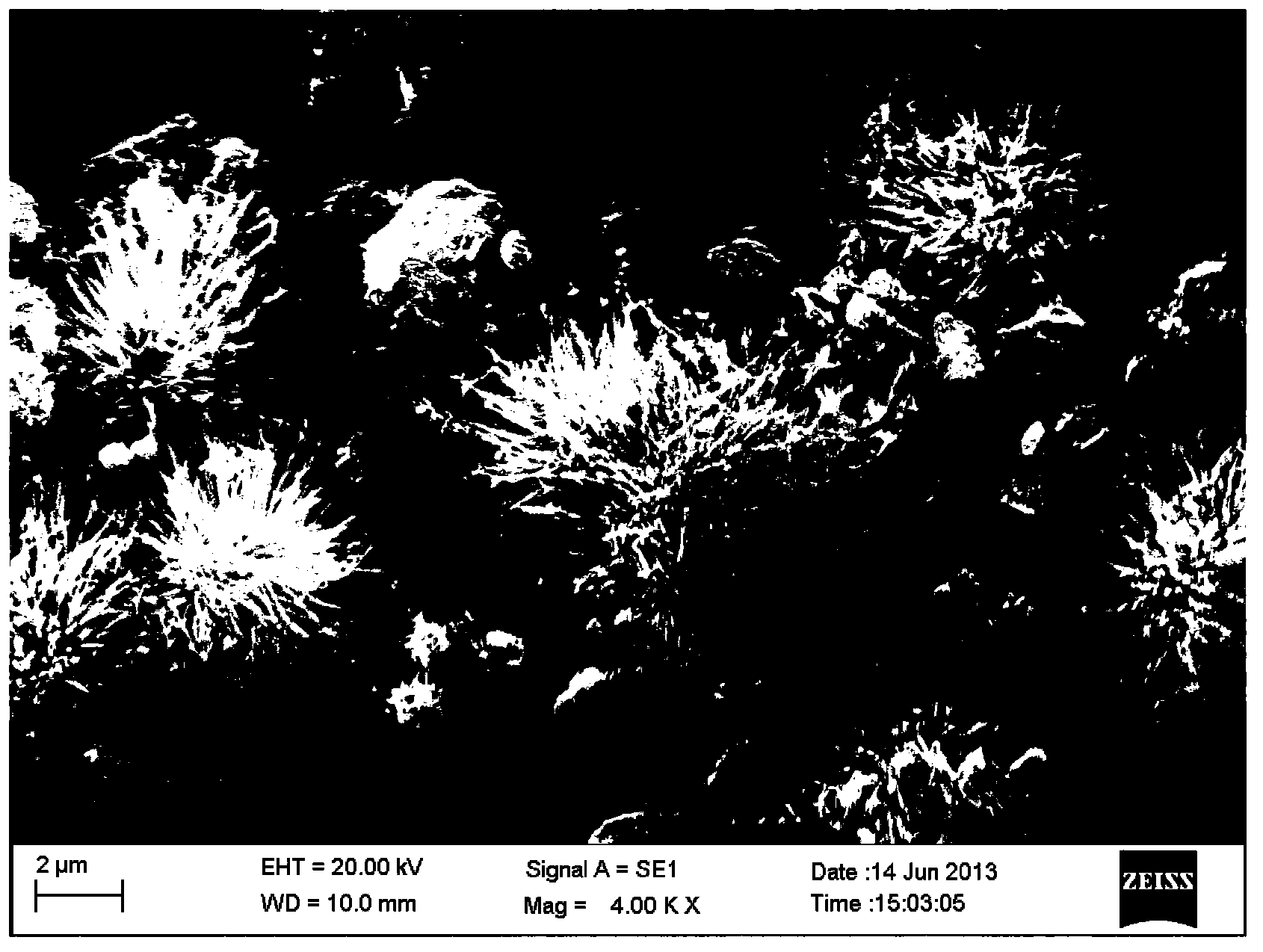

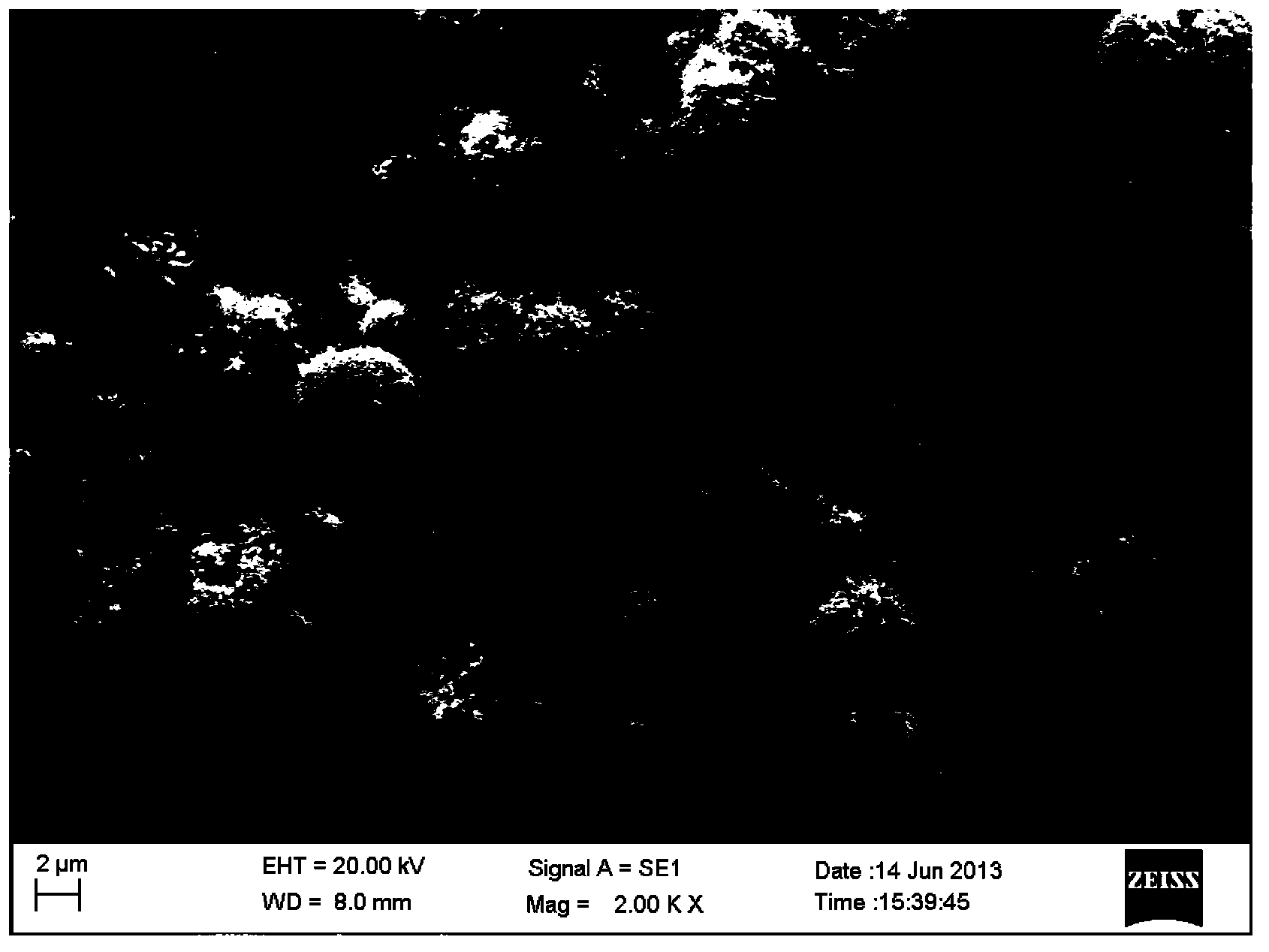

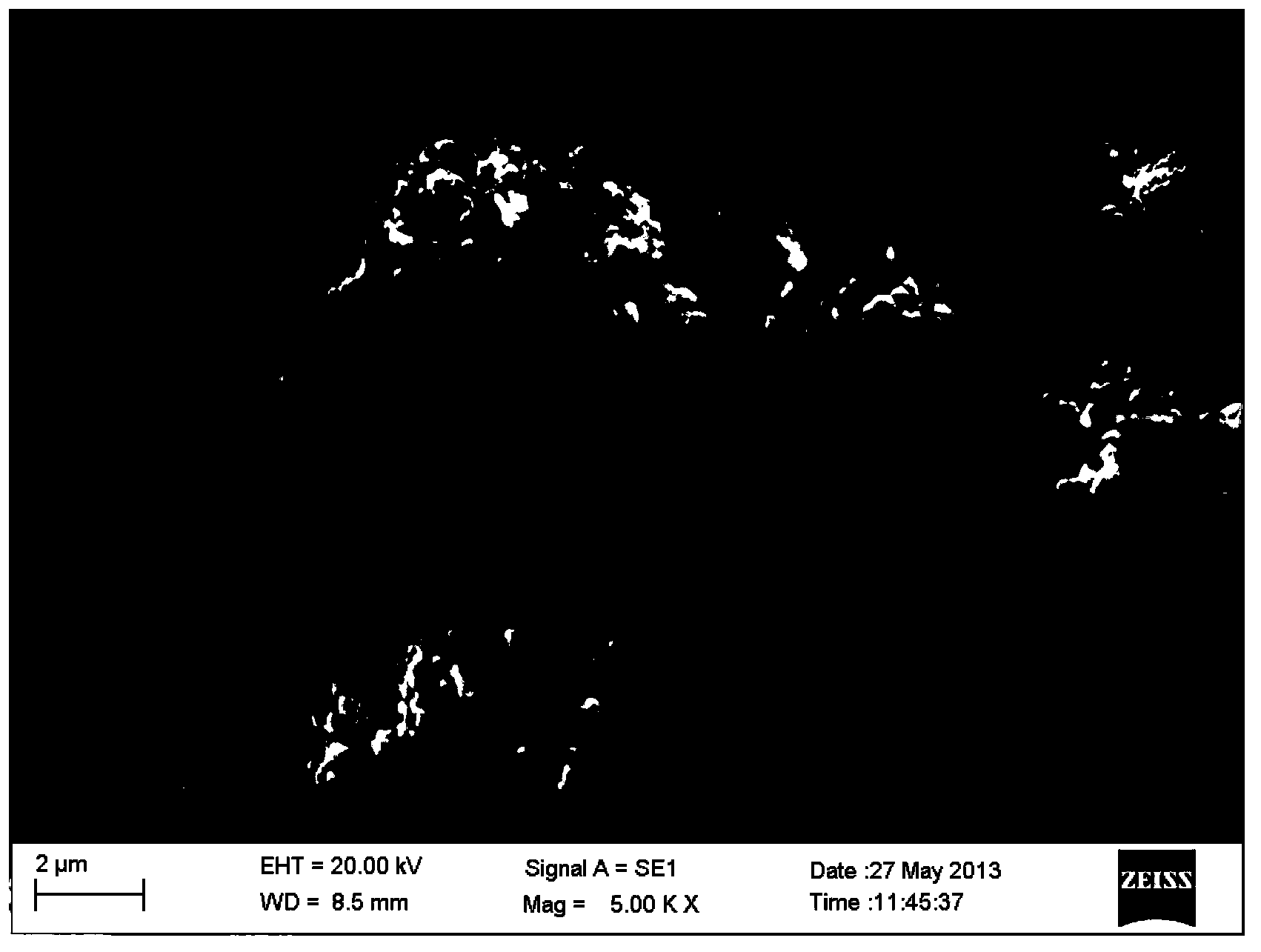

[0054] 1) Mix manganese sulfate and ammonium persulfate in water, mix thoroughly, then add aluminum sulfate solution, mix evenly, then put the mixed material in a stainless steel hydrothermal kettle for hydrothermal reaction, and then heat it in the air to obtain the product Filtration, water washing, alcohol washing and drying are carried out to obtain thorny aluminum-doped spherical nanometer gamma-manganese dioxide.

[0055] The molar ratio of manganese and aluminum elements in the reactant Mn:Al =5~10:0.2~2, the molar ratio of manganese sulfate and ammonium persulfate in the reactant is 1:0.8~1.2; the hydrothermal reaction temperature is 80~140℃; The reaction time is 5-12 hours; the product obtained after the hydrothermal reaction is heated in air at a temperature of 80-150° C., and the heating time is 8-12 hours.

[0056] Preferably, the molar rati...

Embodiment

[0073] A preparation method of high-capacity high-temperature-resistant lithium manganate, comprising the following steps:

[0074] 1) Weigh 13.52g MnSO 4 ·H 2 O, be dissolved in 40mL water, obtain light red transparent solution, weigh 18.26g (NH 4 ) 2 S 2 o 8 , dissolved in 40mL of water to obtain a colorless and transparent solution; the two solutions were mixed and magnetically stirred at room temperature for 3 hours to obtain a solution containing MnO 2 brown-yellow suspension; weigh 3.81g Al according to the molar ratio Mn:Al=7:1 2 (SO 4 ) 3 18H 2 O, dissolved in 5mL of water to obtain a colorless transparent solution, this solution was added to the aforementioned suspension, and stirred evenly. Pour the suspension into a hydrothermal reaction kettle and react at 120°C for 8 hours , The product was filtered, washed with water and ethanol, and baked in an oven at 100°C for 10 hours to obtain brown-black aluminum-doped γ-MnO 2 solid.

[0075] 2) Weigh Li accordi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com